Hybrid Electrical Energy Storage

advertisement

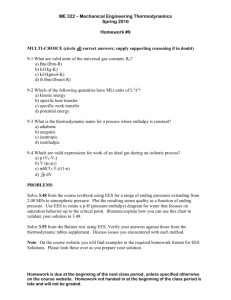

Hybrid Electrical Energy Storage Systems Naehyuck Chang and Massoud Pedram Seoul National University University of Southern California Outline Electrical energy storage systems Energy storage elements Charge management circuits Hybrid Electrical Energy Storage (HEES) systems HEES optimization examples Amortized system cost optimization Maximum power transfer tracking Rate capacity effect mitigation Conclusions 2 Electrical Energy Storage Systems Definition An electrical energy storage (EES) systems use various forms of energy such as chemical, kinetic, or potential energy to store energy that will later be converted to electricity Electrical energy has higher grade of energy quality Converting electrical energy to other types of energy is efficient and easy but the opposite is not true Electrical energy has a greater capacity to feedback and control lower grades of energy quality Examples Supercapacitor: electrical energy Battery: chemical energy Flywheel: kinetic energy CAES (compressed air energy storage): potential energy 3 Electrical Energy Storage Systems EES system functionalities Power supply Energy management Power quality control Peak shaving Ranges of EES systems Power supplies for portable electronics (a few Wh or smaller) Uninterruptible power supplies (hundreds of Wh) Grid-scale EES (GWh or larger) 4 Electrical Energy Storage Systems Conventional EES systems mostly employ a single type of EES element Focus is on the EES element characteristics Try to achieve higher performance by using a more efficient EES element Conventional EES systems have a rather simple architecture Charge/discharge circuit Single power path Straightforward charge/discharge policy EES element: a storage device such as a battery and a supercapacitor EES system: an integrated system including EES element, control electronics, and control policy 5 Conventional EES Systems Architecture A single type of EES element A single power path from input, to the storage, and to output The input and output may be tied together in some configurations The power path may be bidirectional in some cases 6 Examples of EES Systems, I Battery Premium Power PowerBlock 150 Zinc-Flow battery cells 7 Examples of EES Systems, II Flywheel Sun Microsystems, Colorado Data center UPS’s 8 Examples of EES Systems, III CAES (compressed air energy storage) Iowa Stored Energy Park, Iowa (planned) 9 Performance Metrics for EES systems Cycle efficiency, cost per unit capacity, energy density, power capacity, cycle life, and environmental impact including end-of-life disposal cost No single type of EES element can simultaneously fulfill all the desired characteristics of a modern EES system 10 Performance Metrics Capital cost Cost per unit of delivered energy ($/kWh) or per unit of output power ($/kW) Initial investment for EES system installation Lower capital cost is generally against to other performance metrics 11 Performance Metrics, cont’d Charging efficiency Ratio of energy delivered from the energy source to the EES element Discharging efficiency Ratio of energy delivered from the EES element to the load Cycle efficiency Product of charging and discharging efficiencies Significantly affected by charging/discharging profiles and ambient conditions Examples includes rate capacity effect and charge recovery effect 12 Performance Metrics, cont’d Cycle life The capacity or SOH (state of health) tends to gradually deteriorate due to irreversible physical and chemical changes Defined as the number of cycles an EES element can perform before its capacity drops to a specific percentage (60-80% typically) of its initial full-charged capacity Strongly dependent on the depth of discharge (DoD) before that element is recharged Longer cycle life EES elements Electrical, mechanical or thermal technologies Supercapacitor, flywheel, thermal energy storage (TES) and cryogenic energy storage (CES), etc. Shorter cycle life of batteries Due to unavoidable chemical deteriorations 13 Performance Metrics, cont’d Power and energy density Rated output power divided by the volume (or mass) of the EES element Energy density is the stored energy divided by the volume (or mass) Metal-Air batteries have the highest energy density (1-10kWh/kg) Ordinary batteries, TES and CES have medium energy density Supercapacitor and flywheel have the lowest energy density but the highest power density A HEES system can take advantage of the energy density of a primary source for long operational time and the power density of a secondary source for power requirements 14 Performance Metrics, cont’d Self-discharge rate How quickly an EES element will lose its energy when it simply sits on the shelf