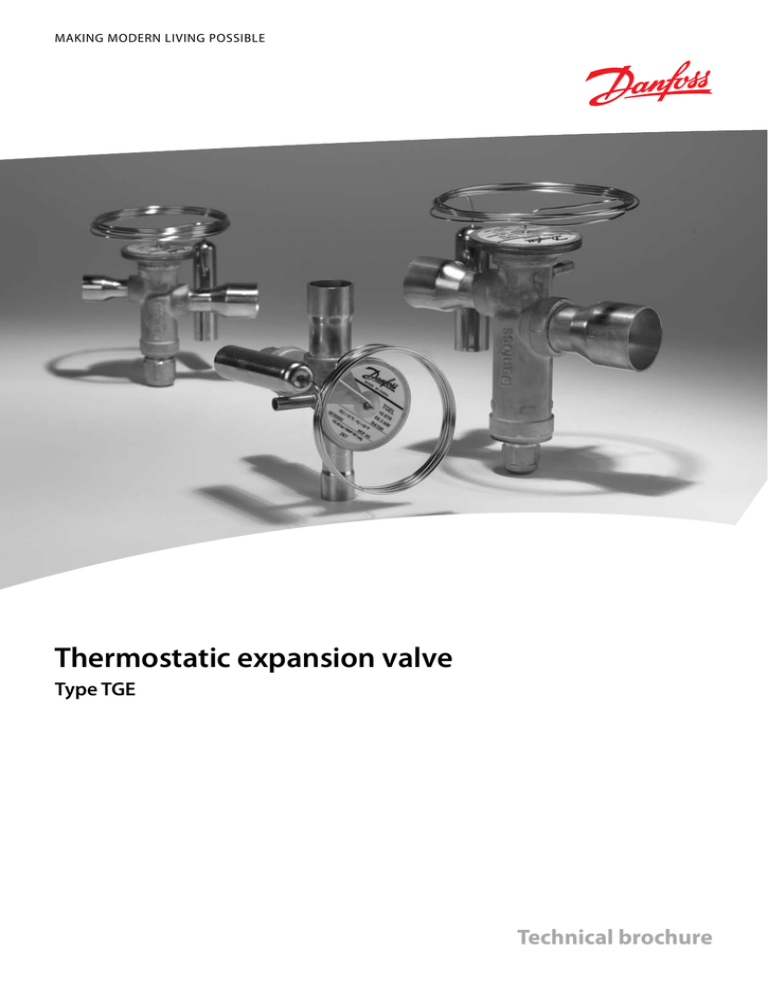

Thermostatic expansion valve

advertisement