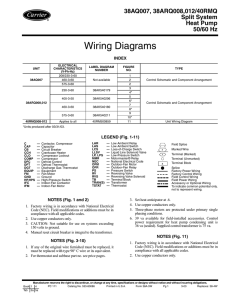

Wiring Diagrams

advertisement

38AQ007/40RMQ008 Split System Heat Pump Wiring Diagrams 60 Hz WIRING DIAGRAM INDEX Fig. No. Control Schematic and Component Arrangement (208/230 V) 38AQ007. . . . . . . . . . . . . 1 Control Schematic and Component Arrangement (460 and 575 V) 38AQ007 . . . . . . . . . 2 40RMQ008 Unit Wiring Detail. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 SEQUENCE OF OPERATION — 38AQ007 OUTDOOR UNIT WITH 40RM008 INDOOR UNIT When power is supplied to unit, the transformer (TRAN) and crankcase heater (CCH) are energized. Cooling — On a call for cooling, the thermostat completes the following circuits: R-G, R-Y, and R-O. If the compressor recycle delay of 3 minutes is complete, the compressor and outdoor fan start. The reversing valve is energized for cooling and the indoor-fan motor starts. When the thermostat is satisfied, the circuits are opened, and the compressor, outdoor-fan motor, and indoor fan motor stop. The reversing valve is deenergized. Heating — On a call for heating, the thermostat completes the following circuits: R-G and R-Y. If the compressor recycle delay of 3 minutes is complete, the compressor and outdoor fan start. The indoor-fan motor will also start. If room temperature continues to fall, the thermostat completes circuit R-W. If the optional electric heat package is used, the heat relay is energized, and the electric heaters are energized. When the thermostat is satisfied, the circuits are opened, and the compressor, outdoor-fan motor, heaters, and indoor-fan motor stop. Defrost — The Defrost board (DB) is a time and temperature control, which includes a field-selectable time period between checks for frost (30, 50, and 90 minutes). Electronic timer and defrost cycle start only when contactor is energized and defrost thermostat (DFT) is closed (below 36 F [2.2 C]). Defrost mode is identical to Cooling mode, except outdoorfan motor (OFM) stops and a bank of supplemental electric heat (if equipped) turns on to warm air supplying the conditioned space. Defrost mode is terminated when the DFT reaches 51 F (10.6 C). Low Ambient — Cooling head pressure control at low ambient conditions is accomplished through a low ambient relay and switch. The switch is factory set to close at 250 psig and open at 100 psig. In Heating mode, the low ambient switch is bypassed by normally closed contacts on the low ambient relay. Air Circulation — When the fan switch is at FAN ON, the indoor-air fans operate continuously to provide ventilation. The thermostat operates the other components as described above. Emergency Heat Cycle — If the compressor is inoperative due to a tripped safety device, the second stage of the thermostat automatically energizes the indoor-air fan and the electric resistance heaters (if equipped). Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations. PC 111 Catalog No. 533-80005 Printed in U.S.A. Form 38AQ-8W Pg 1 4-01 Replaces: New Book 1 4 Tab 5a 5a DANGER: ELECTRICAL SHOCK HAZARD DISCONNECT POWER BEFORE SERVICING CONNECTION DIAGRAM POWER SUPPLY PER N.E.C. AND LOCAL CODES 208/230 VAC, 60 HZ, 3 PH. BL R LOW AMBIENT SWITCH R R L3 L3 T2 L2 L2 COMP BL T1 BK 3 BK LOW AMBIENT RELAY 1 T1 CONTACTOR T2 T2 COMPRESSOR ATTACH GROUND T1 SEC CAP LAS R FAN CAP DEFROST Y-RV CONTROL FM RV BL BR R R PS1 BL BK BK R C BL (WHEN USED) SEN PS2 PS1 R-RV FM DEFROST HEAT W COMPRESSOR HEAT/COOL Y O BL Contactor Capacitor Crankcase Heater Compressor Defrost Control Defrost Relay Fan Motor High-Pressure Switch Low Ambient Switch Low Ambient Relay LEGEND LP PL PS RV TRANS — — — — — RV COIL C COIL LP/HP DF RRV R C LAR 24 VAC Low-Pressure Switch Plug Pressure Switch Reversing Valve Transformer Factory Power Wiring Factory Control Wiring Field Control Wiring Field Power Wiring NOTES: 1. Factory wiring is in accordance with National Electrical Code (NEC). Field modifications or additions must be in compliance with all applicable codes. 