Quality Check with Portal Vision Imaging

advertisement

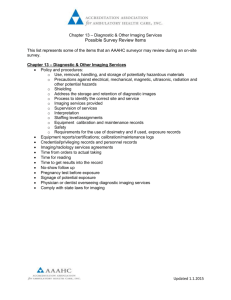

Quality Check with Portal Vision Imaging Thomas Troff European Technical Support January 27-28, 2012 Aarhus Agenda Portal Vision Imager Imaging arm Acquisition System Calibration Positioning of the Cassette Imaging Calibration Imaging problems Imaging arm 3 Generations of Arms S-Arm (swing arm) >16 Years R-Arm (retractable arm) Design 15 Years back Exact arm latest design R-Arm Exact-Arm OBI Acuity Acquisition System 3 Generations of Imaging Systems PV Mark 1 with LC250 PV Mark 2 with LC250/aS500 (IAS2 System) IAS3 aS500-II/aS1000 (IDU11 or IDU20) IAS2 Complete System Overview Image Detection Unit Image Acquisition System 2 (IAS 2) Arm Controller varian Image Acquisition System 2 Clinac R Arm or E-ARM RS-422 Clinac Controller Dose Rate Servo Clinac Stand Dedicated LAN (10Base-T) PortalVision Workstation VARiS / VARiS Vision Network Electronics Cabinet Image Acquisition system 2 controller 1. Communicates with treatment task 2. Performs self tests and initialization 3. Verifies clinac setup and generates timing 4. Acquires and processes signal from IDU IAS3: System Overview Different System names System IAS Resolution IDU Channel 04 1 LC250 2 256 x 256 aS500 2 512 x 384 11/20 aS500-II aS1000 3 3 512 x 384 11/20 1024 x 768 20 2 4 4 Speed 1.27MHz 1.27MHz 2MHz 2MHz IDU 11 / 20 40x30 cm2 512,384 Gate Drivers a-Si Panel IDU Type 11 Top View 1,1 Read-out Electronics IDU Type 11 Bottom View IDU Construction: X-Section of aS500 and aS1000 MeV x-ray copper metal plate 1mm Phosphor 0.4 mm photodiode TFT switch e x-ray converter e- to light converter a-Si:H 1.5um glass substrate 1mm scatter photon • Conversion of a x-ray to optical signal through the phosphors • Conversion of optical signal from the phosphor to charge • Storage of charge on pixel (photo-diode) capacitance aS500 and aS1000 Pixel Schematic & Microscopic View Bias Voltage Line Data Line TFT Gate Line Data Line TFT Gate Line Photodiode Array Pixel Schematic V_bias (-5v) Light makes the photodiode conductive Data Photodiode Voltage is decreasing on Cap Cap has to be on a predefined Level in advance TFT Gate Acquisition Techniques Agenda Portal Vision Imager Imaging arm Acquisition System Calibration Positioning of the Cassette Imaging Calibration Imaging problems Calibration: Iso-calibration 2 3 1 4 Front pointer / optical distance indicator measurement to surface of detector LIC 1,000.0 mm - 11.0 mm = 989.0 mm a-Si 1,000.0 mm - 12.5 mm = 987.5 mm Figure not to scale 1. Isocenter 2. LIC-detector surface 3. Sensitive layer 4. a-Si-detector surface Image Correction Dark field image Flood field image No radiation image (beam OFF) Radiation image (beam ON) Measured 60 times and averaged Measured 30 times and averaged Reflects Reflects Chamber imperfections Field homogeneity Electrical leakage of the photo diodes Individual pixel sensitivity Amplifier gains Gate 1 Object Image BEAM ON Gate= 384 DF FF When to Calibrate Complete calibration DF – FF – Pixel correction After IDU change, DU Change, imaging problem Darkfield only First 3 month every 2 to 3 weeks after IDU replacment After this > Dosimetry cal check What modes to calibrate Last image Hold no Calibration Rad shot mode (low dose / high quality) Continuous mode Dark field / Flood field for 1 RepRate per Energy @ 140cm or most clinically used position Every RR that is clinically used per Energy Integrated mode Every RR that is clinically used per Energy @ isocenter RadShot Calibration Low dose / High quality Integrated mode Agenda Portal Vision Imager Imaging arm Acquisition System Calibration Positioning of the Cassette Imaging Calibration Imaging problems Noise image-Good Image 2 test images subtracted from each other Mean value +- 5 counts aS500 Std dev. <6 aS1000 Std dev. <10 Drift image-Good Image Showing defect lines, pixels etc… Image testing Thank you for your interest and attention Discussion