List of test equipment for IEC 60950 3rd ed.

advertisement

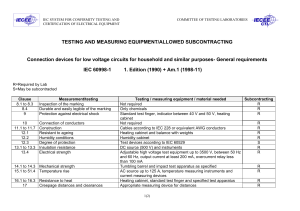

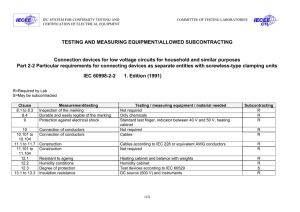

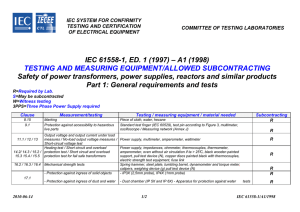

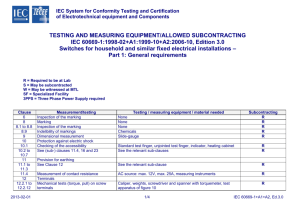

COMMITTEE OF TESTING LABORATORIES IEC SYSTEM FOR CONFIRMITY TESTING AND CERTIFICATION OF ELECTRICAL EQUIPMENT TESTING AND MEASURING EQUIPMENT/ALLOWED SUBCONTRACTING IEC 60669-1:1999-10, Edition 3.0 Switches for household and similar fixed electrical installations Part 1: General requirements R=Required by Lab S=May be subcontracted 3PPS=Three Phase Power Supply required Clause 6 8 8.1 to 8.8 8.9 9 10 10.1 10.2 to 10.7 11 11.1 to 11.3 11.4 12 12 to 12.2.12 July 2006 Measurement/testing Inspection of the marking Marking Inspection of the marking Indelibility of markings Dimensional measurement Protection against electric shock Checking of the accessibility See (sub-) clauses 11.4, 15.2, 16 and 23 Provision for earthing See Clause 12 Measurement of contact resistance Terminals Mechanical tests (torque, pull) on screw terminals Testing / measuring equipment / material needed None None None Chemicals Slide-gauge Subcontracting R R R R R Standard test finger, unjointed test finger, indicator, heating cabinet See the relevant sub-clauses R R See the relevant sub-clause AC source: max. 12V, max. 25A, measuring instruments R R Weights, screwdriver and spanner with torquemeter R 1/3 IEC 60669-1, ed 3 COMMITTEE OF TESTING LABORATORIES IEC SYSTEM FOR CONFIRMITY TESTING AND CERTIFICATION OF ELECTRICAL EQUIPMENT Clause 12.3 to 12.3.10 12.3.12 13 14 14.3 15 15.1 15.2 15.3 16 16.1 16.2 17 18 19 20 20.1 20.2 20.3 20.4 to 20.8 July 2006 Measurement/testing Mechanical tests on screwless terminals Electrical tests ; mV-Meter Conductor deflecting test Constructional requirements Mechanism Slow operation Resistance to ageing, to harmful ingress of water and to humidity Ageing test Ingress of water Humidity treatment Insulation resistance and electric strength Insulation resistance Electric strength Temperature-rise test Testing / measuring equipment / material needed Weights Subcontracting R Specified test apparatus with measuring instruments Test on membranes, heating cabinet, refrigerator Inspection, manual tests Not required See clause 19 R R R R Heating cabinet, climatic chamber Test devices for IP X4 and IP X5 according to IEC 60529 Humidity cabinet R R R DC source (500V) and instruments Adjustable high voltage test equipment (AC) up to 4000V AC source up to 75A, temperature measuring instruments and devices Making and breaking capacity tests specified Test apparatus according to method of actuating the switch, supply according to the ratings source with a short circuit capacity of min. 1500A, adjustable load circuit (resistors and inductors), tungsten filament lamp load, measuring instruments Normal operation, tests specified according See also clause 18, special load circuit for fluorescent lamp loads to the ratings Mechanical strength Impact test Specified test apparatus Mounting test on cylinder surface Specified test arrangement, test screwdriver Test of screwed glands Test spanner Removal of covers, cover-plates Specified gauges 2/3 R R R R 3PPS R R R R R IEC 60669-1, ed 3 COMMITTEE OF TESTING LABORATORIES IEC SYSTEM FOR CONFIRMITY TESTING AND CERTIFICATION OF ELECTRICAL EQUIPMENT Clause 20.9 21 22 22.1 to 22.4 22.5 to 22.7 23 24 24.1.1 24.2 25 26 26.1 26.2 Measurement/testing Pull test on operating member of an cordoperated switch Resistance to heat, treatments according to test specifications Screws, current carrying parts and connections Inspection, manual tests, lightening Inspections and chemical tests on metals of current carrying parts Creepage distances, clearances Resistance of insulating material to abnormal heat, to fire and to tracking Gow-wire test Resistance to tracking Resistance to rusting, treatment EMC requirements Immunity Emission Testing / measuring equipment / material needed Dynamometer, weights Subcontracting R Heating cabinets R Test screwdriver, spanner Instruments for chemical analysis R S Checking by measurement with slide gauges R Test apparatus according to IEC 60695-2-1 Test apparatus according to IEC 60112 Chemicals, humidity cabinet, heating cabinet R R R Not required Not required Note: The presence of equipment alone does not indicate a satisfactory situation. Assessors must evaluate the equipment design, calibration, uncertainty and documentation to ensure compliance with the directions of the standard. The requirements of ISO Guide 25 regarding validation are applicable, as the tests of this standard are not standardized tests. July 2006 3/3 IEC 60669-1, ed 3