The Study of the Stray Load Loss and Mechanical Loss of Three

advertisement

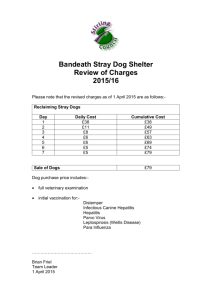

ISSN(Print) 1975-0102 ISSN(Online) 2093-7423 J Electr Eng Technol Vol. 8, No. ?: 742-?, 2013 http://dx.doi.org/10.5370/JEET.2013.8.?.742 The Study of the Stray Load Loss and Mechanical Loss of Three Phase Induction Motor considering Experimental Results Dong-JunKim*, Jae-Hak Choi*, Yon-Do Chun*, Dae-Hyun Koo* and Pil-Wan Han† Abstract – The accurate determination of induction motor efficiency depends on the estimation of the five losses of stator and rotor copper loss, iron loss, mechanical loss and stray load loss. As the mechanical and stray load losses are not calculated by electro-magnetic analysis, the values of these two losses are very important in induction motor design. In this paper, the values of mechanical loss and stray load loss are proposed through investigating testing data from commercial products of three phase induction motors under 37kW. If the values of this paper are applied to motor design, the accuracy of design and analysis can be improved. The losses of motors are obtained by using load and no-load test results following IEC 60034-2-1 standard. Keywords : Stray load loss, Mechanical loss, Efficiency, Induction motor 1. Introduction 2007. One method of this standard followed the IEEE 112B procedure of determining the SLL through test measurements. This standard also provided for assigning the value of stray loss as a percentage of input power which is dependent on motor output power [2]. The representative standards for efficiency test of three phase induction motor are IEEE std. 112, IEC 60034-2-1 and CSA C 390, where the stray load loss (PS) is determined by the means of output power. These standards also determine the PS from assigned values in pre-defined curve, which depend on motor rated output power [1]. The PS is determined by subtracting the conventional losses from the apparent total loss. The dependence of the PS on motor rating is often stated in literature but the analytical calculation of PS is difficult and historical test data have often been relied upon [2]. In squirrel-cage induction motors, the mechanical losses are produced by friction losses in bearings, windage losses of outside cooling fan, friction air losses of rotor and windage losses of internal fans of rotor rings [3]. In IEC 60034-2-1 and IEEE 112B standard, the mechanical loss is determined from no-load operation of the motor at variable voltage [4]. In this paper, the values of mechanical loss and stray load loss are investigated through testing data from 196 commercial products of three phase induction motors under 37kW 2.1 Procedure of efficiency test The test procedure for efficiency and losses is listed in Table 1. The load test is applied at six different load points. The first four load points should be chosen to be approximately equally spaced between not less than 25% and up to and including the 100% load. The remaining two load points should be suitably approximately equally spaced above 100%. In no-load test, test motor is uncoupled from the loading device and operated at a minimum number of 7 values of voltage ranging from 125% of the rated voltage to 20% [4]. 