NPL Industries Private Limited - Gujarat Pollution Control Board

advertisement

NPL Industries Private Limited

Rapid Environmental Impact Assessment Report

Proposed Project of Manufacturing of Textile Binders

& Auxiliaries

Location at: S.No. 748/P, 750/P,777/B/P, 780/P, Village : Bidaj,

Kheda, Gujarat

AUGUST 2012

Prepared By:

Ramans Enviro Services Pvt. Ltd.

SF –23 & 24, Camps Corner, Near AUDA Garden, Prahaladnagar

Ahmedabad 380 015 Phone: 079-26937472. Fax: 079-40064440

E-mail:ramans_consultancy@rediffmail.com,

ramans.consultancy@gmail.com

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES BY

NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

PAGE NO.

SR. NO.

TITLE

I

II

III

IV

IV

V

CONTENTS

LIST OF ANNEXURES

LIST OF TABLES

LIST OF FIGURES

Copy of TOR ISSUED FROM MoEF

COMPLIANCE OF ADDITIONAL TOR

I - IV

IV

V-VI

VIII-IX

X-XIII

XIV-XVIII

CONTENTS

SR. NO.

PAGE NO.

TITLE

1.0

1.1

1.2

1.3

1.4

1.5

INTRODUCTION

Purpose of the report

The Project Proponent

Brief Description of the Project

Justification of the Project

Scope of Study

1.1

1.2

1.3

1.3

1.4

2.0

2.1

2.2

2.3

2.5

2.6

2.7

2.8

2.9

PROJECT DESCRIPTION

Type of the Project

Location of the Project

The Project

2.3.1

Landuse breakup within plant area

2.3.2

Product profile

2.3.3

Resource requirement

2.3.3.1

Raw material requirement

2.3.3.2

Energy requirement

2.3.3.3

Water requirement

2.3.4

Manufacturing Process

2.3.5

Major Equipments

Sources of Pollution

2.4.1

Liquid Effluent

2.4.2

Gaseous Emissions

2.4.3

Solid & Hazardous Waste Generation

Rain Water Harvesting

Green Belt Development Plan

Environment, Health & Safety

Compliance to various Statutory Guidelines

Corporate Social Responsibility

2.1

2.2

2.3

2.3

2.4

2.6

2.6

2.6

2.6

2.11

2.46

2.47

2.47

2.49

2.50

2.51

2.53

2.53

2.53

2.53

3.0

BASELINE ENVIRONMENTAL SETTING

2.4

3.1

3.2

3.2.1

3.3

Introduction

Micrometeorology of the area

Wind rose

Air Environment

3.1

3.1

3.2

3.4

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

I

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES BY

NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

3.3.1

3.3.1.1

3.3.1.2

3.4

3.5

3.6

3.6.1

3.6.2

3.6.3

3.7

3.8

3.8.1

3.8.2

3.9

3.9.1

3.9.2

3.9.3

4.0

4.1

4.2

4.3

Ambient Air Quality

Location of AAQ Monitoring Stations

Baseline Data

Water Environment

Noise

Soil

Baseline data

Physical Characteristics

Chemical Characteristics

Land-use pattern

Ecology

Introduction

Sampling Locations

Socio-economic Environment

Demographic Structure

Economic Structure

Basic Amenities / Village Level

Infrastructure

ANTICIPATED ENVIRONMENTAL IMPACTS & MITIGATION

MEASURES

Introduction

4.1

Identification of impacts

4.2

4.2.1

Identification of impacting activities

4.2

4.2.2

Identification of Environmental Attributes

4.2

Impact Assessment

4.4

4.3.1

Impact on Water Environment

4.4

4.3.2

Impact on Air Environment

4.6

4.3.2.1

Air pollution dispersion modeling of stack

4.6

emissions

4.3.3

Impact on Land / Soil quality

4.18

4.3.4

Impact on Noise Environment

4.19

4.3.5

Impact on Biological Environment

4.20

4.3.6

Impact on Socio-economic Environment

4.20

4.3.7

Impact on Occupational Health & Safety

4.21

5.0

5.1

5.2

5.3

5.4

5.5

ENVIRONMENTAL MONITORING PROGRAM

Objective

Environment Monitoring & Control

Proposed Monitoring Program

Reporting schedules of the monitoring data

Infrastructural Requirement

6.0

6.1

6.2

RISK ASSESSMENT

Introduction

Hazardous materials to be handled at

Proposed Plant

Hazardous Conditions due to Release

Quantities

6.3

3.4

3.4

3.6

3.8

3.13

3.13

3.13

3.14

3.14

3.16

3.20

3.20

3.20

3.59

3.60

3.62

3.67

5.1

5.1

5.2

5.3

5.3

6.1

6.2

6.11

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

II

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES BY

NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

6.3.1

6.3.2

6.3.3

6.4

6.4.1

6.4.2

6.4.3

6.5

6.6

6.6.1

6.6.2

6.6.3

6.6.3.1

6.6.3.2

6.6.3.3

6.6.3.4

6.6.3.5

6.7

6.7.1

6.7.2

6.7.3

6.7.4

6.7.5

6.7.6

6.7.7

6.7.8

6.7.9

6.7.10

6.7.11

6.7.12

6.7.13

6.7.14

7.0

Pool Fire

Vapour Cloud Explosion

Dispersion Toxic Cloud

Effect & Consequence of Release of

Hazardous Chemicals

Thermal Effects

Delayed Ignition and Explosion

Toxic Release

Release & Outcome Scenarios

Consequence Analysis

Introduction

Model used for Consequence Analysis

Consequence Analysis for Release

Scenarios

Rupture of 200 L Methanol Drum

Rupture of 1250 L Vinyl Acetate Container

Rupture of 200 L Styrene Drum

Rupture of 200 L Acrylonitrile Drum

Rupture of 200 L Ammonia Solution

Container

Risk Mitigation Measures

Introduction

Risk Mitigation Measures

Handling of Hazards

General Working Conditions

Safe Operating Procedures

Work Permit System

Emergency Preparedness

Material Handling

Communication System

Accident Reporting, Investigation and

Analysis

Safety Inspections

Risk Mitigation Measures for Spill

Safety Management System

Occupational Health Surveillance

Programme

6.12

6.12

6.12

6.13

6.13

6.13

6.15

6.15

6.15

6.15

6.16

6.16

6.16

6.19

6.23

6.26

6.29

6.31

6.31

6.32

6.33

6.33

6.33

6.34

6.34

6.34

6.34

6.34

6.34

6.35

6.36

6.37

7.1

7.2

7.3

7.4

PROJECT BENEFITS

Improvement in Physical Infrastructure

Improvement in Social Infrastructure

Employment Potential

Other Tangible Benefits

7.1

7.1

7.2

7.2

8.2.1

8.2.2

ENVIRONMENT MANAGEMENT PLAN

Introduction

Administrative aspects for EMP

Operational philosophy

Environment Management Cell

8.1

8.1

8.1

8.2

8.0

8.1

8.2

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

III

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES BY

NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

8.3

8.3.1

8.3.2

8.3.3

8.3.4

8.3.5

Environmental Management Practices

Water environment

Air environment

Land / Soil quality

Noise environment

Occupational Health & Safety

8.4

8.4

8.5

8.5

8.6

8.6

9.0

SUMMARY & CONCLUSION

9.1 – 9.11

10.0

DISCLOSURE OF CONSULTANTS

ENGAGED

10.1 – 10.4

LIST OF ANNEXURES

ANNEXURE

NO.

A

B

DESCRIPTION

Lease agreement between VITPL & NPL

Copy of 7/12 order of land of project

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

IV

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES BY

NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

LIST OF TABLES

TABLE NO.

TITLE

PAGE NO.

