R h e ol o g i ca l

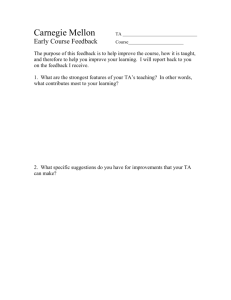

advertisement

R h e ol o g i ca l

Behav i o r

and

P o l ym er

Pr op er t i es

G. C. Berry

Department of Chemistry

Carnegie Mellon University

Colloids, Polymers and Surfaces

e-mail: gcberry@andrew.cmu.edu

web site: http://www.chem.cmu.edu/be rry

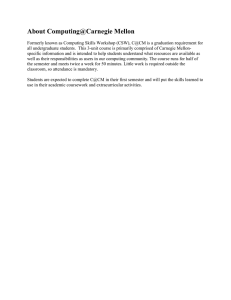

Carnegie Mellon

1

Int roduction

3

(12)

Rheological methods

16

(19)

Linear elastic parameters

26

(5)

Linear visc oelastic functions

33

(12)

Several viscoelastic experiments

44

(16)

Relations among linear visc oelastic functions

62

(10)

Examples of linear visc oelastic functions

73

(9)

Time-temperature equivalence

83

(9)

The glass transition temperature

93

(13)

The visc osity

107

(26)

Effects of polydispersity

134

(4)

Network formation

139

(13)

Isochronal B ehavior

153

(6)

Examples from the literature

160

(45)

Branched and li near metallocene polyolefins

161

(10)

Colloidal d ispersions

172

(9)

Wormlike Micelles

182

(4)

Deformation of rigid materials

187

(4)

Nonlinear shear behavior

192

(16)

209

(6)

Carnegie Mellon Linear and nonlinear bulk properties

2

Carnegie Mellon

Int roduction

Rheological methods

Linear elastic parameters

Linear visc oelastic functions

Several viscoelastic experiments

Relations among linear visc oelastic functions

Examples of linear visc oelastic functions

Time-temperature equivalence (Thermo-rheological simplicity)

The glass transition temperature

The visc osity

Effects of polydispersity

Network formation

Isochronal B ehavior

Examples from the literature

3

POLYMERS

NATURAL

PROTEINS

POLYNUCLEOTIDES

POLYSACCHARIDES

Carnegie Mellon

SYNTHETIC

GUMS

RESINS

THERMOPLASTIC

THERMOSETTING

ELASTOMERS

4

Some Common Elastomers, Plastics and Fibers

ELAS TOME RS

PLAS TI CS

Polyisoprene

polyethylene

polyisobutylene

polytetrafluoroethylene

poybutadiene

polystyrene

FIBERS

poly(methyl methacrylate)

Phenol-formaldehyde

Urea-formaldehyde

Melami ne-formaldehyde

Poly(vinyl chloride)

Polyurethanes

Polysiloxanes

Polyami de

Polyester

Polypropylene

Carnegie Mellon

5

Fraction of Molecules With

Molecular Weight M

Mn

Mw

Mz

Molecular Weight M

A Schematic Illustrat ion of a Typical Distribution

of Molecular We ights, showing Mn, Mw, and Mz

Carnegie Mellon

6

A generalized Average of molecular weights:

wµ is the weight f raction of polymer with molecular w eight Mµ:

M()

=

wµM µ

µ

Special C ases:

Number average:

=

M()/M = 1/ wµM µ

µ

Mw

=

M()/M()

Mz

=

M/M()

Mn

Weight average:

=

wµMµ

µ

z-average:

= wµMµ wµMµ

µ

µ

G. C. Berry "Molec ular Weight Distribution" Encyclopedia of Materials

Science and Engineering, ed. M. B. Bever, Pergamon Press, Oxford, 3759-68 (1986)

Carnegie Mellon

7

Specific Volume

Tm

Temperature

A schematic v-T diagram fo r a typical nonpolymeric material.

Carnegie Mellon

8

Specific Volume

Tg

Tm

Temperature

A schematic v-T diagram for a typical

semi-crystalline polymeric material.

Carnegie Mellon

9

Specific Volume

Tg

Temperature

A schematic v-T diagram fo r a typical

noncrys talline polymeric material.

Carnegie Mellon

10

Stress

Rigid Plastic

Flexible Plastic

Elastomer

Strain

Typical Stress-Strain Behavior for Plastics and Elastomers

Carnegie Mellon

11

F. W. Billme yer Jr. (1976):

J. Po lym. Sc i.: Symp. (1976) 55: 1-10

"…characterization of polymers is inherently more

difficult than that of other materials. Polymers are

roughly equivalent in comple xity to, if not more compl ex

than, other materials, at every physical level of

organization from microscopic to macroscopic…"

"We would wish, ideally, to characterize all aspects of a

polymer structure in enough detail to predict its

performance from first principles. I seriously doubt that

this will ever be possible, and I am sure that even if it

were, it would n ever be economically feasible."

Carnegie Mellon

12

Carnegie Mellon

13

2-D projection of a random arrangement of a chain

with 1000 non-overlapping bonds, each step

otherwise randomly selected

Carnegie Mellon

14

Mean chain dimensions:

For a linear chain with contour length L

(without excluded volume effects):

Mean square-end-to-end dimension:

RL2 = 2âL

â is the persistence length (2â is the Kuhn length)

for a flexible chain, â << L.

Mean square-radius of gyration:

RG2 = RL2 /6 = âL/3

Carnegie Mellon

15

Carnegie Mellon

Int roduction

Rheological methods

Linear elastic parameters

Linear visc oelastic functions

Several viscoelastic experiments

Relations among linear visc oelastic functions

Examples of linear visc oelastic functions

Time-temperature equivalence (Thermo-rheological simplicity)

The glass transition temperature

The visc osity

Effects of polydispersity

Network formation

Isochronal B ehavior

Examples from the literature

16

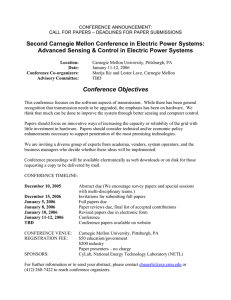

Schematic of Rheometer System

Computer System

for

Data Acquisition

and

Instrument Control

Shear Stress

vs

Time (Frequency)

Shear Strain

vs

Time (Frequency)

Normal Force

vs

Time (Frequency)

Temperature

vs

Time

Carnegie Mellon Output

Interfaces

Torque

Transducer

Force

Transducer

Position

Transducer

Shape

Transducer

Temperature

Transducer

Rheometer

17

CONTROLLED STRESS

IN TENSION

"Frictionless"

Bearing

Position

Transducer

Sample

Removable

Weight

Device

Carnegie Mellon

Tare

Output

Remov able Weigh t

Input

Controlled weight

Positi on Transduc er

Measure of sha ft positi on

Volt age (current)

Controll ed force

18

CONTROLLED DEFORMATION

IN TENSION

Drive Screws

Crosshead

Position

Transducer

Sample

Device

Carnegie Mellon

Output

Crosshead D rive

Input

Controlled Drive

Positi on Transduc er

Measure of sha ft positi on

Volt age (current)

Controll ed force

19

CONTROLLED STRESS RHEOMETER

Controlled

Torque

Drive

Angle

Position

Transducer

Shaft

"Frictionless mount"

Sample

Fixtures

Fixed Shaft

(Alternate: controlled rotation)

Carnegie Mellon

Device

Input

Output

Controlle d To rque Drive

Controlle d vol tage

Controlle d torque

Ang le Posit ion Transdu cer

Measure of shaft angl e

Volt age (current)

20

CONTROLLED DEFORMATION RHEOMETER

Controlled

Rotation

Drive

Angle

Position

T ransducer

Shaft

"Frictionless mount"

Sample

Fixtures

T orque T ransducer

(Force T ransducer)

Carnegie Mellon

Device

Input

Output

Controll ed Deformation D rive

Controll ed vo lt age

Controll ed shaft rotation

21

Electromagnetic Coils

I: A-F

II: a-f

d E

F

e

,

c

D

f

G

Iron Core

C

b

g

a

•

•

Carnegie Mellon

B

A h

H

Aluminum Cylinder

Attached to Rotor

Phasing of the currents in Coils I and II can produce a timedependent torque:

³

Constant torque amplitude

³

Sinusoidal torque amplitude

Torque amplitude may readily be varied over a factor of 10.

