TACOTHERM FRESH PETA X (C/CL)

advertisement

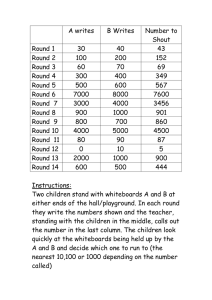

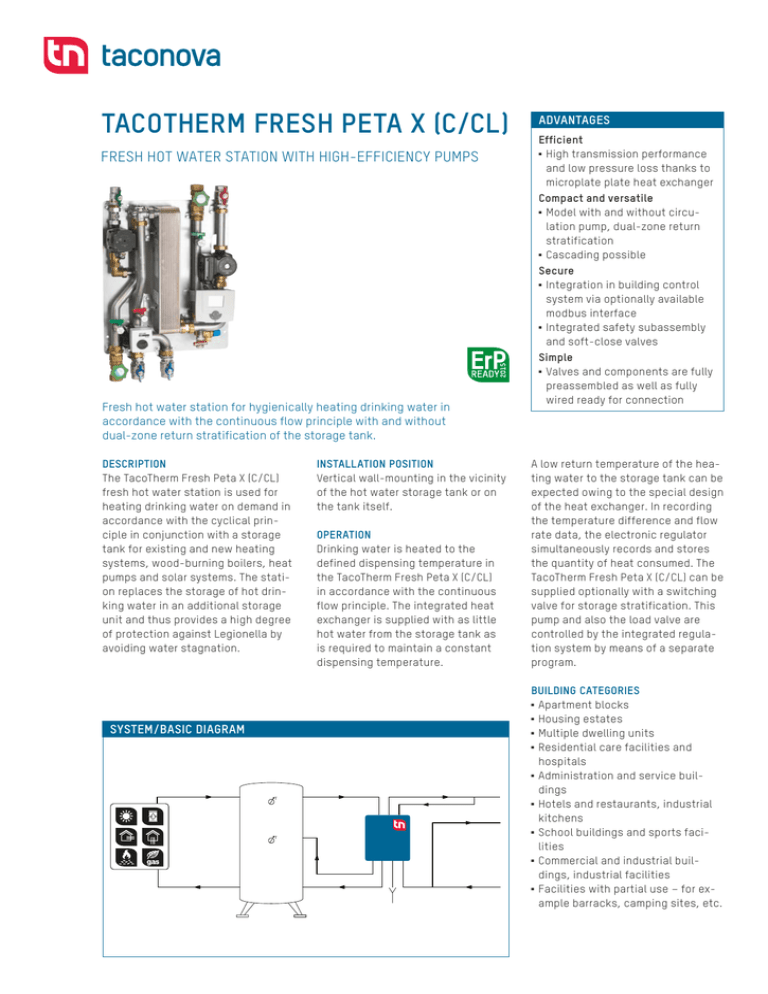

TACOTHERM FRESH PETA X (C/CL) ADVANTAGES Efficient High transmission performance and low pressure loss thanks to microplate plate heat exchanger Compact and versatile Model with and without circulation pump, dual-zone return stratification Cascading possible Secure Integration in building control system via optionally available modbus interface Integrated safety subassembly and soft-close valves Simple Valves and components are fully preassembled as well as fully wired ready for connection FRESH HOT WATER STATION WITH HIGH-EFFICIENCY PUMPS ■■ ■■ ■■ ■■ ■■ ■■ Fresh hot water station for hygienically heating drinking water in accordance with the continuous flow principle with and without dual-zone return stratification of the storage tank. DESCRIPTION The TacoTherm Fresh Peta X (C/CL) fresh hot water station is used for heating drinking water on demand in accordance with the cyclical principle in conjunction with a storage tank for existing and new heating systems, wood-burning boilers, heat pumps and solar systems. The station replaces the storage of hot drinking water in an additional storage unit and thus provides a high degree of protection against Legionella by avoiding water stagnation. INSTALLATION POSITION Vertical wall-mounting in the vicinity of the hot water storage tank or on the tank itself. OPERATION Drinking water is heated to the defined dispensing temperature in the TacoTherm Fresh Peta X (C/CL) in accordance with the continuous flow principle. The integrated heat exchanger is supplied with as little hot water from the storage tank as is required to maintain a constant dispensing temperature. A low return temperature of the heating water to the storage tank can be expected owing to the special design of the heat exchanger. In recording the temperature difference and flow rate data, the electronic regulator simultaneously records and stores the quantity of heat consumed. The TacoTherm Fresh Peta X (C/CL) can be supplied optionally with a switching valve for storage stratification. This pump and also the load valve are controlled by the integrated regulation system by means of a separate program. BUILDING CATEGORIES Apartment blocks Housing estates Multiple dwelling units Residential care facilities and hospitals Administration and service buildings Hotels and restaurants, industrial kitchens School buildings and sports facilities Commercial and industrial buildings, industrial facilities Facilities with partial use – for example barracks, camping sites, etc. ■■ ■■ SYSTEM/BASIC DIAGRAM ■■ ■■ ■■ T ■■ ■■ T ■■ ■■ TACOTHERM FRESH PETA X (C/CL) | FRESH HOT WATER STATION SPECIFICATION TEXT See www.taconova.com TECHNICAL DATA General TacoTherm Fresh Peta controller with display Weight (empty): 52 kg Overall dimensions (incl. hood): W 528 mm × H 854 mm × D 193 mm Material Base plate: Galvanized sheet steel Hood: Varnished sheet steel Pumps: Primary: Cast iron Secondary: PPS (plastic, approved for drinking water) Valve housing: Brass Pipes: Primary/secondary DN 32, stainless steel 1.4403 Circulation DN 25, stainless steel 1.4403 Microplate plate heat exchanger: Plates and connector pieces: Stainless steel 1.4401 Heat exchanger solder: 99.99 % copper (nickel solder model available on request) Seals: AFM flush