2.1

Physical Environmental Setting in vicinity of the Site

2.3

2.2

Land use break up of the Site

2.3

2.3A

Major Product Profile

2.4

2.3B

Detailed Product Profile

2.4

2.4

Raw Material Consumption

2.7

2.4A

Storage Inventory of Hazardous Chemicals

2.9

2.5

Energy Requirement

2.9

2.6

Raw Water Quality

2.10

2.7

Details of Water Usages

2.10

2.8

Major Equipments

2.46

2.9A

Details of Effluent Generation

2.48

2.9B

Details of Effluent Treatment Plant

2.49

2.10

Details of Air Pollution Control Systems

2.50

2.12

Details of Solid / Hazardous Waste

2.50

3.1

Micrometeorological Data

3.2

3.2

Sampling Locations

3.4

3.3

Ambient Air Quality Status of Study Area

3.6

3.4

Water Quality Parameters (Ground water sources-

3.9

Borewell)

3.5

Water Quality Parameters (Surface water Source-

3.11

Pond

3.6

Noise Level Data

3.13

3.7

Particle Size Distribution of Soil samples

3.15

3.8

Physical Characteristics

3.15

3.9

Chemical Characteristics

3.15

3.10

Landuse statistics of the Study ar4ea

3.16

3.11

Enumeration of Species – Flora

3.21

3.12

Species – Fauna and Avifauna (During Visit)

3.53

3.13

Villages covered under Study Area

3.59

3.14

Demographic Structure of Study Area

3.60

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

V

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES BY

NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

3.15

Distribution of Workers and Non-workers

3.63

3.16

Distribution of Workers into sub-categories

3.65

3.17(1) to

Availability of Basic Amenities in Study area

3.69 – 3.84

3.17(20)

4.1

Impact Identification Matrix

4.3

4.2

Resultant Concentration Value

4.9

4.3

24 hr incremental increase in GLC of SO2 (µg/m3) for

4.11

the proposed scenario

4.4

24 hr incremental increase in GLC of NOx (µg/m3) for

4.13

proposed scenario

4.5

24 hr incremental increase in GLC of PM (µg/m3) for

4.13

proposed scenario

5.1

Environment Monitoring Schedule

5.2

6.1

Storage Capacities of Hazardous Chemicals

6.1

6.2

Damage Effects Due to Overpressures

6.14

6.3

Illustrative Damage Effects due to Overpressures

6.14

6.4

Release and Outcome Scenario

6.15

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

VI

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES BY

NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

LIST OF FIGURES

FIGURE

NO.

2.1

2.2

2.3

2.4(A-1)

TITLE

PAGE NO.

Map Showing Site Location

Layout Map of the project site

Water Balance Diagram

Mass balance diagram of Styrene Acrylic Printing

Binder

Mass balance diagram of Pure Acrylic Khadi Binder

2.54

2.55

2.56

2.12

2.14

2.4(D-1)

Mass balance diagram of VAM Acrylic Printing

Binder

Mass balance diagram of Styerene Acrylic Khadi

Binder

Mass balance diagram of Styerene Acrylic Flock

Binder

Mass balance diagram of Co-polymer PVA(Polysol)

Mass balance diagram of Homo polymer PVA

(Polysol)

Mass balance diagram of Homo polymer PVA

(Polysol)

Mass balance diagram of Lamination Adhesive

Mass balance diagram of Pure Acrylic BOPP Tape

Adhesive

Mass balance diagram of Pure Acrylic BOPP Tape

Adhesive

Mass balance diagram of Pure Acrylic Paint Binder

2.4(D-2)

Mass balance diagram of VAM Acrylic Paint Binder

2.24

2.4(D-3)

2.4(D-4)

2.4(E-1)

2.4(F-1)

Mass balance diagram of Styrene Acrylic Paint Binder

Mass balance diagram of Acrylic Thickner

Mass balance diagram of Pure Acrylic Leather Binder

Mass balance diagram of Melamine Formaldehyde

Resin

Mass balance diagram of Loop Accelator

2.25

2.26

2.27

2.28

2.4(F-3)

2.4(F-4)

2.4(F-5)

2.4(F-6)

2.4(F-7)

2.4(F-8)

2.4(F-9)

Mass balance diagram of Dispersing Agent

Mass balance diagram of X-Core Alkali Neutraliser

Mass balance diagram of Sequestering Agent

Mass balance diagram of Peroxide Stabilizer

Mass balance diagram of Dye Fixing Agent

Mass balance diagram of Foaming Agent

Mass balance diagram of Wetting Agent

2.30

2.31

2.32

2.33

2.34

2.35

2.36

2.4(F-10)

Mass balance diagram of Wetting Agent

2.37

2.4(F-11)

Mass balance diagram of Ammonium Stearate

2.38

2.4(A-2)

2.4(A-3)

2.4(A-4)

2.4(A-5)

2.4(B-1)

2.4(B-2)

2.4(B-3)

2.4(C-1)

2.4(C-2)

2.4(C-3)

2.4(F-2)

2.13

2.15

2.16

2.17

2.18

2.19

2.20

2.21

2.22

2.23

2.29

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

VII

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES BY

NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

2.4(F-12)

Mass balance diagram of Micro Amino Silicon

2.39

2.4(F-13)

Mass balance diagram of Cationic Softener

2.40

2.4(F14)

Mass balance diagram of Reactive Softener

2.41

2.4(G-1)

Mass balance diagram of DOM

2.42

2.4(G-2)

Mass balance diagram of DBP

2.43

2.4(G-3)

Mass balance diagram of DBM

2.44

2.4(G-4)

Mass balance diagram of DOP

2.45

2.5

Line diagram of Proposed Effluent Treatment Plant

2.57

3.1

3.3

3.2

3.3

Wind rose Diagram for the month of December 2011

to February 2012

Sampling Location Map

Landuse Distribution of the Study Area

3.5

3.17

3.4

Landuse map

3.18

3.5

Satellite image

3.19

3.6

3.7

4.1

Distribution of workers and Non-Workers

Distribution of workers into sub-categories

Isopleths for Concentration of SO2 due to emission

from stacks for proposed scenario

Isopleths for Concentration of NOx due to emission

3.66

3.67

4.12

4.2

4.14

from stacks for proposed scenario

4.3

Isopleths for Concentration of PM due to emission

from stacks for proposed scenario

4.16

6.1

Maximum Concentration Foot Print for rupture of 200

L Methanol Drum

6.17

6.2

Flash Fire Envelope for rupture of 200 L Methanol

Drum

6.18

6.3

Intensity Radii for Pool Fire for rupture of 200 L

Methanol Drum

6.19

6.4

Maximum Concentration Foot Print for rupture of

1250 L Vinyl Acetate Container

6.21

6.5

Flash Fire Envelope for rupture of 1250 L Vinyl

Acetate Container

6.21

6.6

Intensity Radii for Pool Fire for rupture of 1250 L Vinyl

Acetate Container

6.22

6.7

Maximum Concentration Foot Print for rupture of 200

L Styrene Drum

6.23

6.8

Flash Fire Envelope for rupture of 200 L Styrene

Drum

6.24

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

VIII

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES BY

NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

6.9

Intensity Radii for Pool Fire for rupture of 200 L

Styrene Drum

6.25

6.10

Maximum Concentration Foot Print for rupture of 200

L Acrylonitrile Drum

6.26

6.11

Flash Fire Envelope for rupture of 200 L Acrylonitrile

Drum

6.27

6.12

Intensity Radii for Pool Fire for rupture of 200 L

Acrylonitrile Drum

6.28

6.13

Maximum Concentration Foot Print for rupture of 200

L Ammonia Drum

6.30

6.14

Flash Fire Envelope for rupture of 200 L Ammonia

Drum

6.30

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

IX

X

XI

XII

Untitled Page

Page 1 of 1

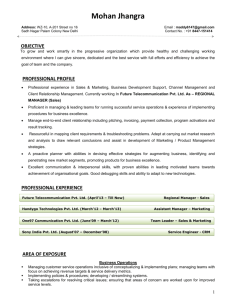

Minutes of 33rd f EAC (Industry - II)meeting dated 21st & 22nd March 2012

33.4.9.