22

Parallel Plates

Sample

Fixtures

Height h

2R

Cone & Plate

Sample

Fixtures

Angle

2R

Concentric Cylinders

Sample

Fixtures

h

2R

Carnegie Mellon

R

23

Geometric Factors in Rheometry

a

Geometry

Measured

Translational geome tries

Parall el Plate

Force:

F

Stress:

= F /wb

Displa cement:

Force:

D

F

Strain:

= D/h

Displa cement:

D

Stress:

Strain:

= F /2š Rh

= D/Rln(1 + /R)

Rotational geometries

Parall el Plate

outer radius R; separation h

Torque :

M

Stress:

= (2r/R)M /R

Rotation:

Strain:

Cone & Plate

outer radius R; cone ang le š -

Torque :

Rotation:

M

Stress:

Strain:

= (3/2)M /R

= (1/)

Concentric Cyli nde rs

inne r radius R; gap ; heigh t h

Torque :

Rotation:

M

Stress:

Strain:

(R/2h)M /R

(r) (R/R) f(R,r)

width,w; breadth b; separation h

Concentric Cyli nde rs

inne r radius R; gap ; heigh t h

Calculated

(r) = (r/h)

2 1 + R

f(R,r) = (R/r) 1 + /2R

a

and are the shea r stress and s train, respectively

Carnegie Mellon

24

Functions and Parameters Used

Function/Para meter

Symbol

Units

Time

t

T

Frequency

Strain Co mponen t

ij

---

Elong ation al s train

---

Shea r strain

---

Rate of shea r

Ý, Ý

T-1

Stress Componen t

Sij

Shea r stress

ML-1T-2

Modulus

G, K, E

ML-1T-2

Compli anc e

J, B, D

M-1LT2

Viscosit y

Carnegie Mellon

T-1

ML-1T-2

ML-1T-1

25

Carnegie Mellon

Int roduction

Rheological methods

Linear elastic parameters

Linear visc oelastic functions

Several viscoelastic experiments

Relations among linear visc oelastic functions

Examples of linear visc oelastic functions

Time-temperature equivalence (Thermo-rheological simplicity)

The glass transition temperature

The visc osity

Effects of polydispersity

Network formation

Isochronal B ehavior

Examples from the literature

26

Linear elastic phenomenology

Shear stress

Shear strain

= J = (1/G)

Elongational s tress

Elongational s train

= D = (1/E)

Pressure ² P

Volume change ² V

² V/V = B² P = (1/K)² P

Carnegie Mellon

27

Linear Elastic Functions

Shear Compliance

J

Shear Modulus

G

Bulk Compliance

B

Bulk Modulus

K

Tensile Compliance

D = J/3 + B/9

Tensile Modulus

1/E = 1/3G + 1/9K

Carnegie Mellon

28

Linear elastic phenomenology

ij

uj

1 ui

= 2 x + x ;

j

i

u is the displacement

vector

2ij = J [Sij –

1

3

Sij = 2G [ij –

ij S] + (2/9)ij B S

1

3 ij

] + ij K

ij = 1 if i = j, and ij = 1 if i ° j

In this notation,

Shear stress = S 12

Shear strain = 212

Carnegie Mellon

29

Relations Among Linear Elastic Constants

K, G

E, G

K, E

K,

E,

G,

K

K

EG

33G – E

K

K

E

31 – 2

2G1 +

31 – 2

E

9KG

3K + G

E

E

3K(1 – 2)

E

2G(1 + )

G

G

G

3KE

9K – E

3K1 – 2

21 +

E

21 +

G

3K – 2G

6K + 2G

E

2G – 1

3K – E

6K

Carnegie Mellon

J = 1/G, B = 1/ K, D = 1/E

30

1 Pa = 1.45·10-4 psi

Graphite whisker

12

Carbon fiber

KevlarTM fiber

PE

chain direction

Cellulose

chain direction

Log E/Pa

11

PVOH

Avg textile fiber

10

PE

Amorphous Glass

9

Nonpolar

Polar

Interchain

stretch forces

Carnegie Mellon

Rotation

Bending

Stretch

Intrachain forces

Deformation Modes

31

Carnegie Mellon

Int roduction

Rheological methods

Linear elastic parameters

Linear visc oelastic functions

Several viscoelastic experiments

Relations among linear visc oelastic functions

Examples of linear visc oelastic functions

Time-temperature equivalence (Thermo-rheological simplicity)

The glass transition temperature

The visc osity

Effects of polydispersity

Network formation

Isochronal B ehavior

Examples from the literature

32

Linear Elastic Functions

Shear Compliance

J

Shear Modulus

G

Bulk Compliance

B

Bulk Modulus

K

Tensile Compliance

D = J/3 + B/9

Tensile Modulus

1/E = 1/3G + 1/9K

Carnegie Mellon

33

Linear Viscoelastic Functions

Shear Compliance

J(t)

Shear Modulus

G(t)

Bulk Compliance

B(t)

Bulk Modulus

K(t)

Tensile Compliance

D(t) = J(t)/3 + B(t)/9

Tensile Modulusa

1/Ê(s) = 1/3Ĝ(s) + 1/9K̂(s)

a. The superscript "ˆ" denotes a Laplace transform.

Carnegie Mellon

34

Linear viscoelastic phenomenology—

Stress Controlled

(t)

J(t – ti) i

=

=

i=

t

(t)

•0

d(u) J(t – u)

(u)

u

(t)

=

(t)

J(u)

•

= Jo(t) + •

du

(t

–

u)

u

0

(t)

•

duJ(t – u)

-•

2

1

(t)

(t)

Carnegie Mellon

t1

t2

t

35

Linear viscoelastic phenomenology—

Strain Controlled

(t)

=

G(t – ti) i

i=

=

(t)

•0

(t)

=

(u)

•

duG(t – u) u

-•

(t)

=

Go(t) +

d(u)G(t – u)

t

•

•0 du (t – u)

G(u)

u

(t)

(t)

(t)

Carnegie Mellon

t1

t2

t

36

Linear elastic phenomenology

ij

uj

1 ui

= 2 x + x ;

j

i

u is the displacement

vector

2ij = J [Sij –

1

3

Sij = 2G [ij –

ij S] + (2/9)ij B S

1

3 ij

] + ij K

ij = 1 if i = j, and ij = 1 if i ° j

In this notation,

Shear stress = S 12

Shear strain = 212

Carnegie Mellon

37

Linear viscoelastic phenomenology

uj

1 ui

ij = 2 x + x ;

j

i

u is the disp lacement vector

Sij(s)

2ij(t) = •

ds{J(t – s) s –

-•

t

1

3

S(s)

ij s

S(s)

+ (2/9)ij B(t – s) s }

ij(s)

Sij(t) = •

ds{2G(t – s) s –

-•

t

(s)

s

1

3 ij

(s)

+ ijK(t – s) s }

In this notation,

Shear stress (t) = S12 (t)

Shear strain (t) = 212(t)

Carnegie Mellon

38

Relation between G(t) and J(t)

1 t

t 0du

•

G(t – u) J(u)

= 1

s2Ĝ(s)Ĵ(s)

= 1

with Laplace transform:

Carnegie Mellon

39

Shear Compliance J(t) and

Recoverable Shear Compliance R(t)

R(t) = J(t) – t/ = J• – J• – Jo(t)

(t): Retardation Function

Shear Modulus G(t)

G(t) = Ge + Go – Ge(t)

(t): Relaxation Function

the (linear) viscosity, w ith 1/ = 0 for a solid,

Ge the equilibrium modulus, with Ge = 0 for a fluid,

Go the "instantaneous" modulus, with JoGo = 1, and

J•

the limit of R(t) for large t:

Solid: J • = Je = 1/Ge; equilibrium compliance

Fluid: J • = Js; steady-state recoverable compliance

Carnegie Mellon

40

Creep Shear Compliance J(t)

R(t) = J(t) – t/

= J• – J• – Jo(t)

Shear Modulus G(t)

G(t)

= Ge + Go – Ge(t)

Linear elastic solid:

1/ = 0,

J• = Je = 1/Ge,

(t) = (t) =

Linear viscous fluid:

1/ > 0,

Go = 0,

(t) = (t) = (t)

Linear viscoelastic soli d:

1/ = 0,

J• = Je = 1/Ge,

0 < (t) < (t) Š 1

Linear viscoelastic fluid:

1/ > 0,

J• = Js (= J oe),

0 < (t) < (t) Š 1

Bulk Compli ance

B(t)

= Be – Be – Bo(t)

Bulk Modulus

K(t)

= Ke + Ko – Ke(t)

41

Carnegie Mellon

42

Simple example of the relation between G(t) and J(t)

Maxwell fluid:

G(t) = Goexp(- t/);

J(t) = Js + t/;

= /Go

Js = Jo = 1/Go

R(t) = Js

Note: (t) = exp(-t/) and (t) = 0 for this model.

Carnegie Mellon

43

Often used relations for (t) and (t)

A weight set of exponentials with N relaxation times:

N-1

(t) =

exp(–t/ ) = J

i

i

m

N

(t)

= exp(–t/ ) =

G

i

1

i

1

•

•

dln L()exp(–t/)

-•

–

J

•

o

1

•

•

dln H()exp(–t/)

o – Ge -•

Notes: i = i = 1, and

m is equal to 0 o r 1 for a solid and flu id, resp.

m0 > 1 > 1 > … > i > i > i+1 > … > N-1 > N

(The contribution 0 is absent for a flu id)

Carnegie Mellon

44

Carnegie Mellon

Int roduction

Rheological methods

Linear elastic parameters

Linear visc oelastic functions

Several viscoelastic experiments

Relations among linear visc oelastic functions

Examples of linear visc oelastic functions

Time-temperature equivalence (Thermo-rheological simplicity)

The glass transition temperature

The visc osity

Effects of polydispersity

Network formation

Isochronal B ehavior

Examples from the literature

45

(b) Stress Relaxation

(t) = o

(t)

0

(•

)

0

(t) = a + bt

R()

Strain

Strain

o

Stress

Stress

(a) Creep & Recovery

(t) = o

(t)

t = Te

0

0

= t - Te

t

t

Tim e

Tim e

(c) Ramp Deformation & Recovery

o

Stress

Stress

(t = Te )

(d) Sinusoid Deformation

(t)

0

(t)

P = 1/2

( )

R

o

Strain

Strain

0

(t)

0

.

