read - Product Liability Prevention

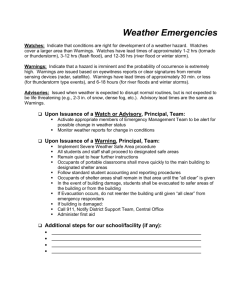

advertisement

Product Liability Warnings and Instructions By Kenneth Ross While the responsibility of providing adequate warnings and instructions should not be taken lightly, having competent legal and technical personnel available to answer difficult questions should alleviate manufacturers’ fears. Answers to Some of My Favorite FAQs Providing advice on warnings and instructions has occupied a good portion of the last 35 years of my professional life. First as an in-house lawyer and then as outside counsel, I have tried to provide both legal and practical advice in this area. Given the lack of law on many issues involving warnings and instructions, it is impossible simply to offer a legal opinion and have it provide useful guidance for a manufacturer. Therefore, those who advise on these subjects must be prepared to use their legal knowledge and combine it with practical judgment to provide a realistic set of options for a manufacturer to use to make decisions. DRI has just published a global compendium on the duty to warn, which discusses the law in all 50 states and the District of Columbia as well as in a number of foreign countries. This will be useful in understanding the law in these various areas, especially when you litigate a case in a particular jurisdiction. But it won’t be that helpful in making decisions about warnings and instructions that will be sold throughout the United States and internationally. Focusing on a particular jurisdiction is not useful when you wish to comply ■ Kenneth Ross is a former partner and now Of Counsel in the Minneapolis office of Bowman and Brooke LLP, where he practices in product safety, regulatory compliance and liability prevention. He served previously as an in-house attorney at Westinghouse Electric and Emerson Electric and has advised on issues involving warnings and instructions for over 30 years. 56 For The Defense November 2012 ■ ■ © 2012 DRI. All rights reserved. with the law in all regions in which a product will be sold. The intent of this article is not to discuss in detail the legal analysis that might apply to answering certain questions, but to provide short practical answers to questions that I and others have received and answered over the years. To the extent that someone has written on the subject previously, I will provide a link to the more comprehensive article. I will assume that a reader understands generally the duty to warn and is familiar with the applicable American National Standards Institute (ANSI) standards. FAQs Are there guidelines that detail the process of developing warnings? ANSI issued a standard dealing with on-­ product warnings in 1991 (ANSI Z535.4) and how to incorporate safety information into collateral instructions in 2006 (ANSI Z535.6). These standards contain guidelines on how to develop, write and format warnings and instructions. In addition, there are product-­specific laws and standards that governments, ANSI and other standards organizations have issued over the years that pertain to warnings such as the Federal Hazardous Substances Act, enforced by the U.S. Consumer Product Safety Commission, for chemicals in consumer products and ANSI Z400.1/Z129.1-2010 for industrial chemicals and material safety data sheets. These product-­specific laws and standards would take precedence and, therefore, need to be identified and considered. The ANSI Z535.4 standard states: There are a number of existing American National Standards that are recognized for particular industries or specific uses. Compliance with such a standard may be considered for the particular industry or use. It is not the intent of this ANSI Z535.4 standard to replace existing standards or regulations that are uniquely applicable to a specific industry or use. In addition to ANSI and other U.S. organizations issuing standards, the International Organization for Standardization (ISO) has issued standards on warnings and instructions for all products (ISO 3864) and also for specific product categories such as ISO 11684 for agricultural equipment, and the European Union has issued directives on products such as machinery that contain warnings requirements. Also, there are various product-­specific guides that have been created by government agencies for particular product categories. For example, the U.S. Consumer Product Safety Commission published “Manufacturer’s Guide to Developing Consumer Product Instructions,” in October 2003; the British Department of Trade and Industry published an excellent booklet called “Writing Safety Instructions for Consumer Products” in November 1998; in 1993, the U.S. Food and Drug Administration (FDA) published “Write it Right: Recommendations for Developing User Instruction Manuals for Medical Devices in Home Health Care,” which incorporates ANSI Z535 concepts; and the European Union issued a “Guide to Application of the Machinery Directive” in June of 2010. Lastly, if a product has a third-party certification, such as Underwriter’s Laboratory (UL) or the Canadian Standards Association (CSA), the manufacturer’s labels and instructions need to comply with the requirements of that standard. For some products, there may be multiple