Section One: Install Junction Box Floating Wall

advertisement

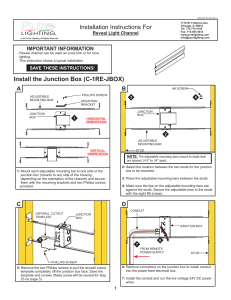

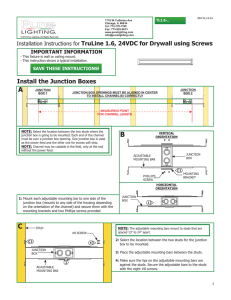

INS# 902-FW-_01 1718 W. Fullerton Ave Chicago, IL 60614 Tel: 773-770-1195 Fax: 773-935-5613 www.purelighting.com info@purelighting.com Installation Instructions For Floating Wall 24VDC © 2013 Pure Lighting. All Rights Reserved. IMPORTANT INFORMATION - This instruction shows a typical installation. - For cove, toe-kick, or corner installations, a 4" Backer Plate is required. SAVE THESE INSTRUCTIONS! Floating Wall Installation Section One: Install Junction Box A B VERTICAL ORIENTATION #8 SCREW 3 ADJUSTABLE MOUNTING BAR 4 JUNCTION BOX JUNCTION BOX 1 2 STUD PHILLIPS SCREW NOTE: The adjustable mounting bars mount to studs that are spaced 13" to 24" apart. HORIZONTAL ORIENTATION JUNCTION BOX NOTE: Junction box must be installed approximately 4" from the ceiling or wall when using the provided backer plate. 1 2: Select the location between the two studs for the junction box to be mounted. 1: Mount each adjustable mounting bar to one side of the junction box (mounts to any side of the housing depending on the orientation of the channel) and secure them with the mounting brackets and two Phillips screws provided. C CONDUIT ADJUSTABLE MOUNTING BAR MOUNTING BRACKET JUNCTION BOX 3: Place the adjustable mounting bars between the studs. 4: Make sure the lips on the adjustable mounting bars are against the studs. Secure the adjustable bars to the studs with the eight #8 screws. D STUD CONDUIT JUNCTION BOX STUD 5 9 8 ADJUSTABLE MOUNTING BAR ADJUSTABLE MOUNTING BAR 8: Connect the red power connector wire of one set to the red remote power supply wire with a wire nut. 5: Remove a knockout to install the power line conduit. 9: Connect the black power connector wire of the same set to the black wire of the same set with a wire nut. 6: Install the conduit and run the two sets of low voltage 24V DC power wires, each set coming from a remote power supply to the junction box. 10: Repeat Steps 8 and 9 for the other set of black and red wires. 7: Refer to the instruction provided with the power supply along with the wiring diagram for proper wiring. 11: Place wire connections into junction box. 1 Section Two: Prepare Channel E FRONT VIEW FRONT MOUNTED VIEW FLOATING WALL CHANNEL DRYWALL SIZE OF INSTALLATION 45° 45° 12 FLOATING WALL CHANNEL 12: After determining the size of the installation, cut each end of the Floating Wall channel sections at a 45° angle. It is recommended to snap the lens in to the channel and cut the channel and lens at the same time for better matching results. NOTE: It is recommended that the horizontal and vertical channel lengths be cut to match with the cuttable sections of LED strip to avoid alignment issues. F CLOSE-UP VIEW CEILING 13 13 DRYWALL 13: Install drywall to studs. Cut opening in drywall where junction box is located. G 14 FLOATING WALL CHANNEL VERTICAL INNER EDGE DISTANCE 14 DRYWALL SECTION 1 DRYWALL SECTION 2 HORIZONTAL INNER EDGE DISTANCE INNER EDGE DISTANCE 14: Mate all channel sections together and measure from inner edge of each horizontal and vertical channel section to determine cut size of Drywall Section 1. NOTE: Cut two sections of drywall. The first section should match the measured inner edge distances. The second section needs to be 3/4" smaller thatn the measured inner edge distances. 2 Section Three: Install Channel H DRYWALL SECTION 1 15 DRYWALL SECTION 1 X X X 15 X X X 15 FLOATING WALL CHANNEL FLOATING WALL CHANNEL NOTE: It is suggested that more than one person assist in the installation of the channel and drywall sections to avoid damage to drywall or fixture. 15: Mount the bottom length of Floating Wall channel and Drywall Section One to the studs by making a countersunk hole to the rear mounting surface with the provided square recessed bit. Use #6 drywall screws to secure channel and drywall section to studs as shown. 16 DRYWALL SECTION 2 DRYWALL SECTION 1 I FLOATING WALL CHANNEL 16: Place Drywall Section Two into the front extrusion of the bottom Floating Wall channel section. J SIDE CHANNEL SECTION DRYWALL SECTION TWO ALIGN CORNERS 17 17 17 17: Slide the side channel sections into the drywall and align the corners with the installed bottom channel. 3 K 18 DRYWALL X #6 DRYWALL SCREWS X 18 18 X X FLOATING WALL CHANNEL 18: Secure the bottom portion of the two side channel sections to the studs by making a countersunk hole (marked red X) to the front surface with the provided square recessed bit. This will ease assembly of the top channel section. Use #6 drywall screws to secure channel and drywall sections to studs as shown. NOTE: Only secure channel and drywall near bottom of channel as shown by a red “X”. This will allow the top section of channel to be assembled. L M 19 FRONT VIEW 20 PLASTER CHANNEL 20 FLOATING WALL CHANNEL PLASTER 19: Gently separate two drywall sections at the top of the installation and insert the top channel section between them. Completely secure all channels to the studs and drywall using #6 drywall screws. 20: Plaster the channel (highlighted in green) to the inner drywall section. Finish the surface properly. Section Four: Install LED Strip N O LED STRIP 21 22 FLOATING WALL CHANNEL 21: Carefully remove the backing from the LED strip, make sure not to remove the tape from the LED strip. Firmly press down the adhesive portion of the LED strip onto the channel surface while removing the rest of the backing, making sure there are no air bubbles that can cause surface irregularities. 22: Apply LED strip around full length of channel. Carefully bend the strip 90° to match the channel corners. Repeat application steps for the second LED strip. 4 P POWER CONNECTOR 23 23: Connect the power connector so that the red wire of the power connecter is aligned with the “+24VDC” marking on the LED strip. Insert the lens into the Floating Wall channel. 5