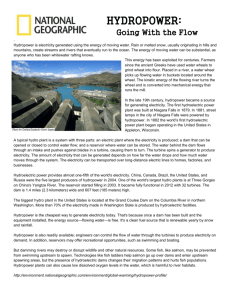

Hydroelectric Power

advertisement