laws, regulations, standards and guides that need to be considered when develop- ing warnings and instructions. That is one reason why personnel involved in developing such information need to be familiar with all of the applicable reference documents that need to be considered. Products do need to comply with some documents, and some might just provide helpful guidance. The goal is to use all of the relevant resources available and be prepared to defend the adequacy of your process and your warnings. For a good overview, see J.P. Frantz, T.P. Rhoades & M.R. Lehto, “Practical Considerations Regarding the Design and Evaluation of Product Warnings,” in Warnings and Risk Communication 291–311 (M.S. Wogalter, D.M. DeJoy, & K.R. Laughery eds., Taylor & Francis 1999). In addition, see Shaver & Braun, Is Your Company Using a Process to Develop Warning Information?, In-House Defense Quarterly, Summer 2007, and Ross & Adams, Legally Adequate Warning Labels: A Conundrum for Every Manufacturer, For The Defense, Oct. 1998. Is there a risk in exceeding the voluntary standards for product labeling applicable to my product? Is that an admission that my product is more dangerous than my competitors, or does this create a problem for my competitors by providing warnings that are better than theirs? The law is clear that mere compliance with standards is not an absolute defense in product liability cases. Therefore, you must meet or exceed the standards. All warnings can be used to support an argument that a product is hazardous and allow a plaintiff to argue that you should have designed the product to eliminate a hazard rather than warned purchasers about it. So excessive warnings can create some problems for you, especially if you warn about risks that are very remote or have low severity. This can also create problems for your competitors in that you have created a “better” warning that will be compared to your competitor’s warnings. It is better for an industry to adopt what everyone thinks are adequate labels as the standard. Then, each manufacturer will comply with the standard and not feel compelled to do better. With that said, if an industry does a poor job in developing a standard or does not have a warnings standard, you should put labels on your product and provide instructions that you believe are appropriate for safety and necessary to comply with the law. In addition, hopefully these also could comply with ANSI Z535. What if there are product-specific laws such as the Federal Hazardous Substances Act (FHSA) or standards such as UL’s that conflict with ANSI Z535.4? Is it imperative that you also follow ANSI Z535? There is no evidence that the ANSI Z535.4 formats are superior to other formats or requirements. It is important to identify and to try to comply with the more product-­ specific requirements first. But, remember that the plaintiff can argue that you should have exceeded the product specific standards and, many times, that would be the Z535.4 standard. Therefore, if you can also comply with the Z535.4 standard, so much the better. Is there a problem if you select the wrong signal word? Z535.4 uses three signal words for injury related hazards: DANGER, WARNING and CAUTION. In the Annex to the standard, there is a detailed process for selecting the correct signal word. Many manufacturers have been concerned about what could happen if they select the wrong signal word, given the definitions in the standard. The signal word is an attention getter and also transmits part of the message concerning probability and severity of harm. However, the word message and the pictorial in the label are more important in communicating the message. So while it is preferable for a signal word and a message panel to be consistent, meaning, for instance, that you want to pair DANGER with “will cause serious injury or death,” I think that it is unlikely that a jury would find a warning label defective if the signal word was wrong. As long as the word message and the pictorial accurately describe the hazard and the probability and the severity, the signal word becomes less important. With that said, once you determine the potential severity of harm as being a risk of serious injury or death, the signal word is usually going to be WARNING. You would save DANGER for risks involving a high For The Defense November 2012 57 ■ ■ Product Liability probability (“will”) of harm and, according to the standard, this signal word should be limited to the “most extreme situations.” Do you always need to state the hazard, consequences and avoidance procedures even if they are obvious? The ANSI Z535.4 standard in Annex B reads: For some products, there may be multiple laws, regulations, standards and guides that need to be considered when developing warnings and instructions. The word message on a hazard alerting sign typically communicates information to a viewer on the type of hazard, the consequence of not avoiding the hazard, and how to avoid the hazard. Many factors must be considered when determining whether to omit consequence, avoidance, or type of hazard information in the word message. Factors to consider include whether the message can be inferred from a symbol, other text messages, user training, or the context in which the safety sign