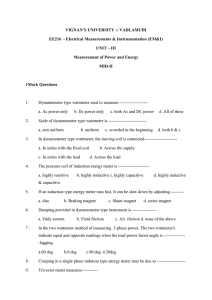

DYNAMOMETER TYPE WATTMETER

advertisement

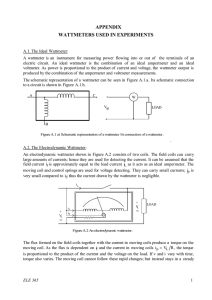

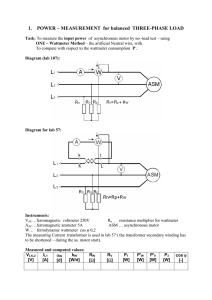

DYNAMOMETER TYPE WATTMETER Following figure shows the dynamometer wattmeter for measuring the power. If two coils are connected such that the current proportional to the load voltage flowing through one coil and the current, proportional to the load current flows through other coil, then the meter can be directly calibrated in watts. This is true because the indication depends on the product of two magnetic fields. The strength of the magnetic fields depends on the values of the current flowing through the coils. Ranges:i. ii. Current circuit 0.25 to 200 A without employing Current Transformers. Potential circuit 5 to 750 V without employing Potential Transformers. Advantages:i. ii. Since deflecting torque is proportional to the true power in both the cases, i.e., dc and ac; and the instrument is spring controlled, the scale of the instrument is uniform. High degree of accuracy can be obtained by careful design, hence these are used as standard for calibration purposes. Disadvantages:i. ii. iii. iv. As there is no iron core in the coils, the field is very weak. Hence a fairly large number of ampere turns are required for the fixed as well as the moving coil. This makes the moving system heavy, as well as there exists a significant amount of power loss in the instrument. A heavy moving element makes the torque-weight ratio small resulting in large frictional error. At low power factor, the error caused by the inductance of pressure coil is very serious. The reading of the instrument is affected by stray fields acting on the moving coil. INDUCTION TYPE WATTMETER In all induction meters, we have two fluxes which are produced by two different alternating currents on a metallic disc. Due to alternating fluxes, there is an induced emf, the emf produces at one point, as shown in the figure given below, interacts with the alternating current of the other side resulting in production of torque. Similarly, the emf produced at point two interacts with the alternating current at point 1, resulting in a torque which is in opposite direction. Due to these two torques produced in two different directions, the metallic disc rotates. This is the basic principle of working of Induction Wattmeter. P1, P2 Points 1 & 2 respectively I1 , I2 Currents 1 & 2 respectively Td1 = - Td2 Ranges:i. ii. Current circuit – upto 100 A without employing Current Transformer. Potential Circuit – upto 750 V without employing Potential Transformer. Advantages :Compared to Dynamometer type wattmeter, this wattmeter has a strong construction, long and uniform scale, free from effects of stray field and has good damping. Disadvantages :i. ii. iii. iv. The wattmeter is less accurate. It is accurate only at stated frequency and temperature. Weight of moving system compared to dynamometer wattmeter is higher. This wattmeter cannot be used on ac system. Power consumption, as compared to dynamometer wattmeter, is higher. ELECTROSTATIC TYPE WATTMETER These watt meters are used for measurement of very small amount of power, where the voltage is high and power factor is low. This type of wattmeter is also used to measure the dielectric loss in cables on alternating voltage and for calibration of wattmeters and energy meters. It consists of a quadrant electrometer used with a non inductive resistor R as shown in the figure below. Advantages:i. ii. iii. Electrostatic wattmeter is a precision instrument and should be used as such. It is free from errors on account of waveforms, frequency and eddy currents. It has a very small working torque. Thus, judging the above wattmeters, we can conclude that Dynamometer type wattmeter is the most suitable wattmeter amongst all. So, the electrician must install Dynamometer type wattmeter in the industry.