M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat

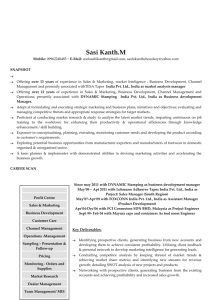

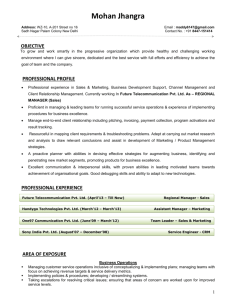

advertisement

M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. LIST OF ATTACHMENTS Annexure – 1 List of Product Page 19 Annexure – 2 Raw Material & Consumption Page 20 Annexure – 3 Manufacturing Process Details Page 21 Annexure – 4 Site Plan Page 24 Annexure – 5 Plot Plan, Google Image Page 25 Annexure – 6 Land Purchase Document Page 27 Annexure – 7 List of Directors Page 57 Annexure – 8 Water Consumption & Wastewater Generation Page 58 Annexure – 9 Water Balance Page 59 Annexure – 10 Details Effluent Treatment Plant Page 60 Annexure – 11 List of Hazardous Wastes Page 62 Annexure – 12 Details of Flue Gas & Process Emissions Page 63 Annexure – 13 List of Hazardous Materials Page 64 Annexure – 14 Project Cost, C. A. Certificate Page 65 Material Safety Data Sheets 26 Pages Page 18 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. ANNEXURE – 1 PRODUCTS & PRODUCTION CAPACITY SN PRODUCTS 1 Viscose Rayon PROPOSED PRODUCTION CAPACITY (MT/MONTH) 500 Page 19 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. ANNEXURE - 2 RAW MATERIAL & CONSUMPTION SN 1 2 3 4 5 RAW MATERIAL Wood Pulp / bleached cotton pulp Caustic Soda Carbon Disulphide Sulphuric Acid Zinc Sulphate Monohydrate RAW MATERIAL CONSUMPTION MT / MONTH 550 350 150 500 5 Page 20 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. ANNEXURE – 3 MANUFACTURING PROCESS DETAILS Rayon is manufactured by Xanthation of rayon grade pulp using Carbon Disulphide (CS2) and Caustic Soda (NaOH) and subsequent regeneration of cellulose as rayon. The industry shall manufacture Rayon in the form of Viscose Filament Yarn. Carbon Disulphide (CS2) used in the process shall be procured from the other sources as raw material. Rayon is made from cellulose, a constituent of all land-growing plant life. Spruce and Eucalyptus yield much of the high-grade cellulose required for Rayon. Their bark, lignin, etc. are removed in pulp mills, and the extracted cellulose is pressed and cut into sheets. Rayon Manufacturing process shall include following steps: 1. Slurry steeping The cellulose is steeped in caustic soda (derived from salt) with which it combines to form alkali cellulose. The excess soda is then pressed out and drained off for recovery and re-use (stage5). 2. Grinding The alkali cellulose is shredded into crumbs to make the processes in stage 3 and 4 quicker and easier (stage 1,2,3 and 4 are all to make the cellulose soluble so that it can be 'spun'). 3. Pre-ageing The alkali cellulose is stored to allow the oxygen in the air to oxidise it. This reduces the 'molecular size' of the cellulose, which is necessary to obtain a 'spinning' solution (stage5) of the correct viscosity. 4. Xanthation The alkali cellulose is combined with carbon disulphide (derived from carbon and sulphur) to give sodium xanthate. 5. Dissolving The sodium cellulose xanthate is dissolved in caustic soda to form the syrup-like 'spinning' solution known as viscose. 6. Ripening To improve its 'spinning' qualities, the viscose is allowed to ripen. Meanwhile it is held under vacuum to remove air bubbles. 7. Filtration The viscose is filtered to remove any un-dissolved particles which might block the jets in the next process. 8. Extrusion The viscose is extruded through the fine holes of a jet into a coagulating bath of sulphuric acid and salts which neturalises the alkaline content of the viscose and regenerates the original Page 21 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. cellulose as continuous filaments. The filaments from a single jet are drawn together as a continuous filament yarn. 9. Collecting Yarn is collected continuously on to thread-advancing reels. 