(t) = t

t = Te

0

= t - Te

t

Tim e

Carnegie Mellon

Tim e

46

Creep and recovery w ith a step shear stress

Stress

Stress history:

(t) = 0

t <0

(t) = o

0 Š t Š Te

(t) = 0

t > Te

(t) = o

0

Strain

(t) = a + bt

R() = (t = T e) - (t)

(t)

t = Te

0

t

Carnegie Mellon

q

= t - Te

Time

47

The strain in creep for t Š T e:

(t)

t

= o•

du J(t – u) (u -

0

= oJ(t) = oR(t) + t/

Carnegie Mellon

48

The strain in creep for t Š T e:

(t)

t

= o•

du J(t – u) (u -

0

= oJ(t) = oR(t) + t/

The strain for = t – T e > 0 in recovery:

Te

t

(t) = o•0 du J(t – u) (u - 0) – o•

du J(t – u) (u - Te)

T

e

() = oJ( + Te) – J() = oR( + Te) – R() + Te/

Carnegie Mellon

49

The strain in creep for t Š T e:

(t)

t

= o•

du J(t – u) (u -

0

= oJ(t) = oR(t) + t/

The strain for = t – T e > 0 in recovery:

T

t

(t) = o•0edu J(t – u) (u - 0) – o•

du J(t – u) (u - Te)

T

e

() = oJ( + Te) – J() = oR( + Te) – R() + Te/

The recoverable strain R() = (Te) – (t) for > 0:

R() = o{J(Te) – J( + Te) – J()}

Carnegie Mellon

= o{R() + R(Te) – R( + Te)}

50

Stress relaxation after a step shear strain

Strain h istory:

(t) = 0

t<0

(t) = o

t •0

Stress

o

(t)

)

(•

Strain

0

(t) =

o

0

t

Carnegie Mellon

Time

51

The stress response for t > 0:

t

(t) = o•

du G(t – u) (u - 0) = oG(t)

0

= o{Ge + (Go – Ge)(t)}

(•) = oGe

Carnegie Mellon

52

Recovery after a ramp shear strain

Strain history:

Stress history:

(t) = 0

t <0

(t) = Ýt

0 Š t Š Te

(t) = 0

t > Te

Stress

(t = T e )

(t)

0

Strain

R(q) =

(t = T

e)

- (t)

.

(t) = t

t = Te

0

=t-T

t

e

Time

Carnegie Mellon

53

The stress response for t Š Te :

t

t

(t) = Ý•

du G(t – u) = ÝGet + (Go – Ge)•

ds (s)

0

0

For a fluid in steady-state deformation, = Ý

, or

•

= (•)/Ý

= Go •

ds (s)

0

The strain for t > Te:

Te

(t) = 0 = Ý•0

(u)

du G(t – u) + •

du G(t – u) u

Te

t

For large Te and t, (full recoil after steady flow) it can be shown

that for a fluid this give s:

c Js =

Carnegie Mellon

•

•

•0 ds s(s)/•0 ds (s)

54

Carnegie Mellon

55

The strain response for t > 0:

t

(t) = o•

du J(t – u)cos(u)

0

In the steady-state limit with large t :

(t) = o{J'()sin(t) – J''()cos(t)}

In-ph ase (or real or storage) dyna mic compliance:

•

J'() = J• – J• – J o•

ds(s)sin(s)

0

Out-of-phase (or imaginary or loss) dyn amic compliance

•

J"() = (1/) + J• – J o•

ds(s)cos(s)

0

Carnegie Mellon

56

Alternatively

(t) = o |J*()|sin t –

"Dynam ic compliance":

2

2

2

|J*()| = J'() + J"()

Phase angle ():

tan () = J"()/J'()

For small :

J'() - J•,

Carnegie Mellon

J"() - 1/,

and

J"() – 1/ -

57

Oscillation with a si nusoid s hear strain

Strain his tory: (t) = 0

t<0

(t) = osin(t)

t •0

The stress response for t > 0 is giv en by

t

(t) = o •

du G(t – u)cos(u)

0

In the steady- state limit with large t,

(t) = o{G'()sin(t) + G''()cos(t)}

In-ph ase (or real or storage) dyna mic compliance:

•

G'() = Ge + Go – Ge•0 ds(s)sins)

Out-of-phase (or imaginary or loss) dyn amic compliance

•

Carnegie Mellon

G''() = Go – Ge•0 ds(s)cos(s)

58

Alternatively

(t) = o |G*()|sin t +

"Dynam ic compliance":

|G*()| = G'() + G"()

2

2

2

Phase angle ():

tan () = G"()/G'()

For small :

•

ds

0

G'() - Ge + Go – G e•

s(s) fluid

( Js

•

flu id

G''() = Go – Ge•

ds(s)

0

Carnegie Mellon

59

Exact relations among the dynam ic modul i and comp liances:

|G*()||J*()| = 1

2

J'() = G'()/|G*()|

2

J"() = G"()/|G*()|

2

G'() = J'()/|J*()|

2

G"() = J"()/|J*()|

tan () = J"()/J'() = G"()/G'()

Carnegie Mellon

60

The dynamic viscosity:

In-pha se with the s train rate:

'() = G"()/

Out-of-pha se with the s train rate:

"() = G'()/

For small :

•

'() = Go – Ge•

ds(s)

0

flu id

•

fluid

''() - Ge/ + Go – G e•

ds

s(s)

Js

0

Carnegie Mellon

61

Carnegie Mellon

Int roduction

Rheological methods

Linear elastic parameters

Linear visc oelastic functions

Several viscoelastic experiments

Relations among linear visc oelastic functions

Examples of linear visc oelastic functions

Time-temperature equivalence (Thermo-rheological simplicity)

The glass transition temperature

The visc osity

Effects of polydispersity

Network formation

Isochronal B ehavior

Examples from the literature

62

Linear Viscoelastic Functions

Shear Compliance

J(t)

Shear Modulus

G(t)

Bulk Compliance

B(t)

Bulk Modulus

K(t)

Tensile Compliance

D(t) = J(t)/3 + B(t)/9

Tensile Modulusa

1/Ê(s) = 1/3Ĝ(s) + 1/9K̂(s)

a. The superscript "ˆ" denotes a Laplace transform.

Carnegie Mellon

63

Relation between G(t) and J(t)

1 t

t 0du

•

G(t – u) J(u)

= 1

s2Ĝ(s)Ĵ(s)

= 1

with Laplace transform:

Carnegie Mellon

64

J(t)

8

Log(Compliance/cgs)

R(t)

-6

6

1/G(t)

G(t)

-8

0

2

4

6

8

10

4

12

Log(Modulus/cgs)

-4

14

Log (Time/sec)

Carnegie Mellon

65

J(t)

8

Log(Compliance/cgs)

R(t)

-6

6

1/G(t)

G(t)

-8

2

0

4

6

8

10

4

12

Log(Modulus/cgs)

-4

14

Log (Time/sec)

-4

Log(Compliance/cgs)

-6

J”(w)

6

-8

G”(w)

4

G’(w)

Log(Modulus/cgs)

8

J’(w)

-10

-14

-12

-10

-8

-6

-4

-2

0

Log(Frequency/sec -1)

Carnegie Mellon

66

-4

Log(Compliance/cgs)

G(t)

J’(w)

-6

6

-8

4

G’(w)

0

2

4

6

8

10

Log (Time/sec) & –Log(Frequency/sec

12

Log(Modulus/cgs)

8

R(t)

14

-1)

Figure 14

Carnegie Mellon

67

An often used relation between G(t) and J(t)

A weight set of exponentials with N relaxation times:

N-1

(t) =

1

•

i exp(–t/i) =

•

dln L()exp(–t/)

J• – Jo -•

m

N

(t) =

i exp(–t/i) = Go 1– Ge •-•• dln H()exp(–t/)

1

Notes: i = i = 1, and

m is equal to 0 or 1 for a solid and fluid

0 > 1 > 1 > … > i > i > i+1 > … > N-1 > N

(0 absent for a fluid)

Carnegie Mellon

68

Determination of L() (or the i-i set) from J(t)

(Similar considerations apply to the determination of

H() (or the i-i set) from G(t))

Derivative methods for L():

1st Approx.:

L()

-

M(m) [R(t)/ln t]t =

M(m) =

2nd Approx.:

Carnegie Mellon

L()

-

lnL()/ln (interative)

[J(t)/ln t – J(t)/ln t)]t = 2

69

Carnegie Mellon

70

Determination of L() (or the i-i set) from J(t)

(Similar considerations apply to the determination of

H() (or the i-i set) from G(t))

Inverse transform methods for i-i:

The inverse transform is "ill-posed", and a stable

solutions requires constraints (e.g., i • 0)

In an often used strategy, a set of logarithmically spaced

i are chosen such that the span in 1/I does not exceed

the time span in the experimental data. A constrained

nonlinear least squares analysis is then used to

determine the i. Commercial packages are available for

this transform.

