Summary report on North Sea regulation and standards

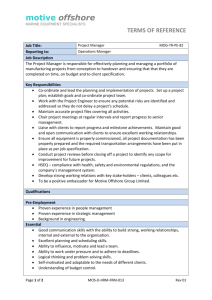

advertisement