Technical Committee on LP-Gas at Utility Gas Plants

advertisement

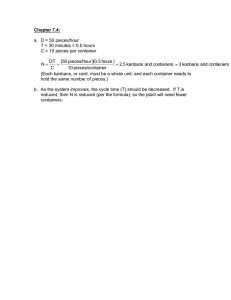

Technical Committee on LP-Gas at Utility Gas Plants Addendum to the Agenda Sheraton Denver Downtown 1550 Court Place Denver, CO 80202 August 7-8, 2013 The following items relate to item 5.B of the Agenda: Attachment A: Suggested change to pressure relief valve sizing Attachment B: Suggested change in legislative text Attachment C: Recommended substantiation for revision Attachment A: Suggested Change to Pressure Relief Valve Sizing 10.2.3 For ASME containers holding propane, with a maximum pressure of 300 psi or less, the minimum rate of discharge of installed pressure relief valves shall be in accordance with Table 10.2.3 or shall be calculated using the following formula: F 53.632A0.82 where: F = flow rate (SCFM air) A = total outside surface area of container (ft2) 10.2.4 For ASME containers not covered by 10.2.3, the minimum rate of discharge of installed pressure relief valves shall be sufficient to relieve vapor produced by vaporization that occurs when a heat input of Q=34,500A0.82 is applied to the vessel, where: Q = heat input (Btu/hr) A = total outside surface area of container (ft2) Table 10.2.3 Pressure Relief Valve Flow Capacity as a Function of Container Surface Area Surface Area (ft2) Flow Rate (SCFM) Surface Area (ft2) Flow Rate (SCFM) Surface Area (ft2) 626 170 3620 600 20 25 751 175 3700 650 30 872 180 3790 700 35 990 185 3880 750 40 1100 190 3960 800 45 1220 195 4050 850 50 1330 200 4130 900 55 1430 210 4300 950 60 1540 4470 1000 65 1640 230 4630 1050 70 1750 240 4800 1100 75 1850 250 4960 1150 80 1950 260 5130 1200 85 2050 270 5290 1250 90 2150 280 5450 1300 95 2240 290 5610 1350 100 2340 300 5760 1400 105 2440 310 5920 1450 110 2530 320 6080 1500 115 2630 330 6230 1550 120 2720 340 6390 1600 125 2810 350 6540 1650 130 2900 360 6690 1700 135 2990 370 6840 1750 140 3080 380 7000 1800 145 3170 390 7150 1850 150 3260 400 7300 1900 155 3350 450 8040 1950 160 3440 500 8760 2000 165 3530 550 9470 — This table is applicable to containers holding propane with a maximum pressure of 300 psi or less. For SI units, 1 SCFM = 0.0283 m3/min. Note: Flow rate in SCFM air. Flow Rate (SCFM) 10,170 10,860 11,550 12,220 12,880 13,540 14,190 14,830 15,470 16,100 16,720 17,350 17,960 18,570 19,180 19,780 20,380 20,980 21,570 22,160 22,740 23,320 23,900 24,470 25,050 25,620 26,180 26,750 27,310 — Annex D Relief Device Sizing This annex is not a part of the requirements of this NFPAdocument but is included for informational purposes only. D.1 Nonrefrigerated Containers. D.1.1 Containers Holding Propane, with a Maximum Pressure of 300 psi or Less.Table D.1.1 should be used to size pressure relief valves. Surface area equals the total outside surface area of the container in square feet. Where the surface area is not stamped on the nameplate or where the marking is not legible, the area can be calculated by using one of the following formulas: (1) Cylindrical container with hemispherical heads: Area = Overall length × outside diameter × 3.1416 (2) Cylindrical container with other than hemispherical heads: Area = (Overall length + 0.3 outside diameter) × outside diameter × 3.1416 (3) Spherical container: Area = Outside diameter squared × 3.1416 Flow rate of air (ft3/min) = required flow capacity in cubic feet per minute of air at standard conditions, 60°F (15.6°C), and atmospheric pressure [14.7 psia (101 kPa)]. The rate of discharge can be interpolated for intermediate values of surface area. For containers with a total outside surface area that is greater than 2000 ft2 (186 m2), the required flow rate can be calculated using the following formula: Flow rate of air ft3 /min53.632A0.82 where A = total outside surface area of the container (ft2) (0.4719 L/s) D.1.2 All Other Nonrefrigerated Containers. Pressure relief valves should be sized by calculating the heat input to the container due to fire exposure, calculating the resulting rate of vaporization, and converting the rate of vaporization to a flow rate of air. Heat input can be calculated using the following formula: Q = 34,500A0.82 where: Q = heat input (Btu/hr) A = total outside surface area of the container (ft^2) The rate of vaporization can