SNOW SHIELD

advertisement

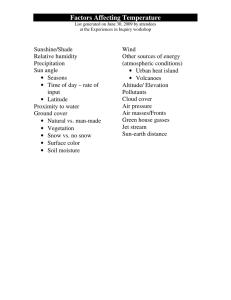

SNOW SHIELD Passive Now UL Listed (cULus) Heated The Snow shield is designed to prevent snow and ice from accumulating on satellite Earth Station Antennas, ranging in size from 0.6 meters to 5 meters in diameter. The passive snow shield system (US patent 5,729,238, additional patents pending) consists of a PTFE coated GOR-TEX® Fabric cover stretched over the reflector. This PTFE coating has the lowest coefficient of friction of any solid material, which makes it difficult for the snow and ice to adhere to the surface. Because of this PTFE coating, under most conditions, snow simply slides off the cover. The Snow Shield PTFE coated GOR-TEX® Fabric covers are made from Radome material that will survive harsh chemical and extreme environmental conditions while providing the lowest transmission loss among all Radome materials. The GOR-TEX® Radome material will not tear, shrink, stretch or swell; and is guaranteed to EXCEED 5 years fabric life. These covers are lightweight, portable, resistant to weather and harsh environments. The fabric is inert and unaffected by the sunlight, UV or ozone. For applications where the weather conditions are more severe, or high availability of the link is required, W.B. Walton Enterprises offers a wide selection of heaters, that will force hot air between the Snow Shield and the antenna. This will remove the existing snow/ice that can accumulate under the right conditions, and will prevent any additional accumulations. Key Features 1. Passive System protects the antenna from the elements and prevents snow accumulation under most weather conditions. 2. Heat can be added without having to replace the existing snow shield for more severe weather conditions or high availability links. 3. The Snow Shield Cover material is Inert and unaffected by sunlight, UV or ozone. 4. The Snow Shield Cover material will not tear, shrink, or swell; and is guaranteed to EXCEED 5 years fabric life. 5. Lightweight and portable. Please also see the W.B. Walton Heaters Data Sheet and Controls Data Sheet for additional information on heated systems. W.B. Walton Enterprises, Inc 6. cULus Listed DE-ICER Air Heater 29KI 1.2kw, 1.7kw, 4kw, 6kw and 12kw www.de-ice.com/contact Snow Shield Material Physical Properties: GORE-TEX® Membrane/GORE-TEX® Fiber Fabric Radome Laminate. LAMINATE TYPE: RA 7943 • Chemical Consistent: 100% fluoropolymer • Construction: Two layers composed of GORE-TEX® membrane (heavy duty) laminated to woven GORE-TEX® fiber fabric • Weave Type: 2 X 2 Basket weave • Mullen Burst (typical) 5515.8 kN/m2/800PSI ASTM D-3786 • Weight: (typical) 515 gr/m2/15 oz/yd2 • Breaking Load: (typical) cross machine direction 53 kN/m / 300 lbs/inch, Machine direction 61.3 kN/ 350 lbs/inch ASTM D-1682 • Nominal Thickness: 0.36 mm / 0.014 inches • Thread Count: Cross machine direction 35 cm-1 / 90 inch-1, machine direction 35cm-1/90 inch-1 • Air Permeability: 0 STRENGHT CHARACTERISTICS • Mullen Burst Strength > 800 PSI, Breaking Load Strength > 350 PSI, Water Entry Pressure > 30 PSI MECHANICAL CHARACTERISTICS • Light Weight (15oz/sq yd), form fitting. Material will NOT tear or swell and is guaranteed to EXCEED 5 years fabric life CHEMICAL CHARACTERISTICS • Oil repellent, Water repellent, UV resistant, Chemically inert, Resistant to acids, Bases, Solvents, Paints, Fungus, Corrosive Reagents, Grease, Oils, and Salt Spray (2000 hours), Non-fading per ASTM D 2244-89 TEMPERATURE CHARACTERISTICS • Range: -3500 F to 5500 F (-2120 C to 2880 C) • Non Flammable per UL 94V-0 Electrical Characteristics of the GORE-TEX® Fabric: Tested Per Fourier Transform Spectrometry 0 .1 5 d B 0 .0 8 d B 0 .0 4 d B 0 .0 2 d B 0 .0 0 d B 1 G H z. 2 G H z. 4 G H z. 6 G H z. 1 0 G H z. 2 0 G H z. 4 0 G H z. 6 0 G H z. 1 0 0 G H z. Transmission loss vs. Frequency (Er – 1.55, tan x = .005 t = .012”) W.B. Walton Enterprises, Inc www.de-ice.com/contact