2.2 Efficiency and mechanical loss calculation Motor efficiency, η is defined as a ratio of output mechanical power to the input electrical power (1) 2. Efficiency Test by IEC 60034-2-1 Table 1. Efficiency test procedure 2.1 D2L sizing equation Order 1 2 3 4 5 6 IEC 60034-2-1 was approved to replace IEC 60034-2 in † Corresponding Author: Electric Motor Research Center, Korea Electrotechnology Institute (pwhan@keri.re.kr) * Electric Motor Research Center, Korea Electrotechnology Institute (pwhan@keri.re.kr) Received: February 25, 2013; Accepted: July 19, 2013 742 Procedure Check of motor specification Measurement of motor resistance Rated load thermal test Load test No load test at variable voltage Calculation of losses and efficiency D Dong-JunKim, J Jae-Hak Choi, Yon-Do Y Chun, Dae-Hyun D Koo and Pil-Wan H Han Fig. 1. 1 Plot to deterrmine mechannical loss Fig g. 2. Plot to determine strayy load loss (op ptimum model) where Ploss is the w t total lossees in the motoor including stator (P Pc1) and rotorr copper loss (Pc2), iron losss(Pi), mechannical looss (Pm) and stray load loss (Ps). Thhe core loss and m mechanical looss are dettermined undder the no--load opperation. The stator, rotor and a stray lossses are determ mined unnder load teests, wherebyy the motor is coupled to t a dyynamometer. The stator loss is meassured as I2R loss in the stator w winding. The rotor r copper loss l is determ mined as a prooduct off the slip (s) and a the airgap power in Eq. (5). × ×s Tab ble 2. Load tesst results of 377kW 4polemo otor Ou utput power/ rated r [%] To orque[Nm] Input[kW] Current[A] C Sp peed[rpm] Tem mperature of winding[°C] Voltage[V] V (2) _ 110 100 75 50 25 2449.9 4 49.9 8 85.6 1767 219.4 43.7 75.9 1772 199.1 39.6 69.3 1775 148.8 29.6 54.2 1780 98.8 19.9 40.4 1788 49.22 10.33 29.33 17933 1001.6 101.8 101.6 99.6 98.3 96.77 3880.9 379.8 380.4 379.6 380.5 380.33 Tab ble 3. No-loadd test results of 37kW 4poleemotor In nput voltage/ rated [%] Voltage[V] current[A] Input[kW] In Eq. (3), subtracting the t no-load stator s copper loss (P Pc1_0) from noo-load input power (Pin_0) gives a consstant looss (Pk) whichh is the sum off mechanical and a core loss. Fig. 1 shows the pllot between Pk and the volltage squared (V2) t results off 37kW inducttion motor (T Table frrom no-load test 3)). Extrapolating a straight line to zero voltage, the zero vooltage axis inttercept is the mechanical m looss (Pm) [4]. _ 1 125 125 100 80 60 50 5 35 200 475 45.0 2.21 380 24.8 0.88 3304 118.0 00.64 228 12.8 0.49 19 90 10 0.5 0.45 133 7.4 0.38 766 5.00 0.31 Y (3) ((5) ( (6) Fig. F 4 shows the t residual loosses at six lo oad points (PL), regrression line (Y Y) and PS of opptimum modeel. Tables T 1 and 3 show the loaad test and no--load test resuults of 37kW 3 4-pole induction motor respectiveely to determine the losses. 2.3 Stray load d loss calculaation In the IEEE standard 1122B and the IE EC 60034-2-1, the sttray load losss (Ps) is deetermined byy subtracting the coonventional loosses from thee apparent tottal loss (Papp). The appparent total loss is the difference beetween the input i poower and outpput power at thhe load point of interest 2.4 Assigning vaalues of strayy load loss The T IEC 60034-2-1 standarrd also allows for assigningg a valu ue for the strayy load loss. T This value is dependent on the t mottor rating and is between 0..5% and 2.5% % of input pow wer in Eq. E (7) [2, 4]. Table T 4 showss the assigned d values of IEE EE std. 112 [5], whicch are the perrcentage of ou utput power annd cann not be comppared with IIEC 60034-2-1 exactly but b sim milar to assigned values of IEC 60034-2--1 of Eq. (7) in outlline. (4) where PL is thee residual losss. The residual loss data at w a six looad points shall s be sm moothed by using u the liinear reegression metthod based on o expressingg the losses as a fuunction of the square of thee load torque in i Eq. (5) wheere