Thermal Performance and Light Distribution Improvement of a Lens

advertisement

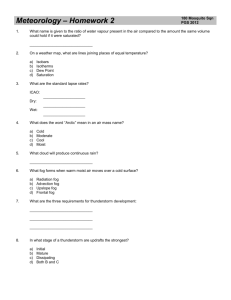

International Journal of Applied Engineering Research ISSN 0973-4562 Volume 11, Number 15 (2016) pp 8668-8672 © Research India Publications. http://www.ripublication.com Thermal Performance and Light Distribution Improvement of a Lens-Attached LED Fog Lamp for Passenger Cars W. S. Sim1 and Y. L. Lee2* Department of Mechanical Engineering, Graduate school, Kongju National University, Korea. 1 Department of Mechanical and Automotive Engineering, Kongju National University, Korea. *Corresponding Author 2 than 60 to 70% of input power into heat, and the junction temperature increases with power supply [6].This increase in junction temperature is known to be a cause of reduced optical power. Chip failure also occurs when the junction temperature exceeds 150℃, thus severely shortening the LED lifespan [7]. Many studies have been conducted to improve the heat dissipation performance of LEDs. Sökmena et al. [8] optimized the heat dissipation performance of a cylindrical fin type heatsink at various temperatures. Kim et al. [9] applied copper oxide (CuO) to an aluminum-alloy heatsink to improve the heat dissipation performance by enhancing thermal radiation emission. Wang et al. [10] improved the heat dissipation performance of LED headlamps through the heat dissipation analysis of a heatsink combined with heat pipes. Figure 1 shows the light distribution patterns of a halogen fog lamp and a regular LED fog lamp. Since the light distribution pattern of LED fog lamps are easily distinguished from that of halogen fog lamps, it is not possible to achieve the same light distribution as the latter without introducing a light distribution lens. The light distribution of light from the LED lamp has a large area, causes glare in drivers’ eyes, and has poor intensity in certain areas. In order to use LED fog lamps, such issues must be resolved. This study seeks to develop a 10W LED fog lamp that has the same light distribution performance as a halogen fog lamp. Heatsink optimization was carried out to enhance the heat dissipation performance, and a light distribution lens was introduced to improve the light distribution. Heat dissipation analysis was performed to optimize junction temperatures for various heatsink shapes, and light distribution analysis was used to improve the shape of the light distribution lens and reflector. Abstract Halogen light sources, which have seen significant developments since the invention of the tungsten filament lamp in 1916, are beginning to be replaced by LED light sources. The purpose of this study was to develop a 10W LED fog lamp that has the same light distribution performance as a halogen fog lamp. Heatsink optimization was carried out to enhance heat dissipation performance, and a light distribution lens was introduced to improve light distribution. The analysis showed that the 16 board-fin type heatsink had the best heat dissipation performance. In addition, the lens-attached LED fog lamp exhibited a similar light distribution performance to that of a halogen fog lamp. Keywords: Fog lamp, light distribution lens, light emitting diode, heatsink, junction temperature INTRODUCTION Halogen, the most widely used light source in automobiles, relies on light emitted during thermal radiation by the tungsten filament when the current passes through a lamp filled with halogen and a noble gas. Halogen lamps involve a simple mechanism and produce natural-looking light, but 95% of energy is released as heat and only the remaining 5% is converted into light. While luminous efficiency and color temperature increase with heat, the filament continues to evaporate and eventually breaks [1].As such, the disadvantages of halogen include poor efficiency and a short lifespan. If fog lamps are produced with LED as a light source, the small size of the LED chip will allow a 60 to 75% size reduction compared to halogen fog lamps. Differentiated designs are also possible through multi-chip modules [2]. LED lamps have a lifespan 100 times longer than halogen lamps due to their smaller energy consumption [3]. Their fuel consumption decreases by 19.5% when driving with lights on, and CO2 emissions are lowered by 19.6% [4]. In 2007, Toyota and Lexus became the first cars to use LEDs in low beam headlights [5]. Recently, Europe has attempted to replace LED with halogen as a light source for not only headlamps, but also fog lamps. In line with this trend, research on LED fog lamps has become popular in Korea. Recent developments in automotive lighting technology have led to high brightness, low power, and high efficiency, as well as the acquisition of characteristics suited to the lighting device. While the aforementioned advantages can be achieved by replacing halogen with LED fog