Wiring Diagrams

advertisement

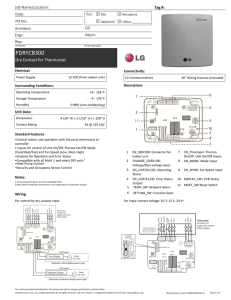

09AW,AZ001-024 Remote Air-Cooled Condenser Wiring Diagrams DIAGRAM INDEX Unit 09 AWH, AWL 001 002 003 004 AWH, AWL 006 008 012 AWH, AWL, AWV, AWW 014 016 018 020 AZH 006 AZL 006 AZH, AZL 008 AZH, AZL, AZV, AZW 012 014 016 UNIT All 09AZ with 50BZ LEGEND SCHEMATICS Voltage 60 Hz 208/230, 575 (1 phase) 208/230, 460 (3 phase) 208/230, 575 (1 phase) 208/230, 460 (3 phase) 208/230 (1 phase) 208/230, 460, 575 (3 phase) 208/230, 575 (1 phase) 208/230, 460 (3 phase) 208/230, 575 (1 phase) 208/230, 460 (3 phase) 208/230, 575 (1 phase) 208/230, 460 (3 phase) 208/230 (1 phase) 208/230, 460, 575 (3 phase) COMPONENT Head Pressure Control Wiring Fan Cycling Head Pressure Control Wiring Head Pressure Control Operation Winter Start Winter Start, Evaporator Defrost Thermostat Liquid Line Solenoid Valve Figure Number 1 2 3 4 5 6 7 CAP EQUIP FB1 FC2 FD1 GND L M MTR NEC PB1 TB1 TRAN — — — — — — — — — — — — — Capacitor Equipment Fused Block Fan Cycling Control Fused Disconnect Ground Line Fan Motor Contactor Fan Motor National Electrical Code Power Terminal Block Terminal Block Transformer Terminal Block Connection Unmarked Terminal Factory Wiring Field Wiring 8 9 10 9 10 11 12 NOTES: 1. Wiring for field power supply must be rated at 60 C (140 F) minimum. Use copper or copper-clad aluminum conductors only. 2. Replacement of factory wires must be with 90 C (194 F) appliance wiring material or its equivalent. 3. Factory wiring is in accordance with NEC. Field modifications or additions must be in compliance with all applicable codes. 4. Fan motors are inherently thermally protected. No overloads required. 5. Motor 1 is located on header end of the unit. 6. Field control connections are made to terminal block TB1. Contactor (when supplied) holding voltage is 24 volts. FIGURE NUMBER 13-16 15 and 16 17 18 19 Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations. Book 2 4 PC 111 Catalog No. 530-905 Printed in U.S.A. Form 09AW,AZ-1W Pg 1 2-99 Replaces: New Tab 4a 4a SAFETY CONSIDERATIONS Factory-Installed Optional Controls Installing, starting up, and servicing this equipment can be hazardous due to system pressures, electrical components, and equipment location (roofs, elevated structures, etc.). Only trained, qualified installers and service mechanics should install, start up, and service this equipment. Untrained personnel can perform basic maintenance functions such as cleaning coils. All other operations should be performed by trained service personnel. When working on the equipment, observe precautions in the literature and on tags, stickers, and labels attached to the equipment. Follow all safety codes. Wear safety glasses and work gloves. Use care in handling, rigging, and setting bulky equipment. FAN CYCLING HEAD PRESSURE CONTROL — This option allows operations to 30 F (depending on load) by stopping the second condenser fan at outdoor temperatures below 60 F. It is recommended that the second fan on all 2 condenser-fan units be equipped with this option to better match load to condenser capacity. See Fig. 15-17 for wiring. HEAD PRESSURE CONTROL — This option contains a fan speed-control device activated by a pressure sensor. With the speed control, the condenser-fan motor speed is controlled in response to the saturated condensing pressure. This factory-installed option maintains the condensing temperature