A (sslop) and B (ooffset) are connstant coefficients. The offsset B iss removed to obtain o the corrrect stray loadd loss. The loppe is used to calculaate the stray looad loss using Eq. (6) [4, 5].. Ps = 0.025P1 for Pn ≤ 1kW 743 The Studdy of the Stray Load L Loss and Mechanical M Loss of Three Pha ase Induction Motor M considerinng Experimenta al Results T Table 4. Assignned value for stray load loss (IEEE std. 112) 1 Rated outpput power (Pn) [kkW] 1 ~ 90 91 ~ 375 3 ~ 1850 376 1851 and a greater than Ps/Pn [%] 1.8 1.5 1.2 0.9 ⎡ ⎛ P ⎞⎤ Ps = ⎢ 0.025 − 0.005 log10 ⎜ 2 ⎟ ⎥ P1 ⎝ 1kW ⎠ ⎦ ⎣ for 1kW < Pn < 10000kW Ps = 0.005P1 (7) for Pn ≥10000kW W Fig. 5. Stray S load losss distribution (6Pole) ( 3. New Assiigned Valuees of Stray Load L Loss an nd Mechan nical Loss mottors, 85 4-polee motors and 559 6-pole mottors. In n these grapphs, red linee (Average) represents the t averrage value off stray load looss (PS) acco ording to outpput pow wer and trianggle-green line is the assigneed value of IE EC 600 034-2-1 calculated by Eq. (77). Most of thee test values are a low wer than assiggned value off IEC 60034-2 2-1. The circlleblacck line is thee value propoosed by consiidering test annd averrage value in this paper whhich is moved d by 1.0% froom the assigned valuue of IEC 600034-2-1. As shown in theese grap phs, it is know wn that the sttray load losss is not affectted by the t number off poles. 3.1. Stray load loss Figs. 3, 4, annd 5 show thee distribution of stray load loss off induction motors m under 37kW tested by b IEC 60034--2-1. A test motorss have 380V or All o 460V/60Hzz rating whichh are m made by motoor manufactuurers and tested for veriffying effficiency in teesting laborato ory of Korea Electrotechno E ology R Research Instittute. The dataa set is comprrised of 52 2--pole 3.2.. Mechanicall loss Figs. F 7, 8, and 9 are the distrribution of meechanical lossses of in nduction motoors under 37kW W of section 3.1. 3 In n Fig. 7, the mechanical losses of 2 pole p motors are a high her than those of 4 and 6 pole motors because of the t high hest speed in the t line start innduction. Thee average valuues are about 3% of output powerr under 5.5kW W rating and 1.5 1 % above a 10KW rating. r In this paper, the meechanical lossses are proposed as Eq. E (8) using ttest and averag ge values. Fig. F 8 shows thhe mechanicall losses of 4 pole motors. The averrage values are about 1.55% of outpu ut power undder 2.2k kW rating andd 1.0% above 3.7kW rating g. The proposed valu ue is expressed by Eq. (9) Fig. 3. Stray load looss distribution (2Pole) Fig. 6. Mechanical M loss distribution (2Pole) Fig. 4. Stray load looss distribution (4Pole) 744 D Dong-JunKim, J Jae-Hak Choi, Yon-Do Y Chun, Dae-Hyun D Koo and Pil-Wan H Han Tab ble 5. Relationn between straay load loss an nd material coost (15kW 4pole 4 motor) 2.2 3.7 0.01 , 0.005 0.005 , 5 5.5 0.000909 , 5.5 11 , (8) , (9) 5.5 244 210 60%↓ 18%↓ 13.9% % ↓ 91% (IEC 600 034-2-1) 0.91% (Propossed value) The T mechaniccal loss of liine start indu uction motor is affeected mostly by b cooling fann. The cooling g fan size has to decrrease to reduuce mechaniccal loss, whille the arbitraary redu uction of coolling fan size results in moto or performancces mallfunction due to the rise in the operating temperature. In this reason, it is important to design or sellect the coolinng fan by consideriing the mechhanical loss and cooling in mottor design. The T two cooliing fans of Fig. 9 have th he different siize and d these are forr 3.7kW 2-pole motor. Thee efficiency teest resu ults are shownn