Carnegie Mellon

71

Carnegie Mellon

72

Carnegie Mellon

Int roduction

Rheological methods

Linear elastic parameters

Linear visc oelastic functions

Several viscoelastic experiments

Relations among linear visc oelastic functions

Examples of linear visc oelastic functions

Time-temperature equivalence (Thermo-rheological simplicity)

The glass transition temperature

The visc osity

Effects of polydispersity

Network formation

Isochronal B ehavior

Examples from the literature

73

Carnegie Mellon

74

Carnegie Mellon

75

H( )

Go

'() = G''()

t/

G(t)

tan ()

L( )

J(t)

Jo

slope = 1/3

slope = 1

logor log

log t

log

Low Molecular Weight Glass Former

Go

G(t)

t/

H( )

'() = G''()

slope = -1/2

tan ()

slope = 1

J(t)

Jo

slope = 1/3

L( )

logor log

log t

log

Polymeric Fluid with M < Me

Go

G(t)

t/

slope = -1/2

Jo

JN

'() = G''()

H( )

GN

tan ()

slope = 1

L( )

J(t)

slope = 1/3

log t

Carnegie Mellon

logor log

Polymeric Fluid with M >> Me

log

76

log (L( )/Pa)

log (R(t)/Pa)

-4

Js

-6

Slope = 1/3

Narrow MWD

-8

-4

Slope = 1/3

-6

3

2

1

-8

-4

-2

0

Narrow MWD

2

4

6

8

10

log (t/s) or log (/s)

Carnegie Mellon

77

Peak I with L() linear in 1/3 before the peak decreases sharply to

zero.

The behavior ascribed to peak I, first reported by Andrade, is

seen in a variety of materials, such as metals, ceramics,

crystalline and glassy polym ers and small organic mole cules;

the decrease of L() to zero being eviden t in examples of the

latter.

The area under peak I provides the contribution JA – Jo to the

total recoverable compliance J s.

It seems likely that th e mechan ism giving rise to peak I may be

distinctly different from the largely entropic origins of peaks II

and III described in the following.

Carnegie Mellon

78

log (L( )/Pa)

log (R(t)/Pa)

-4

Js

-6

Slope = 1/3

Narrow MWD

-8

-4

Slope = 1/3

-6

3

2

1

-8

-4

-2

0

Narrow MWD

2

4

6

8

10

log (t/s) or log (/s)

Carnegie Mellon

79

Peak II that inc reases in peak area with increasing M until reaching

a certain level, beyond which the peak is inva riant with increasing

M, both in area and position in

Peak II is ascribed to Rouse-like modes of motion, ei ther fluidlike for low molecular weight in the range for which the area

increases with M, or pseudo-solid like (on the relevant time

scale) in the range o f M after peak III develops.

For low molecular weight, the Rou se model give s the area of

peak II as

Js – (JA + Jo) = (2M/5RT).

For the pseudo-solid like behav ior, obtaining when peak III has

developed, reflecting the e ffects of intermolecular

entangl ement, the a rea of peak II becomes inva riant with M and

given by

JN – (JA + Jo) = (Me/RT).

Carnegie Mellon

80

log (L( )/Pa)

log (R(t)/Pa)

-4

Js

-6

Slope = 1/3

Narrow MWD

-8

-4

Slope = 1/3

-6

3

2

1

-8

-4

-2

0

Narrow MWD

2

4

6

8

10

log (t/s) or log (/s)

Carnegie Mellon

81

Peak III that deve lops as peak II area ceases to increase with

increasing M, with peak III developing an a rea invariant with

M, and a maximum at MAX that mov es to larger as MAX

(M/Mc)3.4 for M > Mc

The area under peak III, a lso invariant with M, ascribed to the

effects of chain entang lements is given by

2+s

Js – (JN + JA + Jo) = (kMe/ RT),

where k is in the range 6-8 in most cases, and

s - 2( – 1)/(3 – 2) - 0 to 1/4 with = ln RG2 /ln M

Overall,

= (2M/5RT)1 + (

1+s

M/kMc)

2.2

2.0

2

1.8

1.6

S

Log (J ) + Cst.

Js – (JA + Jo)

1.4

1.2

1.0

Carnegie Mellon

1.0

1.5

2.0•

~

Log (X)

2.5

3.0

3.5

82

Carnegie Mellon

Int roduction

Rheological methods

Linear elastic parameters

Linear visc oelastic functions

Several viscoelastic experiments

Relations among linear visc oelastic functions

Examples of linear visc oelastic functions

Time-temperature equivalence (Thermo-rheological simplicity)

The glass transition temperature

The visc osity

Effects of polydispersity

Network formation

Isochronal B ehavior

Examples from the literature

83

Consider the following r educed exp ressions:

[J(t/c) – J o]/Js

= [R(t/c) – J o]/ Js + t/ Js

[J(t/c) – J o]/ Js

= [R(t/c) – J o]/ Js + t/c

c

= Js'(0) (=

Js)

The "time–temperature equivalence" approximation:

[J(t/c) – J o]/Js is a singl e-valued function of t/c over a range o f

temperature.

Although rarely, i f ever, truly accurate for all temperature, it is

never-the-less a useful and widely us ed app roximation for use with

materials exhibit ing no phase transition over the temperature

range of interest.

Carnegie Mellon

84

Since c may not be kno wn over the range o f temperature of

interest, it is often useful to "reduce" data to a common reference

temperature TREF . Formally, this may be accomplished with

[J(t) – Jo]/bTJs(TREF) = [R(t) – Jo]/bTJs(TREF) + t/bTJs(TREF)

[J(t) – Jo]/bTJs(TREF) = [R(t) – Jo]/bTJs(TREF) + t/hTbTc(TREF)

[J(t/aT) – Jo]/bT = [R(t/aT) – Jo]/bT + t/hTbT(TREF)

[J(t/aT) – Jo]/bT = [R(t/aT) – Jo]/bT + t/aT(TREF)

bT

= b(T, TREF ) = Js(T)/Js(TREF )

hT

= h(T, TREF ) = '(0)[T]/'(0)[TREF ] {=(T)/(TREF )}

aT

= bT hT

Carnegie Mellon

85

Carnegie Mellon

86

bT = b(T, TREF ) = Js(T)/Js(TREF )

hT = h(T, TREF ) = '(0)[T]/'(0)[TREF ] (= (T)/(TREF ))

aT = bT hT

log R(t)/bT

0

T3 < T2 < T1

-2

-4

T3

T2

T1

-6

0

2

4

6

8

log t

H. Markovitz J. Polym. Sci. Symp. No. 50: 431-56 (1975)

Carnegie Mellon

87

Carnegie Mellon

88

4

T1 (Highest)

2

Experimental

Time Range

T2

log (J(t)/Pa)

0

T3

-2

T4

-4

T5

-6

T6

-8

T7 (Lowest)

-10

-2

0

2

4

6

log (t/s)

Carnegie Mellon

89

4

T1 (Highest)

2

Experimental

Time Range

T2

log (J(t)/Pa)

0

T3

-2

T4

-4

T5

-6

T6

Hypothetical example of

time-temperature superposition

(bT = 1).

-8

T7 (Lowest)

-10

-4

-2

0

2

4

6

8

10

log (t/s) or log (aT-1t/s)

Carnegie Mellon

90

Carnegie Mellon

91

Carnegie Mellon

92

Carnegie Mellon

Int roduction

Rheological methods

Linear elastic parameters

Linear visc oelastic functions

Several viscoelastic experiments

Relations among linear visc oelastic functions

Examples of linear visc oelastic functions

Time-temperature equivalence (Thermo-rheological simplicity)

The glass transition temperature

The visc osity

Effects of polydispersity

Network formation

Isochronal B ehavior

Examples from the literature

93

Specific Volume

Tg

Temperature

A schematic v-T diagram fo r a typical

noncrys talline polymeric material.

Carnegie Mellon

94

A Free Volume Model:

(vf)i = (v – v o)i at a certain position r i,

v = (specific) volume

vf = free volume

vo = occupied volume

Carnegie Mellon

95

Carnegie Mellon

96

The glass transition temperature Tg

Tg depends on both intramolecular conformation and

intermolecular interactions.

Various Mod els/Treatments:

Iso Free Volume:

f(Tg) =

constant

Iso Viscous:

(Tg) =

constant

Iso Entropic:

² S(Tg) =

constant

None of these are fully s atisfactory are free of arbitrary

assumption s, and all contain pa rameters that can no t be

independ ently evaluated.

The free volume and entropic mod els provide similar expectations

re the dependen ce of Tg on chain l ength and dilu ent.