at 100 ± 10° F (38 ± 6° C) for outdoor temperatures down to −20 F (−29 C). NOTE: Wind baffle may be required. See Installation Instructions. The head pressure control consists of a solid-state circuit on a printed circuit board, sensor, transformer, and single phase compatible condenser-fan motor. See Fig. 14-17 for wiring. NOTE: The fan cycling head pressure control will be installed on all 2 condenser-fan units with head pressure control. ELECTRIC SHOCK HAZARD Open all remote disconnects before servicing this equipment. SEQUENCE OF OPERATION The 09AW,AZ condensing unit may be used with different types of compressor and evaporator combinations. The sequence of operation is dependent on the compressor and specific indoor unit. Field-Installed Accessory Controls DEFROST THERMOSTAT (50BB-900---001) — The defrost thermostat is installed on the evaporator coil and is recommended for use with the winter start control. The thermostat will open the control switch if frost begins to form on the evaporator coil. The compressor will stop but the 09AW or 09AZ unit will continue to run. See Fig. 19 for wiring. SOLENOID VALVE — A field-supplied solenoid valve (locate at indoor unit) wired in parallel with the compressor contactor coil will shut off the liquid line to prevent refrigerant migration back to the compressor during the off cycle. This valve is recommended for installations where piping length is over 75 ft. If 2 liquid line solenoid valves are used (units over 71⁄2 tons), check available transformer voltampere capability. See Fig. 19 for wiring. WINTER START (38AE900021) — When used in conjunction with the speed control option, the winter start control will bypass the low-pressure switch for 3 minutes on compressor start-up to allow system pressures to stabilize. NOTE: If units matched with 09AW or 09AZ condenser units are equipped with a 27 psig low-pressure switch (i.e., 50BZ), the 3-minute low-pressure switch bypass is recommended for operation below 50 F. See Fig. 18 and 19 for wiring. General Applications — Whenever there is a call for cooling, the condenser fan starts with the compressor and runs as long as there is a call for cooling. On 2 circuit units, both fans are activated on the call for first stage and run with the lead compressor. Application with 50BZ Units — The following control sequence is for the 09AW and 09AZ when matched with the 50BZ unit. Cooling — On a call for cooling, the thermostat closes and energizes terminals Y1 and T1 on the 50BZ unit low voltage terminal strip. The fan-motor contactor (M) is energized with 24 v through terminals T1 and C. The fan(s) will continue to run until the thermostat is satisfied. At that time, the thermostat will open T1, and the fan will stop immediately. If the condenser-fan motor overheats due to motor overload or lack of cooling air, the internal fan protector will open the circuit internally in the motor, and the fan will stop. If a safety control in the 50BZ unit opens, the 09AW or 09AZ condenser fan will not be affected, and the fan will continue to run as long as the thermostat is closed. 