Improving Electric Motor Energy Efficiency

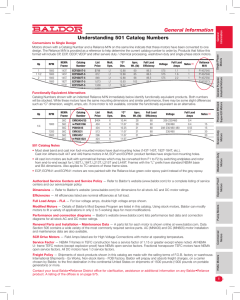

advertisement

we are nema Improving Electric Motor Energy Efficiency Daniel E. Delaney, Agency and Regulatory Manager, Regal Beloit Motors and Chair, NEMA Motors and Generators Section I began my career in electric motors in 1999 as a motor design engineer. I worked on several electric motor platforms including industrial ac and dc motors, as well as ac commercial and residential motors. I’ve been involved with the design of electric motors from thousands of horsepower to one watt, and applications ranging from dockside cranes and mining drag lines to residential appliances and bathroom vent fan motors. Early in my career, I was given an opportunity to manage product offerings for Underwriters Laboratories Inc. (UL), Canadian Standards Association (CSA), and the Conformité Européenne (CE). Presented with this challenge, I did what every good young engineer must do when “volun-told,” and that was to immerse myself in NEMA, International Electrotechnical Commission (IEC), Institute of Electrical and Electronics Engineers (IEEE), UL, and CSA standards. These standards provided me with industry guidance on aspects such as product safety, design performance, energy performance, and mechanical design. Shortly thereafter, I found fellow engineers asking me to review their existing and new motor designs to ensure they complied with the latest national and international standards. As my knowledge of standards evolved, I became motivated to see that the future development of standards also evolved with the latest technology advancements, safety improvements, and regulatory expansions. Once you participate in developing a standard or two, it is very common to be asked to participate in related standards development. Before you know it, someone is referring to you as an industry “expert” and asking you to write an article for a trade magazine or to present the latest standard revision at an industry conference. Participation in these industry standards and conferences has greatly increased my knowledge of the motor industry and has built strong relationships that have been immeasurable for both my employer and my career. One example of my involvement in industry standards has been the evolution of electric motor energy efficiency standards and regulations. In the late 1970s, NEMA developed the baseline for energy-efficient electric motor requirements. As these NEMA requirements matured, the Department of Energy (DOE) initiated regulation—the Energy Policy Act of 1992—around these minimum efficiency requirements. Each time DOE considered expansion of the regulation, multiple electric motor standards—NEMA, IEEE, CSA, and IEC—were consulted for determination of efficiency levels, test methods, design performance criteria, and motor nameplate labelling. It has been possible through multiple standards participation by my peers and me to harmonize many of these global requirements, thus simplifying their implementation; however, this work is never complete. To promote continued harmonization, I agreed to be an IEC convener of an international working group committee (IECEE WG2D) focused on global harmonization of motor energyefficiency requirements. As the induction motor efficiency standards are nearing maturity, efforts have begun to focus on the efficiency determination of motor-driven systems, which include the variable frequency drive, the electric motor, and the driven systems. Over the past six months, I have been serving on an international (IEC TC22G WG18) working group of variable frequency inverter drive, motor, and motor-driven system manufacturers to develop the future for testing and determination of motordriven system efficiencies. ei NEMA electroindustry • January 2015 13