be calculated using the following formula: Wvap = Q / L where: Wvap = rate of vaporization (lb/hr) Q = heat input (Btu/hr) L = latent heat of vaporization of the fluid (Btu/lb) The minimum rate of discharge of the pressure relief valves can be calculated using the following formula: √ ( ) √ √ where: F = relieving capacity in SCFM of air and: ka = 1.4, ratio of specific heats of air Ma = 28.97 lb/lbmol, molecular weight of air Ta = 520°R, absolute temperature of air at standard conditions and the following quantities are evaluated at relieving conditions: Wvap = relieving capacity in lb/hr of product vapor kv = ratio of specific heats of product vapor Mv = molecular weight of product vapor Tv = absolute temperature of product vapor Zv = compressibility factor of product vapor ( ) Table D.1.1 Minimum Required Rate of Discharge in Cubic Feet per Minute of Air at 120 Percent of the Maximum Permitted Start-to-Discharge Pressure for Safety Relief Devices to Be Used on Nonrefrigerated Containers Other than Those Constructed in Accordance with U.S. Department of Transportation Specifications Surface Area (ft2) Flow Rate (SCFM) Surface Area (ft2) Flow Rate (SCFM) Surface Area (ft2) Flow Rate (SCFM) 626 170 3620 600 10,170 20 25 751 175 3700 650 10,860 30 872 180 3790 700 11,550 35 990 185 3880 750 12,220 40 1100 190 3960 800 12,880 45 1220 195 4050 850 13,540 50 1330 200 4130 900 14,190 55 1430 210 4300 950 14,830 60 1540 4470 1000 15,470 65 1640 230 4630 1050 16,100 70 1750 240 4800 1100 16,720 75 1850 250 4960 1150 17,350 80 1950 260 5130 1200 17,960 85 2050 270 5290 1250 18,570 90 2150 280 5450 1300 19,180 95 2240 290 5610 1350 19,780 100 2340 300 5760 1400 20,380 105 2440 310 5920 1450 20,980 110 2530 320 6080 1500 21,570 115 2630 330 6230 1550 22,160 120 2720 340 6390 1600 22,740 125 2810 350 6540 1650 23,320 130 2900 360 6690 1700 23,900 135 2990 370 6840 1750 24,470 140 3080 380 7000 1800 25,050 145 3170 390 7150 1850 25,620 150 3260 400 7300 1900 26,180 155 3350 450 8040 1950 26,750 160 3440 500 8760 2000 27,310 165 3530 550 9470 — — This table is applicable to containers holding propane with a maximum pressure of 300 psi or less. Note: ft2 = 0.09 m2; ft3/min = 0.4719 L/s. Attachment B: Suggested Change in Legislative Text 10.2.3 For ASME containers holding propane, with a maximum pressure of 300 psi or less, The the minimum rate of discharge of installed pressure relief valves installed in ASME containers shall be in accordance with Table 10.2.3 or shall be calculated using the following formula: F 53.632A0.82 where: F = flow rate (SCFM air) A = total outside surface area of container (ft2) 10.2.4 For ASME containers not covered by 10.2.3, the minimum rate of discharge of installed pressure relief valves shall be sufficient to relieve vapor produced by vaporization that occurs when a heat input of Q=34,500A0.82 is applied to the vessel, where: Q = heat input (Btu/hr) A = total outside surface area of container (ft2) Formatted: Font: Not Bold Formatted: Font: Not Bold Formatted: Superscript Formatted: Font: Italic Formatted: Font: Italic Table 10.2.3 Pressure Relief Valve Flow Capacity as a Function of Container Surface Area Surface Area (ft2) Flow Rate (SCFM) Surface Area (ft2) Flow Rate (SCFM) Surface Area (ft2) 626 170 3620 600 20 25 751 175 3700 650 30 872 180 3790 700 35 990 185 3880 750 40 1100 190 3960 800 45 1220 195 4050 850 50 1330 200 4130 900 55 1430 210 4300 950 60 1540 4470 1000 65 1640 230 4630 1050 70 1750 240 4800 1100 75 1850 250 4960 1150 80 1950 260 5130 1200 85 2050 270 5290 1250 90 2150 280 5450 1300 95 2240 290 5610 1350 100 2340 300 5760 1400 105 2440 310 5920 1450 110 2530 320 6080 1500 115 2630 330 6230 1550 120 2720 340 6390 1600 125 2810 350 6540 1650 130 2900 360 6690 1700 135 2990 370 6840 1750 140 3080 380 7000 1800 145 3170 390 7150 1850 150 3260 400 7300 1900 155 3350 450 8040 1950 160 3440 500 8760 2000 165 3530 550 9470 — This table is applicable to containers holding propane with a maximum pressure of 300 psi or less. For SI units, 1 SCFM = 0.0283 m3/min. Note: Flow rate in SCFM air. Flow Rate (SCFM) 10,170 10,860 11,550 12,220 12,880 13,540 14,190 14,830 15,470 16,100 16,720 17,350 17,960 18,570 19,180 19,780 20,380 20,980 21,570 22,160 22,740 23,320 23,900 24,470 