Organic Chemical Unit at Sy.no.777/B/P, 780/P, 750/P, Village Bidaj, District Kheda, Gujarat by M/s NPL Industries Private Limited (TOR). Ministry vide letter dated 14th November, 2011 has awarded the TORs for Organic Chemical Unit at Sy.no.777/B/P, 780/P, 750/P, Village Bidaj, District Kheda,

Gujarat by M/s NPL Industries Private Limited. Now, project proponent has informed that plot area has been reduced from 14552 m2 to 9486.90 m2 and after revised land acquisition, the survey nos. of the plot are

777/B/P, 780/P, 748/P and 750/P, Village Bidaj, Near Vraj Integrated Textile Park, Taluka & District Kheda. The Committee recommended the proposal for amendment in the TOR regarding change of the plot location.

XII

http://environmentclearance.nic.in/Report/minutes.aspx

7/25/2012

COMPLIANCE OF ADDITIONAL TOR AWARDED BY MOEF

TOR NO.

DESCRIPTION OF TOR

COMPLIANCE

1

Executive summary of the project

Refer Chapter 9

2

Justification of the project.

Refer Section 1.4, Chapter 1,

Page no. 1.3

3

Promoters and their back ground.

Refer Section 1.2, Chapter 1,

Page no.1.2

4

Regulatory framework.

Refer Section 1.1, Chapter 1,

Page no. 1.1

5

A map indicating location of the project and

distance from critically/severely polluted

area

Refer Section 2.2, Chapter 2,

Page no. 2.2 for Project

location

Refer Figure no. 2.1 A for

location map

Project location is @ 25 Km

away from Ahmedabad which

is critically polluted area as

per ministry’s O.M. dated 13th

January, 2010.

6

Project location and plant layout.

Refer Section 2.2, Chapter 2,

Page no. 2.2 for Project

location

Refer Section 2.3.1, Chapter

2, Page no. 2.3 for Plant

layout

7

Infrastructure facilities including power

sources.

8

Total cost of the project alongwith total Refer Section 2.1, Chapter 2,

The project location is in the

vicinity of VITPL, an industrial

textile park being developed,

hence, basic infrastructure

facilities are available.

XIV

9

10

capital cost and recurring cost/annum for

environmental pollution control measures.

Project site location alongwith site map of

10 km area and site details providing

various industries, surface water bodies,

forests etc.

Present land use based on satellite

imagery for the study area of 10 km radius.

Page no. 2.1 – 2.2

Refer Section 2.2, Chapter 2,

Page no. 2.2, Figure no. 2.1A

& Table no. 2.1

Refer Section 3.7, Chapter 3,

Page no. 3.16

11

Location of National Park/Wild life Refer Section 2.2, Chapter 2,

sanctuary/Reserve Forest within 10 km Page no. 2.2, Table no. 2.1.

radius of the project.

There isn’t any national park /

wildlife sanctuary/ reserve

forest within 10 Km radius of

the project.

12

Details of the total land and break-up of the Refer Section 2.3.1, Chapter

land use for green belt and other uses.

2, Page no. 2.3, Table no. 2.2

13

List of products alongwith the production Refer Section 2.3.2, Chapter

capacities and list of solvents and its 2, Page no. 2.4 & 2.5, Table

recovery plan.

no. 2.3A & 2.3B

14

Detailed list of raw material required and Refer Section 2.3.3.1,Chapter

source,

mode

of

storage

and 2, Table no. 2.4, Page no. 2.7

transportation.

& 2.8

15

Manufacturing process details alongwith Refer Section 2.3.4, Chapter

the chemical reactions and process flow 2, Page no. 2.10 to 2.44,

chart.

Figure no. 2.4 (A-1 to ) (B-1

to) (C-1 to ) (D-1 to ) (E-1 to )

(F-1 to 15) (G-1 to 4)

16

Action plan for the transportation of raw Refer Section 2.3.3.1,Chapter

material and products.

2, Table no. 2.4, Page no. 2.6

17

Site-specific micro-meteorological data

using temperature, relative humidity, hourly

wind speed and direction and rainfall is

necessary.

Ambient air quality monitoring at 6 locations

within the study area of 5 km., aerial

coverage from project site as per NAAQES

18

Refer Section 3.2, Chapter 3,

Table no. 3.1, Figure no. 3.1,

Page no. 3.2 – 3.3

Refer Section 3.3, Chapter 3,

Page no. 3.4 to 3.8, Table no.

XV

19

notified on 16th September, 2009. Location

of one AAQMS in downwind direction.

One

season

site-specific

micrometeorological data using temperature,

relative humidity, hourly wind speed and

direction and rainfall and AAQ data (except

monsoon) for PM 10 , SO 2 , NOx including

VOCs shall be collected. The monitoring

stations shall take into account the predominant wind direction, population zone

and sensitive receptors including reserved

forests.

Data for water and noise

monitoring shall also be included.

3.3, Figure no. 3.2

For micro meteorological data

refer section 3.2, page no. 3.2

– 3.3

For AAQ data refer section

3.3, page no. 3.4 – 3.8

For water quality data, refer

section 3.4, page no. 3.8 –

3.12, Table no. 3.4 & 3.5

For noise intensity, refer

section 3.5, page no., 3.13,

Table no. 3.6

20

21

22

Air pollution control measures proposed for

the effective control of gaseous emissions

within permissible limits.

Design details of ETP, incinerator, if any,

alongwith control of Dioxin & Furan, boiler,

scrubbers/bag filters etc.

Refer Section 2.4.2, Chapter

2, Page no. 2.49,

Refer Section 2.4.1, Chapter

2, Page no. 2.47 – 2.50,

Figure no. 2.5

Details of water and air pollution and its Refer Section 4.3.1, Chapter

mitigation plan

4, Page no. 4.4 – 4.5 for

water pollution and its

mitigation

Refer Section 4.3.2, Chapter

4, Page no. 4.6 -4.17 for air

pollution and its mitigation

23

24

25

Action plan to control ambient air quality as Refer Section 4.3.2, Chapter

per NAAQES Standards notified by the 4, Page no. 4.6 -4.17 for air

Ministry on 16th September, 2009.

pollution and its mitigation

An action plan to control and monitor and dispersion modeling.

secondary fugitive emissions from all the

sources.

Determination of atmospheric inversion

level at the project site and assessment of

ground level concentration of pollutants

from the stack emission based on siteXVI

26

specific meteorological features. Air quality

modelling for proposed plant.

Permission from the concerned Authority

for the drawl of 150 m3/day water. Water

balance chart including quantity of effluent

generated recycled and reused and effluent

discharge.

Water is to be sourced from

VITPL

which

is

being

developed adjacent to the

site. VITPL has obtained

permission from CGWA for

withdrawal of ground water.

The wastewater will be

reused / recycled back in

process as well as utilities

after providing due course of

treatment, so as to curtail

down

fresh

water

requirement.

27

28

29

30

31

32

33

Action plan for ‘zero’ discharge of effluent

as proposed shall be included. Explore the

recycling of process water.

The details of solid and hazardous wastes

generation, storage, utilization and disposal

particularly related to the hazardous waste

calorific value of hazardous waste and

detailed characteristic of the hazardous

waste. Action plan for the disposal of fly

ash generated from boiler shall be

included.

Precautions to be taken during storage and

transportation of hazardous chemicals shall

be clearly mentioned and incorporated.

A copy of the Memorandum of

Understanding

signed

with

cement

manufacturers indicating clearly that they

will utilized all the organic solid waste

generated.

Authorization/Membership for the disposal

of

liquid

effluent

in

CETP

and

solid/hazardous waste in TSDF.

Risk

assessment

for

storage

for

chemicals/solvents.

Action

plan

for

handling & safety system.

An action plan to develop green belt in 33

% area

Refer Section 2.4.1, Chapter

2, Page no. 2.47 – 2.49

Refer Section 2.4.3, Chapter

2, Page no. 2.50

Refer Section 6.2, Chapter 6,

Page no. 6.2 – 6.11

Not applicable

Membership of CETP is not

applicable for this unit.

