Document 18020654

advertisement

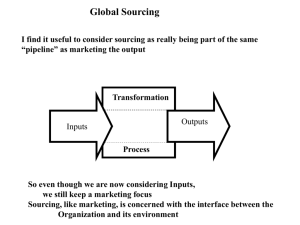

This chapter covers: 21 •Supply chain management •Global sourcing •JIT production Global Operations and Supply Chain Management •Synchronous manufacturing •Six Sigma •Impediments to global standardization •Importance of technology •Classes of activities in manufacturing International Business by Ball, McCulloch, Frantz, Geringer, and Minor McGraw-Hill/Irwin Copyright © 2006 The McGraw-Hill Companies, Inc. All rights reserved. Chapter Objectives Understand supply chain management and the relationship with design Describe the five global sourcing arrangements and appreciate the importance of the added costs of global sourcing Understand the increasing role of electronic purchasing for global sourcing Understand the Japanese efforts to improve quality and lower costs Know the just-in-time production system and its problems Understand synchronous manufacturing and customization Understand Six Sigma systems Identify the impediments to global standardization of production processes and procedures Know the two general classes of activities in manufacturing systems 21-2 Lower Costs/Improved Products Desired results may be obtained through Improvement within existing operations Opening new operations or finding outside sources for inputs Outsourcing Combination of above Process is referred to as supply chain management 21-3 Global Supply Chain Management Supply chain management refers to activities involved in producing a company’s products and services, and how these activities are linked together Involves total systems approach to managing flow of Materials Information Finances Services 21-4 Design of Products and Services Design has a fundamental relationship with type of inputs required Important consideration is extent to which products and services will be standardized or adapted Over-the-Wall approach traditional approach Sequential steps Alternative approach cross-functional participation 21-5 Can involve customers Sourcing Globally Important Reasons for Sourcing Globally Lower price available from foreign sources Availability of foreign products not available locally Firm’s worldwide operation and attitude Advanced technology available from foreign sources Higher-quality products available from foreign sources Outsourcing An increasingly common option 21-7 Focus on core competencies Leverage skills of other companies Reduce costs Improve flexibility and speed of response Enhance quality Can outsource in same country or another country Choices increased by Global access to vendors Falling costs of interactions Improved information technology and communication Outsourcing 21-8 Any part of value chain can be outsourced Product design Input supply Manufacturing or assembly Logistics Distribution Marketing Sales Service Human resources Outsourcing Considerations Costs Control Expertise required Distance Languages Laws and regulations Initially better to outsource simple activities then gradually outsource more complex activities 21-9 The Lure of Global Outsourcing Suppliers with improved competitiveness in terms of Cost Quality Timeliness Less developed countries with low-cost labor Attractive for laborintensive products with low skill requirements Global Sourcing Arrangements Arrangement that provide a firm with foreign products. Wholly owned subsidiary Overseas joint venture In-bond plant contractor Overseas independent contractor Independent overseas manufacturer 21-10 Use of Electronic Purchasing for Global Sourcing In recent years, many firms have set up electronic procurement exchanges to identify potential suppliers or customers to facilitate efficient and dynamic interactions among these prospective buyers and suppliers Purchasing is increasingly being viewed as a strategic function 21-11 Global Electronic Procurement Electronic Exchange Options Catalog purchases Permits buyers and suppliers to interact through a standard bid/quote system Facilitates obtaining letters of credit, contracting for logistics and distribution, and monitoring daily prices and order flows 21-12 Benefits Cut costs Improve productivity Cut invoice and ordering errors Reduce trading cycle time Reduce supply base Improve internal purchasing processes Easily compare bids Reduce paper Global Sourcing Problems Firm’s may be surprised that what initially appeared to be a lower price is not really lower An increase in price occurs due to currency fluctuations E-procurement and electronic commerce as a whole cannot be isolated from the company’s overall business system Exposing internal business systems to access via the Internet can expose the firm to a wide range of potential security issues 21-13 Added Costs International freight, insurance and packing Import duties Customhouse broker’s fees Transit or pipeline inventory Cost of letter of credit International travel and communication costs Company import specialists Reworking of products out of specification 21-14 Advanced Production Techniques Growing international competition requires companies to achieve efficiency and effectiveness in production To improve competitiveness companies have put into place systems such as Just-in-time supply chains (JIT) Highly synchronized manufacturing systems Computer Integrated Manufacturing (CIM) Robots 21-15 Japan’s Use of JIT Requirements to operate without inventory Components had to be defect-free Components had to be delivered to each point at the time they were needed Sellers maintained inventory of finished products Process time required reduction Manufacturers had to simplify product lines Suppliers had to cooperate Designers, managers, purchasing people and marketers had to work as a team 21-16 Total Quality Management 21-17 Managing the entire organization so that it excels on all dimensions of product and services that are important to the customer TQM used Quality Circles Small work groups that meet periodically to discuss ways to improve their functional areas and the quality of the product Problems with JIT in the U.S. Failure to realize JIT is a total system which includes TQM Cultural differences in U.S. workers Highly specialized work No company loyalty Failure to train and integrate suppliers JIT is restricted to operations that produce the same