Specific surface area of overlapping spheres in the presence of

advertisement

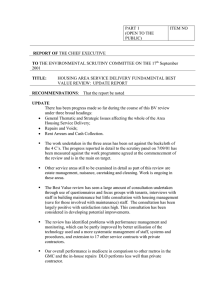

Specific surface area of overlapping spheres in the presence of obstructions D. R. Jenkins Citation: J. Chem. Phys. 138, 074702 (2013); doi: 10.1063/1.4790691 View online: http://dx.doi.org/10.1063/1.4790691 View Table of Contents: http://jcp.aip.org/resource/1/JCPSA6/v138/i7 Published by the American Institute of Physics. Additional information on J. Chem. Phys. Journal Homepage: http://jcp.aip.org/ Journal Information: http://jcp.aip.org/about/about_the_journal Top downloads: http://jcp.aip.org/features/most_downloaded Information for Authors: http://jcp.aip.org/authors THE JOURNAL OF CHEMICAL PHYSICS 138, 074702 (2013) Specific surface area of overlapping spheres in the presence of obstructions D. R. Jenkinsa) CSIRO Mathematics, Informatics and Statistics, Locked Bag 17, North Ryde, NSW 1670 Australia (Received 3 December 2012; accepted 15 January 2013; published online 15 February 2013) This study considers the random placement of uniform sized spheres, which may overlap, in the presence of another set of randomly placed (hard) spheres, which do not overlap. The overlapping spheres do not intersect the hard spheres. It is shown that the specific surface area of the collection of overlapping spheres is affected by the hard spheres, such that there is a minimum in the specific surface area as a function of the relative size of the two sets of spheres. The occurrence of the minimum is explained in terms of the break-up of pore connectivity. The configuration can be considered to be a simple model of the structure of a porous composite material. In particular, the overlapping particles represent voids while the hard particles represent fillers. Example materials are pervious concrete, metallurgical coke, ice cream, and polymer composites. We also show how the material properties of such composites are affected by the void structure. © 2013 American Institute of Physics. [http://dx.doi.org/10.1063/1.4790691] I. INTRODUCTION Examples of composites can be found in nature as well as manufactured materials. Here, a composite means a material whose internal structure consists of a set of different components embedded in a homogeneous matrix. A porous composite has, as one of its components, void space. The simplest porous composite is one consisting of two phases, the matrix and the void; examples include various types of foams. An obstructed porous composite consists of the matrix, voids, and a third phase, most frequently being some sort of solid particles. The term “obstructed” is used to indicate that the third phase components preclude the location of voids within them. Materials that can be considered as obstructed porous composites are metallurgical coke1 (whose 3 components are fused coal components, inert components, voids), ice cream2 (sugar syrup, ice crystals, and voids), various igneous rocks3 (amorphous material, crystals, voids), and pervious concrete4 (cement paste, aggregate, voids). In all of these examples, a primary source of the voids is the development of bubbles during the formation of the materials. Typically the bubbles form/nucleate and grow during a stage when the matrix material is in some sort of liquid state. In the case when there are many growing bubbles, there is a propensity for them to coalesce. At some stage in the process, the matrix will become solid, effectively freezing in the bubble/void configuration. As a result, the configuration of the voids can be quite complicated. The configuration of the microstructure of a composite material has a significant effect on its material properties, such as elastic moduli, thermal and electrical conductivities, permeability, diffusivity, and reactivity. Of particular interest is the configuration of the voids in a porous composite, which can affect all of the above properties.5 Two key properties of the voids are the porosity, φ, being their volume fraction, and a) David.Jenkins@csiro.au. 0021-9606/2013/138(7)/074702/5/$30.00 the specific surface area, s, being their surface area per unit volume of material. In this paper we are concerned with examining the effect of the obstructing particles upon the specific surface area of the voids, for a given porosity. In order to do this in the simplest way, we consider the obstructing particles to be randomly located, non-overlapping (hard) spheres, each having the same radius, Ro , and the voids to be comprised of a set of randomly located, overlapping (fully penetrable) spheres, each having radius, R. Moreover, we allow no overlap between the obstructing particles and the voids. There are several studies of the properties of the porosity of a simple porous composite material6, 7 and in particular of the variation of the specific surface area of voids comprising overlapping spheres with the sphere size and porosity.6 However, there appears to be no particular study that considers the effect of obstructing particles on the properties of the voids. The specific surface area of overlapping spheres has interest from a geometrical point of view, in that it is a rough indicator of the amount of overlap of spheres, as well as from a materials science perspective, as it is important in applications dominated by chemical reactions at surfaces, or