in Table 6 w whose cooling fans are applied to the t same mootor. In this rresults, we can c see that an appropriate selecction of coolinng fan make a contribution to imp prove a motoor efficiency. The temperrature rising of mottor using fan II is increasedd by 5 degreee, which can be b Fig. 9 showss the mechaniccal losses of 6 pole motors. The avverage valuess are about 1.0% of outtput power under u 5.5kW rating and a 0.5% aboove 11kW ratiing. The proposed vaalue is expressed by Eq. (100) 0.015 , 2.2 0.015 0.0033 2.2 0.01 , 3 3.7 [k₩]] Stray load loss(PS) PS/Input poweer Test efficiencyy Volume Activematerial cost c (stteel+copper+alum minum) Assigned A value off stray load loss Remarkk 4.2.. Mechanicall loss Fig. 8.Mechanical . looss distributioon (6Pole) 5.5 11 Motor M (B) 100 0.61 90.8 82 Unit efficciency, volum me and active material cost between 15kkW com mmercial motoors of manufaacturer A and B. Motor B has h low wer stray load loss by 660% than motor m B and it con ntributes to low wer volume aand active maaterial cost. The straay load loss off motor A is 1..48% of input power whichh is closse to the assigned value (1.91%) of IEC I 60034-2--1, whiile those of motor m B is 0.61% close to t the proposed valu ue (0.91%) off this paper. A As the materiaal cost of mottor incrreases for highher efficiencyy, it becomes more m significaant to reduce the cosst in design annd manufacturring process. As A show wn in Table 5, 5 the assigneed value of IE EC 60034-2-1 is slightly higher thhan test resultts of commerccial motor thuus, the new assignedd value is exxpected to be more useful in mottor developmeent. Fig. 7. Mechanical loss l distributioon (4Pole) 0.03 , 5 5.5 0.03 0.00273 5.5 0.015 , 7.5 [W] [%] [%] [%] Motor (A) 250 1.48 91.1 100 Items 11 (10) 4 Effects of Stray Load Loss and Mechanical 4. M L Loss M Design n and Perforrmance to Motor 4.1. Stray load loss Table 5 shoows the compparison of thee stray load loss, Fig. 9. Cooling faan (3.7kW 2po ole) 745 The Studdy of the Stray Load L Loss and Mechanical M Loss of Three Pha ase Induction Motor M considerinng Experimenta al Results T Table 6. Motor efficiency teest results acccording to coooling m fan (3.7kW 2pole motor) Losss[W] Temp. rising Stator Rootor Mech. ΔT Irron copper coppper (Pm/Pn) F Fan Eff. [%] Currrent [A A] I 85.2 8..04 30 173 137 9 98 204 (5.5%) 29 II 87.8 7..87 35 169 133 7 74 98 (2.6%) 41 [6] Stray S l load [7] [8] im mproved by making m fan larger l considdering approppriate m mechanical losss or reducing copper loss annd iron loss. 5. Con nclusion B Dong-Jun n Kim He received B.S degree inn electrical engineering in 2004 from m Kyungnam University. He H received M.S degreee in electriccal engineerinng in 2013 frrom Changwoon National U University. Hee has worked at Korea E Electrotechnology Researrch Institute ((KERI). He is currently a seniior Engineer of o Electric Mootor Research Center, KERII. As the mecchanical loss and stray looad loss are not caalculated by electro-magnnetic analysis and affectedd by m manufacturing process or mechanical m strructure, it is very diifficult to exppect these lossses in designn process. In this paaper, assignedd values of mechanical m looss and stray load looss are propossed under 37kW W by using teest results. As shown inn test results of o commerciall motors, the stray s looad losses disttribute variously but these are a lower thann the asssigned valuees of IEC 600034-2-1. If asssigned valuees of IE EC 60034-2-11 are used in motor designn, motor could be ovver-sized due to stray load loss bigger thhan