2 POWER SCHEMATIC CONTACTOR OPTION M1 MTR 1 NEC DISCONNECT CAP EQUIP GND TRANSFORMER OPTION 24 VAC TRAN CONTROL SCHEMATIC TB1 M1 FROM INDOOR UNIT (24v) Fig. 1 — Field Wiring, Single Phase; 09AWH,AWL001-004, 208/230 and 575-1-60 POWER SCHEMATIC OPTIONAL FUSED DISCONNECT CONTACTOR OPTION M1 MTR 1 EQUIP GND 24 VAC TRANSFORMER OPTION TRAN CONTROL SCHEMATIC TB1 M1 FROM INDOOR UNIT (24v) Fig. 2 — Field Wiring, Three Phase; 09AWH,AWL001-004, 208/230 and 460-3-60 3 POWER SCHEMATIC CONTACTOR OPTION PB1 M1 MTR 1 NEC DISCONNECT CAP M2 EQUIP GND MTR 2 CAP TRANSFORMER OPTION 24 VAC TRAN CONTROL SCHEMATIC TB1 M1 FROM INDOOR UNIT (24v) FC2 M2 OPTIONAL FAN CYCLING Fig. 3 — Field Wiring, Single Phase; 09AWH,AWL006-012, 208/230 and 575-1-60 POWER SCHEMATIC OPTIONAL FUSED DISCONNECT POWER TERMINAL BLOCK CONTACTOR OPTION PB1 M1 MTR 1 M2 EQUIP GND MTR 2 24 VAC TRAN TRANSFORMER OPTION CONTROL SCHEMATIC TB1 M1 FROM INDOOR UNIT (24v) FC2 M2 OPTIONAL FAN CYCLING Fig. 4 — Field Wiring, Three Phase; 09AWH,AWL006-012, 208/230 and 460-3-60 4 POWER SCHEMATIC CONTACTOR OPTION PB1 M1 MTR 1 NEC DISCONNECT CAP M2 EQUIP GND MTR 2 CAP TRANSFORMER OPTION 24 VAC TRAN CONTROL SCHEMATIC TB1 M1 FROM INDOOR UNIT (24v) FC2 M2 OPTIONAL FAN CYCLING Fig. 5 — Field Wiring, Single Phase; 09AWH,AWL,AWV,AWW014-020, 208/230-1-60 POWER SCHEMATIC OPTIONAL FUSED DISCONNECT POWER TERMINAL BLOCK CONTACTOR OPTION PB1 M1 MTR 1 M2 EQUIP GND MTR 2 24 VAC TRAN TRANSFORMER OPTION CONTROL SCHEMATIC TB1 M1 FROM INDOOR UNIT (24v) FC2 M2 OPTIONAL FAN CYCLING Fig. 6 — Field Wiring, Three Phase; 09AWH,AWL,AWV,AWW014-020, 208/230, 460, and 575-3-60 5 POWER SCHEMATIC M1 MTR 1 NEC DISCONNECT CAP EQUIP GND CONTROL SCHEMATIC TB1 M1 FROM INDOOR UNIT (24v) Fig. 7 — Field Wiring, Single Phase; 09AZH006, 208/230 and 575-1-60 POWER SCHEMATIC OPTIONAL FUSED DISCONNECT M1 MTR 1 EQUIP GND CONTROL SCHEMATIC TB1 M1 FROM INDOOR UNIT (24v) Fig. 8 — Field Wiring, Three Phase; 09AZH006, 208/230 and 460-3-60 6 POWER SCHEMATIC CONTACTOR OPTION PB1 M1 MTR 1 NEC DISCONNECT CAP M2 EQUIP GND MTR 2 CAP CONTROL SCHEMATIC TB1 M1 FROM INDOOR UNIT (24v) FC2 M2 Fig. 9 — Field Wiring, Single Phase; 09AZH008 and 09AZL006,008, 208/230 and 575-1-60 POWER SCHEMATIC OPTIONAL FUSED DISCONNECT POWER TERMINAL BLOCK PB1 M1 MTR 1 M2 EQUIP GND MTR 2 CONTROL SCHEMATIC TB1 M1 FROM INDOOR UNIT (24v) FC2 M2 Fig. 10 — Field Wiring, Three Phase; 09AZH006 and 09AZL006,008, 208/230 and 460-3-60 7 POWER SCHEMATIC PB1 M1 MTR 1 NEC DISCONNECT CAP M2 EQUIP GND MTR 2 CAP CONTROL SCHEMATIC TB1 M1 FROM INDOOR UNIT (24v) FC2 M2 OPTIONAL FAN CYCLING Fig. 11 — Field Wiring, Single Phase; 09AZH,AZL,AZV,AZW012-016, 208/230-1-60 POWER SCHEMATIC POWER TERMINAL BLOCK OPTIONAL FUSED DISCONNECT M1 PB1 MTR 1 M2 EQUIP GND MTR 2 CONTROL SCHEMATIC TB1 M1 FROM INDOOR UNIT (24v) FC2 M2 OPTIONAL FAN CYCLING Fig. 12 — Field Wiring, Three Phase; 09AZH,AZL,AZV,AZW012-016, 208/230, 460, and 575-3-60 8 24 VAC POWER SCHEMATIC P66 PRESSURE CONTROL L1 * PB1 M1 M1 MOTOR 1 L1 R MAIN L2 C NEC DISCONNECT AUX. S CAPACITOR EQUIP GND CONTROL SCHEMATIC TB1 M1 FROM INDOOR UNIT (24v) *Maximum available va is 40 and can be used to power contactor and indoor unit. Fig. 13 — Head Pressure Control Wiring, Single Phase; 09AW001-004 and 09AZH006, 208/230 and 575-1-60 9 24 VAC POWER SCHEMATIC P66 SPEED CONTROL L1 * PB1 M1 M1 MOTOR L1 R MAIN L2 C NEC DISCONNECT L3 AUX. S CAPACITOR EQUIP GND CONTROL SCHEMATIC TB1 M1 FROM INDOOR UNIT (24v) *Maximum available va is 40 and can be used to power contactor and indoor unit. Fig. 14 — Head Pressure Control Wiring, Three Phase; 09AW001-004 and 09AZH006, 208/230 and 460-3-60 10 24 VAC POWER SCHEMATIC P66 PRESSURE CONTROL L1 * PB1 M1 M1 MOTOR 1 L1 R MAIN L2 C NEC DISCONNECT AUX. S CAPACITOR EQUIP GND MOTOR 2 M2 