in charge storage devices (e.g., supercapacitors). This paper describes an algorithm for formation of simulated microstructure of obstructed porous composites, then presents calculated results of the variation of specific surface energy with the relative size of obstructing and void spheres. A simple analysis provides an explanation of the mechanism that leads to the minimum in the specific surface energy, and show how material properties of the material are affected by the presence of obstructing spheres. II. MICROSTRUCTURE FORMATION The creation of the microstructure used for this work is based on consideration of a cube, consisting of N × N × N volume elements (voxels), where typically we have used 138, 074702-1 © 2013 American Institute of Physics 074702-2 D. R. Jenkins J. Chem. Phys. 138, 074702 (2013) N = 320, a total of 32 768 000 voxels. The unit cell is considered to be periodic on all faces. Typically, we wish to construct a microstructure consisting of φ o volume fraction of hard particles and φ volume fraction of voids. Particles are laid down in two stages: 1. all voxels within the cube are initially considered to be unoccupied. 2. a voxel is chosen randomly within the cube to act as the centre of a hard particle. If the voxel is already occupied by a hard particle, then another voxel is randomly chosen. The process is repeated until an unoccupied voxel is located. If each voxel within a radius Ro of the centre is unoccupied, then the hard particle is considered to be centred at this point, and all the voxels within the radius Ro are marked as occupied. This process is repeated until the volume fraction reaches φ o . Typically, up to about 35% volume fraction of hard particles can be located in this simple fashion. 3. a voxel is chosen randomly within the cube to act as the centre of a void sphere. If the voxel is already occupied by a hard particle, then another voxel is randomly chosen. The process is repeated until an unoccupied voxel is located. If each voxel within a radius R of the centre is unoccupied by a hard particle, then the void sphere is considered to be centred at this point, and all the voxels within the radius R are marked as occupied by void. This process is repeated until the volume fraction of voids reaches φ. Because we pay no attention to the presence of other voids, this allows for fully overlapping spheres. Once this process is complete, each voxel is marked as being either (a) hard particle, (b) void, or (c) unoccupied, taken to be the matrix. For each voxel marked as a void, we consider whether it has a neighbour (north, south, east, west, up, down) which is not void, in which case it is considered to be a surface voxel. The specific surface area is then the total number of surface voxels divided by the total number of voxels in the cell (N3 ). Calculated in this way, the specific surface area is only approximate, although the accuracy of the approximation will increase with N. 2.5 20% 30% 40% 50% 60% 2 1.5 s'R 1 0.5 0 0 0.5 1 1.5 2 2.5 3 3.5 R o /R FIG. 1. Calculated specific surface area versus relative size of obstructing particles and voids, for different values of the porosity. Each point on the graph is the average of 50 simulations. In all of the cases shown here, the obstructing spheres occupy 20% of the volume. Similarly, Figure 2 shows the calculated specific surface area for different amount of obstructing spheres. It demonstrates that adding obstructing spheres increases the value of Ro /R where s R is a minimum. Figure 3 shows images of the simulated configurations having different values of Ro , when R, φ, and φ o are held constant. The most apparent effect of increasing the size of the obstructing spheres is to yield a more “fractal” like surface for the voids. This is relatively straightforward to understand: as the particle size increases while holding the total volume 2 1.6 III. RESULTS Figure 1 shows the calculated dimensionless specific surface area s R where s is the surface area per unit volume of voids, for the case when 20% of the volume is occupied by obstructing spheres. The quantity s is related to s by s s = . φ 1.2 s'R 0.8 10% 0.4 It is plotted in this way to avoid overlap of the individual curves. Note that, for each value of the porosity, there is a minimum in the specific surface area, and that the value of Ro /R where the curve has a minimum increases with the porosity. Note also that this minimum occurs when Ro /R = O(1), that is, when there is some similarity between the sizes of the two sets of particles. 20% 30% 0 0 0.5 1 1.5 2 2.5 3 3.5 R o /R FIG. 2. Calculated specific surface area versus relative size of obstructing particles and voids, for different volume fractions of obstructing spheres (shown in the legend). Each point on the graph is the average of 50 simulations. In all of the cases shown here, the voids occupy 40% of the volume. 