Refer Chapter 6

Refer Section 2.6, Chapter 2,

XVII

Page no. 2.53

34

35

36

37

38

39

40

41

42

Action plan for rainwater harvesting

measures at plant site shall be included to

harvest rainwater from the roof tops and

storm water drains to recharge the ground

water.

Occupational health of the workers needs

to be carried out. Action plan may be

included

Socio-economic development activities

shall be in place.

Refer Section 2.5, Chapter 2,

Page no. 2.51 – 2.52

Detailed Environment management Plan

(EMP) with specific reference to details of

air pollution control system, water &

wastewater

management,

monitoring

frequency, responsibility and time bound

implementation plan for mitigation measure

shall be provided.

EMP shall include the concept of wasteminimization, recycle / reuse / recover

techniques, Energy conservation, and

natural resource conservation.

Total capital cost and recurring cost/annum

for

environmental

pollution

control

measures.

Public

hearing

issues

raised

and

commitments made by the project

proponent on the same shall be included

separately in EIA/EMP Report in the form

of tabular chart with financial budget for

complying with the commitments made.

Any litigation pending against the project

and/or any direction/order passed by any

Court of Law against the project, if so,

details thereof.

A tabular chart with index for point wise

compliance of above TORs.

Refer Chapter 8

Refer Chapter 6

Refer Section 2.8, Chapter 2,

Page no. 2.53

Refer Chapter 8

Refer Section 2.1, Chapter 2,

Page no. 2.1 – 2.2

Will be part of REIA report on

completion of public hearing.

No case is pending against

the unit.

Part of REIA report.

XVIII

CHAPTER 1

1.1

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

CHAPTER -1

INTRODUCTION

1.1

Purpose of the Project

For g rowing m arket demand o f t he textile b inders a nd a uxiliaries C hiripal

Group ha s in tended to es tablish t he m anufacturing u nit named M/s N PL

Industries Private Limited. Very f ew qualitative m anufacturers are there in

the market, hence with the intention of better market supply and business

development NPL Industries has planned to establish the unit.

NPL Industries P vt. L td. in tends to s erve the c ustomers t hrough p roduction

of textile b inders, t extile a uxiliaries, a dhesive e tc. through inno vative

technology. NP L is looking for service driven business, to work closely with

customers t o m eet t heir s pecific need s a nd henc e, d elivering s atisfying

and efficient solutions.

The unit has a vision for the future; hence, it is working on developing niche

products for industries other than textiles like paint, leather, paper, packing

and surface coating.

The u nit in tends to engage i tself in manufacturing o f s ynthetic a dhesives

and a crylic b ased em ulsions f or the p aint and textile ind ustries in

commitment to world class standards.

The p roposed establishment f alls u nder the Item 5 (f) o f Schedule I of

Environmental Impact Assessment Notification dated 14/09/2006 under the

provisions o f E nvironmental P rotection Ac t, 1986. The location o f t he

proposed project is not within the any notified industrial estate; hence it will

be treated as Category A project.

As p er No tification, f or Category A

Project, it is nec essary to obtain

Environmental C learance C ertificate

(ECC)

from

the M inistry o f

Environment & F orest (MOE&F), GOI, New D elhi. A s a p rocedural p art i t i s

necessary to carry out Environmental Impact Assessment (EIA) Study as per

ToR approved by Expert Appraisal Committee (EAC) of MOE &F.

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

1.2

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

NPL I ndustries had applied to E AC in prescribed F orm -1 f or o btaining

Environmental C learance a nd w ere c alled f or the s coping m eeting on

20/10/2011. Based on the application submitted and discussion held during

the s coping m eeting , TOR w as is sued b y E AC v ide letter no . F. N o. J 11011/382/2011-IA I I (I) dated 14th November, 20 11. TOR w as a mended in

terms of project l ocation (S. No.) as well as project area during the EAC –

Industrial P rojects I I, m eeting dated 2 2nd March, 2012 . The copy o f TO R

awarded by EAC along with its compliance status is the part of the report.

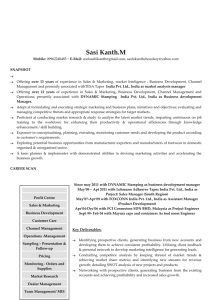

1.2

The Project Proponent

Ahmedabad is the main city in Gujarat for the business of Textile industries.

Textile binders and auxiliaries are an important material for textile industries.

Considering the m arket need , Chiripal G roup h as in tended to es tablish a

new u nit f or textile binders a nd a uxiliaries. The p roposed location also a n

ideal location, a s i t is in

the v icinity of Integrated textile p ark b eing

developed.

The details of key personnel of the unit are as follow :

•

Mr. J aiprakash Devkinandan Chiripal is t he director o f C hiripal

Industries L td. H e is a C ommerce g raduate w ith an experience of

more than 30 years in textile industrial sector. He plays the key role in

expansion a nd im plementation o f p rojects. He is a k ey p erson f or

overall s upervision o f p olicies laid d own b y the B oard of D irectors

and actively contributes in recruiting quality Human Resource.

•

Mr. Sanjay Premchand Bindal is the director of Chiripal Industries Ltd.

He is a Commerce graduate with an experience in chemical division

of textile industrial sector for m ore than 15 years . He l ooks after the

matters r elated to production, s ales, m arketing, f inance a nd

manufacturing.

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

1.3

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

1.3

Brief Description of the Project

The unit will be established at Village – Bidaj, District – Kheda, Gujarat State,

which is in the vicinity to National Highway – 8.

To g ratify t he market d emand o f textile b inders a nd a uxiliaries, M /s NP L

Industries Pvt. Ltd. has deliberated to establish the manufacturing unit. The

proposed p roject will b e es tablished in @ 9500 s q.m. area. For t he

proposed project p ower r equirement will b e @ 2 00 K VA a nd w ill b e

satisfied through local electricity grid of Madhya Gujarat Vij Company Ltd.

Fresh w ater r equirement w ill be @ 1 63 KLD satisfied t hrough water

distribution system of VITPL . Lignite will be used as fuel. The estimated cost

of the proposed establishment is @ Rs. 1737 Lacs.

1.4

Justification of the Project

Chiripal group is the leading group in textile s ector. S ince m any years the

group is w orking in this s ector and ha s a g ood exp erience for the s ame.

This group has many units in textile sectors and has intended to establish a

new unit for manufacturing of textile binders and auxiliaries, which are very

useful materials for textile products.

Demand of the textile binders and auxiliaries has been raised from last few

years in textile units and processing units. There are few manufacturers are

available o f textile chemicals in India but a ll o f t hem ha ving their o wn

limitations. So, there is better market for new manufacturers of Bopp Tapes.

One of Bopp film plant is also there near this proposed area. So, it will also

help us to grow in adhesives. Due to lake of skill and capacity, adhesives

and p aint binders are b eing im ported from C hina a nd hence, there is

good scope for these products.

In Ahmedabad, there are numerous Textiles, Tapes and Paint units. The unit

intends to fulfill raw material requirements of chemicals, binders, adhesives

and auxiliaries with saving of various additional costs

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

1.4

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

1.5

Scope of Study

Present study has been conducted to fulfill the following objectives:

•

To d elineate the p roject a ctivities a long w ith a nticipated

sources o f p ollution a s w ell a s E nvironmental Management

System (EMS) to be adopted.

•

To d escribe t he p revailing b aseline e nvironmental q uality

within the impact zone (study area) based on one season field

studies.

•

To identify and predict the likely impacts due to establishment

of proposed manufacturing facility.

•

To outline EMP describing control technologies to be adopted

for mitigation of adverse impacts.

•

To d escribe the m easures to b e a dopted f or occupational

health a nd s afety of the w orkers a s w ell a s carry o ut R isk

assessment f or t he hazards associated with t he p roposed

project activities.

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

CHAPTER 2

2.1

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

CHAPTER -2

PROJECT DETAILS

2.1

TYPE OF THE PROJECT

Demand of the textile binders and auxiliaries has been rising since last few

years in textile and processing units. Very few qualitative manufacturers are

there in the m arket, hence with the in tention of better m arket supply and

business development NPL Industries has planned to establish the unit.