10. Washing, Desulphurising and Drying The yarns or fibres are washed to remove chemicals left on them from the acid bath, and then dried. This is done continuously as the yarn passes from the back to the front of each threadadvancing reel; it is dried on the last reel which is heated and enclosed. At the end of the processes: Yarn is given a twist and wound on to a bobbin. All consist of pure cellulose (plus a slight content of moisture and lubricant) and are ready for use by the textile industries. Yarn can be woven or knitted direct. The process is schematically shown in below. Page 22 of 68 M/s Subh hlon Industriies Pvt Ltd, Moti M Naroli, Mangrol, Su urat, Gujarat. MANUFAC CTURING PR ROCESS – CONTINOUS C S VISCOSE E FILAMENT T YARN Page 23 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. ANNEXURE – 4 SITE PLAN Page 24 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. ANNEXURE – 5 FACTORY LAYOUT Page 25 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. LOCATION GOOGLE MAP Page 26 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. ANNEXURE – 6 LAND PURCHASE DOCUMENTS Page 27 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 28 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 29 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 30 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 31 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 32 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 33 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 34 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 35 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 36 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 37 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 38 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 39 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 40 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 41 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 42 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 43 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 44 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 45 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 46 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 47 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 48 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 49 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 50 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 51 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 52 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 53 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 54 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 55 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 56 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. ANNEXURE – 7 LIST OF DIRECTORS SN Name 1 Shri Narayan Ratilal Bhagat 2 Shri Tejas Nareshkumar Jeriwala 3 Smt. Anita Narayan Bhagat Address Contact No. 135, Balaji Nagar Society, Ved 9824400387 Dubholi Road, Surat-395004 6/407, Lal Darwaja, Pipla sheri, 9426773622 Surat -395004 135, Balaji Nagar Society, Ved 9824400387 Dubholi Road, Surat-395004 Page 57 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. ANNEXURE - 8 WATER CONSUMPTION AND WASTE WATER GENEARTION WATER CONSUMPTION: Source of Water: Ground water from bore well / River Water SN 1 2 3 Particular Domestic Process Utilities(Boiler & Cooling) Total Industrial Total Industrial & Domestic Consumption , KLD 20 3697 1283 4980 5000 WASTE WATER GENERATION: SN Particular Consumption , KLD 1 2 3 Domestic Process Utilities(Boiler & Cooling) Total Industrial Total Industrial & Domestic 16 3291 568 3859 3875 Disposal: The Industrial & Domestic effluent would be treated in ETP and would be reused in process to the extent possible and/or disposed to on land for plantation and/or to the in-land surface water nearby natural nalla. Page 58 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. ANNEXURE – 10 WATER BALANCE 20 3697 Processing Domestic 16 568 Boiler & Cooling 3291 1283 5000 Bore Well ETP 3875 KLD Treated Effluent reuse/onland for plantation/surface water disposal Note: Mentioned figures are in KL/day Page 59 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. ANNEXURE – 10 DETAILS OF EFFLUENT TREATMENT PLANT Viscose Rayon manufacturing generates effluent from many operations and can be categorized as Acidic, Alkaline and Combined effluent stream. Acidic Effluent stream consists of stream generated from revolving buckets of spinning machines, spin bath make-up tanks, evaporators and washing processes, cooling and condensate waters. The acidic waste water is a mixture of the spent spin bath, make up tanks and spinning machines, evaporator and washings. It has a low pH, high acidity, dissolved solids, sulphate and zinc. The sulphate