BA-100 /150 - Milwaukee Valve

advertisement

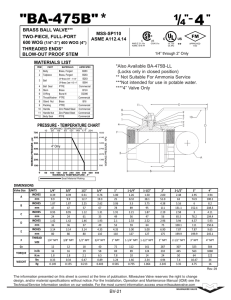

/ BA-100 /150 * BRONZE BALL VALVE, HOSE END, DUST CAP and CHAIN TWO-PIECE, FULL PORT THREADED x 3/4” HOSE END (BA100H) SOLDER x 3/4” HOSE END (BA150H) BLOW-OUT PROOF STEM / 1 "- 3 " 4 2 MSS SP-110 *Not intended for use in potable water. DIMENSIONS UNITS INCHES mm INCHES B (BA-100) mm INCHES B' (BA-150) mm INCHES C A (BA-100) mm INCHES C' (BA-150) mm INCHES D mm E F Cv INCHES mm THREADED INLET Note: DN (Diameter Nominal) = Metric equivalent size. 1/2" DN15 3/4" DN20 0.50 12.7 0.76 19.3 2.70 69 2.90 74 2.55 65 3.05 78 1.10 28 1.30 33 1.10 28 1.45 37 1.88 48 2.14 54 3.81 97 NPT 13 4.62 117 NPT 30 Rev. 15 Do not pressurize cap. Pressure not to exceed 40 psi. MATERIALS LIST MATERIAL BRONZE BRASS BRASS, CHROME PLATED RPTFE, 15% GLASS FILLED BRASS RPTFE, 25% GLASS FILLED PTFE BRASS STEEL, ZINC PLATED VINYL STEEL, ZINC PLATED POLYPROPYLENE EPDM BRASS BEAD ATM SPEC. B584 B16 B16 PRESSURE - TEMPERATURE DATA (See Note) B16 10 B16 NOTE: Pressure / Temperature ratings shown are for valve only. Hose side pressure and temperature limit is based on connected hose and is the users responsibility. WORKING TEMPERATURE - C 93 121 149 177 204 66 38 232 600 4140 500 3450 400 2760 300 2070 200 1380 100 690 0 50 100 150 200 250 300 350 WORKING TEMPERATURE - F 400 450 Seat Material Rating Joint Limits from ANSI B16.18 for 95/5 Solder The information presented on this sheet is correct at the time of publication. Milwaukee Valve reserves the right to change design, and/or material specifications without notice. For the Installation, Operation and Maintenance Manual (IOM) see the engineering section on our website. For the most current information access www.milwaukeevalve.com BV-4 MILWAUKEE VALVE WORKING PRESSURE - Kpa DESCRIPTION BODY TAILPIECE BALL SEAT STEM THRUST WASHER PACKING PACKING NUT HANDLE HANDLE GRIP HANDLE NUT DUST CAP GASKET CHAIN WORKING PRESSURE - psi ITEM 1 2 3 4 5 6 7 8 9 10 11 12 13 14