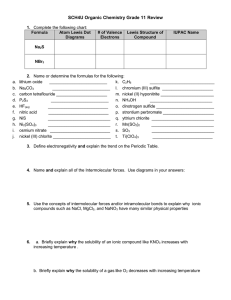

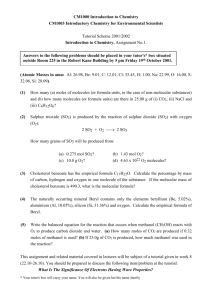

SO Formation During Oxy- Coal Combustion 3

advertisement

155 South 1452 East Room 380 Salt Lake City, Utah 84112 1-801-585-1233 SO3 Formation During OxyCoal Combustion Jiyoung Ahn1, Dana Overacker1, Ryan Okerlund1, Andrew Fry2 and Eric G.Eddings1 1Dept. of Chemical Engineering , University of Utah 2Reaction Engineering International Outline •Background •Methodology and Equipment - Controlled Condensation Method - Pilot-Scale Combustor (L1500) •Equilibrium Calculations •Experimental Results - SO3 Concentration - Mass of SO3 emitted - Effect of Temperature - Effect of Staged Combustion Background : SO3 in Combustion - In general, only a small percentage of the sulfur in fuel is oxidized to sulfur trioxide (SO3). - Negative effects of SO3 on plant operations: 1) The potential for corrosion of metallic surfaces 2) The increased emission of acid aerosols, which create visible plumes and cause acid rain. - The increased amount of O2 in oxy-fuel combustion has a higher chance of affecting the oxidation of SO2 to SO3. - Considering the effects of SO3 on the environment, and the possibility of increasing SO3 emissions in oxy-fuel combustion, it is important to investigate the behavior of sulfur compounds in oxy-fuel combustion. Method of Measurement - The Controlled Condensation Method ( ASTM D 3226-73T) is used to measure SO3 and SO2. - It takes advantage of the difference between the dew point of water and acid to selectively collect SO3. Controlled Condensation Method - SO3 is condensed into a sulfuric acid mist in the condenser. Temperature in the condenser was kept between 167F and 185F. - The first two impingers contain a hydrogen peroxide solution that captures SO2. - The heated quartz filter removes particulate matter. Titration Methodology - The amount of SO3 and SO2 present in the condensed acid and hydrogen peroxide solutions is quantified through a titration using barium perchlorate with thorin indicator (EPA Method 8A). - Due to subtle color changes during titrations, various concentrations of dilute sulfuric acid were used to make standards for comparison. Pilot-Scale Combustor - The 5 million Btu/hr furnace has a 3.2 ft2 internal cross section and is approximately 46 feet in length. - Gas was sampled at three different locations to investigate the effect of temperature on the formation of sulfur oxides during air- and oxy-fired coal combustion. Equilibrium Behavior of SO3 Equilibrium calculations of oxyfiring Illinois 6 coal SR1.2 Oxygen 20% SR1.2 Oxygen 25% SR1.2 Oxygen 30% 2.00E+03 2500 mol fraction of SO2 (ppm) mole fraction of SO3 (ppm) 2.50E+03 1.50E+03 1.00E+03 5.00E+02 0.00E+00 2000 1500 1000 500 0 0 500 1000 1500 Temperature (K) (a) SO3 ppm 2000 2500 0 500 1000 1500 Temperature (K) 2000 (b) SO2 ppm - At higher temperatures (>1273K/1832F), equilibrium favors SO2 formation, not SO3. - The equilibrium is shifted toward the formation of SO3 at lower temperatures, with a maximum value at around 900 K (1160 F). 2500 SO3 Measurement Challenges 1) If the gas is sampled at too high a temperature -> It may be prior to the maximum formation of SO3. 2) If the gas is sampled at too low a temperature -> Some SO3 may have condensed out prior to sampling It is important, therefore, to sample for SO3 in an optimal temperature window to account for the formation that takes place, but to also sample prior to any SO3 condensation. Experiment Results: Coal Analyses Ultimate and Proximate analyses of PRB, Utah, and Illinois 6 coal *HHV=higher heating value Coal Loss on drying Ash C H N S O Volatile Matter Fixed Carbon HHV* [wt. %] [wt. %] [wt. %] [wt. %] PRB 23.69 4.94 53.72 6.22 0.78 0.23 34.11 33.36 38.01 [Btu/l b] 9078 Utah 3.18 8.83 70.60 5.41 1.42 0.53 13.21 38.60 49.39 12606 Illinois 6 9.65 7.99 64.67 5.59 1.12 3.98 16.65 36.78 45.88 11598 Experiment Result : Coal analyses Ash Composition from PRB, Utah, and Illinois 6 coal (wt%) Coal Al Al2O3 PRB 14.78 Utah 14.52 Illinois 17.66 6 Ca Fe CaO Fe2O3 22.2 5.20 6.11 5.09 1.87 14.57 Mg MgO 5.17 1.39 0.98 Mn MnO 0.01 0.02 0.02 P P2O5 1.07 0.59 0.11 K Si Na S K2O SiO2 Na2O SO3 0.35 30.46 1.94 8.83 0.57 60.89 1.41 2.33 2.26 49.28 1.51 2.22 Ti TiO2 1.30 0.88 0.85 Experiment Results: SO2 SO2 concentration (ppm) measured in the pilot scale experiments 20000 Oxy fuel, Illinois 6 Air fuel, Illinois 6 Oxy fuel, Utah Air fuel, Utah Oxy fuel, PRB Air fuel, PRB 18000 SO2 concentration (ppm) 16000 14000 12000 10000 8000 6000 4000 2000 Because of the recycling of the flue gas, the amount of SO2 was much higher in oxy-coal combustion than in air-fuel combustion, ranging from twice as much (PRB) to almost six times as much (Illinois 6) at all temperatures. 