DESIGN AND FABRICATE OF SECURED LCD REMOTE CONTROL

advertisement

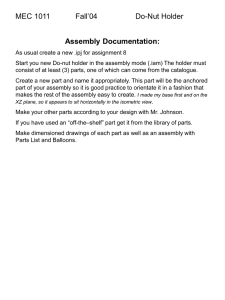

DESIGN AND FABRICATE OF SECURED LCD REMOTE CONTROL HOLDER IN UMP PEKAN LECTURE ROOM FARIS SYAFIQ BIN ZAKARIA Report submitted in partial fulfillment of the requirements for the award of Diploma in Mechanical Engineering Faculty of Mechanical Engineering UNIVERSITI MALAYSIA PAHANG DECEMBER 2010 ii SUPERVISOR’S DECLARATION I hereby declare that I have checked this project report and in my opinion this project is satisfactory in terms of scope and quality for the award of Diploma in Mechanical Engineering. Signature: Name of Supervisor: Miminorazeansuhaila Binti Loman Position: Lecturer Date: 5 December 2010 iii STUDENT DECLARATION I hereby declare that the work in this report is my own except for quotations and summaries which have been duly acknowledged. The report has not been accepted for any degree and is not concurrently submitted for award of other degree. Signature: Name: Faris Syafiq Bin Zakaria ID Number: MB08047 Date: 5 December 2010 iv ACKNOWLEDGEMENT Praise to God for His help and guidance that I am able to complete the task of the Final Year Project. I am thankful and grateful to my supervisor, Mrs Miminorazeansuhaila Binti Loman for her advice and knowledge that she shared in the completion of the project. I appreciate her help for me while I am doing the Final Year Project from week 1 to the day I finished my Final Year Project. I also would like to thank all my friends who have been really helpful during the course of the conducting the Final Year Project. I also would like to thank laboratory assistants especially to Mr Aziha Bin Abdul Aziz and who have help me in conducting machine and sharing knowledge in conjunction with the project that I am conducting. I sincerely grateful to my parents, Zakaria Bin Hassan and Salmah Binti Ismail for they love and sacrifice that they had for me throughout my life and their support for me in all my activities that I have done. I also wanted to that other people who have directly or indirectly help in the completion of my Final Year Project. I sincerely appreciate all your help. v ABSTRACT This report shows the design and fabrication of a secure LCD remote control holder. The objective of the report is to design and fabricate a secure LCD remote control holder. This report also describes the remote holder products which are available around the world with its safety criteria. Design generation is showed and solid three dimensional structures modelling of the remote control holder was developed with computer aided design software. This report also explains the fabrication process that is needed for this project. Material that is being used in this project is zinc sheet metal and mild steel bar, shaft and hollow shaft. The problems encountered during completion of this project are also show in the report. An idea of improvement for the remote control holder is also provided to further improve the remote control holder. The expected result for this project can solve the entire stated problem statement. vi ABSTRAK Laporan ini menunjukkan lukisan dan pembuatan pemegang alat kawalan jauh LCD yang selamat. Objektif laporan ini adalah untuk lukisan dan pembuatan pemegang alat kawalan jauh. Laporan ini juga menerangkan tentang produk-produk pemegang alat kawalan jauh yang terdapat di serata dunia dan cirri-ciri keselamatan. Konsep lukisan telah ditunjukkan dan permodelan struktur-struktur bongkah tiga dimensi untuk pemegang alat kawalan telah dihasilkan menggunakan perisian lukisan bantuan komputer. Laporan ini juga menerangkan proses pembuatan yang diperlukan untuk projek ini. Bahan yang akan digunakan dalam projek ini ialah kepingan zink dan beberapa jenis logam asli. Masalah yang dihadapi semasa menyiapkan projek ini juga terdapat di dalam laporan ini. Idea penambahbaikan untuk pemegang alat kawalan jauh juga disediakan untuk pembaharuan masa akan datang. Keputusan yang dijangkakan bagi projek ini ialah dapat menyelesaikan segala penyataan masalah yang telah di nyatakan. vii TABLE OF CONTENTS Page SUPERVISOR’S DECLARATION ii STUDENT’S DECLARATION iii ACKNOWLEDGEMENTS iv ABSTRACT v ABSTRAK vi TABLE OF CONTENTS vii LIST OF TABLES x LIST OF FIGURES xi CHAPTER 1 CHAPTER 2 INTRODUCTION 1.1 Introduction 1 1.2 Background of the Project 1 1.3 Problem Statement 2 1.4 Objective 2 1.5 Scope 2 1.6 Flow Chart 3 1.7 Gantt Chart 5 LITERATURE REVIEW 2.1 Introduction 6 2.2 Type of Remote Control Holder 6 2.2.1 6 Spinning Remote Control Holder viii 2.2.2 2.2.3 2.2.4 2.3 2.4 CHAPTER 3 CHAPTER 4 Solid Hardwood Ebony Remote Control Holder Sofa Remote Control Holder Sofa Over Arm Caddy 7 8 9 Type of Safety 9 2.3.1 2.3.2 2.3.3 10 10 11 Lock Cable Alarm Fabrication Planning Process 12 2.4.1 2.4.2 2.4.3 2.4.4 2.4.5 2.4.6 12 12 13 14 15 16 Bending Shearing Lathe Milling Drilling Welding METHODOLOGY 3.1 Introduction 18 3.2 Process Flow 18 3.3 Phase 1-Establish Target Specification 19 3.4 Phase 2-Design Concept 19 3.4.1 3.4.2 3.4.3 3.4.4 3.4.5 20 20 21 21 22 Design Concept 1 Design Concept 2 Design Concept 3 Design Concept 4 Design Concept 5 3.5 Phase 3-Select Final Design 22 3.6 Phase 4-Searching Material for the Product 24 3.7 Phase 5-Fabrication of the Product 25 RESULT AND DISCUSSION 4.1 Introduction 30 4.2 Final Products 30 ix 4.2.1 4.2.2 Component of Final