Carnegie Mellon

97

120

PMMA

T g (°C)

100

80

60

40

0

0.2

0.4

0.6

0.8

1

Syndiotactic fraction

Carnegie Mellon

98

Estimation of Tg and Tm via Group Contributions

Tg

-

M-1Yg,i

Tm

-

M-1Ym,i

The Y x,i represent molar group contributions to the relevant property

Higher order approximations a re available for both cases

D. W. van Krevelen, Properties of polymers : their correlation with chemical structure, their

numerical estimation and prediction from additive group contributions, 3rd Ed., Elsevier;

Amsterdam ; New York, 1990.

Carnegie Mellon

99

Carnegie Mellon

100

Carnegie Mellon

101

Carnegie Mellon

102

2.4

2.2

boyer

kre ve len avg

kre ve len cal c

Tm /Tg

2.0

1.8

1.6

1.4

1.2

200

300

400

500

600

700

Tm /K

D.W. Van Krevelen, op cit

R. F. Boyer, Rubber Reviews 36:1303-421

Carnegie Mellon

103

Both free volume and entropic models give results that may be cast

in the forms:

Tg(M) -

Tg (•

) {1 + kM/Mn}

w

1

1 - w

w + R1(1 - w)

=

+ R

Tg(w)

Tg;DIL

Tg(Mn)

Both KM and R are model specific parameters, best evaluated

experimentally.

For example, in the free volume model, KM and R arise from the

extra free volume provided by chain ends and diluent, respectively:

typ ically, R is in the range 0.5 to 1.5.

Note, that if Tg;DIL > Tg(Mn), then Tg(w, Mn) is increased by the

diluent.

[G. C. Berry J. Phys. Chem. 70:1194-8 (1966) ]

Carnegie Mellon

104

120

100

T g(°C)

Free Radical

p(Syndio) ~ 0.76

80

p(Syndio) ~ 0.50

60

0

1

2

3

4

5

10 4/Mn

Carnegie Mellon

105

Carnegie Mellon

106

Carnegie Mellon

Int roduction

Rheological methods

Linear elastic parameters

Linear visc oelastic functions

Several viscoelastic experiments

Relations among linear visc oelastic functions

Examples of linear visc oelastic functions

Time-temperature equivalence (Thermo-rheological simplicity)

The glass transition temperature

The visc osity

Effects of polydispersity

Network formation

Isochronal B ehavior

Examples from the literature

107

(T) - LOC(T) F (large scale structure, T)

- LOC(T) F (large scale structure)

"Arrheniu s" form:

LOC(T) expW/T

if T > (1.5-2)Tg

For melts of crystalline polym ers, Tm > (1.5-2)Tg, permitting use

of this simple form.

"Vogel-Fulcher" form:

For amorphous polymers with 0 Š (T – Tg)/K < - 200:

LOC(T) expC/(T – To)

Carnegie Mellon

if T < (1.5-2)Tg

108

Carnegie Mellon

109

The temperature dependence of the viscosity:

(T) - LOC(T) F (large scale structure, T)

- LOC(T) F (large scale structure)

For amorphous polymers with 0 Š (T – Tg)/K < - 200:

LOC(T) expC/(T – To)

if T < (1.5-2)Tg

"WLF form":

LOC(T)/LOC(TREF ) = expC/(T – To) – C/(TREF – To)

C(T – TREF )

= exp –

REF (T – TREF + REF )

with C and To being con stants, and ²

Carnegie Mellon

REF

= TREF – To.

110

If TREF = Tg then

K (T – T g)

LOC(T)/LOC(Tg) = exp– T – T +

g

where = Tg – To and K = C/.

For many polym ers:

K = 2300 K and = 57.5 K

These parameters may be in terpreted in t erms of the "free-volume"

model

Carnegie Mellon

111

Carnegie Mellon

112

Viscosity of Polymers and Their Solutions

M, c, T - LOC(T) F (M, c, T)

Dilute solutions

LOC(T) - Solvent(T)

F (M, c, T) - 1 + []c + …

[] = šN AKRG2 RH/M

G. C. Berry J. Rheology 40:1129-54 (1996)

Carnegie Mellon

113

F (M, c, T) - 1 + []c + …

[] = šN AKRG2 RH/M

Spherical Particles

R = RH = (5/3)1/2RG;

K = 50/9

[]c = (5/2)

Carnegie Mellon

114

F (M, c, T) - 1 + []c + …

[] = š NAKRG2 RH/M

Flexible Chain L inear Polyme rs

RG2 = (âL/3)2; the cha in expansion factor

â the pe rsistence length

Carnegie Mellon

115

F (M, c, T) - 1 + []c + …

[] = šN AKRG2 RH/M

Flexible Chain Linear Polyme rs

RG2 = (âL/3)2; the chain exp ansion factor

â the persistence length

High M:

3RH/2 - RG L1/2;

K - 10/3

ML[] = šN A(20/9)(â/3)3/23L1/2 = '(â/3)3/23L1/2

Carnegie Mellon

116

F (M, c, T) - 1 + []c + …

[] = šN AKRG2 RH/M

Flexible Chain Linear Polyme rs

RG2 = (âL/3)2; the chain exp ansion factor

â the persistence length

High M:

3RH/2 - RG L1/2;

K - 10/3

ML[] = šN A(20/9)(â/3)3/23L1/2 = '(â/3)3/23L1/2

Low M:

RH - L;

ML[] = šN A(â/3)L

Carnegie Mellon

K - 1

(Debye)

117

Flexible Chain B ranched Polymers

ML[] = š NAKRG2 RH/L

g = RG2 /(RG2 )LIN; calculated = 1

High M:

h = RH/(RH)LIN;

h - g1/2

K - KLINf(g, shape)

[] = f(g, shape)g3/2[]LIN

Carnegie Mellon

118

Flexible Chain B ranched Polymers

ML[] = š NAKRG2 RH/L

g = RG2 /(RG2 )LIN; calculated = 1

High M:

h = RH/(RH)LIN;

h - g1/2

K - KLINf(g, shape)

[] = f(g, shape)g3/2[]LIN

Star:

[] = g1/2[]LIN

Comb:

[] = g3/2[]LIN

Rando m:

[] = g[]LIN

Carnegie Mellon

119

Flexible Chain Branched Polymers

ML[] = šN AKRG2 RH/L

g = RG2 /(RG2 )LIN; calculated = 1

High M:

h = RH/(RH)LIN;

h - g1/2

K - KLINf(g, shape)

[] = f(g, shape)g3/2[]LIN

Star:

[] = g1/2[]LIN

Comb:

[] = g3/2[]LIN

Random:

[] = g[]LIN

Low M:

[] = šN AKRG2 RH/LML

RH - L;

Carnegie Mellon

K - 1

120

[] = g[]LIN

(c)

2

1

Entanglement

Interactions

log([](c)/[])

1

0.8

Scaled screening

of

Intramolecular

Interactions

0.6

0.4

0.2

Virial

Expansion

0

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

log(RG/L)

Carnegie Mellon

121

Viscosity of Polymers and Their Solutions

M, c, T - LOC(T) F(M, c, T)

Concentrated solutions and undiluted linear flexible

chain polymers

LOC(T) - LOC(Tg)exp{–K(T – Tg)/(T – Tg +² )}

F(M, c, T) - 1 + [](c)c

Low M (Rouse behavior; = 1):

~

~

F(M, c, T) - 1 + X - X

~

X = [](c)c;

ML[](c)

=

a modified Fox parameter

š NA(â/3)L;

([](c) ind ependen t of c in this

range )

Carnegie Mellon

122

Carnegie Mellon

123

High M (Entang lement regime)

~ ~ ~

~ ~ ~

F (M, c, T) - 1 + XE (X/Xc ) - XE (X/Xc )

~ ~

~ ~

E (X/Xc ) = {1 + (X/Xc )4.8}1/2

~

Xc = šN A(â/3)Mc - 100

for many polym ers

~

Mc = Xc/šN A(â/3) - 100/šN A(â/3)

Carnegie Mellon

124

Carnegie Mellon

125

The dependenc e of Tg on the diluent conc entration must be

considered for polymer solutions:

K (T – Tg)

LOC(T)/LOC(Tg) = exp –

T – Tg +

where = Tg – To and K = C/².

