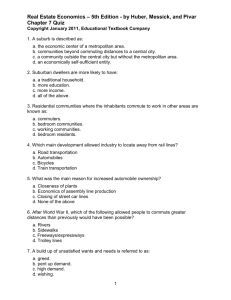

Return unit for vehicle in motion rail system 920

advertisement

Technical leaflet 150022 1 Date 2012-03-07 Trolley Return Unit for 920/1500 Automatic return unit for a suction trolley •Up to 35 meter Rail. •Fast loop time 0.75 m/s (45 – 50 seconds for 35 m). •Can be combined with 920 - mechanical, electromagnetic and pneumatic suction units. •Safe and reliable. •Everything included. The trolley return unit is very suitable for high capacity drive through applications such as vehicle inspection centres and bus garages. The system is fully automated. The fan is automatically started when the hose is pulled down to attach the nozzle to the vehicle’s exhaust pipe. The vehicle pulls the trolley along the straight rail to the disconnection point at the end of the rail. After disconnection, the hose hoist will lift up the hose, close the automatic damper, and start the motorized return of the trolley. Manual return by pushing a button or completely automatic return is selected with a switch setting on the panel. The system is designed for easy operation and high reliability. The trolley return unit is an accessory for the 920 rail and suits both mechanical, electromagnetic and pneumatic suction units of type 1500. Included •Drive motor •Control box •Motor damper •Internal wiring To be ordered separately • Rail and suction unit to be ordered separately. (See separate Technical leaflets 9884012 and 150021.) Safe and reliable • Emergency stop. •Drive release, if obstacle in-way. •Limited drive function even if limit switches fails. •Built-in failure mode logics. •Automatic damper closing when the trolley return is activated. Manual or automatic trolley unit return •Manual control (push button). •Automatic return of trolley unit when the nozzle is disconnected from the hose. Product Trolley Return Unit for 920/1500 Accessory Bus bar extension 2.5 m trolley return Part no. 20801144 Part no. 20376472 Trolley Return Unit for 920/1500 Main components Suction rail End cover Bus bar SLX3 Motor damper Drive unit driving slot Connection box 1 Guide pulley (on the middle of the rail´s mounting brackets) Balance block Wire stop with spring Control box (start / stop) Limit switch SLX Limit switch SL4 Idler pulley unit Wire Control box (manual / auto) Disconnection arrow SLX1 Figure 1 (Overview components) Technical information Rail length max. 35 m Suction unit (1 per rail) 920-1500 Voltage, primary side 100/115/200/230/240 V Return time for suction trolley Phase, primary side Frequency, primary side Voltage, secondary side Protection class Connection box 2 Inductive sensor SL2 < 1 min. 1-phase 50 / 60 Hz 24 V Ambient temperature working range for electrical components Temperature resistance Weight complete Environmental data Recycling level Energy consumption 0 - 40ºC 30 kg 100% 300 W IP21 www.nederman.com