Determined by the inner structure and chemistry, as well as ambient temperature and humidity Ordinary batteries can store energy reliably up to tens of days Lithium primary batteries can be stored 10 years on the shelf Flow batteries have very small self-discharge rate and thus are suitable for long-term energy storage Supercapacitors have large self-discharge rate and are useful for short-term energy storage for a maximum of several hours or a couple of days 15 EES Elements: Commercial Off-the-Shelf Lead-acid battery Short cycle life (500-800 cycles) Low energy density (30-50 Wh/kg) Poor low temperature performance and thus a thermal management system is required Relatively high power density (75-300 W/kg), able to supply high surge currents Medium energy efficiency (70-90%) Low cost (100-200 $/kWh) Suitable in motor vehicles to provide the high current demand for automobile starter motors Used in large-scale commercial energy management systems 16 EES Elements, cont’d NiCd battery Relatively high energy density (40-60 Wh/kg or 50-150 Wh/L) Moderate cycle life (as high as 2,000 cycles) Relatively high self-discharge rate (10% per month) High cost (800-1,000 $/kWh) Undesirable environmental effect due to the use of toxic heavy metal Specific energy 40–60 Wh/kg Volumetric energy density 50–150 Wh/L Specific power 150 W/kg Charge/discharge efficiency 70%–90% Self-discharge rate 10%/month Cycle durability 2,000 cycles Nominal cell voltage 1.2 V 17 EES Elements, cont’d NiMH battery Energy density (60-80 Wh/kg) is twice as large as lead-acid batteries and 40% higher than that of NiCd batteries Cheaper to purchase than Li-ion batteries Suffer from the memory effect, although much less pronounced than that in the NiCd batteries Relatively high self-discharge rate (0.5-1% per day) High power density (250-1,000 W/kg) Due to the high power density, these batteries are widely used in high current drain consumer electronics, such as digital cameras with LCDs and flashlights Widely used in hybrid electric vehicles such as the Toyota Prius, Honda Insight, Ford Escape Hybrid, etc. 18 EES Elements, cont’d Li-ion battery High energy density (100-250 Wh/kg or 250-360 Wh/L) High efficiency (almost 100%) Long cycle life (as high as 10,000 cycles) No memory effect Low self-discharge rate (0.1-0.3% per day) High cost (above 600 $/kWh) In many portable electronic devices and growing in military, electric vehicle, and aerospace applications 19 EES Elements, cont’d Supercapacitor High cycle efficiency (almost 100%) and long cycle life (up to 1,000,000 cycles) Significantly high volumetric power density (above 100,000 W/kg) but low energy density (2.5-15 Wh/kg) Large self-discharge rate compared with ordinary batteries About 20% energy may be lost per day Suitable for energy storage with frequent charging/discharging cycles or periodic high current pulses. May be used in battery-supercapacitor hybrid systems Terminal voltage variation whereby the terminal voltage is linearly proportional to its SOC (state of charge) May affect conversion efficiency in the power converters connected to the supercapacitors 20 EES Elements, cont’d Metal-Air battery The anode is made of pure metal and cathode is connected to an inexhaustible source of air The highest energy density (theoretically more than 10 kWh/kg) and are relatively inexpensive to produce Environmentally friendly Currently suffer from the low efficiency of the required electrical recharging process Many manufacturers offer refuel units where the consumed metal is replaced mechanically 21 EES Elements, cont’d Emerging technologies Compressed air energy storage Medium efficiency (70%) Cryogenic energy storage (CES) No environmental burden (because of the use of liquid nitrogen or liquid air) Relatively high energy density (150-250 Wh/kg) Low capital cost and relatively long storage period Low efficiency currently (40-50%) http://www.engineering.leeds.ac.uk http://www.matternetwork.com 22 Performance Comparison of EES Elements EES Elements Lead-acid Capital cost ($/kWh) Cycle efficiency Cycle life 100-200 70-90% 500-800 NiCd battery 800-1,000 70-90% 2,000 NiMH battery 450-1,000 66% 500-1,000 Li-ion battery 600-2,500 >90% 1,000-10,000 300-500 87% 2,500 10-60 <50% 100-300 20,000-50,000 >90% 500,000-1,000,000 1,000-5,000 >90% 20,000+ High-temperature TES 30-60 30-60% - CES 3-30 40-50% - NaS battery Metal-Air battery Supercapacitor Flywheel 23 Performance Comparison, cont’d EES Elements Self-discharge per day Energy density Power density Lead-acid 0.1-0.3% 30-50 Wh/kg 75-300 W/kg NiCd battery 0.2-0.6% 40-60 Wh/kg 150-300 W/kg NiMH battery 0.5-1% 60-80 Wh/kg 250-1,000 W/kg Li-ion battery 0.1-0.3% 100-250 Wh/kg 250-340 W/kg ~20% 150-240 Wh/kg 150-230 W/kg Very small 1-10 kWh/kg - 20-40% 2.5-15 Wh/kg 100,000+ W/kg 100% 10-30 Wh/kg 400-1,500 W/kg High-temperature TES 0.05-1% 80-200 Wh/kg - CES 0.5-1% 150-250 Wh/kg 10-30 W/kg NaS battery Metal-Air battery Supercapacitor Flywheel 24 EES System: Amortized Cost Life time of each EES element Total energy cost per day Total amortized cost per day Sum of the purchase price, setup/disposal costs, and energy usage cost per day 25 Switching Mode DC-DC Converter Buck (step down) converter Lower the output voltage compared to the input voltage LC filtering of the switching output Average output voltage is determined by the power switch’s turn-on duty ratio Boost (step up) converter Increase the output voltage compared to the input voltage Add the energy stored in the inductor capacitor Average output voltage is determined by the switch turn-off duty ratio 26 DC-DC Converter, cont’d Inverted Buck-Boost converter Inverted output Low efficiency due to presence of the diode Simple and easy to control 4-switch Buck-boost converter Non-inverted output High efficiency Complex control Synchronous switches replace the freewheeling diode Selectively operated as a buck or a boost converter according to the input and output voltages 27 Constant Current Charger Linear charger Current regulator using power MOSFET in saturation mode Precise current control without noise Low efficiency due to the IR loss in the MOSFET Switching mode charger Current feedback buck-boost converter Provide basic charging protocol and protection features Switching noise 70-80 % conversion efficiency 28 Charger, cont’d Constant current charger using high efficiency buck-boost converter module Linear technology LTM4607 buck-boost converter micro module 4-switch buck-boost topology On-chip power switches Very high conversion efficiency: ~98% 29 Charger, cont’d Constant current charger using high efficiency buck-boost converter module Voltage and current feedback loop modifications Safe and efficient charging operation 30 Charge Management Circuits Battery/suepercapacitor charger Power converter specialized for charging batteries or supercapacitors Charge management for various cell configurations and multiple chemistry Combined charging schemes (e.g., constant voltage + constant current) for reliability and efficiency Charger efficiency issue Generally, batteries are charged by the AC power, and so conversion efficiency has not been a critical issue When a renewable power source such as a solar cell or fuel cell is used, power conversion efficiency should be taken into consideration 31 Charge Management Circuits: Summary Bridge diode AC-DC rectifier Make DC to AC with diode bridge Voltage regulator Zener-diode regulator Regulate the voltage using breakdown voltage Voltage regulator using OP-amp Regulate the voltage using the feedback loop Three-terminal voltage regulator Widely used in common DC power supplying circuit Switching mode DC-DC converter Buck DC-DC converter Step down the voltage according to the switching duty cycle, Dt Boost DC-DC converter Step up the voltage according to the switching duty cycle, (1- Dt) H-bridge DC-AC inverter Make DC to AC by alternatively switching the H-bridge 32 Charge Management Circuits, cont’d Power converters and efficiency EES systems involve AC-DC and DC-AC conversions Low conversion efficiency directly results in a high operational cost Designing the power converters should consider operating cost (efficiency) as well as the implementation cost The energy efficiency of the power converters are affected by Design such as switch resistance, inductor and transformer performance Operational conditions such as input voltage, output voltage, load current, switching frequency Energy efficiency of an EES element is often measured under the best condition 1/25 C discharge rate Best temperature condition With brand new batteries 33 Charge Management Circuits, cont’d Sources of power loss in a switching regulator ESR (Equivalent Series Resistance) of each component I2R power dissipation in switch, inductor and etc. Dependent on the load current Parasitic capacitances of MOSFET switching gate Power dissipation to drive two switches Independent of load current Control circuitry Power dissipation for PWM control and miscellaneous circuits Independent of load current 34 Charge Management Circuits, cont’d Conversion efficiency of a DC-DC converter by a power MOSFET configuration 35 Charge Management Circuits, cont’d Power efficiency of LTC3414 and TPC62320 36 Charge Management Circuits, cont’d Switching charger power dissipation Sum of the conduction, switching, and controller power losses Conduction loss IR loss in the MOSFET switches, inductor, and ESR of the bulk capacitor Proportional to the equivalent resistance of the components and