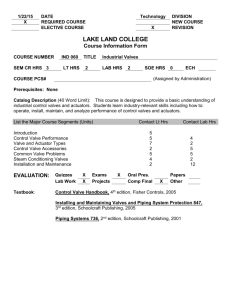

Valves and Actuators Catalog

advertisement