R MAIN C AUX. S CAPACITOR CONTROL SCHEMATIC TB1 M1 FROM INDOOR UNIT (24v) FC2 M2 *Maximum available va is 40 and can be used to power contactor and indoor unit. Fig. 15 — Head Pressure Control and Fan Cycling Head Pressure Control Wiring for Two-Fan Units, Single Phase; 09AW008-020 and 09AZL006-016, 208/230 and 575-1-60 11 24 VAC POWER SCHEMATIC P66 PRESSURE CONTROL L1 * PB1 M1 M1 MOTOR 1 L1 R MAIN L2 C NEC DISCONNECT AUX. L3 S CAPACITOR MOTOR 2 M2 EQUIP GND CONTROL SCHEMATIC TB1 M1 FROM INDOOR UNIT (24v) FC2 M2 *Maximum available va is 40 and can be used to power contactor and indoor unit. Fig. 16 — Head Pressure Control and Fan Cycling Head Pressure Control Wiring for Two-Fan Units, Three Phase; 09AW008-020 and 09AZL006-016, 208/230, 460, and 575-3-60 12 JOHNSON CONTROLS P66 PERFORMANCE CURVE MOTOR VOLTAGE 97% 90% 10% TO 40% OF LINE (AS SPECIFIED) NO FAN OPERATION IN THIS PRESSURE RANGE ETR 30 TO 60 PSIG 0 PSIG OPERATING RANGE (190/250 PSIG) OPERATING RANGE PLUS 20 OR 30 PSI* 350 PSIG PRESSURE INPUT OPERATIONAL SEQUENCE Pressure Input Motor Voltage (VAC, True RMS) Pressure Input is Between 0 PSIG and the Low End 0 to 5 Volts of the Operation Range. Pressure is at the Low End Start Voltage 10% to 40% of Line of the Operation Range. Motor Voltage Varies Directly with Pressure is in the System Pressure from Start Operation Range. Voltage to 90% of Line Voltage. Pressure is at the High End Output Voltage is 90% of of the Operation Range. Line Voltage. A Further Pressure Increase of Pressure is Above the 20 to 30 PSI Will Increase Motor Operation Range. Voltage to 97% of the Applied Voltage. LEGEND ETR — Effective Throttling Range *20 PSI for 30 PSI ETR, 30 PSI for 60 PSI ETR. NOTES: 1. When using this control on a 3-phase system, the 24-v control circuit and the line voltage must be on the same phase. 2. The P66 is a single-phase control that can only be used with singlephase motors. Fig. 17 — Head Pressure Control Operation; P66 Performance Curve, Operational Sequence T TDR C LPS LEGEND C LPS T TDR — — — — Contactor Coil Low-Pressure Switch Time Delay Relay Coil Time Delay Relay (38AE900021) Factory Wiring Field Wiring Fig. 18 — Wiring for Winter Start Control (Indoor Unit Wiring Modification) 13 TB2 FIELD THERMOSTAT NEC CLASS II R CONT BRN R1† G AUTO COOL T1 Y1 TC1 X OFF C ORN LOGIC 3 2 1 TDR1 ORN RED 2 X LOGIC 1 CLO1 BRN 3 BLU LPS1 HPS1 BLU BLU C1 C1 C2 BLU BRN C1 CR C2 M1 WIRING IN 09AZ CONTROL BOX LLS* DT TDR WINTER START FC2 T M2 C1 CLO1 CONT CR DT FC2 M1/M2 HPS1 LLS — — — — — — — — — Compressor Contactor (in 50BZ) Cycle-LOC™ Control (in 50BZ) Continuous Fan Control Relay (in 50BZ) Defrost Thermostat (Accessory) Fan Cycling Control Motor Contactor (in 09AZ) High-Pressure Switch (in 50BZ) Liquid Line Solenoid (Accessory) LEGEND LPS1 NEC R1 T TB2 TC TDR TDR1 — — — — — — — — Low-Pressure Switch (in 50BZ) National Electrical Code Resistor Timer Low-Voltage Terminal Block (in 50BZ) Thermostat Cooling Winter Start Control (38AE900021) Time GuardT Time Delay (in 50BZ) *Solenoid valve is field-supplied. †Resistor may be internal to CLO on some models. Fig. 19 — Wiring for 09AZ Unit with 50BZ Using Winter Start, Evaporator Defrost Thermostat, and Liquid Line Solenoid Valve 14 Copyright 1999 Carrier Corporation Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations. Book 2 4 PC 111 Catalog No. 530-905 Printed in U.S.A. Form 09AW,AZ-1W Pg 16 2-99 Replaces: New Tab 4a 4a