lamps, LED converts more (a) Halogen fog lamp 8668 International Journal of Applied Engineering Research ISSN 0973-4562 Volume 11, Number 15 (2016) pp 8668-8672 © Research India Publications. http://www.ripublication.com (b) LED fog lamp Figure 1: Light distribution patterns of the halogen fog lamp and LED fog lamp NUMERICAL METHODS AND LIGHT DISTRIBUTION LENS The LED fog lamp of this study was comprised of an LED module, silicone mold, PCB, light distribution lens, and a heatsink. Figure 2 shows the schematic diagram of the three heatsinks used to enhance heat dissipation performance. The three shapes used were the circular-fin type, cross-fin type, and board-fin type, and they each had a heat dissipation area of 0.0139m2. The flow was steady-state, three-dimensional, and laminar, and thermal radiation was considered in the heat dissipation analysis. Catia[11] was used for the geometric modeling of the LED fog lamp, while Fluent [12] was employed for the heat dissipation analysis. The heatsink shape with the most outstanding heat dissipation was determined through heat dissipation analysis before optimizing the number of fins. To attain the same light distribution performance as a halogen fog lamp, this study introduced a light distribution lens, as shown in Figure 3. The condensing section at the bottom collects light, and the reflecting section at the top has been treated with Ag non-reflective coating. The material of the light distribution lens was assumed to be polycarbonate. Light distribution analysis was performed on the LED fog lamp equipped with the reflector [13] shown in Figure 4. Figure 3: Schematic diagram of the polycarbonate light distribution lens Figure 4: Schematic diagram of the LED fog lamp reflector (a) Circular-fin (b) Cross-fin (c) Board-fin RESULTS AND DISCUSSION Heat dissipation performance of the LED fog lamp Figure 5 shows the junction temperature contours for the different heatsink shapes when a power of 8W is applied to the LED fog lamp. The results for all three shapes fell below the limit of 120oC, and the board-fin type had the most Figure 2: Three heatsink shapes considered for the LED fog lamp 8669 International Journal of Applied Engineering Research ISSN 0973-4562 Volume 11, Number 15 (2016) pp 8668-8672 © Research India Publications. http://www.ripublication.com outstanding heat dissipation, followed by the circular-fin type and cross-fin type. The board-fin type is not only the most efficient in heat dissipation, but can also be easily mass produced using serration techniques. For these reasons, the board-fin type heatsink was selected for the purpose of this study. Figure 6 shows changes in junction temperature after a light distribution lens is added to the LED fog lamp. The junction temperature of the lens-attached fog lamp rose by 0.3oC to 109.2oC, which can be considered a negligible increase. As such, we can see that the light distribution lens has no significant influence on the heat dissipation performance of the LED fog lamp. (a) Circular-fin type (a) Without the light distribution lens (b) Cross-fin type (b) With the light distribution lens Figure 6: Changes in the junction temperature of the fog lamp To further optimize the heat dissipation performance of the lens-attached LED fog lamp, heat dissipation analysis was performed while varying the number of heatsink fins. As shown in Figure 7, we can see that the junction temperature of the fog lamp decreases with an increasing number of fins. The junction temperature rapidly declines at first, but the rate of decrease becomes more gradual as the number of fins continues to increase. The most outstanding heat dissipation performance was attained when there were 24 fins. Compared (c) Board-fin type Figure 5: Temperature contours in relation to heatsink shape 8670 International Journal of Applied Engineering Research ISSN 0973-4562 Volume 11, Number 15 (2016) pp 8668-8672 © Research India Publications. http://www.ripublication.com Figure 10 shows the irradiance of the halogen fog lamp and LED fog lamp. The results for irradiance are similar to light distribution patterns. When a light distribution lens is attached, the LED fog lamp exhibits a similar irradiance to the halogen fog lamp due to the enhanced light distribution performance. However, the irradiance of the LED fog lamp still has room for improvement. to the case of 16 fins, the area of heat dissipation expanded by 35%, while the junction temperature dropped by 0.3oC. The weight of the fog lamp at 24 fins was also 10% heavier. Although heat dissipation is better at 24 fins, the 16-fin heatsink is more practical given the weight difference and negligible decrease in junction temperature. Figure 7: Changes in junction temperature with the number of fins (a)Halogen fog lamp Light distribution analysis of fog lamp with reflector Figure 8 shows the principle