For many polyme rs:

K = 2300 K and = 57.5 K

² is approximately independen t of the polym er concent ration

Carnegie Mellon

126

400

Polystyrene/Dibenzyl ether

Temperature/K

300

Tg

200

To

100

Tg – To

0

0

0.2

0.4

0.6

0.8

1

Volume Fraction Polymer

G. C. Berry and T. G Fox Adv. Polym. Sci. 5:261-357 (1968)

Carnegie Mellon

127

1.0

5

0.75

4

0.50

log( /Pa·s)

3

2

0.25

1

0.125

0

-1

-2

3

4

5

6

log( M w)

Carnegie Mellon

128

Viscosity of Polymers and Their Solutions

M, c, T - LOC(T) F(M, c, T)

Branched Chain Polymers (Concentrated or undiluted)

LOC(T) - [LOC(T)]LIN; Rare excep tions to this kno wn

F(M, c, T) - 1 + [](c)c

ML[](c)

=

š NA(â/3) gL

~ ~ ~

F(M, c, T) - 1 + XE(X/Xc );

~

X = [](c)c

~ ~

~ ~

E(X/Xc ) = {1 + B(g, MBR /Mc)(X/Xc )4.8}1/2

B(g, MBR /Mc) - 1 unless the branch molecular MBR > Mc

~

Xc = š NA(â/3)Mc - 100 for many polym ers

Carnegie Mellon

129

6

Slope >3.4

Linear

Logc )

~~

4

Slope 3.4

2

Branched

0

Slope 1

-2

-2

0

2

Log (w)

Carnegie Mellon

130

Carnegie Mellon

131

Moderately Concentrated Solutions

(c)

2

1

Entanglement

Interactions

log([](c)/[])

1

0.8

Scaled screening

of

Intramolecular

Interactions

0.6

0.4

0.2

Virial

Expansion

0

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

log(RG/L)

Carnegie Mellon

132

Viscosity of Polymers and Their Solutions

M, c, T - LOC(T) F(M, c, T)

Moderately Concentrated Solutions

LOC(T) - [LOC(T)]1c -=µ0LOC(T)]µc = ; µ - = c/

F(M, c, T) - 1 + [](c)c

ML[](c)

=

š NA(â/3)(c)2(RH(c)/L)L

~ ~ ~

F(M, c, T) - 1 + H(c)XE(X/Xc );

~

X = [](c)c

~ ~

~ ~

E(X/Xc ) = {1 + (X/Xc )4.8}1/2

~

Xc = š NA(â/3)Mc - 100 for many polym ers

[G. C. Berry J. Rheology 40:1129-54 (1996)]

Carnegie Mellon

133

Carnegie Mellon

Int roduction

Rheological methods

Linear elastic parameters

Linear visc oelastic functions

Several viscoelastic experiments

Relations among linear visc oelastic functions

Examples of linear visc oelastic functions

Time-temperature equivalence (Thermo-rheological simplicity)

The glass transition temperature

The visc osity

Effects of polydispersity

Network formation

Isochronal B ehavior

Examples from the literature

134

Molecular Weight Polydispersity

LOC(T) scales with Mn through Tg

LOC(T) scales with Mw, except pe rhaps for unusual

distributions

Peak I in L() is essentially unaffected by molecular weight

dispersion

Peak II in L() may comp rise two pieces:

i) an area proportional to LMzMz+1 /Mw, with the averages

calculated for chains with M < Me at volume fraction L, and

ii) an area proportional to (1 – L)Me for chains with M > Mc at

volume fraction 1 – L

Peak III in L() has an a rea proportional to

(1 – L)-2(Mz/Mw)2.5

The maxima for peak s II and III separate in as (1 – L)Mw

Carnegie Mellon

135

Theoretical treatments are usually ca st in terms of G(t), often in the

form:

G(t) = { wiGi(t) }

i

Gi(t) = shear modulus for chains with Mi

at weight fraction wi

For example:

= 1 in the "reptation mode l

= 1/2 in the "double-reptation" model

Carnegie Mellon

136

Carnegie Mellon

137

Theoretical treatments are usually ca st in terms of G(t), often in the

form:

G(t) = { wiGi(t) }

i

Gi(t) = shear modulus for chains with Mi

at weight fraction wi

For example:

= 1 in the "reptation mode l

= 1/2 in the "double-reptation" model

The effects of increased dispersity of molecular species is usually

most prominent in Peak III in L(), followed by effects in P eak II

in L(). This is seen in L() for a polym er undergoing

crosslinking to form a branched polymer, leading to a network

polymer

Carnegie Mellon

138

Carnegie Mellon

Int roduction

Rheological methods

Linear elastic parameters

Linear visc oelastic functions

Several viscoelastic experiments

Relations among linear visc oelastic functions

Examples of linear visc oelastic functions

Time-temperature equivalence (Thermo-rheological simplicity)

The glass transition temperature

The visc osity

Effects of polydispersity

Network formation

Isochronal B ehavior

Examples from the literature

139

log (L()/Pa)

-2

Cross link prior to

gelation

-4

-6

Initial

-8

-4

-2

0

2

4

6

8

10

log (t/s) or log (/s)

Carnegie Mellon

140

Incipient gelation

log (L()/Pa)

-2

?

Cross link prior to

gelation

-4

-6

Initial

-8

-4

-2

0

2

4

6

8

10

log (t/s) or log (/s)

Carnegie Mellon

141

Incipient gelation

log (L()/Pa)

-2

?

Cross link prior to

gelation

-4

-6

"Weak"

gel

"Gel”

Initial

-8

-4

-2

0

2

4

6

8

10

log (t/s) or log (/s)

Carnegie Mellon

142

Carnegie Mellon

143

Carnegie Mellon

144

Carnegie Mellon

145

Power-law behavior

G(t) = [Go – Ge](t) + Ge

J(t)

= Jo + (t) + t/

(t) = (Js – Jo)[1 – (t)]

Suppose that for all t (note, this involves permissible, but peculiar

behavior for large t):

(t) = (t/)

With this expression, and 1/ = 0:

[J'() – Jo]/Jo = µ(µ)cos(µš /2) ( )-µ

J"()/Jo = µ(µ)sin(µ š /2) ( )-µ

Use of the convolution integral relating J(t) and G(t) gives

(t) = Eµ(-kµt/)µ)

with Ge = 0 and 1/ = 0, where kµ = µ(µ) and

•

Carnegie Mellon

Eµ(x) =

(nµx + 1) :

n=0

n

The Mittag-Leffler function

146

For small µ,

G(t) - Go{1 + t/)µ}

For any µ, for large t/

G(t) Gosin(µ š) /µš t/)µ

G(t)J(t) sin(µ š) /µš < 1

(G'() – Ge)/(Go – Ge) (-) sin[(-)/2] ( )

G"()/(Go – Ge) (-) cos[(-)/2] ( )

[J'() – Jo]/Jo = µ(µ)cos(µš /2) ( )-µ

J"()/Jo = µ(µ)sin(µ š /2) ( )-µ

Carnegie Mellon

147

Bounded power-law behavior for (t) migh t be obtained in th e form

(t) = 1;

for t Š

= (/t); for < t Š , with 0 < µ < 1

= (q/t)m; for t > ,

with m > 1

where q = (/)m.Then,

G'() – Ge and G"() for << 1/;

G'() = Go and G"() = 0 for >> 1/;

(G'() – Ge)/(Go – Ge) (-) sin[(-)/2] ()

G"()/(Go – Ge) (-) cos[(-)/2] ()

for the interval 1/ < < 1/.

Carnegie Mellon

148

An alternativ e relation th at also exhibits partial power-law behavior is given

by:

(t)

n/m

n/m

=

(/i)

exp(–t/i)/

(/i)

i =

i =

where i = /im; m = 2 and n = 0 in the Rouse model.

For the intermediate int erval 1/ < < 1/,

(G'() – Ge)/(Go – Ge) {/2m sin[(-)/2]} ()

G"()/(Go – Ge) {/2m sin[(-)/2]} ()

CarnegieµMellon

where

= (1 + n)/m (µ =, for the Rouse model).

149

0

0

-2

-2

N = 1000

µ = n/(1 + m) = 1/2

N = 300

µ = n/(1 + m)

-4

µ = 1/3

m = 6; n = 1

-4

-6

0

log G'() or log G''()

-6

m = 4; n = 1

0

-2

-2

-4

-4

-6

0

µ = 1/2

m = 4; n = 1

m = 3; n = 0.5

0

-2

-2

-4

-4

m= 2; n = 0

-6

0

m = 1; n = 0.5

-2

0

-2

µ = 2/3

m =3; n = 1

-4

-4

0

2

4

6

log( c )

Carnegie Mellon

8

µ =1

m = 2; n = 1

-6

-8

0

2

4

6

log( c )

8

150

Carnegie Mellon

151

Carnegie Mellon

152

Carnegie Mellon

Int roduction

Rheological methods

Linear elastic parameters

Linear visc oelastic functions

Several viscoelastic experiments

Relations among linear visc oelastic functions

Examples of linear visc oelastic functions

Time-temperature equivalence (Thermo-rheological simplicity)

The glass transition temperature

The visc osity

Effects of polydispersity

Network formation

Isochronal B ehavior

Examples from the literature

153

ISOCHRONAL BEHAVIOR

•

In some cases, the temperature is scanned while the dynamic

properties are determined at fixed frequency; such experiments

might typically be reported as G'(;T) and tan (; T) or '(;T)

versus T, depending on the application.

•

Insofar as G'(c(T)) and G"(c(T)) as functions of c(T) are

independent of T, the isochronal plots are seen to be mappings

in which c(T) increases with decreasing temperature with:

K

c(T) expT - (Tg - )

•

For a reference temperature equal to the glass temperature Tg,

so that a = c(T)/c(Tg):

K T - Tg

ln a = ln – 1 + (T - Tg)

k + k(T - Tg) +

…

with the linear approximation valid for (T - Tg) << ; k = ln and

Carnegie Mellon

k= K /.

