Contactor Life Expectancy - Sprecher + Schuh B2B Portal

advertisement

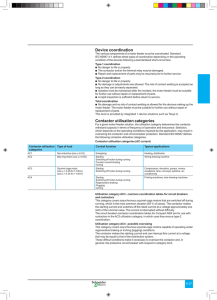

Contactor Life Expectancy What does it really mean? Contactor Life Expectancy What does it really mean Table of Contents Testing Standards…………………………………………………………… 3 Finding Electrical Life on a Life Curve………………………………………… 4 Determining Service Life…………………………………………………… 5 Summary…………………………………………………………………… 7 Revised from material published in the 1986 Sprecher + Schuh manual 2200T “Contactor selection made easy”. The 2200T manual is no longer available in print. 2 Tech-ContactLife_v115 02/2015 Contactor Life Expectancy What does it really mean The electrical life of switchgear is defined by the total number of possible operating cycles under operating conditions. When this number is reached, the wearing parts must be replaced or revised. Testing for electrical life expectancy is an expensive process, requiring precise measurements and actual components for testing. The manufacturer usually does testing and publishes the data in technical specification guides. These numbers can vary widely from product to product, and application to application. What does this figure really mean to the plant or machine designer? How long is this contactor going to operate before routine repairs and down time make it a replacement cost? To determine this, two things are needed: the expected electrical life, and the expected service life. On Sprecher + Schuh Series CA6 contactors, the main contacts can be replaced and are available as replacement parts. In the case of CA6, mechanical life and electrical life can mean two very different things, as the contacts can be replaced over and over. However, this is not possible on the many smaller series contactors, so the electrical life applies to the entire device. Sprecher + Schuh contactors have published electrical life data from 100,000 operations for a definite purpose contactor to 1.3 million electrical operations on a general purpose midrange size contactor. These numbers are the result of stringent quality testing in the factory. Testing Standards To insure accurate testing, the specifications of various utilization categories are used for the testing criteria. The results of these tests are published in contactor life curves. Life load curves are shown in Sprecher + Schuh literature for the most frequent applications, including the following example (Table 1). IEC Utilization Category UL/CSA Ratings Definition AC-1 Continuous Current Resistance Furnaces (Does not include lighting loads) Non inductive or slightly inductive loads, Resistive Furnaces AC-2 Essentially an obsolete technology Slip-ring motors Starting and stopping of running motors AC-3 Inductive HP rated Squirrel-cage motors Starting and stopping of running motors (Breaking FLA) AC-4 Inductive HP rated Squirrel-cage motors Starting, plugging, and inching (Plugging is understood as stopping or reversing the motor rapidly by reversing the motor primary connections while the motor is running. Inching [or jogging] is understood as energizing a motor once or repeatedly for short periods to obtain small movements of the driven mechanism.) AC-15 Amps for Electromagnets general purpose and control relays Electromagnets for contactors, valves, solenoid actuators Table 1: IEC Utilization Categories The electrical life of a device, determined under test conditions for the various utilization categories, is expressed in a graph as a function of the rated operational current. These values Tech-ContactLife_v115 02/2015 3 Contactor Life Expectancy What does it really mean provide a sound general basis for selecting contactors. In practical operations, any deviation of the main influencing factor – the breaking current – will be on the safe side. After startup, the motor usually carries a smaller current than its rated operational current, and in a prolonged inching phase, the break-away starting current is already slightly reduced. This usually compensates for the influence of unfavorable circumstances which may not have been observed. With these graphs, the electrical life for any application (for example, inching of motors with very high or very low starting currents), including any form of mixed operations can be determined. Contact Life (Millions of Operations) Ue = 230…400…460 VAC CA7-97 CA7-85 CA7-60 CA7-43 CA7-37 CA7-30 CA7-23 CA7-16 10 CA7-12 CA7-9 Switching of squirrel-cage motors while starting CA7-72 Finding Electrical Life on a Life Curve 1 0.1 1 10 100 Rated operating current Ie AC-3 [A] Figure 1 Figure 1 shows the Life load curve for Series CA7 contactors for utilization category AC-3 up to 460V AC. Using this graph we can determine the electrical life of a contactor based on the application specifications it will be used for. Example: Given a squirrel-cage motor 3-phase 10 HP, 380 V, 16 A, AC-3 (switched-off only when the motor is running). What is the expected contact life of a CA7-16 contactor? 