Unit 2 Components of Computer Integrated Manufacturing: CAD/CAM

advertisement

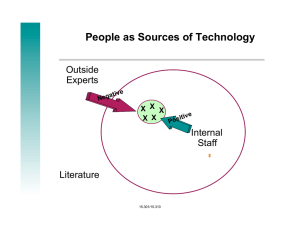

Unit 2 Components of Computer Integrated Manufacturing: CAD/CAM Computer-Integrated Manufacturing (CIM) • CIM is the manufacturing approach of using computers to control the entire production process. • This integration allows individual processes to exchange information with each other and initiate actions. • Through the integration of computers, manufacturing can be faster and less error-prone. CIM Components or Subsystems Include: • • • • • • • • • CAD CAM CAPP CAE ERP PLC CAE Computers Automated conveyors • • • • • • • • • CNC DNC Robotics Controllers FMS ASRS AGV Monitoring equipment Others Chapter 3 Product Design and Production Engineering Product Design and Production Engineering • These areas or departments are appropriate starting points for a detailed study of CIM • The two have embraced and encouraged the use of technology to reduce many tedious manual tasks • The initial creation of data starts in these areas • It is appropriate to have a common data base for all the data Sample CIM Sub-Systems Design Prod Eng Sales & Mark Man Design Information Flow • The product area is responsible for product design and analysis, material selection, and design and production documentation. • The production engineering area adds production standards for labor, process, and quality to the product data from design area. • Engineering release is responsible for product change control. The Design Process: A model Although there is a five-step design process, marketing plays a role before design engineering picks up Step 1: Conceptualization • Conceptualization (recognition of need & definition of the problem) – Form (shape, style, and character) – Fit (marketing fit or order winning criteria) – Function is determined with data from marketing • Divided into two: Typical and atypical • Typical design relates to repetitive design • Atypical design is for new product Step 2: Synthesis • Specification of material • Addition of geometric features • Inclusion of greater dimensional details to conceptualized design • Removes (filters) cost-adding features and materials • Employs DFM and DFA to ensure good design • About 70% of manufacturing cost is fixed in steps 1 and 2 activities Step 3: Analysis • Analysis means determining/describing the nature of the design by separating it into its parts to determine the fit between the proposed design and the original design goals • Two categories of analysis are mass properties and finite • Can be performed manually, but the computer increases analysis capability and reduces its time Step 4: Evaluation • Checks the design against the original specifications • Often requires construction of a prototype to test for conformance • Often employs rapid prototyping technique Step 5: Documentation • Creating all necessary product and part views in the form of working drawings, detailed and assembly drawings • Addition of dimensions, tolerances, special manufacturing notes, and standard components • Creation of part numbers, bill of materials, and detailed part specifications • Creation of product electronic data files used by manufacturing planning and control, production engineering, marketing and quality control Types of Data Generated in Design 1. Product names 2. Parts names 3. Part views 4. Design notes 5. Product materials 6. Bill of materials (BOM) 7. Material shapes and forms 8. Product quantities 9. Material suppliers 10. Products and parts dimensions 11. Product and parts tolerances 12. Part numbers 13. Drawing numbers 14. Product cost 15. Others Design Database Design Subsystem Material Suppliers Cost CAD Parts BOM Dimensions Part Nos. Types of CIM Subsystems CAE CAD Data Base CAPP CAM Chapter 4: Design Automation: CAD • CAD is the application of computers and graphics software to aid or enhance the product design from conceptualization to documentation. • Computer-aided drafting (CAD) automates the drawing or product documentation process. • Computer-aided design (CAD) is used to increase the productivity of the product designers. CAD System Capabilities Include: • Stand-alone PC and RISC-based CAD workstations at each engineering and design drafting location • The ability to share part data and product information with every station in the system CAD System Capabilities Include: • Access to part data files from the mainframe computers on the network • Shared peripheral resources such as printers and plotters • Concurrent work on the same project from multiple workstations, one of the reasons our team project needs a web site or data base. Basic CAD System Includes: • Keyboard • Input devices • Output devices Application of CAD to Manufacturing Systems • Concept and repetitive design (product, fixtures, gauges, pallets, mold, etc.) • Drafting • New product development management (PDM) and the Internet Computer-aided Manufacturing (CAM) CAM is the effective use of computer technology in the planning, management, and control of production for the enterprise. One of the major applications of CAM is in CAD/CAM where the part geometry created with CAD in the design engineering is used with CAM software to create machine code (NC/CNC) capable of machining the part. Computer-aided Manufacturing Includes the use of CAD files to: 1. Define the machine tool that will process the part 2. Define the stock or material 3. Define the features to machine 4. Generate operations 5. Select the origin 6. Generate tool paths 7. Simulate tool paths 8. Generate NC code 9. Download NC programs 10. Operate the CNC machine that will cut the part Data Communication Processes in CAD/CAM In CAD/CAM: • Data is created • Data is generated • Data is simulated • Data is transformed • Data is translated • Data is cleaned • • • • • • • Data is stored Data is communicated Data is manipulated Data is managed Data is analyzed Data is retrieved Data is interpreted Numerical Control (NC), Computer Numerical Control (CNC), and Distributive Numerical Control (DNC) • NC • CNC “behind the reader” system • DNC minicomputer system Computer Integrated Manufacturing Network Demands A common database for enterprise information flow Easy, accurate and instantaneous movement of part geometry files and product data between departments An enterprise network is a communications system that supports communications and the exchange of information and data among various devices connected to the network over distances from several feet to thousands of miles Data is Defined as: Information Statistics Facts Figures Number Records Report Account Minutes Proceedings How Data is Acquired and Used in a CIM Environment By Simple Data Acquisition, such as: Given Data Measurement Data By Data Generation (from CAD) By Data Importation (from CAD) By Data Analysis (from CAD) By Data Computing (from CAD) By Data Conversion (from CAD) By Data Formatting (from CAD) By Data Processing (from CAD) By Data Translation Product As Origin Of Data Des Lay Sup CUS M/H MA R Insp Mat e Product Ana l Pro c Cos t Wor Co m Unit Life Sch Design 1Conceptual design (parts and assembly) 2Synthesis (materials, geometry, DFM etc.) 3Analysis (meeting original design goals) 4Evaluation (using prototypes) 5Documentation (views, BOM, part numbers, dimensions etc.) 6Bill of materials (BOM) creation 7Product structure diagram Manufacturing 1MRP & daily production scheduling tasks 2Capacity & production activity control tasks 3Part manufacture (material processing) 4Product assembly 5Quality and inspection tasks 6Material handling tasks 7Storage & retrieval tasks CIM Database Sub-Systems of CIM Mkt Des CIM DATABASE Man Pro Eng System-To-System CAD CAM Worker-To-System Worker CAPP System-To-Worker CNC Machine Operator Worker-To-Worker CAD (Designer) CAE (Man Engineer) INS CA D CUS RO B BOM MA R CAP P MR P CIM DATABASE AG V CAE EST CN C DO C PUR AN A CA M Current Capabilities and Applications Networks Hardware communications Embedded computers Systems integration Problems to Overcome in Implementing CIM Interdepartmental support/politics CIM justification Intangible benefits Sample CIM Sub-Systems Design Prod Eng Sales & Mark Man INS CA D CUS RO B BOM MA R CAP P MR P CIM DATABASE AG V CAE EST CN C DO C PUR AN A CA M Design Sample CIM Network Man Prod Eng Sales & Mark