of light distribution when light from the fog lamp bounces off the reflector. Light is refracted since it moves sideways instead of going straight due to the light distribution lens, and a suitable light distribution pattern is achieved. Figure 9 shows the light distribution patterns of the halogen fog lamp and the LED fog lamp using the same reflector. The halogen fog lamp has a long and thin pattern suitable for the fog lamp, whereas the LED fog lamp has a pattern concentrated in the center. Compared to the regular LED fog lamp of Figure 3, the lens-attached LED fog lamp has a light distribution performance closer to that of the halogen fog lamp. The light distribution performance is expected to improve further through the use of multi-face LED fog lamps. (b)LED fog lamp Figure 9: Light distribution patterns of the halogen fog lamp and LED fog lamp (a) Halogen fog lamp Figure 8: Principle of light distribution for the LED fog lamp with a reflector 8671 International Journal of Applied Engineering Research ISSN 0973-4562 Volume 11, Number 15 (2016) pp 8668-8672 © Research India Publications. http://www.ripublication.com [2] [3] [4] (b) LED fog lamp [5] Figure 10: Irradiance of the halogen fog lamp and LED fog lamp [6] CONCLUSION This study performed heat dissipation and light distribution analyses of an LED fog lamp in relation to the heatsink shape and the attached light distribution lens. Through the analysis, the heat dissipation performance of the 10W LED fog lamp was optimized and the light distribution performance improved. The conclusions derived in this study are as follows: 1. The LED fog lamp with the 16 board-fin type heatsink offers the most outstanding heat dissipation performance. In addition, the board-fin type is suitable for mass production. 2. When a light distribution lens is introduced to improve light distribution performance, the junction temperature remains almost the same, and the heat dissipation performance is also satisfactory. Here, the junction temperature is approximately 10.8oC lower than the limiting temperature. 3. The lens-attached LED fog lamp showed an improved light distribution performance compared to the regular LED fog lamp. However, to achieve the same light distribution performance as the halogen fog lamp, further improvements such as the use of multi-face LED fog lamps are needed. To enhance light distribution performance, optimization studies can be performed on variables such as the position and number of LED modules and LED chip arrangement. ACKNOWLEDGEMENT This study was supported by a grant of the SME R&D project for the Start-up & Grow stage company. Small & Medium Business Administration. (S2333652) REFERENCES [1] C. S. Kim., S, J, Shin. and K, D, Kwack., 2008, "Lifetime Estimation of an Automotive Halogen 8672 [7] [8] [9] [10] [11] [12] [13] Lamp", Journal of Mechanical Science and Technology, Autumn Scientific Congress, pp. 12591264 J, H, Shin., K, S, Kim., D, Y, Cho. and K, J, Park., 2011, "A Study on design direction of automotive lamp through diver cases applied LED technology", Journal of Korean society of design science 24, pp. 47-57 Richard B, T, Price., Corey A, Felix. and P, Andreou., 2005, "Knoop hardness of ten resin composites irradiated with high-power LED and quartz-tungstenhalogen lights", Biomaterials 26, pp. 2631-2641 B, D, Kang., K, S, Park., B, J, Yong. and H, G, Kim., 2009, "Evaluation of fuel consumption between LED headlamp and halogen headlamp", KSAE09-A0294 pp. 1709-1714 I, Tetsuaki., W, Shinya. and Y, Yuji., 2008, "LED Head Lamp Development for mass production", SAE Technical Paper 2008-01-0339 B, L, Ahn., C, Y, Jang., S, B, Leigh., S, H, Yoo. and H, G, Jeong., 2014, "Effect of LED lighting on the cooling and heating loads in office buildings", Applied Energy 113, pp1484-1489 Y, Lai., N, Cordero., 2006, "Thermal management of bright LEDs for automotive applications", Proceedings of the 7th EuroSimE Conference 2006, Como, Italy K, F, Sökmen., E, Yürüklü. and N, Yamankaradeniz., 2016, " Computational thermal analysis of cylindrical fin design parameters and a new methodology for defining fin structure in LED automobile headlamp cooling applications", Applied Thermal Engineering 94, pp. 534-542 D, H, Kim., J, H, Lee., J, H, Kim., C, H, Choi. and W, S, Chung., 2015, "Enhancement of heat dissipation of LED module with cupric-oxide composite coating on aluminum-alloy heat sink", Energy Conversion and Management 106 pp.958-963 J, Wang., Y, X, Cai., X, J, Zhao. and C, Zhang., 2014, "Thermal design and simulation of automotive headlamps using white LEDs", Microelectronics Journal 45 pp.249-255 CATIA Version 5.18. Dassault Systems 1994-2007 FLUENT Version 14, ANSYS Inc. H, Wu., X, Zhang. and P, Ge., 2015, "Design method of a light emitting diode front fog lamp based on a freeform reflector", Optics & Laser Technology 72 pp.125-133