seal Primary side Operating temperature TO max: 95 °C Operating pressure PO max: 10 bar Primary pump: Grundfos UPMXL GEO 25-125 Secondary side Modules on secondary side with drinking water certifications Operating temperature TO max: 85 °C Operating pressure PO max: 9 bar Safety valve (intrinsic safety) 10 bar discharge pressure Circulation pump: Grundfos UPM3 CIL Performance data See design diagram Electrical connection data Mains voltage: 230 VAC ± 10 % Mains frequency: 50...60 Hz Power consumption: max. 250 W, 3.5 AT fuse Optional interface for M-BUS Protection type: IP 40 Flow media Heating water (VDI 2035; SIA 384/1; ÖNORM H 5195-1) Cold water ■■ ■■ ■■ TYPE OVERVIEW TacoTherm Fresh Peta X / Peta X C / Peta X CL | Fresh hot water station Order no. Rp Version Version Without dual-zone stratification, 273.6652.000 1 ¼" IT XC with circulation With dual-zone stratification , 273.6650.000 1 ¼" IT X CL with circulation Without dual-zone stratification, 272.6650.000 1 ¼" IT X without circulation Modbus interface for integration with 296.7027.000 1 ¼" IT building control system ■■ DIMENSIONAL DRAWING 530 322 ■■ ■■ 3 175 35 92 44 12 42 ■■ 5 1 6 ■■ ■■ ■■ ■■ 7 8 ■■ 515 ■■ 6 10 854 648 ■■ 11 ■■ 470 9 12 ■■ 4 ■■ 2 42 85 116 ■■ 2 6 ■■ 257 PRODUCT DIAGRAM 3 5 1 ■■ ■■ ■■ T ■■ T T 7 ■■ 8 • V 6 10 ■■ T ■■ T ■■ 12 9 M ■■ ■■ ■■ 4 2 2 ■■ ■■ 1 2 3 4 5 6 Primary hot water flow Primary hot water return 1 + 2 (CL version) Circulation Cold water connection Hot water connection Primary pump 7 8 9 10 11 12 Circulation pump Flow rate sensor Safety valve Heat exchanger Regulator Switching valve (CL version) TACOTHERM FRESH PETA X (C/CL) | FRESH HOT WATER STATION FLOW AND PRESSURE LOSS DIAGRAMS COLD WATER HEATING AT 50K (10 ... 60 °C) D) Secondary pressure loss 1 Secondary pressure loss 2 Secondary pressure loss in circulation 3 Pump characteristic in circulation 1000 900 1000 Pressure loss (mbar) 800 900 1 700 800 1000 600 700 900 1000 900 500 600 800 400 500 700 800 700 2 300 400 600 200 300 500 600 500 3 100 200 400 0 100 300 400 300 0 10 200 10 100 200 100 0 25 25 77.5 85 100 40 55 70 77.5 Dispensing volume (l/min) 40 55 70 85 100 85 100 100 0 C)10Return 25 10 temperatures 25 40 40 22 55 55 70 77.5 70 8577.5 65 °C 22 20 19 20 22 18 19 20 18 20 16 19 16 18 Return temperature (° C) 22 19 18 70 °C 75 °C 14 14 12 14 a10 12 10 a10 12 10 a10 a10 105000 10 25 25 40 55 70 77.5 85 100 25 40 55 70 77.5 85 100 85 100 100400 25 40 Dispensing volume (l/min) 40 55 55 70 77.5 70 8577.5 5000 water heating at 50K A) Cold 4500 4500 4000 65 °C 70 °C 75 °C 400 5000 4000 3500 4500 4500 3500 3000 350 4000 4000 3000 2500 300 3500 3500 2500 2000 3000 3000 2000 1500 2500 2500 1500 1000 2000 2000 1000 500 1500 1500 500 10 10 1000 Hot water demand (l/h) 5000 1000 500 10 500 Output kW 250 200 150 25 40 55 70 77.5 85 25 40 55 70 77.5 85 350 300 400 300 250 350 250 200 300 200 150 250 150 100 200 100 50 150 50 0 100 100 100 0 50 100 50 0 10 25 25 40 40 55 5000 B) Residual 5000head | Primary pressure loss 4500 400 350 55 70 77.570 8577.5 85 100 0 100 4500 4000 Hot water demand (l/h) 14 16 12 kW 16 5000 5000 4000 3500 4500 4500 3500 3000 4000 4000 3000 2500 3500 3500 2500 2000 3000 3000 2000 1500 2500 2500 1500 1000 2000 2000 1000 500 1500 1500 500 100 1000 100 1000 500 (∆p) (∆p) (∆p) (∆p) 300 500 650 700 750 900 300 500 650 700 750 900 700 750 900 650 500 650 700 750 900 500 100 300 100 Dispensing