074702-3 D. R. Jenkins J. Chem. Phys. 138, 074702 (2013) 7 R o /R = 3.33 6 FIG. 3. Simulated configurations for different values of Ro /R being (a) 1, (b) 2, (c) 3. The black components are the obstructing spheres, the dark grey components are the overlapping spheres, and the light grey is the matrix phase. relative volume 5 4 3 2 1 0 1 11 21 31 41 51 61 71 81 91 101 111 121 131 141 151 161 171 181 191 void number 24 R o /R = 0.769 22 20 18 16 relative volume of particles constant, the average spacing between particles increases. As a result, for sufficiently large particles, relative to the void spheres, the particles have minimal effect upon the location of the voids. However, for small particles, the spacing between particles is smaller, and thus much more overlap of voids is required in order to achieve the required porosity. As a result, the surface of the voids is smoothed and the specific surface area decreased. In essence, this explains the change in specific surface area at the right hand end of Figures 1 and 2. In order to better understand the reason for the existence of the minimum in the curves, however, we considered the number of isolated (i.e., non-connected) voids in the simulations. Because, for most cases considered, the void fraction exceeds the percolation threshold for uniform overlapping spheres of about 29%,8 almost all of the void spheres are connected. In general, the void space consists of a single connected void that comprises virtually all of the porosity, along with a small number of isolated voids. In the situation where Ro /R is large, these isolated voids are mostly single spheres, but when Ro /R is small, there is a larger percentage of isolated voids comprised of multiple overlapping spheres, as shown in the graphs of Figure 4. Moreover, if we consider the number of isolated voids (i.e., the number of voids excluding the largest, highly connected void) per unit volume, nB , then we see that there is a steep increase around Ro /R ≈ 1, as shown in the graph of Figure 5. Consequently, the large connected void comprises a lower percentage of the total porosity. The reason can again be related to the spacing between obstructing particles. When Ro /R > 1, there is sufficient space between the obstructing particles for overlapping voids to create a single connected void that occupies most of the voidage. However, at low values of Ro /R, the spacing between obstructing particles is too small for the largest void to occupy as much of the total porosity, so more isolated voids, comprising multiple void spheres, are created. An increase in the number of isolated voids will generally increase the overall specific surface area, thus accounting for the increase in s R at the left hand end of Figures 1 and 2. In order for the obstructing particles to cause the breakup of the major connected void, there needs to be regions of the volume in which the obstructing particles form an effective “cage” for the void spheres. This is more likely as the size of the obstructing particles decreases, for a given value of φ o , since the average spacing between the particles decreases. If, instead of locating the obstructing spheres randomly, they are 14 12 10 8 6 4 2 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 void number FIG. 4. Graphs showing the volume of isolated voids, relative to the volume of a single void sphere, for two different values of Ro /R. In each case there is 20% volume fraction of obstructing spheres and 30% volume fraction of voids. located on the vertices of a cubic lattice, then it is straightforward to show that no void spheres can overlap if 1 Ro < , R α−1 where 2π . α3 = √ 3 2φo In the examples shown in Figure 5, where φ o = 0.2, this yields Ro < 1.054, R which is shown by the dotted line in the graph. Even though the obstructing particles are randomly placed in these 074702-4 D. R. Jenkins J. Chem. Phys. 138, 074702 (2013) 0.3 35 2 20% 30% 30 40% 50% 0.25 1.7 relative permeability 25 nB 20 15 s'R 0.2 1.4 0.15 1.1 10 5 0.1 0.8 0 0.5 1 1.5 2 2.5 R o /R 0 0.5 1 1.5 2 2.5 3 3.5 R o/R FIG. 5. Graph showing the number of isolated voids per unit volume, as a function of Ro /R, for different values of φ o , as shown in the legend. The vertical dotted line marks the point Ro /R = 1.054, indicating the point at which obstructing spheres on a cubic lattice would preclude overlap of void spheres. examples, there is a clear change in the number of isolated voids in the vicinity of this point. IV. EFFECT ON MATERIAL PROPERTIES We have shown that the presence of obstructing particles causes a significant change in the nature of the packing of overlapping spheres. In particular, as the size of the obstructing particles reduces (for a given volume fraction), they initially lead to more overlap, as evidenced by the reduction in the specific surface area of the voids, but then there is a change in the structure as the particle size is further reduced, as the single connected void breaks up due to the obstacles. While this is of interest itself in terms of the geometrical structures formed, it is most relevant to materials science applications, since it is likely that the nature of the structure thus formed will affect the properties of this type of composite material. As examples of this, we have calculated the effective permeability and Young’s modulus of the structures simulated here, using a commercial finite element tool (MesoProp9 ). In the implementation used by us, the size of the unit cell was limited to 80 × 80 × 80 voxels. Calculated permeabilities from the simulations are shown in Figure 6. Note that, in these simulations, only the voids are assumed to be permeable. The figure shows that there is a pronounced drop in permeability, starting at the point at which there is a minimum in