4 Tech-ContactLife_v115 02/2015 Contactor Life Expectancy What does it really mean • Step 1: Locate the rated operating current of the contactor along the bottom of the graph (x-axis). • Step 2: Follow the bold (orange) line for the contactor up until it breaks off to the left. Follow this imaginary horizontal line to the left. The y-axis is the contactor life in millions of operations. At standard operating levels, CA7-16 has an electrical life expectancy of 1.3 million operations. The contactor electro-mechanical data is published in Sprecher + Schuh catalogs in the technical information sections for each series. Now that we can determine what the manufacturer’s test has shown the electrical life of the contactor to be, we can translate that number into a real lifetime, taking into consideration how many operations we need per hour, per week and per year. The service life of electrical contacts depends on the number of operating cycles per hour and the total number of operating cycles. By knowing the tested electrical life plus the number of operations to be performed per hour/ per week/ per shift, the contactor life in approximate real time can be determined, not just a vague number in the millions. Figure 2 illustrates how this real time life expectancy can be determined from the total operating cycles determined by the manufacturer and the number of operating cycles per hour the unit is expected to perform. Figure 2 makes the following assumptions regarding shift operation Determining Service Life • 1 shift operation: 50 weeks/year, 44 hours/week, 2200 hours/ year • 2 shift operation: 50 weeks/year, 88 hours/week, 4400 hours/ year • 3 shift operation: 365 days/year, 24 hours/day, approx. 8800 hours/ year Figure 2 By knowing two factors of the table we can find the unknown factor. Let us find the following unknown factors. Tech-ContactLife_v115 02/2015 5 Contactor Life Expectancy What does it really mean Example 1: What is the number of permissible operations per hour if the planned service life is 20 years under a single shift operation. The manufacturer’s rated electrical life is listed at 1.2 million operating cycles. • Step one: Start at the known life of the contactor (1.2) just above the 1 on the Y-axis of the table. Follow the imaginary horizontal line to the right until it enters the Service Life area for 20 years under 1 Shift (shaded in orange in Figure 3). • Step two: Now move down the imaginary vertical line towards the X-axis, Number of operating cycles per hour. The approximate number of cycles per hour for this selection would be 26. If this is insufficient for the application, proceed to Example 3 with the desired number of operations per Figure 3 hour. Example 2: What is the expected service life of a contactor with a published electrical life of 1.3 million operations, operating on 1 shift at 4 cycles per hour? See Figure 4. • Step one: Find the known life of the contactor (1.3) on the Y-axis of the table. • Step two: Find the desired operations per hour (4) on the X-Axis. • Step three: Follow the vertical line from 4 up until it intercepts the imaginary horizontal line for 1.3 (red lines in Figure 4). The two lines intersect above the maximum Service Life line (in orange). The life expectancy is over 32 years. Figure 4 6 Tech-ContactLife_v115 02/2015 Contactor Life Expectancy What does it really mean Example 3: What is the required life to operate a contactor at 20 cycles per hour on 2 shifts with a service life desired for 12 years? See Figure 5. • Step one: Locate the number of cycles per hour on the X-axis (20). • Step two: Follow the vertical line up until it interposes within the service life area for 12 years under 2 shifts (orange area in Figure 5), approximately between 8 and 16 years. • Step three: Follow the horizontal line to the left to find published life. The approximate number of operations required to meet the desired life and operations per hour is 1 million. Figure 5 Summary Tech-ContactLife_v115 While estimating the life expectancy of a specific contactor under specific operating specifications can be difficult, by using the known or desired factors involved for the product, and applying them to the chart, the expected service life in real time can be estimated. This turns a vague number of operations into a real expectation of how long your product should operate under normal conditions. 02/2015 7 Contactor Life Expectancy What does it really mean? Tech-ContactLife_v115 02/2015 Sprecher + Schuh US Division Headquarters 15910 International Plaza Drive Houston, TX 77032 Customer Service: (877) 721-5913 Fax: (800) 739-7370 Sprecher + Schuh Canadian Deivision 10 Spy Court Markham, ON L3R 5H6 Customer Service: (905) 475-6543 Fax: (905) 475-0027 www.sprecherschuh.com Sprecher + Schuh has provided reliable control and protection solutions for its customers since 1903. Today, Sprecher + Schuh offers a wide range of low-voltage industrial control products, including contactors, a variety of relays, starters, push buttons, switches, terminals and controllers, to name a few. All of our products are crafted with precision and tested rigorously for performance — far exceeding industry standards. Moving forward, we continue along the path of constantly seeking innovative ways to provide solutions for our customers. It is by this philosophy that Sprecher + Schuh has come to be the industrial control manufacturer of choice for many customers around the globe seeking quality, reliability, and a name they can trust.