parts repeatedly because it is a balanced system 21-18 Because JIT is a balanced system, if one operation stops, the entire production line stops Achieving a balanced system is difficult because production capacities differ among the various classes of machines JIT makes no allowances for contingencies. Much trial and error are required to put the system into effect Advanced Production Techniques Synchronous Manufacturing Also called Theory of Constraints (TOC) Scheduling and manufacturing control system Focus on bottlenecks Mass Customization Use of flexible, computer-aided manufacturing systems Can customize for demands of individual customers Six Sigma A business management process that combines analytical tools with infrastructure and leadership to solve problems and optimize processes 21-19 Logistics Movement of materials Must interface with sourcing , manufacturing, design, engineering and marketing Packaging and transportation requirements can greatly increase logistics costs Many companies now outsource logistics 21-20 Standardization of Global Operations In most countries standards have been developed across product lines and for various functions In Europe, the most-used standard for quality is the ISO 9000 The most comprehensive of standards is the ISO 9001 This standard applies to industries involved in the design, development, manufacturing, installation, and servicing or products and services 21-21 Reasons for Global Standardization of Systems Advantage of synchronous manufacturing and TQM Customers everywhere want quality products at low prices Simplifies the manufacturing organization at HQ Increases effectiveness in keeping production specifications current Guarantees parts manufactured in various plants will be interchangeable 21-22 Reasons for Global Standardization of Systems Manufacturing rationalization Division of production among a number of production units thus, enabling each unit to produce only a limited number of components for all of a firm’s assembly plants Purchasing Control Quality control Production and maintenance control 21-23 Reasons for Global Standardization of Systems Building new plants will be both simpler and quicker with standardization Design engineers need only to copy the drawings and list of materials that they have in their files Vendors will be requested to furnish equipment that they have supplied previously The technical department can send the current manufacturing specifications without alterations Labor trainers experienced in the operation of the machinery can be sent to the new location without undergoing special training on new equipment Reasonably accurate forecasts of plant erection time and output can be based on experience with existing facilities 21-24 Impediments to Standardization Economic Forces Wide range of market sizes Cost of production 21-25 capital-intensive labor-intensive process computer-integrated manufacturing High-capacity machines Backward vertical integration Impediments to Standardization Cultural Forces Developing countries may lack skilled workers Resources directed to professional vs. technical education Use of specialized machines favored Absenteeism creates further problems 21-26 Political Forces Country needs new jobs Government insists on most modern equipment Design solutions include Hybrid designs Intermediate technology Appropriate technology depends on economic, sociocultural and political variables Design of the Manufacturing System A manufacturing system is essentially a functionally related group of activities for creating value Factors involved in the efficient operation of a manufacturing system Plant location Plant layout Materials handling Human element 21-27 Design of the Manufacturing System Plant location Effects both production and distribution costs Need labor, raw materials, water and power Must locate in export processing zones Plant layout 21-28 Arrangement of machinery, personnel and service facilities Materials Handling Careful planning can save production costs Poor handling can result in excessive inventory, idle machinery, late deliveries and damaged goods Human element Effectiveness depends on people People are affected by the system Operation of the Manufacturing System Once the manufacturing system has been put into operation, two general classes of activities must be performed Productive activities Supportive activities 21-29 Operation of the Manufacturing System Manufacturing Activities After the initial trial period management will expect the system to produce at a rate sufficient to satisfy market demand Obstacles to Meeting Manufacturing Standards Low output Inferior quality Excessive manufacturing costs Obstacles to Meeting Manufacturing Standards Low Output Supplier problems Poor coordination of production scheduling Culture differences in attitudes, educational levels, and planning Absenteeism Inferior Product Quality Good quality is relative Lack of maintenance and operating skills 21-31 Excessive Manufacturing Costs Low output Budget problems Overoptimistic sales forecast Supplier problems Water or power failures Overstocked inventory Resistance to lay off workers Supportive Activities 21-32 Quality control Inventory control Purchasing Must consider costs Have to seek out and develop suppliers Must know import procedures and have connections with key government officials Must monitor foreign exchange Supportive Activities Maintenance Goal is to ensure acceptable level of production Two alternatives Preventive Breakdown Technical Function Provides operations with manufacturing specifications Check quality of inputs and finished products Influential in selecting sources of supply 21-33 The ISO 9000 family is primarily concerned with "quality management". This means what the organization does to fulfil: - the customer's quality requirements, and - applicable regulatory requirements, while aiming to - enhance customer satisfaction, and - achieve continual improvement of its performance in pursuit of these objectives. The ISO 14000 family is primarily concerned with "environmental management". This means what the organization does to: - minimize harmful effects on the environment caused by its activities, and to - achieve continual improvement of its environmental performance.