0 500 600 700 800 900 1000 Gas temperature at the point of measurement (K) 1100 Experimental Results: SO3 SO3 concentration (ppm) measured in the pilot scale experiments 60 Oxy fuel, Illinois 6 - For Illinois 6 coal, which had the Air fuel, Illinois 6 highest sulfur composition, the Oxy fuel, Utah Air fuel, Utah concentration of SO3 at the Air fuel, PRB 50 SO3 concentration (ppm) optimum sampling temperature (755.2K/900F) increased up to 5 times for oxyfuel combustion compared to air-fuel combustion. - At higher sampling temperatures, limited difference was found between oxy- and air-fuel combustion for Illinois 6 coal. 40 30 20 10 0 500 700 900 1100 1300 Gas temperature at the point of measurement (K) 1500 Experimental Results: SO3 mole fraction of SO3 SO3 Concentration (ppm) 50 40 30 20 10 SR1.1, Oxygen 20% 60 SR1.1, Oxygen 25% SR1.1, Oxygen 30% 50 Oxy fuel, Illinois 6 1.20E-02 60 1.00E-02 8.00E-03 40 6.00E-03 30 4.00E-03 20 2.00E-03 10 Oxy fuel, Illinois 6 0.00E+00 0 800 810 820 830 840 850 Gas temperature at the point of measurement (K) 0 500 1000 1500 2000 2500 Temperature (K) 0 3000 - An increase in temperature of 40K in the critical sampling zone can decrease the SO3 concentration by 10-15 ppm - The data from Illinois 6 is in the region of very steep gradients in the equilibrium predictions. However, for Utah coal, small changes in the same temperatures didn’t affect SO3 concentration as greatly Measured SO3 Concentration (ppm) SO3 concentration (ppm) measured in a small range of temperatures and comparison with the equilibrium calculations Experimental Results: SO3 SO3 concentration (lb/MMBtu) from the pilot scale experiments 0.045 Oxy-fuel, Illinos 6 Air-fuel, Illinois 6 Oxy fuel, Utah Air fuel, Utah Air fuel, PRB 0.04 SO3 concentration (lb/MMBtu) 0.035 0.03 0.025 0.02 0.015 0.01 When actual furnace exhaust emissions are computed on a mass basis, mass of SO3 per million Btu is lower for oxy-fuel than air-fuel fired conditions, due to the reduced volume of flue gas. 0.005 0 400 600 800 1000 1200 Gas temperature at the point of measurement (K) 1400 Experimental Results: SO3 SO3 concentration of Illinois 6 coal measured in oxy-fuel combustion 0.035 SO3 Concentration ( ppm ) 60 0.03 SO3 Concentration (lb/MMBtu) 50 0.025 40 0.02 30 0.015 20 10 0.01 Measured at 800K Measured at 842K 0 20.00% 25.00% 30.00% 35.00% Overall oxygen concentration (wt%) (a) Molar concentration (ppm) 0.005 0 20.00% 25.00% 30.00% 35.00% Overall oxygen concentration (wt%) (b) Mass concentration (lb/MMBtu) - An increase in temperature of 40K in the critical sampling zone can decrease the SO3 concentration by 10-15 ppm, and by 0.01 0.015 lb/MBtu. - SO3 concentration shows an inverse relationship with overall oxygen concentration in oxy-fuel combustion. Experimental Results: SO3 SO3 concentrations measured with Illinois #6 coal under staged and unstaged air- and oxy-fired combustion 60 Oxy fuel at 800K Air fuel at 800K SO3 Concentration (ppm) 50 40 - Because SO3 formation is favored at lower temperatures, it is anticipated that SO3 is formed primarily downstream of the burner. → It is unlikely that the concentration of SO3 would be affected by staged combustion. 30 20 10 0 0.5 0.7 0.9 1.1 Burner stoichiometric ratio - The figure does not indicate any significant correlation between SO3 concentration and staged or unstaged combustion. 1.3 Conclusions - - Temperature at the point of measurement has a strong impact on the amount of SO3 captured in the sample. - Measurements of SO3 taken around 800 K (980.6F) during combustion of a high-sulfur coal showed that the SO3 concentration was three to five times higher during oxy-coal combustion as compared to air-fired conditions, but the difference was strongly coal- or S-content-dependent. - At higher sampling temperatures (922K/1200F), roughly the same amount of SO3 was measured in both air- and oxy-fired combustion. Future Work - More detailed investigation of the effects of O2and CO2 concentration on the amount of SO3 formed for both air- and oxy-fired combustion - Development of fundamental understanding of the chemistry of N2 and CO2 and associated effects on the formation of SO3 - Investigating the influences of limestone (CaCO3) on SO3 formation Acknowledgments This material is based upon work supported by the U.S. Department of Energy under Award Numbers DENT0005015 and DE-NT0005288. Questions?