NPL Industries P vt. L td. intends t o serve the c ustomers t hrough p roduction

of textile b inders, t extile a uxiliaries, a dhesive e tc. through inno vative

technology. NPL is looking for service driven business, to work closely with

customers t o m eet t heir s pecific need s a nd henc e, d elivering s atisfying

and efficient solutions.

The unit has a vision for the future, hence, it is working on developing niche

products for industries other than textiles like paint, leather, paper, packing

and surface coating.

The u nit in tends to engage i tself in manufacturing o f s ynthetic a dhesives

and a crylic b ased em ulsions f or the p aint a nd textile ind ustries in

commitment to world class standards.

The p roducts o f textile a pplications w ill b e m arketed w ith the na me o f

“CHIRITEX” brand. It is also having application in finishing of fabrics f various

types, bonding for flock powder on various fabrics, various effects like pearl

and novel etc.

The products having specific application in p aint industries will be marked

under brand name of “CHIRIBOND” and will have qualities like fast drying,

durability, r esistance t o w ashing, s crubbing, hig h g lass a nd water v apour

permeability.

There will be different products for external as well as internal applications

and coatings with finishes like high sheen and matt.

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.2

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

The c ost for the p roposed m anufacturing p lant w ill b e @ Rs. 1 737 lacs,

which in cludes cost o f l and, b uilding a nd machineries. Out o f this,

approximately Rs. 5 0- 55 Lacs w ill b e toward implementation of E nv.

Pollution control measures. Recurring cost towards the same will be @ Rs. 5

Lacs/ month.

2.2

LOCATION OF THE PROJECT

The proposed p roject is c oming u p in the v icinity o f Textile P ark located

near village Bidaj, District Kheda, Gujarat S tate. National Highway – 8 is @

500 m d istance f rom t he p roject s ite. The c o-ordinate o f the s ite is

22°50'23.70"N & 72°36'35.00"E. The present land bearing S. No. 748/P, 750/P,

777/B/P & 780/P has been acquired by Vraj Integrated Textile Park Ltd. and

same ha s b een g iven to the u nit o n L ease f or 20 y ears. The l ease

agreement and copy of 7/12 is attached as Annexure A & B respectively.

The l ocation m ap is a ttached as Figure No. 2.1. The l ocation is

approximately @ 30 Km distance from Ahmedabad, w hich is d eclared a s

Critically polluted area as per O.M. of MoEF dated 13th January, 2009.

The selection of the site has been done based on following:

• Existence of park

• Availability of the adequate land

• Suitability

of

the

land f rom t opographical an d ge ological

considerations

• Minimum ha ulage d istance f or transportation of fuel a s well a s

finished goods.

The details o f physical environmental setting in t he v icinity o f t he project

site ha ve been g iven a t Table no. 2.1 and location m ap c overing 1 0 K m

radius is given at Figure no. 2.1A.

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.3

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

TABLE NO. 2.1 PHYSICAL ENVIROMENTAL SETTING IN VICINITY OF THE SITE

Sr. No.

1

Particulars

Latitude and Longitude of the site

2

3

Nearest village

Nearby Water body

4

National Highway

5

6

Heritage Site

National park / Wild life sanctuary /

Reserved forest

2.3

Description Distance from Site

22°50'23.70"N

-72°36'35.00"E

Bidaj

2.23 Km

Gobhlaj

2.90 Km

Tank

NH - 8

@ 500m away

from the site

-Not within radius

of 10 Km from site.

--

THE PROJECT

2.3.1 Landuse Breakup within Plant Area

Land ar ea acquired by M /s. N PL Industries Pv t. L td. for the p roposed

project is @ 9500 sq.m., layout map of the same is shown at Figure no. 2.2.

The details of landuse break up is given at Table no. 2.2.

TABLE NO. 2.2 LAND USE BREAKUP OF THE SITE

Sr.

No.

1

2

3

Particulars

Land area

(sq.m.)

Plant facilities

Storage Area

(Raw materials & Finished

goods)

Administrative & other

buildings

Utilities

ETP area

HW storage area

Open Area & Roads

Green Belt / space

% of Total

Area

1250.00

1050.00

13.17

11.07

245.00

2.58

4

470.00

4.95

5

270.00

2.85

6

250.00

2.64

7

3451.90

36.38

8

2500.00

26.36

TOTAL

9486.90

100.00

The p lant l ayout s hown a t Figure no. 2.2 is p repared c onsidering

environmental and safety aspects and it is tentative. The unit will approach

the f actory d epartment f or the a pproval o f p lant / f actory b uilding a nd

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.4

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

final plant layout will be as per approval of factory department. The layout

is b eing planned c onsidering the nee d o f p lant machineries, separate

storage r equirements f or different chemicals, a dministration and p arking

requirement, p revailing wind d irection, nea rby inf rastructure facilities,

requirement of a pproachable p eripheral r oad f or exc avation a nd

emergency purpose of vehicular movement etc.

2.3.2 Product Profile

Details of products to be manufactured alongiwth its quantification is

presented at Table no. 2.3A & 2.3B.

TABLE NO. 2.3A MAJOR PRODUCT PROFILE

Sr.

No.

Name of Product

Production Capacity

(MT/M)

1

Textile Binders

1000

2

Textile Polysols

1000

3

Adhesives

1200

4

Paint Binder

600

5

Lather Binder

200

6

Auxiliaries

500

7

Plasticizers

500

TOTAL

5000

TABLE NO. 2.3B DETAILED PRODUCT PROFILE

Sr. No.

1

2

3

4

5

PRODUCTS

TEXTILE BINDERS

STYRENE ACRYLIC PRINTING BINDER

PURE ACRYLIC KHADI BINDER

VAM ACRYLIC PRINTING BINDER

STYRENE ACRYLIC KHADI BINDER

STYRENE ACRYLIC FLOCK BINDER

QUANTITY

1000 MT

200 MT

100 MT

400 MT

100 MT

200 MT

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.5

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

1

2

3

1

2

3

1

2

3

4

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

3

4

TEXTILE POLYSOLS

CO – POLYMER PVA (POLYSOL)

HOMO POLYMER PVA (POLYSOL)

HOMO POLYMER PVA (POLYSOL)

ADHESIVES

LAMINATION ADHESIVE

PURE ACRYLIC BOPP TAPE ADHESIVE

PURE ACRYLIC BOPP TAPE ADHESIVE

PAINT BINDERS

PURE ACRYLIC PAINT BINDER

VAM ACRYLIC PAINT BINDER

STYRENE ACRYLIC PAINT BINDER

ACRYLIC THICKNER

LEATHER BINDERS

PURE ACRYLIC LEATHER BINDER

AUXILIARIES

MELAMINE FORMALDEHYDE RESIN

LOOP ACCELATOR

DISPERSING AGENT

X – CORE ALKALI NEUTRALISER

SEQUESTERING AGENT

PEROXIDE STABILIZER

DYE FXING AGENT

FOAMING AGENT

WETTING AGENT

WETTING AGENT

AMMONIUM STEARATE

MICRO AMINO SILICON

CATIONIC SOFTNER

CATIONIC SOFTNER

REACTIVE SOFTNER

PLASTICIZERS

DOM

DBP

DBM

DOP

TOTAL

1000 MT

400 MT

300 MT

300 MT

1200 MT

200 MT

800 MT

200 MT

600 MT

100 MT

200 MT

200 MT

100 MT

200 MT

200 MT

500 MT

100 MT

30 MT

30 MT

20 MT

20 MT

30 MT

40 MT

30 MT

30 MT

20 MT

30 MT

20 MT

40 MT

30 MT

30 MT

500 MT

150 MT

150 MT

100 MT

100 MT

5000 MT

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.6

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

2.3.3 Resource Requirement

2.3.3.1 Raw Material Requirement

The list of raw material required alongiwth its monthly requirement is given

at Table no. 2.4. It will b e p urchased f rom t he l ocal market. The d etails

regarding storage of major hazardous chemicals is given at Table no. 2.4A.