is used. Certainly, it is clear that many hazards and avoidance procedures can be readily inferred when a label is on a product and near the hazard. Studies also support this view. It has been said that “[f]rom a practical standpoint, this study affirms ANSI Z535.4’s acknowledgment that people can infer a variety of information about hazards in the context of product use without reading explicit statements on a label.” J.P. Frantz, T.P. Rhoades, R.J. Shah, S.M. Hall, J.J. Isaacson & C.G Burhans, ANSI Z535 signal words and the ability to infer hazard and consequence information—1992 versus 2004 in Proceedings of the Human Factors and Ergonomics Society (HFES) 49th Annual Meeting 1790–94. (HFES 2005). But you need to be careful about delet- 58 For The Defense November 2012 ■ ■ ing some of these statements just to save a little space. If you think that a message is “obvious” from viewing a product, you could test that assumption by asking a small focus group or even just a few people at your company. For example, you might delete the avoidance procedure when a product becomes extremely hot during operation and you say that there is a burn hazard. To avoid the burn, you don’t touch the product when it is operating. That is pretty obvious. The problem is that the product may stay hot for a while after it is turned off and that will not be obvious, particularly for a bystander who didn’t even know that the product had been in operation. In addition, you might not warn about a particular hazard because it is obvious. For example, you might not warn about a crush hazard in a conveyor belt. However, the severity and the probability also have to be obvious before I would omit a hazard warning. Taking the crush hazard in a conveyor belt example, it may not be obvious that a user’s hand can be cut off or crushed, and the user might just think that his or her hand could be pinched. When can you use pictorials instead of text on labels and in the manual? And if you do, can you rely on pictorials without human factors testing? I have written extensively on this subject. See The Duty to Warn Illiterate and Non-­English-­Reading Product Users, InHouse Defense Quarterly, Winter 2008, and Warnings and Instructions: Updated U.S. Standards and Global Requirements, DRI Product Liability Committee Newsletter, Fall 2011. Even though this is a complex subject that is not readily susceptible to a short answer, I will attempt to provide one. There are some pictorials that can readily be used in labels in the United States in place of certain text. Most of them show the hazard and the consequences and have been used for decades. Some of them show the avoidance procedure. One example is the circle and slash. While many of these pictorials are very understandable, the general view among most lawyers, including me, is that, with some exceptions, it is risky to use no-text labels with only pictorials in the United States. Some messages are difficult, if not impossible, to trans- mit with pictorials alone, and a label with many pictorials really needs to be studied for a while for a reader possibly to understand the entire message. That defeats the purpose of a label, which should be understandable at a glance. One way to use pictorials in lieu of text is to do human factors testing as described in ANSI Z535.3. However, such testing is expensive, and the results may still be challenged by a plaintiff who says that he or she didn’t understand the pictorial. The use of no-text labels outside the United States is much more prevalent and certainly less of a legal risk. However, a company should consider the likelihood that products shipped outside the United States with no-text labels could end up being sold to consumers in the United States. Should label and/or manual be tested for usability and comprehension? Testing is done very infrequently and in only very specific circumstances. Most of the time, a word message is clearly understandable to foreseeable users and does not need to be tested for comprehension. If new pictorials are created or a pictorial is used for a young child or someone with similar comprehension ability, some testing may be appropriate. When testing is undertaken for the pictorial, it usually just tests comprehension and not compliance. In addition, when we test a pictorial, we can also test the words to confirm that they are understandable. For more information on testing, see J.P. Frantz, T.P. Rhoades & M.R. Lehto, “Practical Considerations Regarding the Design and Evaluation of Product Warnings,” supra, at 305–06, and Ross, Warnings and Instructions: Updated U.S. Standards and Global Requirements, supra. Should labels and manuals in the United States be bilingual (English and Spanish)? Again, this is a very complex issue, and I have written about it extensively. See The Duty to Warn Illiterate and Non-­English-­ Reading Product Users, supra, and Multilingual Warnings and Instructions: An Update, DRI Product Liability Committee Newsletter, Fall 2012. However, the quick answer is that the law does not generally require any lan- guage other than English. Despite that, Whether adequacy requires in any given some retailers do demand at least Spanish case that warnings be placed directly on warnings and instructions sold