Products Function of Final Product Component 4.3 How to Use This Remote Control Holder 32 4.4 Project Problem 33 4.4.1 4.4.2 4.4.3 4.4.4 33 33 33 33 4.5 Literature Review Designing and Sketching Material Preparation Fabrication Process How this Project Achieves the Objective and Solves the Problem Statement CHAPTER 5 31 32 34 CONCLUSION AND RECOMMENDATION 5.1 Introduction 35 5.2 Conclusion 35 5.3 Recommendation 35 5.3.1 35 Material Selection REFERENCES 36 APPENDICES 38 A Gantt Chart 38 B Each Part of the Project with Dimension 39 C Machine use 45 x LIST OF TABLE Table No. Page 3.1 Process flow 18 3.2 Screening method 23 3.3 List of material 24 4.1 Function of every part 32 xi LIST OF FIGURE Figure No. Page 1.1 Flow Chart 3 2.1 Spinning remote control holder 7 2.2 Solid Hardwood Ebony Remote Control Holder 8 2.3 Sofa remote control holder 8 2.4 Sofa over-arm caddy. 9 2.5 Lock 10 2.6 Cable 11 2.7 Sensor switch 11 2.8 Bending 12 2.9 Shearing Process 13 2.10 Important element of lathe machine 14 2.11 Slot Cut 15 2.12 Drilling Process 16 2.13 MIG Welding Process 17 3.1 First Design Concept 20 3.2 Second Design Concept 20 3.3 Third Design Concept 21 3.4 Fourth Design Concept 21 3.5 Fifth Design Concept 22 xii 3.6 Finalize design 24 3.7 Mild steel shaft and hollow shaft. 25 3.8 Remote control holder. 25 3.9 Remote control battery slot 26 3.10 key slot 26 3.11 Remote control holder door 27 3.12 Remote control holder support 27 3.13 Mild steel shaft 28 3.14 Mild steel hollow shaft. 28 3.15 Remote control holder part 29 3.16 Remote control holder support part. 29 3.17 Final product 29 4.1 Drawing final product 30 4.2 Final product (side view) 31 4.3 Component of final product 31 CHAPTER 1 INTRODUCTION 1.1 INTRODUCTION CHAPTER 1 is the introduction chapter of this project. Generally, it discuss about the project background, problem statement, the objective, scope of project, project flow and project Gantt chart. 1.2 BACKGROUND OF THE PROJECT Safety storage is one of the important things in our life. People need storage that can secure their most important stuff. In order to reach it, manufacturer had come out with ideas to produce some good storage which may help people to keep their stuff safely. Today, manufacturer had come with innovative and creative ideas to achieve high productive for the competition with other manufacturers. As example, safety storage today had come out with so many designs depending on their function and working place. In lecture room, there is one thing that needs to be secure. It is LCD remote control that is use to monitor LCD projector. Innovative productivity means improving efficiency in order to do the job well. Safety storage is needed so that it is easier to be found and avoid people to steal and play with the remote. 2 1.3 PROBLEM STATEMENT There is currently no holder available to secure the LCD remote control storage in lecturer room at University Malaysia Pahang campus Pekan. I decide to design a secured remote holder to make it easier to store and use the remote control in more suitable placing and storing. 1.4 OBJECTIVE The objective of this project is: (i) To design a secured holder in small in size in lecture room. (ii) To fabricate a secured LCD remote control holder. 1.5 SCOPE In this project, scope performed a range in the completion of a project. The scopes of this project are: (i) This study is focused on making a secured LCD remote control holder. (ii) Function to secure LCD remote control and easier to be found. (iii) This holder only for Sanyo LCD remote control. (iv) The holder secure by lock. 3 1.6 FLOW CHART Start Problem identification Objective of the project Scope of the project New Conceptual Design or by Improving Market Design No Concept selection Yes Finalize Design Fabrication Verification Result and Discussion End Figure 1.1: Flow Chart 4 The project starts identify the problem. It is a first step for the project flow in order to find the problem in current product. This step helps to create a different design to improve the product. After identify the problem for the project, project continues with identify the objective. The objective is very important in every work because every procedure to make a project will depend on it. It will help to know the main point to make the project success or not. The project continues with identify the scope of the project because this scope can help the progress to create the new product design for the project and to make sure the method chose will be within the range of achievable objective. Next continue it with literature review and research about the title. This consist a review of the design of holder, and type of safety. These tasks have been done through research on the internet. From the flow chart, start to design new concept. Use datum as reference. Then improve the design. Try to come with several concepts. Then compare the criteria from each design which are the best. If the best design chosen still needed to be improved go back to the previous step. If no improvement is needed go to next step. Produce the drawing together with dimension of the product and the type of materials needed. After completing the previous task, start the fabrication process. Gather the parts needed for the project to proceeds the fabrication process. Here come the testing and evaluation process. The secured LCD remote control holder will be test to see if it full fills the requirement such as safety, ability and strength. During the testing, if a problem occurs, the process of fabrication remote holder will step back to the previous process. The reason to step back is to fix the error. After all the parts had been joined together and no error, here comes the phase of result and discussion. In this part, how the remote holder functions will be informs. Beside, how to achieve objective and solve problem statement of the project will be discuss in this phase. 