2.3.3.2 Energy Requirement

The p ower requirement @ 200 K W will be satisfied Captive p ower plant o f

Vraj I ntegrated T extile P ark L td. (VITPL). It is a lso p roposed to ins tall Diesel

based D.G. set of @ 100KVA, which will be operated in case of emergency

during p ower f ailure. During t he o peration of D.G. s et (@100 K VA), d iesel

will be consumed @ 20 L/hour.

The energy requirement in terms of power and fuel for proposed project is

presented at Table no. 2.5.

2.3.3.3 Water Requirement

The w ater r equirement f or the p roposed p roject w ill b e f or p rocess, u tility

(Boiler & C ooling), w ashing a nd d omestic p urpose. T he f resh w ater

requirement of @163 KLD will be satisfied through an integrated textile pakr

- VITPL w hich is b eing d eveloped j ust adjacent to the s ite.

VITPL ha s

obtained the p ermission o f C GWA for withdrawal o f g round water. T he

copy of lease deed between VITPL & NPL Industries Pvt. Ltd. is attached as

Annexure A.

The r aw w ater q uality being s upplied b y VITPL is g iven a t Table no. 2.6

whereas the pattern of water usage is given at Table no. 2.7.

The w ater b alance d iagram f or p roposed p roject ha s b een s hown a t

Figure no. 2.3.

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.7

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

TABLE NO. 2.4 RAW MATERIAL CONSUMPTION

SR. NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

RAW MATERIAL

EPICHLOROHYDRINE

DMA 40

DEG

METHANOL

FORMALDEHYDE

PARAFORMALDEHYDE

BOREX

MELAMINE

REFINED SALT

EMULSIFIER CO 400

TRO

AMINO OIL 8630

AMINO OIL 4730

AMINO OIL 4910

EMULSIFIER STERO 13065

EMULSIFIER STERO 1309

EMULSIFIER STERO PEG 600

EMULSIFIER STERO 1203

ACETIC ACID

MALIC ANHYDRIDE

ACRYLIC ACID

HYDROGEN PEROXIDE

CAUSTIC SODA

EMULSIFIER HEDP

EMULSIFIER SA 100

MAGNESIUM CHLORIDE

EMULSIFIER STERO PEG 4000

EMULSIFIER STERO CSA 20

EMULSIFIER STERO COB

SOPAMINE P

SAWAX BW 300

PARAFIN WAX

EMULSIFIER CDA

DOM

OT PASTE

EMULSIFIER TDA 6 MOLE

DTC 100

STEARIC ACID

EMULSIFIER RJT 292

DEFORMER COMPOUND

QTY (KGS/Month)

16400

19200

5000

17000

43730

27900

500

20000

12050

10800

750

880

440

440

710

440

260

1080

60

1980

9550

510

4050

15760

1800

6090

8280

3360

810

7600

2346

795

852

32800

1500

8000

1000

8730

3780

300

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.8

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

SR. NO.

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

RAW MATERIAL

CITRIC ACID

FORMIC ACID

BUTYL

STYRENE

VAM

ETHYL ACRYLATE

ACRYLAMIDE

DBM

POTTASIUM PER SULPHATE

NITRASOL JR

SODIUM BI CARBONATE

EMULSIFIER OCA 25

EMULSIFIER RJT 329

MAA

AMMONIUM PER SULPHATE

LIQUER AMMONIA

SODIUM META BI SULPHITE

EMULSIFIER RJT 336

EMULSIFIER AOS

EMULSIFIER RJT 345

EMULSIFIER SLS LIQ.

EMULSIFIER X – 301

PVA GH 17

EMULSIFIER DIANOL 25

EMULSIFIER X – 405

EMULSIFIER RE – 610

EMULSIFIER ALPHOX 500

MMA

EMULSIFIER L 61

ACRYLONITRILE

BUTANOL & ISOMERS

OCTANOL & ISOMERS

PTHALIC ANHYDRIDE

MALEIC ANHYDRIDE

PARATOLUENE SULPHONIC ACID

QTY (KGS/Month)

7660

680

757340

115840

620440

143840

22745

89600

4800

6400

3500

5678

1600

24200

1620

18680

7065

1000

2250

5200

12610

6350

17800

3880

600

3100

600

26500

2000

9200

14400

15300

6200

9800

450

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.9

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

TABLE NO. 2.4A STORAGE INVENTORY OF HAZARDOUS CHEMICALS

Sr.

No.

Name of

Hazardous

Chemicals

Maximum Storage

Quantity

1

Acrylamide

2

Ammonia

3

Formaldehyde

4

Vinyl Acetate

Monomer

Acrylonitrile

5

6

7

8

9

10

12

13

14

20 MT @ 25/50 Kg

bag

15 MT @ 220 Kg

drum / 1250 Kg

container / Tank

50 MT @220 Kg

drum / 1250 Kg

container / Tank

500 MT @ 40 MT*1

5 MT @ 25 Kg

Carboys /

Container

Methanol

10 MT

Epichlorohydrine 10 MT

Acetic acid

20 Kg

Hydrogen

150Kg

peroxide

Styrene

75 MT

Vinyl Acetate

40 MT

Monomer

Ammonia

10 MT

Formic acid

300 Kg

State of

Operation

Temperature &

Pressure

Ambient

Possible

type of

Hazards

Ambient

Toxic /

Flammable

Ambient

Flammable

Ambient

Flammable

Ambient

Fire, Toxic

Toxic

Ambient

Ambient

Ambient

Ambient

Ambient

Ambient

Ambient

Ambient

TABLE NO. 2.5 ENERGY REQUIREMENT

Sr. Particulars

No.

1

Fuel requirement : Lignite / Agro briquettes for

IBR Boiler

2

Power requirement

3

Diesel for D.G. set 100 KVA (for emergency)

Quantity

400 Kg / Hour

200 KW

20 L/hour

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.10

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

Table No. 2.6 Raw Water Quality

Sr.

No.

Parameters

Unit

Value

1

pH

--

7.40

2

Colour

--

Colourless

3

Total dissolved solids

mg/L

1276.00

4

Suspended solids

mg/L

3.00

5

Total hardness as CaCO 3

mg/L

269.00

6

Magnesium hardness as CaCO 3

mg/L

50.00

7

Calcium hardness as CaCO 3

mg/L

34.00

8

Alkalinity

mg/L

445.00

9

Fluoride

mg/L

0.67

10

Sulphates

mg/L

211.0

(Source : RESPL)

Table No. 2.7 Details of Water Uses

Sr. No.

Source

Quantity (m3/day)

A

Domestic

B

Industrial

1

Process

75.5

2

Boiler Feed

36.5

3

Cooling Make up

19.0

4

Washing

15.0

5

Others – Gardening

10.0

TOTAL

7.0

163.0

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.11

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

2.3.4 Manufacturing Process

The manufacturing process description has been described in the section

below, whereas process flow diagram has been given at Figure no. 2.4 to.

The major product profile is as under :

A. Textile binders

B. Textile polysols

C. Adhesives

D. Paint binder

E. Leather binder

F. Auxiliaries

G. Plasticizers

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.12

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

(A) TEXTILE BINDERS

1. STYRENE ACRYLIC PRINTING BINDER

MONOMER VESSEL

Take DM water in vessel. Add emulsifier. Mix properly.

Charge butyl acrylate and styrene monomer. Add n-methylol

Acrylamide and methacrylic acid and mix properly.

ACTIVATOR

Take DM water and add ammonium per sulphate. Mix well.

REACTOR

Take DM water in vessel. Heat up to 85 degree. Add emulsifier.

Add partially monomer. Then start continuous addition of monomer

And activator for 3 hrs. Temp 90 +/-1 deg.

