Milestone helps Nissan UK identify production issues and increase

advertisement

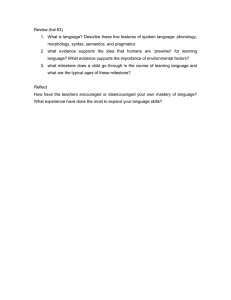

Milestone Customer Story November 2011 Milestone helps Nissan UK identify production issues and increase efficiencies at its state-of-the-art Sunderland Plant Milestone XProtect® Enterprise IP video management software enables Nissan UK’s managers to use IP video to deliver quality and process improvements Challenge: To assist Nissan managers to continually improve production processes and find efficiencies Nissan has always recognized the importance of using video to monitor and improve production processes. The use of video across the plant had grown ad hoc, using equipment often ill-suited to a factory environment. Nissan managers wanted to use video to quickly identify and remedy production issues. Speed and flexibility was vital. Any time saved through the improvement of a process or restoring production after a stoppage delivers real bottom-line benefits. Any new system also needed to use Nissan’s existing network infrastructure, rather than demanding new coaxial cabling. With managers driving the uptake of video across the plant, the new system needed to allow managers to specify their own video requirements – choosing their own cameras, camera locations, video recording times and frame rates to suit a specific application. Any system also needed to provide instant viewing and playback from any network desktop PC. Solution: Open platform for best-in-class IP components Milestone XProtect Enterprise IP video management software enables 300 Nissan managers and supervisors to manage more than 300 IP cameras from a range of manufacturers, including Axis, Panasonic and Sony. All IP cameras use the plant’s high-speed fiber-based network. Nissan has inhouse IT expertise to manage its Milestone XProtect Enterprise IP video management system, and works in partnership with Nissan UK’s networking partner – Express IT. Result: Milestone XProtect Enterprise recognized as a vital tool for production monitoring and quality assurance Using Milestone XProtect Enterprise has eliminated the need for ad hoc, standalone analog camera and digital video recorder (DVR) installations and fully uses Nissan’s high-speed network infrastructure. Managers are in control of their own cameras, with minimal ongoing assistance from their IT team. They also now have instant access to live video and recorded images from any of 300 cameras across the Nissan factory. Production problems are quickly identified and remedied, saving the plant managers a good deal of time and money. With any line stoppage costing thousands of pounds per minute, speed is vital when solving problems. Milestone XProtect Enterprise provides Nissan with the flexibility to scale the IP video system to meet the exact needs of its management team as new cars go into production. 1 Milestone Customer Story November 2011 "Since 2006 Milestone has enabled Nissan Motor Manufacturing UK to proactively use IP video to identify production issues and then deliver quality improvements. As an open system, Milestone manages expansion effortlessly and has allowed our managers total flexibility to build IP video systems to fit their exact requirements. Wherever our IP video journey takes us, Milestone helps us achieve our goals," says Damian Adams, IT Support Engineer, Nissan Motor Manufacturing UK. Nissan Motor Manufacturing UK Nissan Motor Manufacturing UK was founded in 1984 with the purchase of a 3.2 square kilometer site, located between Sunderland and Washington in Tyne and Wear. This state-of-the-art plant used the very latest robotics technology and car manufacturing thinking to begin building cars in 1985. The first Nissan Bluebirds rolled off the production line that year, with the Nissan Micra following in 1992 and Nissan Almera in 2000. By 2009, the plant directly employed 4,168. By then Nissan had invested £2.5bn and turned the Sunderland plant into the largest car factory in the UK, the UK’s largest car exporter and one of the most efficient plants in Europe. It currently builds the Nissan Note, Juke and Qashqai –producing 386,555 cars in 2009 and 5.5 million since 1985. More than 80 percent of production is destined for one of 45 export markets. In 2010, the plant was named as the European production center for the electricpowered Nissan Leaf, with the first UKproduced Leafs due in 2013. Nissan – quality assurance Nissan is committed to class-leading quality assurance and continual improvement across its business. Making cars is a technology-intensive business, and similar to other car manufacturers, it has always used machine vision tools in its production. Highly specialized cameras are used to inspect individual processes, decide whether the correct part is in its exact location, take precise measurements and act as the "eyes" for the robots. Machine vision cameras do not give an overall view of a process; they are designed to focus solely on one specific movement or task. Getting cameras to capture entire processes, to see each stage in action, was the next key step. The Sunderland factory is dominated by three key areas: the body shop, the paint shop and the trim shop. Each area has specific challenges and needs and managers within each area are tasked with driving through quality and efficiency improvements. Since the early days of the Sunderland