25,050 25,620 26,180 26,750 27,310 — Annex D Relief Device Sizing This annex is not a part of the requirements of this NFPAdocument but is included for informational purposes only. D.1 Nonrefrigerated Containers. D.1.1 Containers Holding Propane, with a Maximum Pressure of 300 psi or Less. Table D.1.1 should be used to size pressure relief valves. Surface area equals the total outside surface area of the container in square feet. Where the surface area is not stamped on the nameplate or where the marking is not legible, the area can be calculated by using one of the following formulas: (1) Cylindrical container with hemispherical heads: Area = Overall length × outside diameter × 3.1416 (2) Cylindrical container with other than hemispherical heads: Area = (Overall length + 0.3 outside diameter) × outside diameter × 3.1416 (3) Spherical container: Area = Outside diameter squared × 3.1416 Flow rate of air (ft3/min) = required flow capacity in cubic feet per minute of air at standard conditions, 60°F (15.6°C), and atmospheric pressure [14.7 psia (101 kPa)]. The rate of discharge can be interpolated for intermediate values of surface area. For containers with a total outside surface area that is greater than 2000 ft2 (186 m2), the required flow rate can be calculated using the following formula: Flow rate of air ft3 /min53.632A0.82 where A = total outside surface area of the container (ft2) (0.4719 L/s) D.1.2 All Other Nonrefrigerated Containers. Pressure relief valves should be sized by calculating the heat input to the container due to fire exposure, calculating the resulting rate of vaporization, and converting the rate of vaporization to a flow rate of air. Heat input can be calculated using the following formula: Q = 34,500A0.82 where: Q = heat input (Btu/hr) A = total outside surface area of the container (ft^2) Formatted: Indent: First line: 0" Formatted: Centered, Indent: First line: 0" Formatted: Superscript Formatted: Indent: First line: 0" The rate of vaporization can be calculated using the following formula: Wvap = Q / L where: Wvap = rate of vaporization (lb/hr) Q = heat input (Btu/hr) L = latent heat of vaporization of the fluid (Btu/lb) Formatted: Centered, Indent: First line: 0" Formatted: Indent: First line: 0" The minimum rate of discharge of the pressure relief valves can be calculated using the following formula: √ Formatted: Centered, Indent: First line: 0" ( ) √ √ where: F = relieving capacity in SCFM of air ( ) Formatted: Indent: First line: 0" and: ka = 1.4, ratio of specific heats of air Ma = 28.97 lb/lbmol, molecular weight of air Ta = 520°R, absolute temperature of air at standard conditions Formatted: Indent: First line: 0" and the following quantities are evaluated at relieving conditions: Wvap = relieving capacity in lb/hr of product vapor kv = ratio of specific heats of product vapor Mv = molecular weight of product vapor Tv = absolute temperature of product vapor Zv = compressibility factor of product vapor Formatted: Indent: First line: 0" Table D.1.1 Minimum Required Rate of Discharge in Cubic Feet per Minute of Air at 120 Percent of the Maximum Permitted Start-to-Discharge Pressure for Safety Relief Devices to Be Used on Nonrefrigerated Containers Other than Those Constructed in Accordance with U.S. Department of Transportation Specifications Surface Area (ft2) Flow Rate (SCFM) Surface Area (ft2) Flow Rate (SCFM) Surface Area (ft2) Flow Rate (SCFM) 626 170 3620 600 10,170 20 25 751 175 3700 650 10,860 30 872 180 3790 700 11,550 35 990 185 3880 750 12,220 40 1100 190 3960 800 12,880 45 1220 195 4050 850 13,540 50 1330 200 4130 900 14,190 55 1430 210 4300 950 14,830 60 1540 4470 1000 15,470 65 1640 230 4630 1050 16,100 70 1750 240 4800 1100 16,720 75 1850 250 4960 1150 17,350 80 1950 260 5130 1200 17,960 85 2050 270 5290 1250 18,570 90 2150 280 5450 1300 19,180 95 2240 290 5610 1350 19,780 100 2340 300 5760 1400 20,380 105 2440 310 5920 1450 20,980 110 2530 320 6080 1500 21,570 115 2630 330 6230 1550 22,160 120 2720 340 6390 1600 22,740 125 2810 350 6540 1650 23,320 130 2900 360 6690 1700 23,900 135 2990 370 6840 1750 24,470 140 3080 380 7000 1800 25,050 145 3170 390 7150 1850 25,620 150 3260 400 7300 1900 26,180 155 3350 450 8040 1950 26,750 160 3440 500 8760 2000 27,310 