Craft Brewer Increases First-Pass Yield and Throughput with New

advertisement

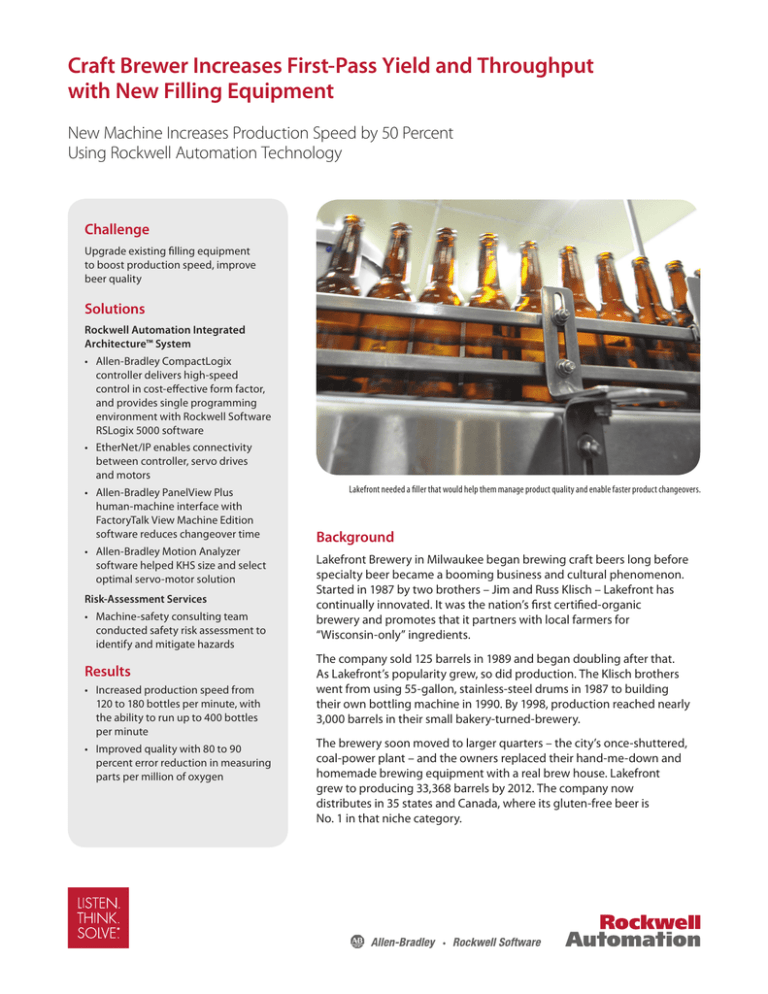

Craft Brewer Increases First-Pass Yield and Throughput with New Filling Equipment New Machine Increases Production Speed by 50 Percent Using Rockwell Automation Technology Challenge Upgrade existing filling equipment to boost production speed, improve beer quality Solutions Rockwell Automation Integrated Architecture™ System • Allen-Bradley CompactLogix controller delivers high-speed control in cost-effective form factor, and provides single programming environment with Rockwell Software RSLogix 5000 software • EtherNet/IP enables connectivity between controller, servo drives and motors • Allen-Bradley PanelView Plus human-machine interface with FactoryTalk View Machine Edition software reduces changeover time • Allen-Bradley Motion Analyzer software helped KHS size and select optimal servo-motor solution Risk-Assessment Services • Machine-safety consulting team conducted safety risk assessment to identify and mitigate hazards Results • Increased production speed from 120 to 180 bottles per minute, with the ability to run up to 400 bottles per minute • Improved quality with 80 to 90 percent error reduction in measuring parts per million of oxygen Lakefront needed a filler that would help them manage product quality and enable faster product changeovers. Background Lakefront Brewery in Milwaukee began brewing craft beers long before specialty beer became a booming business and cultural phenomenon. Started in 1987 by two brothers – Jim and Russ Klisch – Lakefront has continually innovated. It was the nation’s first certified-organic brewery and promotes that it partners with local farmers for “Wisconsin-only” ingredients. The company sold 125 barrels in 1989 and began doubling after that. As Lakefront’s popularity grew, so did production. The Klisch brothers went from using 55-gallon, stainless-steel drums in 1987 to building their own bottling machine in 1990. By 1998, production reached nearly 3,000 barrels in their small bakery-turned-brewery. The brewery soon moved to larger quarters – the city’s once-shuttered, coal-power plant – and the owners replaced their hand-me-down and homemade brewing equipment with a real brew house. Lakefront grew to producing 33,368 barrels by 2012. The company now distributes in 35 states and Canada, where its gluten-free beer is No. 1 in that niche category. at certain points in the brewing process – like before fermentation – its absence is just as important during filling to avoid stale, undesirable tastes.” Lakefront needed a filler that would help them manage product quality and also enable faster product changeovers from 12-ounce to 24-ounce bottles, and from year-round to seasonal brews. “Production speed and machine reliability were key requirements for us,” Klisch said. “We were looking to streamline our operating efficiency by reducing the number of shifts in a 10-hour day, and the only way to do that was to improve machinery uptime and make product faster.” In keeping with its indigenous brewing approach and loyalty to local suppliers whenever possible, Lakefront selected fellow Wisconsin-headquartered machine builder KHS USA Inc. to help them upgrade the filling equipment. Solutions Leveraging more than 140 years of experience building fillers for large beverage producers, KHS designed a machine to provide this midsized business with affordable automation equipment. The quality of Lakefront’s beer has improved, partially due to an 80 to 90 percent error reduction in measuring parts per million of oxygen content during the filling process. Challenge For a local craft brewer, it can be a challenge to determine the appropriate amount of technology investment that will provide value to the business without requiring high upfront costs. After discussing the options, the Klisch brothers decided to upgrade their bottle-filling equipment in 2013 to keep pace with expanding consumer demand. The duo began searching for an affordable, reliable and flexible filler machine that would also fit the unique production requirements of their brewing applications. “We needed filling equipment that would ensure low oxygen content at the right points in the process, along with appropriate sterilization, and high-accuracy filling of plus or minus 1.5 milliliters,” explained company president Russ Klisch. “While the presence of oxygen is critical The KHS machine, called the Innofill Micro Glass-Bottle Filler, fills Lakefront bottles with beer at the required temperature and pressure using a proven mechanical valve that achieves the required high-accuracy filling. KHS worked with engineers at the Rockwell Automation sales office in Milwaukee to jointly design and develop the new machine. “With Rockwell Automation on the design team from the beginning, we were able to create a costeffective, high-performance solution for producing small beer outputs in a high-throughput, sterile environment,” said Jeff Gilberg, director of engineering at KHS. “This also helped us design a solution that would allow KHS to penetrate a new market globally.” The team worked together to keep the machine’s eventual energy consumption as low as possible. KHS virtually linked models created