volume (l/min) 500 300 Pressure loss (mbar) EXAMPLE FOR INTERPRETING THE FLOW RATE AND PRESSURE LOSS DIAGRAMS Given Hot water dispensing volume: 77 l/min Primary heating flow temperature: 70 °C ■■ ■■ Sought Hot water demand (l/h) Primary heating return temperature in °C Secondary pressure loss in mbar Primary pressure loss in mbar ■■ ■■ ■■ ■■ Approach In Diagram A) the hot water demand at the intersection point of the dispensing volume of 77.5 l/min and primary flow temperature of 70 °C is 4500 l/h. In Diagram B) the primary pressure loss for a hot water demand of 4500 l/h is 650 mbar. The pump delivery head is 750 mbar, discounting the pressure loss this gives rise to a residual pump head of 100 mbar (Δp). ■■ ■■ ■■ ■■ In Diagram C) the primary return temperature for a given dispensing volume of 77.5 l/min and the selected flow temperature of 70 °C is 19 °C. In Diagram D) the secondary pressure loss for the given data is 500 mbar TACOTHERM FRESH PETA X (C/CL) | FRESH HOT WATER STATION FLOW AND PRESSURE LOSS DIAGRAMS COLD WATER HEATING AT 35K (10 ... 45 °C) 1000 1000 900 900 1000 1000 800 800 900 900 700 700 800 600 800 600 700 500 700 500 600 400 600 400 500 300 500 300 400 400 200 200 300 300 100 100 200 2000 0 20 100 100 20 00 20 20 1 2 3 40 40 40 40 80 80 100 100 120 120 60 60 80 80 100 100 120 120 48 °C 50 °C 55 °C 60 °C 65 °C 70 °C 75 °C 20 20 40 40 20 20 40 40 10 10 60 60 80 80 60 80 60 80 (l/min) Dispensing volume 100 100 120 120 100 100 120 120 Hot water demand (l/h) A) Cold water heating at 35K 4500 4500 4000 4000 4500 4500 3500 3500 4000 4000 3000 3000 3500 3500 2500 2500 3000 3000 2000 2000 2500 2500 1500 1500 2000 2000 1000 1000 1500 1500 500 500 20 1000 1000 20 500 500 20 20 50 °C 55 °C 60 °C 48 °C 40 40 40 40 60 60 80 80 100 100 60 60 80 80 100 100 Dispensing volume (l/min) 450 450 400 400 450 450 350 350 400 400 300 300 350 350 250 250 300 300 200 200 250 250 150 150 200 200 100 100 150 150 50 50 100 100 0 120 50 0 50 120 00 120 120 B) Residual head | Primary pressure loss 65 °C 70 °C 75 °C Hot water demand (l/h) Return temperature (° C) 60 60 Dispensing volume (l/min) C) Return temperatures 20 20 19 19 20 20 18 18 19 19 17 17 18 18 16 16 17 17 15 15 16 16 14 14 15 15 13 13 14 14 12 12 13 13 11 11 12 12 10 10 11 11 1 Secondary pressure loss 2 Secondary pressure loss in circulation 3 Pump characteristic in circulation kW Pressure loss (mbar) D) Secondary pressure loss 4500 4500 4000 4000 4500 4500 3500 3500 4000 4000 3000 3000 3500 3500 2500 2500 3000 3000 2000 2000 2500 2500 1500 1500 2000 2000 1000 1000 1500 1500 500 500 100 1000 1000 100 500 500 100 100 300 300 500 500 700 700 900 900 300 300 500 500 700 700 900 900 Pressure loss (l/min) NOTE The stations heat interface units use a copper-soldered stainless steel plate heat exchanger as standard. It must be checked prior to use in the framework of system planning whether the issues of corrosion protection and scale formation have been sufficiently taken into account in accordance with DIN 1988200 and current drinking water analyses according to DIN EN 8065. See datasheet „Plate Heat Exchanger Requirements - Limit Values for Drinking Water Quality“. CONTACT AND FURTHER INFORMATION TACONOVA.COM Taconova Group AG | Neunbrunnenstrasse 40 | CH-8050 Zurich | T +41 44 735 55 55 | F +41 44 735 55 02 | group@taconova.com Subject to modification. 04/2016 REQUIREMENTS FOR FLOW MEDIA