in their on the product involves a balance of the stores. Unless there is a customer request, significance of the hazard, the user’s a manufacturer should preferably add more need for the information, the availabilpictorials rather than add a foreign lanity of a feasible means to place the warnguage to try to communicate with non-­ ings on the product, and other factors English-­reading product users. Once you in the calculus of risk. If feasible, reaadd a foreign language, you have to decide son normally suggests that important which one to add, and then you need to be warnings be placed on the product itself sure that the instruction manual is also in rather than in a pamphlet, booklet, or that language. And sometimes Spanish is information sheet that can be damaged, not the only language that needs to be conlost, destroyed or stuffed in an office sidered. Lastly, adding other languages will drawer.… Depending on the circumsometimes diminish the conspicuity of the stances, however, a warning may still English message and thereby increase the be adequate even if it is provided off the potential liability for English-­reading users product in a manual or other writing. who have a hard time finding the English Product Liability Law 601 (2d ed. Thomportion of the message. son West 2008). For a more extensive discussion, see my When can safety messages be in the article Location of Warnings: On Product manual and not in the label? When or in the Manual?, DRI Product Liability on the label and not in the manual? Committee Newsletter, Summer 2008. Also There is very little guidance in the law or see J.P. Frantz, T.P. Rhoades, & M.R. Lehto, the general warnings standards on these “Practical Considerations Regarding the questions. Some product-­specific standards, Design and Evaluation of Product Warnincluding UL requirements, do specifically ings,” supra, at 303. say whether the warning must be on a product or in the manual. Without that require- What about warnings and instructions ment, it is up to a manufacturer to decide. on component parts that an original My operating principle is based on an product manufacturer (OEM) analysis of whether the reader needs to inserts into its final product? see the information each time that he or An OEM is responsible for providing adeshe uses a product, or whether he or she quate warnings and instructions for its can read the manual and then refer to that finished product, including all of its cominformation later on as needed. Steve Hall ponents. Therefore, any inadequacies could from Applied Safety and Ergonomics and result in liability for the OEM. However, chair of the ANSI Z535.4 subcommittee the component part supplier can also be responsible for inadequacies in the warnsaid on this question: There is no hard and fast rule, but gener- ings and instructions provided with its ally you want to try to provide messages component. The OEM should try to buy components in a way that gives people a reasonable chance to read them at an appropri- from suppliers that appear to have adequate ate time. So, for tasks that are expected warnings and instructions. Therefore, if a to involve referring to the manual (e.g., component has warnings, for example, that assembly, troubleshooting, mainte- do not comply with ANSI Z535.4 or any of nance, etc.), it is generally reasonable to the other standards, then the OEM should provide safety messages in the relevant ask the supplier to upgrade the labels. If part of the manual, and not on a label. the OEM assumes the duty to revise comConversely, for scenarios where the tar- ponent part labels, it could also become liaget audience is not reasonably expected ble for any inadequacies in the warnings. to have access to a manual, a label may The burden should really be on the supplier to provide adequate information and be more appropriate. In addition, Professor David Owen not the OEM. In the component part purchasing proaddressed this issue in his product liacess, an OEM should provide requirements bility hornbook: and guidelines to the component supplier about how the OEM wants the warnings and the instructions to appear and be provided. The OEM will then need to decide if it will provide the component supplier’s instructions as a separate manual or incorporate them into the final product manual. If they are incorporated into the manual, and the OEM makes changes, the supplier should approve the final version of the OEM’s manual. And the supplier should indemnify the OEM in case there are inadequacies in the supplier’s warnings and instructions. Let’s change the facts and say that the component part supplier doesn’t know how its component will be used, where it will be placed and where the operator will be standing in relation to its component. How can the component part supplier provide warnings and instructions that will be adequate for all uses and locations? Well it can’t, and it shouldn’t be required to do so. But the supplier should have some idea of the various ways in which its product can be used and should attempt to provide some guidance to the OEM on safety information that needs to be incorporated into the instructions depending on the various uses that the supplier can anticipate. The supplier might also provide to the OEM