165 3530 550 9470 — — This table is applicable to containers holding propane with a maximum pressure of 300 psi or less. Note: ft2 = 0.09 m2; ft3/min = 0.4719 L/s. Attachment C: Recommended Substantiation for Revision Substantiation: This proposed change to NFPA 59 aims to correct a deficiency in the sizing method for nonrefrigerated container relief devices. Jim Stannard raised the concern in Committee Inputs 57, 58, and 59 that the current relief valve sizing method, which was added in the 1953 edition, uses a fixed value for the latent heat of vaporization of the product. The committee statement associated with CIs 57, 58, and 59 says, “The 1953 caclulation, which is still in effect in the most recent editions of both NFPA 58 … and NFPA 59 … is based upon a total heat input Q: Q=34,500A0.82 Btu/hr. The heat flux value of 34,500 Btu/ft2-hr is also adopted in several NFPA codes and standards with some modification for larger vessels. The calculations that led to the adoption of ‘CFM air=53.632A0.82’ in the 1953 edition were apparently based upon a single value for the ‘latent heat of vaporization’ (∆h) regardless of either pressure or composition. (i.e. butane or propane)” The latent heat of vaporization used in the equation from the 1953 edition was L=110 Btu/lb, which is the latent heat of vaporization for saturated propane at 300 psig. Using this same value for lower relieving pressures is conservative, because the latent heat of vaporization increases with decreasing pressure, which in turn lowers the relieving flow rate needed. However, if the relief valve has a relieving pressure greater than 300 psig, using the same value for L would result in undersized relief valves. Similarly, the latent heat of vaporization of butane is always less than that of propane at the same conditions, so using the same value of L=110 Btu/lb would result in undersized relief valves. The proposed change to section 10.2.3 addresses this issue by limiting the applicability of the equation F=53.632∙A0.82 to propane only, with a maximum pressure of 300 psig. Most applications will fall under this section, and the same equation and Table 10.2.3 may continue to be used. In other cases, the new section 10.2.4 must be used. This section requires that the rate of discharge of the relief valve be enough to handle the same heat input of Q=34,500A0.82 Btu/hr, but doesn’t proscribe a formula or specific values for the amount of vapor produced or the equivalent air flow rate. The intention is that the system designer will have to perform their own calculations to justify that the relief valve can handle the same heat input on the tank. A suggested, nonbinding method to calculate relief valve size is added to the annex in section D.1.2. This method follows the same method used in the derivation of the 1953 equation, but stops short of substituting in the material properties of the product. Derivation of D.1.2: ASME BPVC Section VIII Division 1 Appendix 11, “Capacity Conversions for Safety Valves,” provides the following equation for relief valve capacity. √ Here, W is the capacity in pounds per hour, K is the coefficient of discharge, A is the discharge area of the safety valve, in square inches, P is the absolute relieving pressure, M is the molecular weight of the gas or vapor, Z is the compressibility factor, and T is the absolute temperature at the safety valve inlet. C is in turn defined by the following equation in terms of k, the ratio of specific heats. √ ( ) We apply this in turn to the product vapor, designated with the subscript v, and test air, designated with the subscript a. We will assume that the compressibility of air is 1, so it will drop out. Note that K and A are properties of the safety valve, so they will not change. The inlet pressure will be the same when relieving product as when testing the valve on air, so P will be constant as well. √ √ We can also substitute in the formula for C. √ ( √ ( ) √ ) √ Dividing these equations, and cancelling like terms, we get the following. √ ( ) √ √ ( ) Finally, we relate the mass flow rate of air to the standard volume flow rate of air using its standard density. Here, F is in SCFM and Wa is in lb/hr. Substituting and rearranging yields the final equation. √ ( ) √ √ ( )