Hold for 1 hr. Cool and add post activation. Adjust pH and pack

Figure 2.4(A-1) : Mass balance diagram of Styrene Acrylic Printing Binder

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.13

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

2. PURE ACRYLIC KHADI BINDER

MONOMER VESSEL

Take DM water in vessel. Add emulsifier. Mix well properly.

Add ethyl acrylate. Add n-methylol acrylamide and acrylic acid

Mix properly.

ACTIVATOR

Take DM water and add potassium per sulphate. Mix well.

Take DM water and add sodium meta bi sulphite. Mix well.

REACTOR

Take DM water in vessel. Add activator partly. Start continuous

Addition of monomer and activator. Control temperature

by cooling tower. Addition time 3 hrs, temp 62 +/- 1deg.

Hold for 1 hr. Cool and add post activation. Adjust pH and

As per specification.

Figure 2.4(A-2) : Mass balance diagram of Pure Acrylic Khadi Binder

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.14

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

3. VAM ACRYLIC PRINTING BINDER

MONOMER VESSEL

Take DM water in vessel. Add emulsifier. Mix properly.

Add ethyl acrylate and vinyl acetate monomer. Add n-methylol

Acrylamide and mix properly.

ACTIVATOR

Take DM water and add ammonium per sulphate. Mix well.

REACTOR

Take DM water in vessel. Heat up to 85 degree. Start continuous

Addition of monomer and activator. Control temperature

By cooling tower. Addition time 3 hrs, temp 80 +/- 1deg.

Hold for 1 hr. Cool and add post activation. Adjust pH and

As per specification.

Figure 2.4(A-3) : Mass balance diagram of VAM Acrylic Printing Binder

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.15

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

4. STYRENE ACRYLIC KHADI BINDER

MONOMER VESSEL

Take DM water in vessel. Add emulsifier. Mix properly.

Charge butyl acrylate and styrene monomer. Add n-methylol

Acrylamide and acrylic acid and mix properly.

ACTIVATOR

Take DM water and add potassium per sulphate. Mix well.

REACTOR

Take DM water in vessel. Heat up to 85 degree. Add emulsifier.

Add partially monomer. Then start continuous addition of monomer

And activator for 3 hrs. Temp 85 +/-1 deg.

Hold for 1 hr. Cool and add post activation. Adjust pH and pack

As per specification.

Figure 2.4(A-4) : Mass balance diagram of Styerene Acrylic Khadi Binder

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.16

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

5. STYRENE ACRYLIC FLOCK BINDER

MONOMER VESSEL

Take DM water in vessel. Add emulsifier. Mix properly.

Charge butyl acrylate and styrene monomer. Add n-methylol

Acrylamide and mix properly.

ACTIVATOR

Take DM water and add ammonium per sulphate.mix well.

Take DM water and add sodium meta bi sulphite.mix well.

REACTOR

Take DM water in vessel. Heat up to 82 degree. Start continuous

Addition of monomer and activator. Control temperature

Hold for 1 hr. Cool and add post activation. Adjust pH and

Pack as per specification.

Figure 2.4(A-5) : Mass balance diagram of Styerene Acrylic Flock Binder

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.17

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

(B) TEXTILE POLYSOLS

1. CO - POLYMER PVA ( POLYSOL)

MONOMER VESSEL

Take vinyl acetate monomer and di-butyl maleate.

Mix properly.

ACTIVATOR

Take DM water and add potassium per sulphate. Mix well.

REACTOR

Take DM water and add natrosol jr powder prepares colloidal solution.

Hold for 1 hrs. Add buffer. Then start continuous addition

Of monomer and activator for 6 hrs. Control temp 80 deg.

Hold for 1 hrs. Cool and add post activation and adjust as

Per specification.

Figure 2.4(B-1) : Mass balance diagram of Co-polymer PVA(Polysol)

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.18

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

2. HOMO - POLYMER PVA ( POLYSOL)

MONOMER VESSEL

Take vinyl acetate monomer.

ACTIVATOR

Take DM water and add potassium per sulphate.mix well.

REACTOR

Take DM water add PVA powder and prepares colloidal solution.

Hold for 1 hrs. Add buffer. Then start continuous addition

Of monomer and activator for 6 hrs. Control temp 80 deg.

Hold for 1 hrs. Cool and add post activation and adjust as

Per specification.

Figure 2.4(B-2) : Mass balance diagram of Homo polymer PVA(Polysol)

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.19

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

3. HOMO - POLYMER PVA ( POLYSOL)

MONOMER VESSEL

Take vinyl acetate monomer.

ACTIVATOR

Take DM water and add potassium per sulphate.mix well.

REACTOR

Take dm water add PVA powder prepares colloidal solution.

Hold for 1 hrs. Add buffer. then start continuous addition

Of monomer and activator for 6 hrs. Control temp 80 deg.

Hold for 1 hrs. Cool and add post activation and adjust as

Per specification.

Figure 2.4(B-3) : Mass balance diagram of Homo polymer PVA(Polysol)

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.20

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

(C) ADHESIVES

1. LAMINATION ADHESIVE

MONOMER VESSEL

Charge vinyl acetate monomer, butyl acrylate, di – butyl maleate,

Di – octyl maleate, acrylamide and emulsifier

ACTIVATOR

Take DM water and add potassium per sulphate.mix well.

REACTOR

Take DM water in vessel. Heat up to 85 degree. Add emulsifier.

Add partially monomer. Then start continuous addition of monomer

And activator for 5 hrs. Temp 85 +/-1 deg.

Hold for 1 hr. Cool and add post activation. Adjust pH and pack

Per specification.

Figure 2.4(C-1) : Mass balance diagram of Lamination Adhesive

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.21

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

2. PURE ACYLIC BOPP TAPE ADHESIVE

MONOMER VESSEL

Take DM water in vessel. Add emulsifier. Mix properly.

Add butyl acrylate and methacrylic acid. Mix well

ACTIVATOR

Take DM water and add potassium per sulphate. Mix well.

REACTOR

Take DM water in vessel. Heat up to 82 degree. Start continuous

Addition of monomer and activator. Control temperature

By cooling tower. Addition time 3 hrs, temp 85 +/- 1deg.

Hold for 2 hr. Cool and add post activation. Adjust pH and

Pack as per specification.

Figure 2.4(C-2) : Mass balance diagram of Pure Acrylic BOPP Tape Adhesive

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.22

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

3. PURE ACYLIC BOPP TAPE ADHESIVE

MONOMER VESSEL

Take DM water in vessel. Add emulsifier. Mix properly.

Add butyl acrylate and methacrylic acid. Mix well

ACTIVATOR

Take DM water and add potassium per sulphate.mix well.

REACTOR

Take DM water in vessel. Heat up to 82 degree. Start continuous

Addition of monomer and activator. Control temperature

By cooling tower. Addition time 3 hrs, temp 85 +/- 1deg.

Hold for 2 hr. Cool and add post activation. Adjust pH and

Pack as per specification.

Figure 2.4(C-3) : Mass balance diagram of Pure Acrylic BOPP Tape Adhesive

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.23

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

(D) PAINT BINDERS

1. PURE ACRYLIC PAINT BINDER

MONOMER VESSEL :-

Take dm water in vessel. Add emulsifier and acrylamide. Mix properly.

Charge butyl acrylate and methyl methacrylate. Add methacrylic acid.

ACTIVATOR :-

Take DM water and add potassium per sulphate. Mix well.

REACTOR :-

Take DM water in vessel. Heat up to 85 degree. Add emulsifier.

Add partially monomer. Then start continuous addition of monomer

And activator for 3 hrs. Temp 85 +/-1 deg.

Hold for 1 hr. Cool and add post activation. Adjust pH and pack

Per specification.

Figure 2.4(D-1) : Mass balance diagram of Pure Acrylic Paint Binder

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.24

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

2. VAM ACRYLIC PAINT BINDER

MONOMER VESSEL :-

Charge butyl acrylate and vinyl acetate monomer

ACTIVATOR :-

Take DM water and add potassium per sulphate. Mix well.

REACTOR :-

Take DM water in vessel. Add PVA powder and prepare colloidal solution.

