High-Reliability Meets Pb-free and Halogen-Free

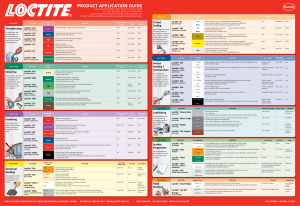

advertisement

Halogen-Free Solder Paste that Goes the Distance Brian Betti The Electronics Group of Henkel While many manufacturers -- particularly in the US -- are still uncertain as to the benefits of moving to a halogen-free solder paste, advances in material capability have made this possible transition all the more appealing. Logically, assembly specialists have been concerned about the effect that halogen elimination would have on solder paste performance. Indeed, covalently bonded halogen delivers tremendous benefits for the soldering process including printer open time, thermal stability, the reflow process window and the shelf-life. Replacing halogen with an activator that can deliver a wide process window -- while also retaining or increasing reliability -- is the challenge now facing the industry’s materials formulators. When halogen is removed from a flux, it’s not as easy as replacing it with other metal oxide active molecules as they don’t offer the same stability as halogencontaining compounds. Balancing a halogen-free formula for optimal flux performance is exceptionally difficult, particularly when not intentionally adding halogen. For this critical piece, Henkel leveraged its decades of solder formulation expertise and designed two zero-halogen flux systems that deliver robust soldering performance. LOCTITE MULTICORE HF 200 and LOCTITE MULTICORE HF 212 contain zero deliberately added halogen and are under the limit of detection for chlorine and bromine when subjected to rigorous testing. With consistent print performance and minimal hot slump – even in regions with temperatures that exceed 86°F (30°C) and relative humidity (RH) as high as 80% -- these materials offer exceptional stability and environmental adaptability. Both solder paste systems exhibit extremely low voiding in CSP via-in-pad joints, good coalescence and excellent solderability over a wide range of surface finishes including Ni/Au, Immersion Sn, CuNiZn, Immersion Ag and OSP copper. In addition, both zero-halogen materials have very low residues which further enhances reliability, as halide-containing post-reflow residue has been shown to cause corrosion or lower insulation resistance. But, while these formulations were developed for sustainability, Henkel recognizes that customers want a material that delivers outstanding performance, regardless of its halogen status. Therefore, the materials were designed to address demanding assembly requirements alongside environmental benefits. Unsurprisingly, LOCTITE MULTICORE HF 200 and LOCTITE MULTICORE HF 212 are already proving their superb performance to many assembly specialists. For US vehicle safety lighting manufacturer, Missouri-based Peterson Manufacturing, LOCTITE MULTICORE HF 212 delivers on numerous fronts, not the least of which is cost savings. “We decided to evaluate LOCTITE MULTICORE HF 212 because we were having some printing challenges with our previous paste,” explains Ken Horky, Electronics Manufacturing Process Engineer at Peterson Manufacturing, where the new solder paste is being used for all of the company’s LED lighting products. “The printing results with Henkel’s new paste are excellent, and one of the biggest benefits for our operation is the material’s very long stencil life. In an environment where cost control is essential, the ability to leave the paste on the stencil for very long periods of time – even until the next shift – with no degradation in quality is a huge advantage. We don’t discard nearly as much paste as before, which is a tremendous cost savings.” In addition to the printability and long stencil life, Horky also notes LOCTITE MULTICORE HF 212’s very low residues. “This material also has great aesthetics,” he says. “There is very little paste residue, which is really important to customers.” LOCTITE MULTICORE HF 212 is optimized for use on components with pitches of 0.3 mm and greater and is an ideal material for larger, high-value boards often used in industrial, networking and lighting applications. What’s more, the novel solder paste has been proven to deliver excellent wetting results on parts such as CuNiZn shields that can be particularly problematic for alternative paste materials. This alloy is commonly used in RF shielding applications. For consumer market applications, LOCTITE MULTICORE HF 200 provides excellent print characteristics required for smaller board sizes. Print speeds of 200 mm per second down to very fine-pitch 0.3mm CSPs enable high throughput, high yield operations. Abandon times of up to four hours and a work life of greater than eight hours also makes LOCTITE MULTICORE HF200 very process-adaptable. For more information on Henkel’s halogen-free materials, LOCTITE MULTICORE HF 200 and LOTCITE MULTICORE HF 212, log onto www.henkel.com/electronics or call 1-888-943-6535 in the Americas, +32 1457 5611 in Europe or +86 21 3898 4800 in Asia.