loose warning labels with instructions on where to place them, depending on how the component is incorporated into the final product and where the hazard will be located for the user. Putting the burden on the OEM to make the final decision on the warnings and instructions is appropriate in this situation. Whether you can get an OEM to take that responsibility depends on the sophistication of the OEM. If an OEM doesn’t know what it is doing, then maybe the component supplier should visit the OEM’s plant and “approve” the installation of the component and placement of the warnings. Do you always need to provide a hard copy of the instruction manual, or can you put the manual on a CD and include it with the product or have a reference (website link or QR code) on the label to the manual on the company’s website? The standards don’t discuss whether a hard copy instruction manual is required, or whether the information can be provided in another way. The reason is probably that For The Defense November 2012 59 ■ ■ Product Liability most manufacturers provide their instructions in a hard copy. However, there have been manufacturers of certain products that have recently asked about not providing a hard copy. Instead they want to include the instructions as an electronic file in a product or in a CD format or just provide on a label a link to the manual on a website. Examples of such products would be cell phones, computers, TVs and certain machinery or equipment run by computers. I have seen no law that discusses this issue and since, except as discussed below, virtually no laws or standards say one way or another, a manufacturer could omit the hard copy and argue that what it provided was adequate under the circumstances. The ANSI Z535.6 subcommittee has been discussing the increased use of social media and company websites and how that relates to the required instructions. I anticipate that the committee will add some sections on this subject in the 2016 ANSI Z535.6 revision. However, for now, the ANSI Z535.6 standard does mention “supplemental directives,” which could include references to website links, QR codes and other recognized types of safety messages. In Europe, the Guide to the EU Machinery Directive specifically requires that a hard copy of the manual accompany machinery. Until the Guide changes, manufacturers of machinery have no other choice. However, in March 2012, the European Commission approved the use of electronic forms of instructions with certain medical devices intended for use exclusively by medical professionals. Manufacturers of active implantable medical devices, implantable medical devices, fixed installed medical devices and medical devices fitted with visual display systems will be able to provide in electronic form use instructions previously provided on paper. Manufacturers providing electronic instructions will be required to include notices on product packaging on how to access the electronic forms of instruction, or provide supplementary printed instructions on how to access electronic instructions. Even before the ANSI committee includes provisions on electronic instructions, manufacturers should consider using new technology to transmit safety information more effectively and efficiently. The ability to pro- 60 For The Defense November 2012 ■ ■ vide animations, videos, expanded illustrations and other more interesting ways to explain how to safely use products should be considered and utilized when possible. There is even technology being developed to allow attaching verbal warning labels to a product. Vesstech Inc., http://www.vesstech. com/ (last visited Oct. 1, 2012). At a minimum, the on-­product warnings should tell a user to read the manual before using a product and tell the user how to obtain a replacement manual if one is missing. This can be done by providing an 800 number to call, an email address of a company employee, or a website link from which the user could download a replacement manual. How do you incorporate safety information into the company website? There are several excellent examples of comprehensive websites that discuss product safety. See Safety.cat.com, Caterpillar, http://safety.cat.com/ (last visited Oct. 1, 2012), and Safety Resources, Toro, http://www.toro. com/en-us/safety/pages/default.aspx (last visited Oct. 1, 2012). They go well beyond just including links to manuals. They incorporate videos, interactive manuals and safety tips. The ANSI Z535.6 subcommittee will be considering future revisions, which could discuss how to incorporate safety information into websites. At the moment, there are no requirements to have extensive safety information similar to the Caterpillar and Toro websites mentioned above. However, to the extent that there is a growth in such websites, the “state of the art” in safety websites will be raised and other manufacturers may be inclined to provide much more information than they currently do. When should new or improved warnings and instructions be offered to prior customers? When do you need to tell the government? New and improved warnings and instructions might be considered safety improvements, or they might be considered an admission that the earlier warnings and instructions were defective. The common law