the specific surface area, as Ro /R is decreased. We conjecture that this is related to the reduction in the amount of voids available for percolation, due to the breakup of the main void. Similarly, we used MesoProp to determine the effective elastic properties of the composite material. Figure 7 shows the calculated (relative) Young’s modulus as a function of FIG. 6. Calculated effective permeability (left hand axis) and specific surface area (right hand axis) versus Ro /R, when φ o = 0.2. Each point on the graph represents an average of 25 simulations. Ro /R. Note that, in these calculations, both the obstructing particles and the matrix material are assumed to have the same elastic properties, while the voids are assumed to have the properties of air. Accordingly, the variation of Young’s modulus is due entirely to the configuration of the voids in this case. The figure shows that there is a significant variation in the Young’s modulus of the composite as Ro /R is varied. Moreover, there appears to be a change in the rate of variation of Y at around the point where s R is a minimum, showing that it is important to consider the size of the obstructing particles when determining material properties of composite materials. The relevance of these results to materials science applications needs to be considered. First, we note that the Young's modulus 0 0.8 2 0.6 1.7 s'R 0.4 1.4 0.2 1.1 0 0.8 0 0.5 1 1.5 2 2.5 3 R o/R FIG. 7. Calculated effective Young’s modulus (left hand axis) and specific surface area (right hand axis) versus Ro /R, when φ o = 0.2. Each point on the graph represents an average of 25 simulations. 074702-5 D. R. Jenkins minimum in specific surface energy occurs over a relatively wide range of porosity, φ, and across a range of volume fractions of the obstructing particles. Next, the minimum in specific surface area occurs when Ro and R are of similar size. If R Ro , then the obstructing particles are not likely to affect the formation of the porosity. As an example, the formation of a vesiculated volcanic rock.10 Once the bubbles/vesicles become considerably larger than the crystals within the melt, then the crystals are likely to move within the melt and not contribute to obstructing the final porosity in the way considered here. Conversely, if Ro R then there is minimal obstruction of the voids in any case. Finally, the accuracy of the method is reduced at large and small values of Ro /R, due to the effect of voxel size relative to the size of the different elements of the microstructure. A key issue not considered here is the mechanism of formation of porous composites. In particular, the growth, collapse and coalescence of bubbles within a composite are likely to be impacted by the structures within the material. For example, the presence of small inert particles in the melt comprising the bridges between expanding bubbles may increase the likelihood of the bridges breaking, thus causing the bubbles to coalesce.10 Thus it may be possible to use the approach described here to find an optimal configuration for a microstructure for a specific material requirement, but the challenge of creating such a microstructure remains. V. CONCLUSION The results shown in this paper have an intrinsic interest in terms of the properties of the formation of random structures, as well as relevance to the properties and behaviour of real composite materials. While the work presented here has J. Chem. Phys. 138, 074702 (2013) considered spheres of a uniform size for both the overlapping and hard components, it is natural to examine whether similar behaviour occurs in real materials, where the voids are likely to have a distribution of sizes and hard particles are rarely spheres. In fact, in at least one example, that of simulations of metallurgical coke microstructure,1 which motivated this work, it appears that a minimum in specific surface area exists in the same way as considered here. In that study, the hard particles were considered to be cylinders whose length and diameter were both chosen from a random distribution, and the voids were considered to be overlapping spheres whose radius was chosen from a size distribution. This result indicates that the behaviour presented here is robust in terms of the size and shape of components of composites and hence likely to be relevant to a range of porous composite materials. ACKNOWLEDGMENTS The author acknowledges valuable discussion with Dr. M. J. Buckley, CSIRO Mathematics, Informatics and Statistics. 1 D. R. Jenkins, M. R. Mahoney, and A. D. Miller, Proceedings of the 6th International Congress on the Science and Technology of Ironmaking, Rio de Janeiro, Brazil, October 2012. 2 C. Clarke, Phys. Educ. 38(3), 248–253 (2003). 3 D. Zandomeneghi, M. Voltolini, L. Mancini, F. Brun, D. Dreossi, and M. Polacci, Geosphere 6(6), 793–804 (2010). 4 O. Deo and N. Neithalath, Mater. Sci. Eng., A 528, 402–412 (2010). 5 S. Torquato, Int. J. Solids Struct. 37, 411–422 (2000). 6 P. A. Rikvold and G. Stell, J. Chem. Phys. 82, 1014 (1985). 7 S. B. Lee and S. Torquato, J. Chem. Phys. 89, 3258–3263 (1988). 8 C. D. Lorenz and R. M. Ziff, J. Chem. Phys. 114, 3659 (2001). 9 A. A. Gusev and H. R. Lusti, Adv. Mater. 13(21), 1641–1643 (2001). 10 A. A. Proussevitch, D. L. Sahagian, and V. A. Kutolin, J. Volcanol. Geotherm. Res. 59, 161–178 (1993).