output current Switching loss MOSFET switch gate drive loss Proportional to the input voltage, switching frequency, and gate capacitance Controller loss Static power dissipated by the switch controller General characteristics The charger efficiency decreases when the input and output voltage difference is large Boost converters are less efficient than buck converters 37 Charge Management Circuits, cont’d Switching chargers Switching chargers transfer energy from a power source to an EES element The charging efficiency is not constant, but depends on the input voltage, output voltage, and output current Example: efficiency and power consumption of a Linear Technology LTC3531 38 Charge Management Circuits, cont’d Charging efficiency variation in supercapacitor charging Charging efficiency variation should be considered when the input/output voltages are not constant Example: input from solar cell and output to supercapacitor Conventional MPPT (maximum power point tracking) techniques are not necessarily energy efficient here Maximizing the charger input power may not maximize the charger output current 39 Charge Management Circuits, cont’d Monitoring and control BMS (battery management system) Maintains stability and sources of important information for the charge management policies Estimates the SOC and SOH, controls the voltage, current, and cell balances (distributing SOC evenly across the bank), and provides diagnostics functionality CAN, FlexRay network for monitoring SCADA (supervisory control and data acquisition) system for HCI 40 Hybrid Electrical Energy Storage (HEES) Systems Motivation Computer memory hierarchy No single type of memory, device can achieve short access time, high density, balanced read/write performance, low cost per bit, low power consumption, non-volatility, etc. Concept of hybrid EES systems Each EES element has different characteristics such as cycle efficiency, leakage current, cycle life, storage cost, and volumetric energy density, power rating, and so on No single type of EES element can simultaneously fulfill all the desired characteristics Exploit the advantages of each EES element and hide its disadvantages Hybrid EES systems consist of both low unit cost (e.g., lead-acid batteries) and high unit cost (e.g., supercapacitors) EES elements Should be minimized by allocating the amounts of low-cost vs. high-cost EES elements while meeting other performance constraints Different types of energy storage elements can be organized in an appropriate storage hierarchy and reconfigured on the fly 41 HEES System Architecture 42 HEES System Architecture, cont’d To provides enhanced cycle efficiency, extended cycle life for each element, increased energy storage capacity, and output power rating Heterogeneous EES elements Generalized power migration buses High-efficiency power converters Optimal charge management policies Logically hierarchical, physically flat structure to shorten the charge transfer paths The architecture is closer to scratch pad memory rather than cache memory in that: Both allocation and replacement policies are required Flat physical structure (cache is hierarchical) 43 HEES System Architecture, cont’d Charge migration path can be a multiple power bus or a crossbar network Allows optimal simultaneous migration operations The optimal power bus voltage for each migration is a function of the EES elements and their SOC A shared power bus requires the same voltage level of all the power converters for simultaneous migration operations Reconfigurability for enhanced cycle efficiency Each EES bank consists of multiple homogeneous EES elements to meet certain voltage, power and capacity requirements maintaining balancing Charging/discharging efficiency is a strong function of SOC as well as voltage and current levels A fixed array structure cannot always guarantee desirable cycle efficiency For example, a supercapacitor bank may have very low terminal voltage with low SOC 44 HEES System: Charge Allocation (charging) Charge allocation problem is to determine the destination EES banks that maximize the charging efficiency Charging efficiency is dependent on Type and SOC of the bank Voltage and current characteristics of the power source Degree of MPTT (maximum power transfer tracking) for the power source, and so forth The most efficient EES bank changes over time as SOC changes during charging When the SOC of the destination EES has a significant change during the charging process, reconfiguration of the internal connections may be desirable 45 HEES System: Charge Replacement (discharge) Charge replacement is to determine the most efficient EES banks which are capable of supplying electrical energy to a given load demand Discharging efficiency is dependent