5 1.7 GANTT CHART Gantt chart is an important to guide work process during this project. With gantt chart what need to be done first can be plan accordingly. Other than that, this project will run smoothly and finish on time. Refer Appendix A to see a gantt chart that being used for this project. CHAPTER 2 LITERATURE REVIEW 2.1 INTRODUCTION CHAPTER 2 is the literature review of the project. In this chapter, there is a type of holder and safety. Besides that, it is consists with the design which were available at the market. 2.2 TYPES OF REMOTE CONTROL HOLDER There are two types of remote control holder are the table top holders, and the sofa arm remote control holder. This is most common holder that has in market and use by many people. The table top remote holder made of metal, or wood, and look like caddies similar to pen holders, with different compartments. Some come in very creative designs, and can hold other things like magazine. Some are also made to spin. Furthermore, the sofa arm remote control holder made of fabric and cotton. This holder is fit with sofa arm. Some of this type come in very creative design and can hold other things such as magazine, pen, glasses and snack table. 2.2.1 Spinning Remote Control Holder This remote control holder based on Figure 2.1 made from brown leather. It has four storage compartments for remote controls. Other than that, it can store a few DVD 7 or television channel listing at the large center compartment. The special of this holder is can spins freely and allows easy access to all remotes. Figure 2.1: Spinning remote control holder Source: Remotecontrolholder 2.2.2 Solid Hardwood Ebony Remote Control Holder This remote based on Figure 2.2 is made from wood. It just a simple table remote holder. It can holds up to six remote in one time. This holder used for remote control only. 8 Figure 2.2: Solid Hardwood Ebony Remote Control Holder Source: Google image 2.2.3 Sofa Remote Control Holder This type of remote control holder is fit over the sofa arm based on the Figure 2.3. It can washable and dryable. This holder provides three-pocket for remote control. Figure 2.3: Sofa remote control holder Source: Tobitas-crochet 9 2.2.4 Sofa Over-Arm Caddy This holder based on Figure 2.4 made from durable fabric construction with a stylish blue color. It has three sides; one of the sides has two large pockets for full magazines. The other side has one large pocket and three smaller pockets for pens, glasses and remotes control. Last part is flat surface in the center to keep items from sliding off. Figure 2.4: Sofa over-arm caddy Source: organize 2.3 TYPES OF SAFETY Safety is important to our life to secure the important thing. Without safety life is dangerous and might feel worry all the time because need to care a important thing by self. It has many types and each type depends on the thing that needs to be secured. The most common type of safety is lock, cable, alarm and CCTV. 10 2.3.1 Lock Lock has two types which is using a key based on Figure 2.5 or using a code. Basic application of this lock is to lock motorcycle, house gate and locker. Figure 2.5: Lock Source: ambcomputers 2.3.2 Cable These are simply the most effective and convenient. It is low cost range of PC cable locks. Most of thing that secure by cable is laptop and computer based on Figure 2.6, hand phone display, iPod and camera. 11 Figure 2.6: Cable Source: eos.ncsu 2.3.3 Alarm Alarm has two types which is using sensor based on Figure 2.7 and switch. The function of alarm is to alert when there is danger. Some examples of situation that use alarm are flood and fire. As for vehicles alarm is widely use to prevent being stole. Figure 2.7: Sensor switch Source: geeky-gadgets 12 2.4 FABRICATION PLANNING PROCESS 2.4.1 Bending Bending is a process by which metal can be deformed by plastically deforming the material and changing its shape. The material is stressed beyond the yield strength but below the ultimate tensile strength. The surface area of the material does not change much. Bending usually refers to deformation about one axis. Bending is a flexible process by which many different shapes can be produced. Standard die sets are used to produce a wide variety of shapes. The material is placed on the die, and positioned in place with stops and/or gages. It is held in place with holddowns. The upper part of the press, the ram with the appropriately shaped punch descends and forms the v-shaped bend. For this project I plan to use bending to make a remote control holder. The item that will bend is zinc sheet metal. Figure 2.8 is example of bending. Figure 2.8: Bending Source: efunda 2.4.2 Shearing Cutting processes are those in which a piece of sheet metal is separated by applying a great enough force to cause the material to fail. The most common cutting