UFGS 26 51 00 Interior Lighting - The Whole Building Design Guide

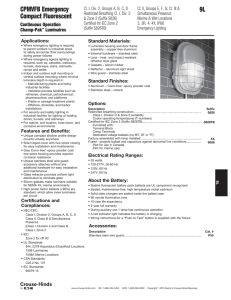

advertisement