154

1

Log G' /Go

T - Tg = 0

0

Log tan

Log G' /G o and Log tan

-1

-2

-3

-4

-2

0

2

4

log (a T )

1

=1s

0

-1

Log tan

-1

Log G' /Go

-2

-3

Carnegie Mellon

-10

10

0

T - Tg

20

155

Carnegie Mellon

156

"Iso-chronal" behavior for Poly(v inyl C hloride);

(No rotational is omers for the side group)

10

Poly(vinyl chloride)

log G'/Pa

(Fixed )

8

tan = E"/E'

Tg

Main-chain rotation

0.1

0.01

-200

-100

0

100

Temperature (°C)

Carnegie Mellon

157

Carnegie Mellon

158

Carnegie Mellon

159

Carnegie Mellon

Int roduction

Rheological methods

Linear elastic parameters

Linear visc oelastic functions

Several viscoelastic experiments

Relations among linear visc oelastic functions

Examples of linear visc oelastic functions

Time-temperature equivalence (Thermo-rheological simplicity)

The glass transition temperature

The visc osity

Effects of polydispersity

Network formation

Isochronal B ehavior

Examples from the literature

160

Examples from the literature

Carnegie Mellon

Branched and li near metallocene polyolefins

Colloidal d ispersions

Wormlike Micelles

Deformation of rigid materials

Nonlinear shear behavior

Linear and nonlinear bulk properties

161

5

4

log G''()

3

2

log G'()

1

Unmodified Linear

0

-1

0

1

2

log

Metallocene polyethylenes

Claus Gabriel and Helmut Münstedt Rheol. Acta 38: 393-403 (1999)

Carnegie Mellon

162

Carnegie Mellon

Metallocene polyethylenes

Claus Gabriel and Helmut Münstedt Rheol. Acta 38: 393-403 (1999)

163

Carnegie Mellon

Metallocene polyethylenes

Claus Gabriel and Helmut Münstedt Rheol. Acta 38: 393-403 (1999)

164

Carnegie Mellon

Metallocene polyethylenes

Claus Gabriel and Helmut Münstedt Rheol. Acta 38: 393-403 (1999)

165

Carnegie Mellon

Metallocene polyethylenes

Claus Gabriel and Helmut Münstedt Rheol. Acta 38: 393-403 (1999)

166

0

log '( '(

-1

-4

log J'()/b

Unmodified Linear

-5

Modified Branched 1

Modified Branched 2

2

3

4

5

6

log '(0) b

U

Carnegie Mellon

M1

M2

log '(0)

3.28 3.68 4.00

log b

-0.7 0

0

167

log J(t) or log R(t). Pa-1

0

mLDPE-Linear

J(t)

mLDPE-Branched

LDPE-Branched

-2

R(t)

-4

-6

-2

0

2

4

log t/s

C. Gabriel and H. Münstedt Rheo. Acta, 38:393-403 (1 999)

Carnegie Mellon

168

From creep/recovery

Carnegie Mellon

169

log '()/'(0)

0

mLDPE-Linear

mLDPE-Branched

-1

LDPE-Branched

0

2

4

6

log '(0)

C. Gabriel and H. Münstedt Rheo. Acta, 38:393-403 (1 999)

Carnegie Mellon

170

Carnegie Mellon

171

Examples from the literature

Carnegie Mellon

Branched and li near metallocene polyolefins

Colloidal d ispersions

Wormlike Micelles

Deformation of rigid materials

Nonlinear shear behavior

Linear and nonlinear bulk properties

172

Colloidal dispersions:

Linear and nonlinear

viscoelastic behavior.

Dilute dispersion of spheres interacting via a hard-core

potential:

LOC{1 + (5/2) + k'(5/2) + …}

2

Carnegie Mellon

2

= volume fraction = c/

(5/2)

= c

LOC

-

solv.

k'

-

1.0

173

Concentrated dispersion of hard-core spheres:

Empirical relations:

-

LOC{1

– /n –5n /2

-

LOC{1

– (5/2)1 – /n –5n k'/2

1

1

2

2

designed to force agreement with the v iri al expans ion at least to order and ,

respectively,

n1

=

5/8 to give k' - 1.0

n1

=

max

- 0.64

Theoretical relations:

=

LOC{1 + (5/2) + k'1() + 2()(5/2)22}

1(): hyd rodyna mi cs

2(): thermodyna mi cs

1() + 2() =1

U:

Carnegie Mellon

1() - (4/5)(1 – /max)

2() - (1/5)(1 – /max)

(semi- empircial)

2

174

Carnegie Mellon

175

Concentrated dispersion of hard-core spheres:

Linear Viscoelastic Response:

'() = '(0) for small , as exp ected, but als o show a plateau '() - '(L) for a

regim e at an in termediate range of - L, before decreasing to zero wit h increasing

.

'(L) is estima ted wit h () = 0, reflecting the suppression o f thermodyna mi c

interactions at high

G'(L) - G1;

G1R3/kT2 - 0() for spheres of radius R

0() - 0.78('(L)/solv)g(2 , )

g(2 , ) is the radia l distribution at the contact cond iti on r/R = 2

Theory :

g(2, ) = (1 – /2)2/(1 – )3 for < 0.5 and

g(2, ) = (6/5)(1 – /max) for •0.5

Carnegie Mellon

176

Carnegie Mellon

177

Concentrated dispersion of hard-core spheres:

Linear Viscoelastic Response:

Theory:

'()

=

LOC{1 + (5/2) + k'1() + 2()(5/2)22}

'(L)

=

LOC{1 + (5/2) + k'1()(5/2)22}

J'EFF()

-1/2 for a rang e of < L

J'EFF(L)

-

1/G'(L) - 1/G1 - R3/kT20()

Carnegie Mellon

178

Carnegie Mellon

179

Concentrated dispersion of interacting spheres:

Van der Waals interactions

Electrostatic interactions among charged spheres

Interactions among spheres and a dissolved polymer

True or apparent yield behavior may obtain

Carnegie Mellon

180

Carnegie Mellon

170 nm beads (0.05 to 0.2 volume fraction), in 15% polystyrene solution

D. Meitz, L. Yen, G. C. Berry and H. Markovitz J. Rheol. 32:309-51 (1988)

181

Examples from the literature

Carnegie Mellon

Branched and li near metallocene polyolefins

Colloidal d ispersions

Wormlike Micelles

Deformation of rigid materials

Nonlinear shear behavior

Linear and nonlinear bulk properties

182

Wormlike micelles

Certain amphillic molecules organize to form curvilinear cylinders, or wormlike

micelles. For example, in an aqueous medium, the amphiphile might organize

with its hydrophobic parts aggregated in the interior of the cylinder, and its

hydrophopic pieces arranged on the "surface" of the cylinder

The micelle structure will exhibit a lifetime ruptu re for rupture of its components

If ruptu re is less than a longest rheological time constant rheol the intact wormlike

micelle would exhibit, then the rupture dynamics may dominate the observed

rheological behavior,

The chain may respond to a deformation by micellar dynamics similar to those

for a structure without rupture, abetted by the rupture process.

With one model, this approximates Maxwell behavior with a time constant

eff ective - ruptu reruptu re

Carnegie Mellon

183

Cetyl triethylammonium tosylate

-T

CTA+

hydrophobic

–

+

hydrophilic

+

+

+ + +

++

-

-

+ + +

+

+

+

+

+

+ +

+ + + +

micelles grow

10 nm

micellar

network

Schematic courtesy Dr. Lynn M. Walker

Carnegie Mellon

184

In an extreme case, the system might approximate behavior for the Maxwell model, with a single

relaxation time eff ectiveso that

J(t) = Js

+ t/;

with Js = eff ective

G(t) = (1/Js)exp(-t/eff ective)

With this simple model,

J'() = Js

2

'() = (1/Js)/[1 + (eff ective) ]

Carnegie Mellon

185

0

10%

-1

'/p J'()/Jp T (°C)

30

35

-2

◊ The rate of decrease of '() with

increasing for larger , to the extent

of an increase in '() with increasing

for the data on the less concentrated

Sample

40

p

-3

3

Calculated

2

◊ The increase of J'() above the imputed

Js for smaller for the data on the more

concentrated sample

p

1

-1

-2

20%

s

log J /Pa

0

-3

solvent

4. 5

-2

log

log '/ or log J'()/J

These data reveal several deviations

from simple Maxwell behavior, including:

4. 0

10%

3. 5

20%

-3

30

-4

-3

35

T emperature (°C)

-2

40

0

-1

1

2

◊ It may be likely that these samples exhibit

solid-like behavior with a Je at smaller

than the experimental range, and that Jp

is truly Js

◊ The relatively constant J'() is expected

with the Maxwell model, but this may be

fortuitous

log p J p

Carnegie Mellon

J. F. A. Soltero and J. E. Puig Langmuir 12: 141-8 (1996)

186

Examples from the literature

Carnegie Mellon

Branched and li near metallocene polyolefins

Colloidal d ispersions

Wormlike Micelles

Deformation of rigid materials

Nonlinear shear behavior

Linear and nonlinear bulk properties

187

Deformation of Rigid Materials

Creep and Recovery in Tension

Creep for 0 Š t Š Te

(t) = oD(t) = o[DR(t) + DNR(t)]

