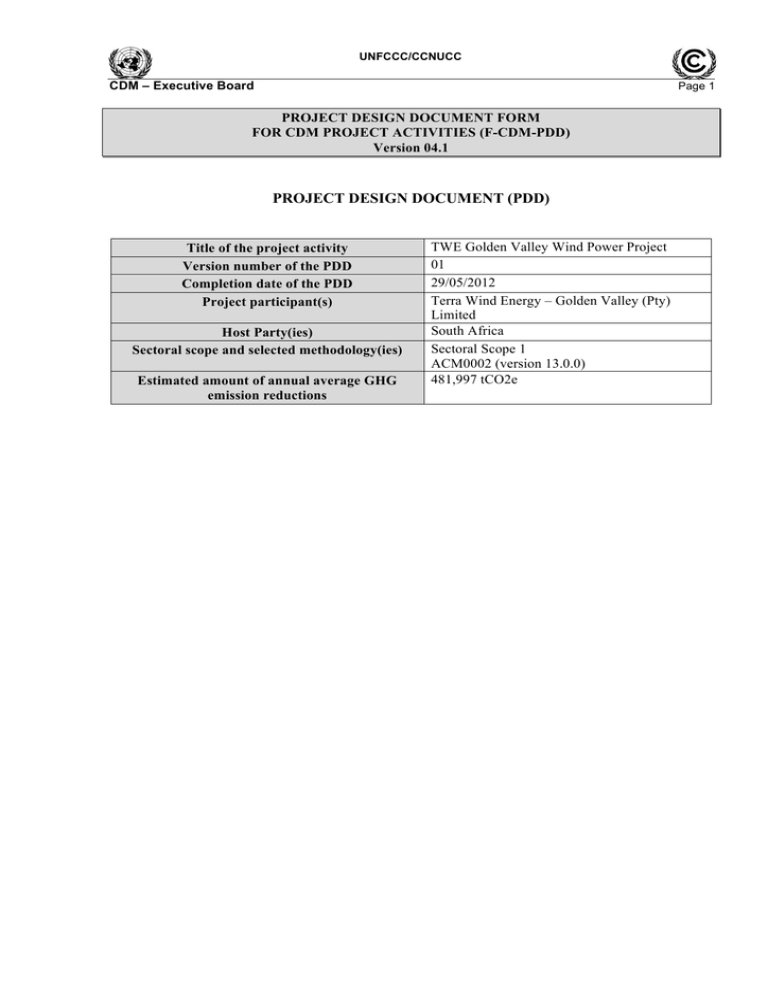

TWE Golden Valley Wind Power Project

advertisement