Vertical Axis Wind Turbines: History, Technology and

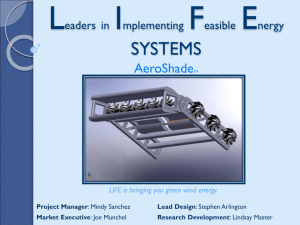

advertisement