Recovery for = t – T e > 0

(, Te) = o[DR( + Te) – DR() + DNR(Te)]

R(, Te) = (Te) – (, Te)

= o{DR(Te) – DR( + Te) + DR()}

Carnegie Mellon

188

G. C. Berry J. Polym. Sci.: Polym. Phys. Ed. 14:451-78 (1976)

Carnegie Mellon

189

Andrade Creep (with DNR(t) = 0)

A frequently ob served nonlin ear behavio r

DR(t, o) = DA{1 + R(o)t1/3}

oR 106

(sec 1/3)

sinh(o/A)

R(o) - R()

; A a constant

o/A

30

299°C

20

231

50

10

34.5

0

0

20

40

60

80

100

/Mdyn/cm 2

Carnegie Mellon

190

Andrade Creep (with DNR(t) ° 0)

A nonrecoverable logarithmic creep is frequently obs erved under

larger stress:

DNR(t) - DL ln(1 + µt/DL)

(a)

µt/DL <<1

µt

(b)

D(t)/MPa

-1

3

2

1

0

0

5

10

(t/sec)1/3

Carnegie Mellon

15

20

0

5

10

15

20

25

(/sec)1/3 or [ + T )/sec] 1/3– ( /sec)1/3

191

Examples from the literature

Carnegie Mellon

Branched and li near metallocene polyolefins

Colloidal d ispersions

Wormlike Micelles

Deformation of rigid materials

Nonlinear shear behavior

Linear and nonlinear bulk properties

192

An "Incompressible" Isotropic Elastic Material

Suppose K >> G, then for infinitisimal strains

Sij = 2 G {ij – 3ij } – ij P

More generally, for finite strains:

-1

Sij = W1 Bij + W2Bij – ij P

Wi = Wi (I B;1, IB;2) –

ŽW

ŽIB;i

For simple extension:

f/A - 2(2 – -1)(W1 + W2/)

For simple shear:

S12 = 2(W1 + W2) G

Carnegie Mellon

S11 – S33 = 2W1 2 ;

S22 – S33 = – 2W2 2

193

An expansion of the strain energy function gives the

Mooney–Rivlin Equation for small deformations:

W - C1 (IB;1 – 3) + C2 (IB;2 – 3)

W1 = C1 and W2 = C2

For the original Kinetic Theory of Rubber Elasticity the

contributions to C1 are entropic in origin, and.:

2C1 = EkT = RT/MXL

2C2 = 0

stress

chains

E = Number of chains under

MXL = Molecular weight of

between crosslinks

The preceding estimates for C1 and C2 are not

accurate, and have been modified in more modern

Carnegie Mellon

theories, e.g., these give C 2 > 0.

194

An "Incompressible" Viscoelastic Material

Suppose K(t) >> G(t), then for infinitisimal strains

t

Sij(t) =

2 G(t

–

-•

ij(s)

s) s

–

ij

(s)

s ds – ijP

Several relations are proposed for finite strains,

including that due to Bernstein, Kearsley and Zapas::

t

Sij(t) =

U

2 I

B;1

-•

Carnegie Mellon

U

-1

B(t)ij(s) – I B(t)ij(s) ds – ijP

B;2

195

An "Incompressible" Viscoelastic Material

Suppose K(t) >> G(t), then for infinitisimal strains

t

Sij(t) =

2 G(t

–

-•

ij(s)

s) s

–

ij

(s)

s ds – ijP

Several relations are proposed for finite strains,

including that due to Bernstein, Kearsley and Zapas::

t

Sij(t) =

U

2 I

B;1

-•

Carnegie Mellon

U

-1

B(t)ij(s) – I B(t)ij(s) ds – ijP

B;2

196

Nonlinear Response in Simple Shear for a

Fluid

(In the appro ximation with t >> R)

Shear Stress (t) = S12(t):

•

G(u)

(t) = – [(t,u)] F1[(t,u)] u du

t

(u)

(t) = G(t – u) u M1[(t,u)] du

-•

(t,u) = (t) – (u)

Carnegie Mellon

F1(

M1[(t,u)] =

n F 1()

= F1()1 +

n

197

Nonlinear Response in Simple Shear for a

Fluid

(In the appro ximation with t >> R)

First–Normal Stress Difference (1)(t) = 11(t) – 22(t) :

•

G(u)

(t) = – [(t,u)] F1[(t,u)] u du

t

(u)

(t) = G(t – u) u M2[(t,u)] du

-•

F1(

M2[(t,u)] =

Carnegie Mellon

n F 1()

= F1()2 +

n

198

A Theoretical Expression for the Strain Function:

The theory du e to Doi and Edwards

F1() = [1 + (||/'')];

'' - 2.13

An Approximate form of the Strain Function:

F1 () = 1

for || Š '

F1 () = exp[ – (||– ')/'']

for || > '

log F1 ( )

0

'/ ''

[1 + (||/'')]

-1

-1

exp(-| - '|/")

-2

1

Carnegie Mellon

2

|

3

| / ''

4

199

Response to a Step Shear Strain

Strain Jump: (t)

t = 0+

°

=

t

° G(t-s)(0)

(t) =

F1()1

°G(t) F1(°)

=

S12 (t, )/ °

n F1()

+

n ds

(t)

0

-1

0.01

2.5

5

R

-2

c

-3

Carnegie Mellon

-4

-2

0

log t/sec

2

200

Response to a Ramp Deformation

(t)

=

· t

t>

Stress Growth:

(t) =

(t) =

· G(s)

n F1(· s)

ds

F1(· s)1 +

n · s

t

·2 sG(s)

t

F1(· s)2 +

Carnegie Mellon

·

n F1( s)

ds

n · s

201

Steady-State Flow

Viscosity

·

lim (t) = SS(

t >> c

· = SS(/

· ·

(

· = (0) =

lim (

=

· = (0) H · /''

(

c

•

G(u)M [ u]du

1

0

·

Hc· /'' =

Carnegie Mellon

•

G(u)du

0

202

Steady-State Flow

First-Normal Stress Difference

·

lim (t) = ()

t >> c

SS

· = ()/2{

·

·

N()

()}

SS

SS

· = Js

lim N()

=

· = Js S /''

·

N()

c

N

•

uG(u)M [ u]du

2

0

·

·

S c/''

=

N

Carnegie Mellon

•

uG(u)du

0

•

-2

·

0 G(u)M1[ u]du

•

G(u)du

0

203

Steady-State Flow

Steady-State Recoverable Compliance

·

lim (t,) = ()

R

t; >>c

R

· = ()/

· ()

·

R ()

SS

R

SS

· = J

lim R ()

s

SS

=

· = J S /''

·

R ()

s

R

c

SS

·

SRc/''

= Result of an iterative calculation

involving G(t) and F1()

Carnegie Mellon

204

Suppose

G(t) = Go•iexp(–t/i);

•i =

1

Then, with the app roximate F1() given above

(· ) = Go•i i H(·i/'')

H(·i/'') -

1

;

·

[1 + (i/ '')]

- 6/5, - 1

By comparison,

1

'() =Go•i i [1 + (i)]

In bo th cases, the factors i i in the terms in the su mmation are

weighted by functions that decrease term–by–t erm with increasing ·or

.

Consequently, th ese expressions exhib it the Cox-Merz approximation:

Carnegie Mellon

(·) - '·

205

Narrow MWD

Broad MWD

-1

.

.

log H(); log SN()

0

-2

-2

-1

0

log

Carnegie Mellon

.

1

2

3

c

206

-1

s

·

0

s

log[J )/J ]

·

·

s

-1

0

(1)

log[ )/ )]

log[S )/J ]

0

-1

-3

-2

-1

0

1

2

3

·

log( )

c

Polyethylene

K. Nakamura, C.-P. Wong and G. C. Berry J. Poly m. Sci: Polym. Phys. Ed . 22:1119 -48 (1984)

Carnegie Mellon

207

-1

-1

s

·

0

(1)

0

-2

-1

-2

log[S )/J ]

s

log[J'( )/J ]

-2

0

·

log[ ()/ )]

log[ '( )/ )]

0

-1

-1

0

1

2

3

·

log( )

c

Linear and nonlinear behavior for a polymer with a relatively narrow MWD

Carnegie Mellon

208

Examples from the literature

Carnegie Mellon

Branched and li near metallocene polyolefins

Colloidal d ispersions

Wormlike Micelles

Deformation of rigid materials

Nonlinear shear behavior

Linear and nonlinear bulk properties

209

Carnegie Mellon

210

Carnegie Mellon

211

An Inherent Nonlinearity in Response

B(t) = B() + B(t)

^

(t) = (t/)

But

= (V,T)

An attempt to account for this effect makes use of an

material time constant averaged over the time

interval of interest:

1

(t ,t) = (t - t )

t2

t1

(u) du

V(t) – V()

P(s)

t

=

B[(t

–

s)

(t

,s)

-•

V()

s ds

Frequently,

Carnegie Mellon

B(t) =

BA{1 + (t/A)1/3}; t <

212

Carnegie Mellon

213

Carnegie Mellon

214

Carnegie Mellon

215