Add partially monomer. Then start continuous addition of monomer

And activator for 5 hrs. Temp 80 +/-1 deg.

Hold for 2 hr. Cool and add post activation. Adjust pH and pack

Per specification.

Figure 2.4(D-2) : Mass balance diagram of VAM Acrylic Paint Binder

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.25

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

3. STYRENE ACRYLIC PAINT BINDER

MONOMER VESSEL

Take DM water in vessel. Add emulsifier and acrylamide. Mix properly.

Charge butyl acrylate and styrene monomer. Add acrylic acid

ACTIVATOR :-

Take DM water and add potassium per sulphate. Mix well.

REACTOR :-

Take DM water in vessel. Heat up to 85 degree. Add emulsifier.

Add partially monomer. Then start continuous addition of monomer

And activator for 3 hrs. Temp 85 +/-1 deg.

Hold for 1 hr. Cool and add post activation. Adjust pH and pack

As per specification.

Figure 2.4(D-3) : Mass balance diagram of Styrene Acrylic Paint Binder

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.26

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

4. ACRYLIC THICKNER

MONOMER VESSEL :-

Take DM water in vessel. Add emulsifier. Mix properly.

Charge ethyl acrylate and methacrylic acid. Mix well

ACTIVATOR :-

Take DM water and add ammonium per sulphate.mix well.

REACTOR :-

Take DM water in vessel. Heat up to 90 degree. Start continuous

Addition of monomer and activator. Control temperature

By cooling tower. Addition time 2 hrs, temp 90 +/- 1deg.

Hold for 2 hr. Cool and add post activation. Pack as per specification.

Figure 2.4(D-4) : Mass balance diagram of Acrylic Thickner

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.27

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

(E) LEATHER BINDERS

1. PURE ACRYLIC LEATHER BINDER

MONOMER VESSEL :-

Take DM water in vessel. Add emulsifier and acrylamide. Mix properly.

Charge butyl acrylate, ethyl acrylate and acrylonitrile

Add acrylic acid and mix well

ACTIVATOR :-

Take DM water and add potassium per sulphate. Mix well.

REACTOR :-

Take DM water in vessel. Add emulsifier and partially monomer

Then start continuous addition of monomer and activator for 3 hrs.

Temp 72 +/-1 deg. Hold for 2 hr. Cool and add post activation.

Adjust pH and pack as per specification

Figure 2.4(E-1) : Mass balance diagram of Pure Acrylic Leather Binder

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.28

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

(F) AUXILLARIES

1. MELAMINE FORMALDEHYDE BASE RESIN

In vessel, charge methanol, formaldehyde and rec. Methanol

Then under stirring add melamine, deg, borex, paraformaldehyde, refined salt

Material heat up to 80 degree then reaction holds for 5 hrs. Then adjust ph.

Start vacuum and collect recovered methanol

Then send sample in lab for qc report

Then cool and pack as per specification

Figure 2.4(F-1) : Mass balance diagram of Melamine Formaldehyde Resin

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.29

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

2. LOOP ACCILATOR

Charge DM water in vessel. Add emulsifier co 400 and TRO for half an hour.

Hold for 1 hrs. Then cool and pack as per specification

Figure 2.4(F-2) : Mass balance diagram of Loop Accelator

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.30

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

3. DISPERSING AGENT

Charge DM water in vessel. Add malic anhydride heat up to 60 degree.

Then cool up to 45 degree and add caustic soda for 1 hr

Again heat up to 100 degree. Addition of acrylic acid and hydrogen peroxide

For 4 hrs. Hold for 3 hrs. Then cool and pack as per specification

Figure 2.4(F-3) : Mass balance diagram of Dispersing Agent

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.31

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

4. X – CORE ALKALI NEUTRALISER

Charge DM water in vessel under stirring.

Then add citric acid and formic acid

Stir well four half hour and pack as per specification

Figure 2.4(F-4) : Mass balance diagram of X-Core Alkali Neutraliser

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.32

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

5. SEQUESTERING AGENT

Charge DM water and add emulsifier HEDP under stirring in vessel for half

Hour.

Pack as per specification

Figure 2.4(F-5) : Mass balance diagram of Sequestering Agent

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.33

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

6. PEROXIDE STABILIZER

Charge DM water in vessel and heat up to 70 degree temp.

Then add emulsifier OCA 25, emulsifier SA 100 and magnesium chloride under

Stirring. Control temp @ 70 degree

Hold for 2 hr. Cool and add post activation. Pack as per specification

Figure 2.4(F-6) : Mass balance diagram of Peroxide Stabilizer

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.34

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

7. DYE FIXING AGENT

Charge DM water, DMA 40 and di ethylin glycol in vessel.

Then addition of epichlorohydrine for 8 hrs.

Control temp @ 40 degree

Hold for 1 hr. Cool and add post activation. Pack as per specification

Figure 2.4(F-7) : Mass balance diagram of Dye Fixing Agent

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.35

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

8. FOAMING AGENT

Charge DM water and emulsifier SLS liq. In vessel and heat up to 80 degree

Then add emulsifier peg 4000, CSA 20, STERO 1203 and stero COB

Hold for 1 hr. Cool and add post activation. Pack as per specification

Figure 2.4(F-8) : Mass balance diagram of Foaming Agent

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.36

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

9. WETTING AGENT

Charge DM water in vessel and heat up to 70 degree temp. Then added DTC 100

Then addition of emulsifier TDA 6 mole for 2 hrs. Control temp @ 70 degree

Hold for 1 hr. Cool and add post activation. Pack as per specification

Figure 2.4(F-9) : Mass balance diagram of Wetting Agent

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.37

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

10. WETTING AGENT

Charge di – octyl maleate, methanol and OT paste

Then add solution of water and sodium meta bi sulphate

Heat up to 103 degree and reaction timing 4 hrs

Cool and pack as per specification

Figure 2.4(F-10) : Mass balance diagram of Wetting Agent

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.38

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

11. AMMONIUM STEARATE

Charge DM water in vessel and heat up to 70 degree temp. Then added stearic

Acid and emulsifier CDA and ammonia

Reaction timing 2 hrs. Control temp @ 65 to 70 degree

Hold for 1 hr. Cool and add post activation. Pack as per specification

Figure 2.4(F-11) : Mass balance diagram of Ammonium Stearate

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.39

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

12. MICRO AMINO SILICON

Under stirring addition of amino oil 8630, amino oil 4730, amino oil 4910

Then addition of emulsifier stero 13065, emulsifier stero 1309, emulsifier

Stero peg 600, emulsifier stero 1203 and acetic acid stir well for 1 hr.

Addition of water half an hour properly then heat up to 60 degree

Then cool and pack as per specification

Figure 2.4(F-12) : Mass balance diagram of Micro Amino Silicon

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.40

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

13. CATIONIC SOFTNER

Charge DM water in vessel and heat up to 100 degree temp. Then add sawax

BW 300, parafin wax, emulsifier CDA, emulsifier CSA 20 and refined salt

Reaction timing half hour. Control temp @ 100 degree

Hold for 1 hr. Cool and add post activation. Pack as per specification

Figure 2.4(F-13) : Mass balance diagram of Cationic Softner

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.41

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

14. REACTIVE SOFTNER

Charge water in vessel under stirring. Add emulsifier OCA 25 and RJT 292.

Then addition of epichlorohydrine for 2 hrs.

Control temp 65 +/-1 deg.

Hold for 1 hr. Cool and add post activation deformer. Adjust pH and pack

As per specification.

Figure 2.4(F-14) : Mass balance diagram of Reactive Softner

CONSULTANT :

RAMANS ENVIRO SERVICES PVT. LTD., Ahmedabad

2.42

EIA STUDY REPORT : MANUFACTURING PLANT OF TEXTILE BINDERS AND AUXILARIES

BY NPL INDUSTRIES PVT. LTD. AT VILLAGE : BIDAJ, Dist. : Kheda, Gujarat

(G) PLASTICIZERS

1. PLASTICIZING ESTER (DOM)