plant, Nissan has used surveillance cameras to provide an overview across specific stages of production, especially in areas of the plant where it is not suitable for employees to enter while in operation, such as the 5,000 tonne steel press in the body shop. Video was first used by maintenance teams working in both the body shop and paint shop, allowing them to view and record an individual process and use video as a diagnostic tool to examine exactly when and where a process was going wrong. Analog cameras and camcorders were regularly used in those early years, feeding back to a viewing 2 Milestone Customer Story November 2011 station or recorded onto a DVR. Some of the systems were short-lived as both the cameras and DVRs purchased were not ideally suited to a factory environment. In 2002 Nissan began to invest in its network infrastructure for its factory, culminating in 2006 with the introduction of a full duplex, fiber-based Gigabit network backbone offering full redundancy. With a new, fast network in place, the three-strong IT engineering support team at Nissan suggested using IP cameras for the first time – and selecting cameras fit for the environment. The first nine Axis 206 IP cameras were purchased in 2006 by the engineering and maintenance teams working in the trim shop. These small, entry-level cameras proved ideal for the factory environment. Nissan then purchased its first ever video management system with a nine-camera license for Milestone XProtect Enterprise through a local reseller called Advantix. Milestone provides open platform for IP video growth The first nine IP cameras were all installed by the in-house team, supervised by Damian Adams, IT Support Engineer for Nissan. Damian was instrumental in making the switch away from ad hoc, standalone installations of analog cameras and recording equipment which was proving unreliable and did not allow for any integration. Damian admits that in 2006 Nissan UK was pioneering in its use of IP video. The capability of the cameras, as well as storage and computer processing power, were constraints compared to today. But the company could clearly see the immediate benefits of using Milestone XProtect Enterprise with live video monitoring, instant recording and playback all available from a standard PC. The cameras were used to capture process faults with the cameras regularly moved to sections of the trim shop which needed investigation. Members of the maintenance team could log in to XProtect on their own PC and use the video footage to determine why a line had stopped or a fault had developed, even providing advice remotely when they were working at other sites. This saved vital time and prevented costly stoppages. Managers from the three plant areas saw the potential of using IP video and the effectiveness of Milestone XProtect Enterprise. The simplicity of accessing images via a PC, being able to switch between cameras by a click of a mouse, even comparing two videos side-by-side to examine how different employees work on a process, quickly established IP video as a vital tool for Nissan. Between 2006 and 2009, IP camera numbers grew to 70 and Milestone XProtect Enterprise user licenses swelled to 90. Milestone XProtect Enterprise scales up effortlessly, accommodating an unlimited number of cameras and supporting more than 900 IP products from 79 vendors. With each department responsible for its own budget, Nissan UK’s IT engineering department worked with a networking reseller partner Express IT, based nearby in County Durham. Express IT supplied extra Milestone user licenses and Axis IP cameras, installing the cameras where required, although in reality many of the cameras were supplied pre-configured and installed by Nissan employees. With 70 IP cameras and Milestone XProtect Enterprise available for 90 users across the factory, using IP video became engrained into Nissan UK’s quality assurance process. It was helping to fix problems faster. An issue with a conveyor system which transports spare parts was resulting in the automated conveyor carriers being bent in transit, for example. The problem was unresolved for weeks until an IP video camera was installed to capture the movement of the conveyor. Within three shifts the issue was spotted and resolved – saving substantial amounts of time and cost. Such was the success of IP video implementation and the usage of Milestone XProtect Enterprise that all shop floor managers and supervisors wanted to substantially increase the number of production 3 Milestone Customer Story November 2011 processes covered – in some instances to provide video from the start right to the end of their individual production cycles. In 2009, the IT engineering department estimated it had demand for up to 300 IP cameras and 300 Milestone XProtect Enterprise user licenses. For Milestone XProtect Enterprise, the increase to 300 cameras and 300 users was easily achieved. But for such a significant increase in spending, the IT engineering department had to make a strong business case. The department also understood that it would need to substantially develop its server provision for the increased storage and computer processing required to run it. Nissan is very supportive of technology which clearly supports its quality ethos. IP video and the use of Milestone XProtect Enterprise had already proved itself time and