using SolidWorks design software from DS SolidWorks with control designs in Rockwell Software® RSLogix™ 5000 software to model the new small-output application with Allen-Bradley® Motion Analyzer software. The Motion Analyzer tool helped KHS size and select the optimal servo-motor solution based on torque requirements. “With Rockwell Automation on the design team from the beginning, we were able to create a cost-effictive, high-performance solution for producing small beer outputs in a high-throughput, sterile environment.” – Jeff Gilberg The Innofill Micro Glass-Bottle Filler fills bottles with beer, and then gently discharges them to a filler jetter, where the beer is agitated with a fine microstream of sanitary hot water. The hot water produces a fob of foam that covers the top of each bottle to prevent any oxygen from settling in. A crowner pushes down on the fob to displace the foam, resulting in a sterile spot to place the bottle cap. The filled bottles of beer are conveyed to a case packer and transported to retail suppliers. The machine uses an Allen-Bradley CompactLogix™ programmable automation controller that is tightly synchronized with Allen-Bradley Kinetix® 6500 servo drives and Allen-Bradley MP Series™ servo motors via the EtherNet/IP™ network, providing integrated motion control on one standard industrial network. This eliminates the need for a dedicated motion network, reducing cabling and removing the need to create gateways to get information to or from secluded networks. It also improves diagnostics and simplifies maintenance. Results A seamless installation prevented any interruptions to the brewing process, and the new filler meets Lakefront’s small-footprint requirements. More importantly, the machine dramatically reduced Lakefront’s productchangeover, maintenance and troubleshooting time because operators can store and recall recipes using the Allen-Bradley PanelView™ Plus human-machine interface and FactoryTalk® View Machine Edition software. Production speed has increased from 120 to 180 bottles per minute, and the Innofill Micro Glass-Bottle Filler is capable of producing up to 400 bottles per minute in the Lakefront facility. In addition, using a single programming environment streamlines engineering efforts. To improve machine safety, Rockwell Automation conducted a risk assessment and implemented safety relays and safe limited speed modules to mitigate operator safety risks identified during the assessment. The safe limited speed technology helps increase productivity by allowing operators to perform maintenance and other tasks while the machine is in motion, yet operating safely. The risk-assessment process also helped ensure compliance with appropriate global safety standards. “Fast changeovers are crucial when you’re a craft brewery producing 22 different types of beer throughout the year, and only 12 of those are brewed year-round,” Klisch explained. “The new filler allows easy switchover from year-round to seasonal brews.” Production speed has increased from 120 to 180 bottles per minute, and the Innofill Micro Glass-Bottle Filler is capable of producing up to 400 bottles per minute in the Lakefront facility. The Innofill Micro Glass-Bottle Filler fills bottles with beer and then gently discharges them to a filler jetter, where the beer is agitated with a fine microstream of sanitary hot water. “Now, we’re experiencing an average of 90 percent machine uptime compared to 70 percent prior to the new machine,” Klisch said. “In addition, we only have one 10-hour shift each day instead of two, saving costs and making our jobs easier.” Most importantly, the quality of Lakefront’s beer has improved, which is partially due to an 80 to 90 percent error reduction in measuring parts per million of oxygen content during the filling process. “The new filler machine improves the quality and integrity of the beer, while also enhancing sanitary conditions for clean-in-place procedures,” Gilberg said. “It also reduces process loss of beer to ensure high throughput and minimize spillage.” The new machine also has reduced other types of waste. “Before the new filler machine, we had product quality and consistency challenges,” Klisch said. “For example, we’d have six or seven cases of beer with wrong fill levels or missed crowns. With the new KHS machine and Rockwell Automation control platform, we’ve lowered our scrap rate by 80 percent.” “Ultimately, the team designed an affordable automated filling machine that is exceeding our expectations,” A seamless installation prevented any interruptions to the brewing process. Klisch said. “The technology investment for us as a small-output craft brewer has definitely paid off with the impressive improvements we’re seeing.” The results mentioned above are specific to Lakefront Brewery’s use of Rockwell Automation products and services in conjunction with other products. Specific results may vary for other customers. Allen-BradlAllen-Bradley, CompactLogix, FactoryTalk, Integrated Architecture, Kinetix, MP-Series, PanelView, Rockwell Software and RSLogix are trademarks of Rockwell Automation Inc. EtherNet/IP is a trademark of ODVA. . Publication FOOD-AP034A-EN-P – May 2014 Copyright © 2014 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.