is in the form of sodium sulphate and as sulphuric acid. The organic content of the acidic wastes is quite low. Notwithstanding its small volume this waste consists of the strongest and most highly toxic component of rayon wastes. Alkaline Effluent stream consists of stream generated from dialysers, ripening and deaerating vessels, filter presses from desulphurizing process and washing operations. The alkaline waste water has a high pH, a variable total dissolved solids and suspended solids. Combined Effluent stream consists of stream generated from bleaching and antichlor wastes. The combined waste is generally acidic and has high total dissolved solids and low biochemical and chemical oxygen demand. Zinc is present in variable concentration, often exceeding the permissible limits. The sulphate content is high but the chloride content is low. The alkaline effluent shall be collected for Caustic Soda Recovery and its reuse. The acidic effluent shall be subjected to Zinc Recovery at pH 9.0 followed Sodium Sulphate Recovery by Evaporation. The other acidic, alkaline and combined effluent streams shall be collected and equalized in the Equalisation Tank. The equalized effluent shall be subjected to neutralization followed with flocculation in Flash Mixing Tank and Flocculation Chamber. The neutralized effluent shall be held under quiescent condition in the Primary Clarifier for the separation of solids from the neutralized effluent. The clear supernatant from the top of the Primary Clarifier shall be mixed with domestic sewage and then be subjected to Aerobic Biological Treatment in Aeration Tank. The biologically treated effluent shall be clarified of the suspended biomass in the Secondary Clarifier. The bottom of Secondary Clarifier shall be recirculated to Aeration Tank to maintain the desired level of active biomass. The clear supernatant from the top of the Secondary Clarifier shall be subjected to Tertiary Treatment comprising of Pressure Sand Filter, Activated Carbon Filter and followed with Ultra filtration. The treated effluent shall be reused for on land plantation, cooling towers, process and washing operations. Excess treated effluent shall be disposed in the nearby surface water body. The schematic diagram of the effluent treatment plant would be as shown in the figure. Page 60 of 68 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. PROPOSED EFFLUENT TREATMENT SCHEME Caustic Recovery Plant Alkaline Effluent Stream pH makeup Tank Acidic Effluent Stream Zn(OH)2 Recovery Combined Effluent Stream Equalisation Tank Caustic Soda Reuse Clarifier Evaporator Belt Press Na2SO4 Recovery Neutralisation Tank Flocculation Tank Belt Filter Press Primary Clarifier Sludge Tank Dewatered Sludge to TSDF Aeration Tank Secondary Clarifier Filter Feed Tank Pressure Sand Filter Ultra Filtration Treated Water for Reuse / Onland Plantation / Disposal to Surface Water Body Page 61 of 66 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. . ANNEXURE – 11 DETAILS OF HAZARDOUS WASTE SN Type Category Schedule 1 36.4 Quantity Mode of Disposal 1 ETP Sludge 185 MT/Year Collection, Storage, Transportation and Disposal at TSDF/ By Dumping in low lying areas 2 Used Oil 5.1 Discarded Containers 33.3 1200 L/Year 500 Nos/Year Reused within the premises/ sell to authorized recyclers Collection, Storage, Decontamination, reuse within premises/sale to registered recycler 3 Page 62 of 66 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. ANNEXURE – 12 DETAILS OF FLUE GAS & PROCESS EMISSION SN 1 2 2 Stack Attached to Boiler (25 TPH) D.G.Set Process vents APCM Stack Height Fuel & Consumption Parameter Multi Cyclone + Bag Filters Alkali scrubbers/ Claus Kiln 30m Lignite-4.0 TPD / Natural Gas 8500 m3/day LDO - PM SO2 NOx <150 mg/NM3 <100 ppm <50 ppm CS2 H2S <21 Kg/t of fibre <6.3 kg/t of fibre 9m 1x 60m Permissible Limit Page 63 of 66 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. ANNEXURE – 13 LIST OF HAZARDOUS MATERIALS SN 1 2 Hazardous Material Carbon Disulphide Sulphuric Acid Storage Capacity 200 MT 200 MT Type of Storage SS Tanks HDPE Tanks Page 64 of 66 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. ANNEXURE – 14 PROJECT COST, C. A. CERTIFICATE Page 65 of 66 M/s Subhlon Industries Pvt Ltd, Moti Naroli, Mangrol, Surat, Gujarat. Page 66 of 66