on Rate capacity effect Power rating Terminal voltage, and so on The most efficient EES bank changes over time as SOC changes during discharging 46 HEES System: Charge Migration Each EES element has different selfdischarge rate Long-term energy storage necessitates charge migration among various EES banks Only a part of EES banks can accommodate high current charge/discharge demand Such banks may have very high selfdischarge rates - supercapacitor banks Remaining charge in the high-leakage bank may be transferred to low-leakage banks for long-term storage Charge migration is expensive because of charge loss during both discharge and recharge processes Should be carefully performed by predicting the future load demand as well as energy supplied by the external power source 47 HEES System: Joint Charge Optimization Charge allocation, replacement and migration cannot be optimized separately because of their sometimes conflicting natures as well as the strong couplings among them For example charge migration may become inefficient in a system designed for optimal charge allocation Thus the joint optimization of allocation, replacement and migration is a challenging, yet critical, problem 48 Examples of Optimizing HEES Systems Amortized system cost optimization in a HEES system for large-scale energy storage Maximum power transfer tracking in a solar energy harvesting system Rate capacity effect mitigation in a system supporting widely varying load currents 49 Example I: Amortized System Cost Optimization Amortized cost optimization example Daily and weekly energy usage profiles 50 Example I: Amortized System Cost Optimization Amortized cost optimization example Assumptions Installation and disposal costs are included in the cost per capacity Energy cost is 10 ¢/kWh Two energy storage elements Criteria Battery Supercapacitor Cyclelife 2,000 100,000 Cost per capacity ($/kWh) 1,000 40,000 Cycle efficiency 80% 100% Self discharge rate (%/day) 0.1% 15% 51 Example I: Amortized System Cost Optimization Amortized cost optimization example Conventional EES approaches Battery-only EES Suffer from low cycle efficiency and short cycle life Supercapacitor-only EES Not suitable for long-term storage HEES approach Use batteries for weekly energy storage Large capacitance: low cost-per-capacity required Long storage duration: low self-discharge rate required Use supercapacitors for daily energy storage Frequent charge/discharge: high cycle efficiency and long cycle life required 52 Example I: Amortized System Cost Optimization Amortized cost optimization example Cost ($/week) Battery-only EES Supercapacitoronly EES Hybrid EES Storage cost 160.3 181.6 153.3 Energy cost 40.1 45.4 38.3 Total cost 200.4 227.0 191.6 Low storage cost due to battery cycle life enhancement using supercapacitors as daily energy storage Low energy cost due to high cycle efficiency of supercapaictors 53 Example II: Solar Energy Harvesting System Solar energy harvesting is a promising method for self-sustainable systems Harvested energy is necessary to be stored in an EES system for stable power supply Continuous operation in cloudy weather or at night A rechargeable battery and/or supercapacitor is used Energy transfer involves energy loss 54 Solar Energy Harvesting Example, cont’d Optimal solar energy harvesting system Maximizing the harvested energy at the minimum cost Energy conversion efficiency should be maximized Charger conversion efficiency Significantly affected by the state of the energy source (PV module) and energy storage (supercapacitor) The environment and system state change over time, and maximizing the systemwide efficiency is non-trivial Previous battery-based energy harvesting techniques may not be efficient for supercapacitors No attempt to find the system-wide optimal design considering the energy source and storage for supercapacitors For a given energy harvesting requirement, the minimum size of a PV cell array and the minimum capacity of a battery are typically considered 55 Solar Energy Harvesting Example, cont’d Comparison between batteries and supercapacitors (revisit) Supercapacitors are suitable for frequently charged and discharged energy storage Significant voltage change, which may result in poor efficiency, should be overcome Battery Metric Supercapacitor High Energy density Low Low Power density High Low Cycle life High Low Cycle efficiency High Small Self-discharge rate Large Large Negative impact on environment Small Low Cost High Small Voltage change Large 56 Solar Energy Harvesting Example, cont’d Maximum power point tracking (MPPT) technique Maximizes the output power from the PV module Does not guarantee the maximum energy accumulation Charger output power by the MPPT technique may be less than that