time again in so many areas, including early identification of production problems, analysis of production flow throughout the plant, and even supporting the design of new processes. IP camera functionality was increasing and prices were simultaneously falling, which made the upgrade more affordable by 2009. The business case was passed and Nissan’s IT engineering department embarked on a project to manage the four-fold increase in cameras and users. Rather than invest heavily in new servers, the IT engineering department chose to embark on a virtualization strategy, working with leading vendor VMWare. Using VMWare’s Enterprise virtualization solution provided Nissan with a high availability system which uses processor capacity on PCs and servers spread across the factory. Most of the IT hardware used by Nissan incorporates dual or quad core processors, and Milestone XProtect Enterprise runs happily as a single processor application – this allows four or up to six instances of Milestone XProtect Enterprise to run on a single piece of hardware. Nissan did invest in some new blade servers but the investment was minimized thanks to the virtualization strategy. VMWare automatically manages the load placed on it as users open up Milestone XProtect Enterprise on their PCs and manages the storage demands of the 300 IP cameras. If a server fails or is unavailable, VMWare instantly switches to another available server. Working together with support from Milestone’s technical team and Express IT, the virtualization system was fully implemented by early 2010 and has been a runaway success, delivering HA to support the huge upswing in demand for cameras and Milestone users. Now with 300 IP cameras, Nissan managers and supervisors expanded IP video coverage to provide near complete coverage of the car manufacturing process. Managers always have their Milestone XProtect Enterprise application open on their desktop to provide reassurance that their plant is running smoothly and it provides the ability to instantly scrutinize specific processes. It also provides insight into inhospitable areas of the plant, such as inside the paint shop tunnels and heavy steel presses which were hidden before. Pan-tilt-zoom (PTZ) cameras are now in use in some areas such as the paint shop. Here Milestone XProtect Enterprise enables full PTZ control for simple viewing adjustment. Managers also experiment with "zoning" here, to see whether specific parts have been taken from a specific area and fitted by the robots. Unlike security surveillance, video storage requirements are much shorter. Typically, a manager only wants to focus on three consecutive working shifts to provide a comparison of two shifts together. Milestone XProtect Enterprise provides complete flexibility, enabling managers to specify their own storage requirements. Frame recording rates also vary, some processes move very fast and require maximum frame rates (30-50 frames per second) but over short time periods – dedicated local servers are used to facilitate fast data transfer. 4 Milestone Customer Story November 2011 Benefits of managing processes Nissan recognizes the vital role that Milestone and IP video has played in improving the quality and efficiency of its factory. Nissan is a company which actively encourages its employees to be creative and innovative in their use of new tools and methods to continually drive quality. Its managers had always experimented with video to help record processes and use the video to work out how to improve and refine each process. But the analog cameras and recording equipment was proving unreliable and involved proprietary, standalone systems which would not integrate. The introduction of a high-speed fiber network made IP video possible, and Nissan could see that IP video eliminated the need for ad hoc, coaxial installations and enabled all plant managers to access vital video images from their desktop PC. Nissan management embraced IP video as a maintenance and production tool. Many times IP video has prevented production issues and virtually eliminated the causes of temporary stoppages. Since 2006 Milestone’s open system approach has enabled Nissan to manage the exceptional growth of the system, allowing managers to add and change cameras, configure each camera to their specifications – with managers having the confidence to do all this without the need to involve their IT team. With new products such as the all-electric Nissan Leaf in planning, managers are already incorporating the use of Milestone and IP video into their plans. Extending IP video with Milestone XProtect Enterprise Nissan now plans to extend its use of Milestone XProtect Enterprise and IP video to its security surveillance system. Working with its integration partner Express IT, it is now replacing some 150 analog cameras across the whole Nissan site and installing a range of Panasonic, Axis and Sony IP cameras. Many of the cameras will offer high-definition (HD) images. All images will be recorded for 28 days using a new dedicated blade server. Such has been the success of IP video for the plant that the word has spread to the plant’s security team which is now considering using Milestone XProtect Enterprise to replace their aging DVR-based systems which they currently use for storage and management of surveillance images in and around the plant. www.milestonesys.com 5