LRv5i1 FACTUAL PHOTOMETRIC TEST REV1

advertisement

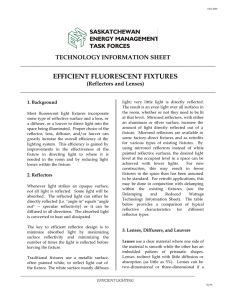

LIGHT READING™ The Newsletter of The Light Edge, Inc. Volume 5 Issue 1 – January 2006 REV1 February 2010 FACTUAL PHOTOMETRIC TEST ©2010 The Light Edge, Inc. For additional technical information please visit our website at www.thelightedge.com or call us at (503) 968-9968 Fixture Efficiency Defined Fixture efficiency is defined by the IESNA Lighting Handbook, Ninth Edition, as: “a measure of how effectively the lamp and the reflector and/or refractor work to get the lamp lumens out of the luminaire”. Thus, in the example below, while its source is most inefficient, 100% of the light produced by the source leaves the fixture, making the fixture efficiency 100%. This is indeed an efficient fixture, but it must be modified to direct the light to where it’s needed, and to shield light from where we don’t want it. To do any of these requires lowering the overall fixture efficiency by trapping, refracting, or reabsorbing light. Many lighting manufacturers perform photometric testing in their own ‘in-house’ photometric laboratories, while some rely on independent testing labs for neutral-party testing. Because of this, there are concerns that test reports are not all performed to the same standard. Let’s explore “fixture efficiency” ratings. Consider a generic fluorescent fixture – it doesn’t matter what type - in this conservative illustration of losses experienced by a luminaire using the best high-grade materials. Loss type Initial efficiency Reflector finish loss Interreflected light loss Lens transmittance loss loss % 0% 5% (0.95 x 100) 5% (0.95 x 95) 8% (0.92 x 90.25) = = = = net efficiency 100% 95% 90.25% 83.03% Note that the losses are not additive, but cumulative; first there is only so much light striking a reflective portion of the reflector, then some of it is absorbed by the reflector finish, then that amount is further reduced by refractive/absorption properties of the lens: Start with 100% fixture efficiency. • Unimpeded, in a perfect world, a free-burning lamp will deliver 100% of the light produced by the source. The Light Edge, Inc. Proudly Made in the USA. Next we add a reflector system, to direct the light where we desire. We’ll use a highly specular (95%) hardanodized aluminum, so now our efficiency is reduced by 5%, and we’re down to 95% adjusted efficiency. • Note: Polyester powder coat paint on the reflector is at best 93% reflective (Rohm Haas Technical Brief: maximum 92 – 93% achievable with high gloss white of 1.8 mils thickness), and pre-painted reflector stock can be as low as 78% reflective. Keep in mind that any reflector system will re-direct some of the light back into the lamp, as well as into any deadend spots between the reflector and the housing, etc. We’ll be very kind, and assume only 5% of the light is lost this way, so now we’re at 90.25% efficiency. • This varies dramatically depending on the reflector shape, depth, faceting, etc. and may be as high as 20 30% loss. This fixture will be lensed. We’ll use standard acrylic at 92% transmissivity, so we’re losing another 8%, bringing us down to 75.61% cumulative efficiency. • According to Hubbell, Inc., the transmittances of typical lenses is: Polycarbonate = 86 -89%; High Impact Acrylic = 89%; Standard Acrylic = 92%). Next, let’s review a purported 90% efficient real-world fixture, with a formed steel white-painted reflector, a lens, and a diffusion medium to obscure lamp image: Loss type Initial efficiency Reflector finish loss Interreflected light loss Diffusion medium loss* Lens transmittance loss loss % 0% 9% (0.91 x 100) 8% (0.92 x 91) 9% (0.91 x 83.72) 8% (0.92 x 76.19) net efficiency = 100% = 91% = 83.72% = 76.19% = 70.09% *Some manufacturers install a diffusion medium, usually a polymer or Mylar film that will help obscure lamp image. This means at least another 9% loss of light. • According to Rosco, Inc., the highest transmissivity through a typical polymer light-diffusing medium is maximum 91% (Rosco “Filter Facts” L05 FFA01 0199) How can one possibly trust a claim of 90% efficiency in a fixture of this type? Reviewing some basic principles of physics will immediately dismiss the spurious claims in excess of 100% efficiency that we have seen of late, and further consideration will question the validity of most any in-house tests claiming efficiencies above 80%, unless the fixture is unlensed. It’s said that liars figure, but figures don’t lie. It’s also said that buyers should beware. How can the industry assure that forthright photometry is made available? What would happen if that 90% efficient fixture were to be tested in an independent testing laboratory? Would the efficiency be similar to the derated results we arrived at above? How is a designer to know what to believe? Manufacturers carry a UL or ETL mark for electrical safety compliance, but there are no such standards to guarantee or confirm photometric performance. There are, however, standardized testing methods that, if followed correctly, should produce “apples to apples” comparative test results. The issue, of course, is that many manufacturers publish test results obtained in their own labs, using their own (sometimes home-built) goniometers. Perhaps a regulated reporting metric will be unenforceable; it would surely add costs to the manufacturing process. But it would be in the designer’s best interest to insist on independent test laboratory photometric reports to ensure accurate reporting of product efficiencies. The Light Edge, Inc. publishes photometry produced only by ITL, an independent testing laboratory in Boulder, CO. The Light Edge, Inc. Proudly Made in the USA.