Lecture 16 – Introduction to Optical Lithography

advertisement

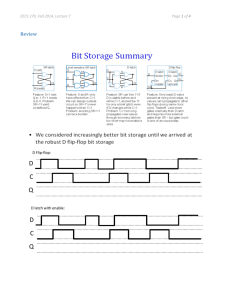

Lecture 16 – Introduction to Optical Lithography EECS 598-002 Winter 2006 Nanophotonics and Nano-scale Fabrication P.C.Ku Optical Lithography An optical system that transfers the image from the mask to the resist layer + the process of forming an etching mask (i.e. the resist development and etc.) EECS 598-002 Nanophotonics and Nanoscale Fabrication by P.C.Ku 2 Resolution limits for imaging Small features correspond to large (kx, ky) components. In traditional optical microscopes, the detector sees the k light in the far field region. k 2 = ω 2 µ0ε = k x2 + k y2 + k z2 ⇒ k x2 + k y2 < ωn / c ⇒ k&,max = 2π n / λ 17.5 15 Resolving power = λ / ( 2n ) ≡ λ / 2 12.5 k-space real-space 10 eff 7.5 = diffraction limit 5 2.5 −2π n / λ 2π n / λ k& -2 -1 EECS 598-002 Nanophotonics and Nanoscale Fabrication by P.C.Ku 1 2 λ /n 3 Finite-size lens In a real system, the cutoff spatial frequency is often limited by the size of the lens which is quantitatively described by a numerical aperture (NA). NA ≡ n sin θ k&,max 2π NA ⇒ = sin θ ⇒ k&,max = k λ θ Resolving power Æ λ / ( 2NA ) ≡ λeff / 2 where λeff = λ / NA EECS 598-002 Nanophotonics and Nanoscale Fabrication by P.C.Ku 4 Patterning process Dissolution rate resist x I aerial image x Dissolution rate + I EECS 598-002 Nanophotonics and Nanoscale Fabrication by P.C.Ku 5 Some clarifications The minimum feature size: Process window: The fundamental limit of optical lithography is not determined by the optical system alone but rather is an overall contributions from the optics, resist, develop and etching processes. Capability of printing small features does not always guarantee a good quality and a repeatable and controllable patterning. Alignment: Alignment to the underlying layer is equally as important as the optics. EECS 598-002 Nanophotonics and Nanoscale Fabrication by P.C.Ku 6 How was our prediction in the past? 1.0 µm 0.7 µm 0.5 µm 0.35 µm 0.25 µm 0.18 µm 0.13 µm 0.10 µm ? EECS 598-002 Nanophotonics and Nanoscale Fabrication by P.C.Ku 7 ITRS prediction in 1998 ITRS 1998: 193 DUV litho cannot produce 65 nm process. EECS 598-002 Nanophotonics and Nanoscale Fabrication by P.C.Ku 8 ITRS 1999 157 nm appears on the map. EECS 598-002 Nanophotonics and Nanoscale Fabrication by P.C.Ku 9 ITRS 2005 report Note: 157 nm off the chart now. EECS 598-002 Nanophotonics and Nanoscale Fabrication by P.C.Ku 10 Major challenges (at this moment…) Data from ENIAC. EECS 598-002 Nanophotonics and Nanoscale Fabrication by P.C.Ku 11 Evolution of optical lithography Contact and proximity printing 1:1 projection printing Defects, gap control Overlay, focus, mask cost Step-and-repeat projection printing Reduction possible Step-and-scan projection printing Easier focus; better usage of lens area EECS 598-002 Nanophotonics and Nanoscale Fabrication by P.C.Ku 12 A step-and-scan system (stepper or scanner) Mask Wafer EECS 598-002 Nanophotonics and Nanoscale Fabrication by P.C.Ku 13 Step-and-repeat vs step-and-scan Step-and-repeat Step-and-scan scan EECS 598-002 Nanophotonics and Nanoscale Fabrication by P.C.Ku 14 Evolution of optics From Introduction to Microlithography EECS 598-002 Nanophotonics and Nanoscale Fabrication by P.C.Ku 15 An example of the optics (NA=0.6, 4X reduction) US Patent 5969803 EECS 598-002 Nanophotonics and Nanoscale Fabrication by P.C.Ku 16 Challenges in lens design Larger lens (required by better resolution) Æ aberration Suitably rotating the lens in the step-and-scan system can minimize the aberration Finite linewidth of laser source Æ dispersion Aspheric lens Æ more expensive Tighter spec on surface quality of lens Shortening the wavelength Æ more expensive raw materials EECS 598-002 Nanophotonics and Nanoscale Fabrication by P.C.Ku 17 Resolution vs minimum linewidth Resolution often refers to the smallest pitch of a dense line/space pattern. It is limited by the diffraction limit. Important for DRAM/flash. Minimum linewidth is the minimum line or space that we can resolve. It has no fundamental limit. Important for logic chips (e.g. the gate length of a transistor) EECS 598-002 Nanophotonics and Nanoscale Fabrication by P.C.Ku 18 There’s no fundamental limit to optical lithography! EECS 598-002 Nanophotonics and Nanoscale Fabrication by P.C.Ku 19 Fundamentals of lithographic optics Diffraction Partial coherence Depth of focus Reflection and interference Polarization dependence EECS 598-002 Nanophotonics and Nanoscale Fabrication by P.C.Ku 20 Fraunhofer diffraction (scalar; far-field) η y ξ x z Mask plane U ( x, y ) = ikz e e Image plane i k 2 2 (x +y ) 2z iλ z F [U (ξ ,η )] f x = x / λ z fy =x/λz EM field EECS 598-002 Nanophotonics and Nanoscale Fabrication by P.C.Ku 21 Diffraction from an aperture F [U (ξ )] f a x =x /λz Intensity ⎛ ax ⎞ = a sin c ⎜ ⎟ ⎝ λz ⎠ ⎛ ax ⎞ ∝ a 2 sin c 2 ⎜ ⎟ ⎝ λz ⎠ 1 0.9 0.8 0.7 Before the lens 0.6 0.5 0.4 0.3 0.2 0.1 0 -4 -3 -2 -1 0 1 2 EECS 598-002 Nanophotonics and Nanoscale Fabrication by P.C.Ku 3 4 λz/a 22 Diffraction of a line/space (N spaces) pattern s N π px ⎞ ⎛ sin ⎜ ⎟ λ I ( x) ∝ ⎜ π px ⎟ ⎜ sin ⎟ λ ⎠ ⎝ p 2 π sx ⎞ ⎛ sin ⎜ λ ⎟ ⎜ π sx ⎟ ⎜ ⎟ ⎝ λ ⎠ 2 1 1 1 0.9 0.9 0.9 0.8 0.8 0.8 0.7 0.7 0.7 0.6 0.6 0.6 0.5 0.5 0.5 0.4 0.4 0.4 0.3 0.3 0.3 0.2 0.2 0.2 0.1 0.1 0.1 0 -5 0 N=5 5 0 -5 0 N=10 EECS 598-002 Nanophotonics and Nanoscale Fabrication by P.C.Ku 5 0 -5 0 5 N=100 23 Basic lithographic optics configuration illumination mask projection lens EECS 598-002 Nanophotonics and Nanoscale Fabrication by P.C.Ku photoresist (image plane) 24 Image formation Need to have at least the 0-th and the 1st diffraction orders being collected to recover the pitch information. +1 0 0 -1 -1 Oblique incidence can improve the minimum pitch but result in a less image contrast. EECS 598-002 Nanophotonics and Nanoscale Fabrication by P.C.Ku 25