2. Use copper conductors only. 3. CAUTION: Not suitable for use on systems exceeding 150 volts to ground. 4. Manual reset circuit breaker is integeral to the transformer. Fig. 1 — Control Schematic and Component Arrangement — 38AQ007 (208/230 V) 2 SEN O Y W COMMON R — — — — — — — — — — CC DEFROST CONTROL PS2 LP/HP TWO SWITCH WIRING O C CAP CCH COMP DFC DFR FM HP LAS LAR LP/HP RV PS1 O Y W BL Y-RV FAN Y DF BK BR R TRANSFORMER NOTE 4 24V Y PS2 DFC 2 USED) 208/230V BL BL CC 1 FAN LOW AMBIENT RELAY (WHEN BK RV BK COIL RESET BK PL CONT. T3 CCH BK G COIL L1 T1 L2 CONTACTOR T3 COIL TRANS 2 CCH +t° L1 L1 DIAGRAM L3 BK PRI BL GROUND EQUIPMENT PER N.E.C. AND LOCAL CODES. T2 T3 BL T3 LADDER 208/230 VAC, 60 HZ, 3 PH POWER SUPPLY DEFROST HEAT COMPRESSOR HEAT/COOL COMMON 24 VAC DANGER: ELECTRICAL SHOCK HAZARD DISCONNECT POWER BEFORE SERVICING CONNECTION DIAGRAM LADDER BL 575/460 VAC 60 HZ 3PH R R R LOW AMBIENT SWITCH T3 T3 L3 L3 T2 L2 L2 BL PRI T1 L1 BK TRANS LOW AMBIENT RELAY 1 BL G 1 DEFROST RELAY SEC 2 L1 BK BL COIL COMPRESSOR T3 CCH 2 Y COIL T2 T2 ATTACH GROUND BK COIL CONT. CONTACTOR T3 BK 3 L1 T1 L2 CONTACTOR T1 BK 3 CCH +t° L3 T2 COMP BL DIAGRAM 575/460 VAC 60 HZ 3PH T1 CAP R FAN FM DEFROST Y-RV CONTROL BK BK RV R RV COIL 24V DFR RV PL PS1 Y R C PS2 BK BK DF FM DEFROST HEAT COMPRESSOR HEAT/COOL COMMON 24 VAC W O BL R — — — — — — — — — — Contactor Capacitor Crankcase Heater Compressor Defrost Control Defrost Relay Fan Motor High-Pressure Switch Low Ambient Switch Low Ambient Relay LEGEND LP PL PS RV TRANS — — — — — C DEFROST CC CONTROL PS2 LP/HP TWO SWITCH WIRING Y COIL Y-RV RV COIL LP/HP PS1 PS1 O Y W O C CAP CCH COMP DFC DFR FM HP LAS LAR LP/HP FAN SEN R-RV BL 1 3 TRANSFORMER NOTE 4 Y PS2 BK BR R 2 575/460V BL BL CC BL BR R 1 LOW AMBIENT DEFROST RELAY RELAY RESET CAP BL LAS Y SEN DF RRV R C O Y W LAR DEFROST HEAT COMPRESSOR HEAT/COOL COMMON 24 VAC Low-Pressure Switch Plug Pressure Switch Reversing Valve Transformer Factory Power Wiring Factory Control Wiring Field Control Wiring Field Power Wiring NOTES: 1. Factory wiring is in accordance with National Electrical Code (NEC). Field modifications or additions must be in compliance with all applicable codes. 2. Use copper conductors only. 3. CAUTION: Not suitable for use on systems exceeding 150 volts to ground. 4. Manual reset circuit breaker is integeral to the transformer. Fig. 2 — Control Schematic and Component Arrangement — 38AQ007 (460 and 575 V) 3 LEGEND IFC IFM TB TSTAT — — — — Indoor-Fan Contactor Indoor-Fan Motor Terminal Block Thermostat Factory Wiring Field Control Wiring NOTES: 1. Factory wiring is in accordance with National Electrical Code (NEC). Field modifications or additions must be in compliance with all applicable codes. 2. Use copper conductors only. Fig. 3 — 40RMQ008 Wiring Detail Copyright 2001 Carrier Corporation Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations. PC 111 Catalog No. 533-80005 Printed in U.S.A. Form 38AQ-8W Pg 4 4-01 Replaces: New Book 1 4 Tab 5a 5a