by the MPTT technique Three design considerations PV cell configuration Charger selection Supercapacitor configuration 57 Solar Energy Harvesting Example, cont’d PV module configuration: voltage and current characteristics depend on series and parallel configuration More PV cells in series: higher voltage More PV cells in parallel: higher current The minimum number (cost-optimal) of cells and their energy-optimal configuration should be derived 58 Solar Energy Harvesting Example, cont’d MPTT problem statement and solution Given Energy requirement Solar irradiance profile Charger efficiency data Unit PV cell characteristic Find Optimal PV module configuration (number of connected cells) Optimal supercapacitor capacitance Solution Approximate harvested energy for given configuration Iteratively increase the number of PV cells Charger design may also be optimization object to increase the energy efficiency (e.g., power switch, switching frequency, etc.) 59 Solar Energy Harvesting Example, cont’d Charger selection Charger maximum output and current rating IR loss and gate drive loss 60 Solar Energy Harvesting Example, cont’d Supercapacitor capacitance consideration Smaller capacitance: higher voltage Larger capacitance: lower voltage Energy-optimal capacitance should be derived Cost of the supercapacitance is determined by the given energy requirement, not its capacitance 61 Solar Energy Harvesting Example, cont’d Maximum charge power surface The MPTT method maximizes the power into the supercapacitor at all times The maximum power transferred into the supercapacitor is a function of the irradiance level and the supercapacitor voltage 62 Example III: High Efficiency for Variable Loads Rate capacity effect in batteries Undeliverable charge according to the battery operating condition Energy impact Power loss in the battery caused by battery internal resistance Discharge with different constant current Discharge with constant and pulsed current 63 Variable Load Support Example, cont’d A typical load profile for military radio systems An EES system may be designed to be capable of handling a (variable) load of average power between 5 and 50 watts, which may also contain significant (up 100watts) transient spikes The EES system must handle both positive and negative transient load power pulses 64 Variable Load Support Example, cont’d Parallel connection Connect the battery and supercapacitor in parallel Straightforward solution Filtering voltage fluctuation Godfrey Sikha and Branko N. Popov, Performance optimization of a battery–capacitor hybrid system, Journal of Power Sources 134 (2004) 130–138 Parallel connection Voltage and current response 65 Variable Load Support Example, cont’d Constant-current charger-based hybrid architecture Constant-current charger Separate the battery current from the load current Widely used for battery and supercapacitor management Simple circuit implementation Rate-capacity effect reduction Mitigate current fluctuation Converter efficiency Supercapacitor terminal voltage should be maintained in a high-efficiency range Voltage and current response Constant current hybrid 66 Variable Load Support Example, cont’d Energy density of the storage elements Li-ion batteries: 250 ~ 300 Wh/L Supercapacitor: 10 ~ 20 Wh/ L Conversion efficiency Depends on input/output voltage and current Supercapacitor capacitances Small capacitance results in large supercapacitor voltage variation and low charger/regulator efficiency Parallel connection Large capacitance increases volume of the system Constant current hybrid 67 Variable Load Support Example, cont’d Controller board 68 68 Variable Load Support Example, cont’d Battery Li-ion GP2N1051 cell 2SP1 pack 8.4 V 350 mAh Supercapacitor NessCap ESHSR-0010C0 4S array 2.5F, 10.8V Parallel connection 7.7 % deliverable energy gain Constant current hybrid 69 Variable Load Support Example, cont’d Voltage and current waveform The HEES system architecture shows smaller current fluctuation compared with the parallel connection Parallel connection Constant current hybrid 70 Conclusions Initial work on hybrid electrical energy storage (EES) systems by using a combination of various EES elements No single EES element can fulfill all requirements of a modern EES system Architectural consideration of the hybrid EES system based on the computer memory hierarchy (scratch pad memory) concept Setup the concept of key EES management operations Charge allocation, replacement, and migration HEES optimization examples Peak shaving Maximum power transfer tracking Rate capacity mitigation Future work Systematic (mathematical) approaches for holistic optimization of a HEES system Simultaneous optimization of charge allocation, replacement and migration processes 71