in practice. In thhis reason, thhe new assignned values of o stray load loss coould be a guiideline for motor m manufaccturers who trry to reeduce the mateerial costs. In case of thhe mechanicall losses, if thee proposed vaalues arre used in mootor design, it is expected to be helpful for deeveloping hiigh efficienccy motor annd selecting fan sppecification. S., Jae-Hak Choi He recceived the B.S M.S., andd Ph.D. degrees in Electriccal Engineerinng from Hany yang Universiity in 1999, 22001 and 200 05 respectively. From 2005 to 2007, hee worked at LG L electronicss. Since 2008, he has workked at Korea Electrotechno ology Researrch Institute ((KERI). He is currently a seniior researcherr of Electric M Motor Research h Center, KER RI. Refeerences [11] [22] [33] [44] [55] Polyphase Induction I Mottors and Geneerators,” 2004. A. Bogliettti, “Impact off the Supply Voltage on the t Stray-Load Losses in Indduction Motorrs”, IEEE Tranns. on Ind. Apppl., vol. 46, noo. 4, pp. 1374--1380, 2010. K. Bradleyy, “Evaluatioon of Stray Load Loss in Induction Motors M with a Comparison of Input-Outpput and Caloriimetric Methoods”, IEEE Trans. on Innd. Appl., vol. 21, no. 3, pp. 682-689, 200 06. A. Boglieetti, “Internaational Stand dards for the t Induction Motor M Efficieency Evaluatiion: A Criticcal Analysis of o the Stray-Load Loss Determination D n”, IEEE Transs. on Ind. Apppl., vol. 40, no. n 5, pp. 129941301, 2004. S., Yon-Do C Chun He received the B.S M.S. and Ph.D. degrees in electriccal Engineerinng from Hany yang Universiity in 1996, 11998 and 200 01, respectively. From 20001 to 2003, he received a Japan Socciety for the Promotion of Science (JJSPS) fellowship and he was w with the Department of Electriccal Eng gineering at Waseda W Univversity as a visiting v scholar. From m 2004 to 2012, 2 he hass worked at Korea Electrrotech hnology Reseearch Institutee (KERI). Hee is currentlyy a chieef researcher, Principal Ressearcher and technical t leadder of Electric E Motorr Research Ceenter, KERI. A. T. de Almeida, A F. T. E. Ferreira, J. J F. Busch, annd P. Angers, “Comparative “ e analysis of IEEE 112-B and IEC 34-22 efficiency tessting standardds using stray load losses inn low voltagge three-phasee cage inducction motors”, IEEE Trans. Ind. Appl., vol. v 38, no. 2, pp. 608-614, Mar./Apr. 20002. E.B. Agaamloh, “An Evvaluation of induction macchine stray loadd loss from coollated test ressults”, IEEE Trans. T Ind. Appll., vol. 46, no. 6, pp. 2311-22318, Nov. 2010. T.A. Lipo, “Introducttion to AC Machine M Desiign”, Wisconsiin Power Electronics E R Research Ceenter, Universitty of Wisconsiin, 2004, pp 302-304. IEC 600334-2-1, “Stanndard methodss for determiining losses annd efficiency from f tests (exxcluding machhines for tractioon IEEE Stdd. 112, “IEEE E Standard Test T Proceduree for 746 Dong-JunKim, Jae-Hak Choi, Yon-Do Chun, Dae-Hyun Koo and Pil-Wan Han Dae-Hyun Koo He received the B.S. and M.S. degrees in Electrical Engineering from Hanyang University in 1989 and 1991, respectively. From 1991, he has worked at Korea Electrotechnology Research Institute (KERI). In 2002, he received Ph. D. degree from Dong-A University. He is currently a director of Electric Motors Research Center, KERI. Pil-Wan Han He received the B.S., M.S. and Ph.D. degrees in Electrical Engineering from Hanyang University in 1998, 2000 and 2013 respectively. From 2000 to 2005, he worked at LG electronics. Since 2005, he has worked at Korea Electrotechnology Research Institute (KERI). He is currently a senior researcher of Electric Motor Research Center, KERI. 747