is clear that manufacturers are not required to offer safety improvements to prior customers if the earlier product was not defective. The problem is how do you decide whether the earlier product might be con- sidered defective and the new safety information used as evidence to support the claim? It is a difficult decision and one that is fraught with potential problems, no matter what you do. Certainly, if the earlier warnings and instructions are compliant with the standards and the law and the new versions are just updated and made a little better, then it is arguable that these are just improvements. However, if the earlier warnings and instructions did not comply with the standards or law and were very bad, or if there have been a number of lawsuits alleging a failure to warn or several jury verdicts ruling the warnings defective, then the new warnings and instructions might be more than just safety improvements. This is an important analysis where competent defense counsel can also provide valuable assistance in addition to your safety counsel. Since you don’t know where any future case will be brought, it is hard to know which state’s law to consider. The best approach is to consult with counsel who you trust and who is familiar with your products and your litigation. Then the question is, in the case of consumer products, do you need to inform the U.S. Consumer Product Safety Commission, Health Canada or the Australian authorities about the new warnings and instructions? The reporting laws are different from country to country, and you need to consider whether the issuance of new warnings and instructions to prior customers could arguably be considered a “recall” and create a reporting responsibility to any of these agencies. For more information on the reporting requirements, see Ross, New Safety Laws May Result in Significant New Liability, In-House Defense Quarterly, Fall 2011. If customers are not properly using or maintaining a product and not following the label or manual, should you send out a reminder to customers about the necessity to follow the instructions and precautions? In this question, we assume that the earlier warnings and instructions are adequate. They just aren’t being followed. This is always foreseeable. But that doesn’t create a post-sale duty. However, once we become aware of this fact and accidents or near misses have occurred as a result, a postsale duty could arise in some states. See Ross and Soule, Post-sale Duties: A Minefield for Manufacturers, In-House Defense Quarterly, Fall 2006. If accidents have occurred and there is some way to get the reminder to your customers, it is probably a good idea to do it. If you can’t find your customers easily, then maybe placing a reminder on your website is appropriate. Of course, a manufacturer may decide to redesign future products so that there is less of a hazard when users do not follow the warnings. In that case, they then have another difficult decision: whether to retrofit old products with the new designs, such as a new safety guard, if that is possible. Your instructions warn users not to service a product or to perform certain repairs. But you know that users are going to do it anyway. What do you do? When you tell users not to do something but you know that they will do it anyway, and there are safe and unsafe ways to do it, then you might be inclined to tell them how to do it safely. But then aren’t you “authorizing” them to do the service or repair that you don’t really want them to do? On balance, as long as it is reasonably foreseeable that they will do the servicing and repairs and there are hazards in them doing so, then I would continue to encourage them strongly not to do it, but then add some basic instructions on how to do it correctly and safely. One way to handle this is to state that the repair or the service instructions are for professional service personnel and not for the consumer even though the instructions are contained in the manual that accompanied a product. Conclusion There are many other questions that I have been asked over the years and to which I have had to supply answers. There is very little law on these important but narrow issues. And most of them are not answered by any of the standards. Despite that, a manufacturer must consider them and make a decision. While designing a safe product is not an easy task, providing adequate warnings and instructions is a tough job. It is so easy to add words, make a label bigger, provide more illustrations in a manual and do other things that some jury might believe would have prevented an accident. While manufacturers shouldn’t be paralyzed by the fear of not providing adequate warnings and instructions, they should not take this responsibility lightly. They should use competent legal and technical personnel to help, especially on the difficult kinds of questions represented above. In addition to providing information that hopefully will reduce the risk of harm, better warnings and instructions might also help make a product more marketable in that it will be perceived by customers to be easier to assemble, use and maintain. And they will certainly be easier for defense counsel to defend if an incident occurs. For The Defense November 2012 61 ■ ■