College of Medical, Veterinary and Life Sciences

College of Medical, Veterinary and Life Sciences

Institute of Molecular, Cell and Systems Biology

COSHH, Risk Assessment and Biological Safety

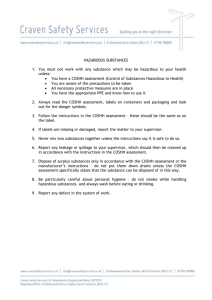

The following information and instructions supplement the Safety Policy for the Institute, and are key elements to ensure that the Safety Policy is implemented effectively.

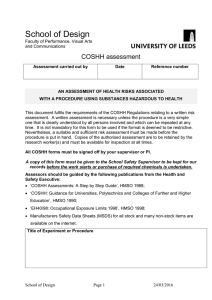

COSHH – Control of Substances Hazardous to Health

A COSHH Risk Assessment Form (RA2 – biological risks) should be completed, and easily accessed by users in the laboratory, be kept updated with regular reviews and available for inspection by a member of the Institute’s safety committee.

Blank risk assessment forms are available to download from the Institute’s safety website.

COSHH (2002) The Risk Assessment exercise for any activity is the key link to ensuring that we comply with legislation for safety at work. Written evidence, where appropriate, is the key factor in ensuring that there is a consistency of high standard across the College and that all staff and students are aware of, and respond correctly to potential hazards.

You should ensure that you know the categorisation of the organism(s) being used, and follow the appropriate recommendations given by the Advisory Committee on Dangerous

Pathogens. The documentation 'Approved List of Biological Agents' is currently available in printed format from Paul Phillips, or in the Useful Links section of the Institute’s safety website . Particular care should be exercised when handling material of human origin and any member of staff responsible for bringing such material into the building must ensure that it has been adequately screened (especially for HIV and hepatitis B, C & D viruses) before its arrival in the building wherever feasible. Appropriate records of such material must be maintained. Staff working with such materials should be familiar with the recommendations contained in the HSAC and ACDP guidance documents and give advance notice of work being carried out in the building to the Divisional Safety Coordinator.

Guidance Documents available from Paul Phillips:-

1.

Safe Working and the Prevention of Infection in Clinical Laboratories (1991);

2.

Revised Advice on laboratory containment measures for work with tissue samples

(2001).

3.

Supplement to above Revised Advice for Work in Clinical Cytogenetic

Laboratories;

4.

Protection against blood borne infections in the workplace – HIV & Hepatitis; TSE

Agents; Safe Working and the Prevention of Infection.

5.

Anti-Terrorism, Crime and Security Act (2001) List of Schedule 5 Pathogens and

Toxins.

Handling of Cultures

Before starting work, you must:-

read the relevant COSHH assessment and ensure that you know the categorisation of the organism(s) being used.

Microbiological hazards must be assessed under COSHH (section 2.2 of this handbook) and ACGM (section 2.2.9 of this handbook) as appropriate.

ensure that supplies of an appropriate disinfectant (eg 1% chloros or Virkon) are available.

On finishing or interrupting work, you must:-

Never leave contaminated material unattended unless it is sealed and clearly labelled.

On leaving the laboratory, swab benches and worktops.

The safe handling of microbial cultures requires manipulative skill and so anyone intending to handle cultures must obtain advice from a member of their Department experienced in dealing with micro-organisms. In addition, the following points must be noted:-

Wire loops should not be over-charged with liquid when flamed; the loop may 'spit' if heavily charged and the material which flies off is not necessarily sterile.

Cultures of micro-organisms must not be pipetted by mouth. Use a propipette.

Contaminated pipettes must not be laid on the bench, but released tip downwards into a jar of disinfectant (0.25% chloros) and completely immersed.

Contaminated Pasteur pipettes and slides should also be totally immersed in a (separate) plastic jar (eg Jencons Sharp-Safe) of disinfectant; after disinfection, the jar should be drained, capped and incinerated.

Syringe needles, unsheathed, must be disposed of in a CinBin. Do not attempt to resheath needles.

Destruction/Disposal of Cultures

Each lab group must have a written policy appropriate for the destruction of any viable micro-oranisms used.

Microbiologically contaminated material should only be washed up or disposed of after effective treatment with disinfectant or after additional sterilisation by autoclaving or incineration.

For pelleted material, cell supernatants or spilled live organisms (included contaminated glassware, swabs, etc) use fresh 1% chloros (1 in 100 dilution; 10,000 ppm) for at least

1 hour.

For pipettes and mildly contaminated glassware use 0.25% chloros (1 in 400 diluton;

2,500 ppm), prepared fresh daily, for at least 1 hour.

Used solutions should be disposed of down the sink with copious (at least 20-fold) volumes of water. If there is to be no additional sterilisation by autoclaving, disinfection should be extended for at least 24 hours.

Autoclaving of contaminated material should be carried out using a 'kill' run (ie,

134degC for 18 minutes). Polypropylene tubes (but not polycarbonate ones) can be autoclaved. Polycarbonate tubes may be disinfected by soaking them in Hibitane 1/2000 or hypochlorous acid solutions (eg Presept) but not in phenolic disinfectants.

All microbiologically contaminated materials must be sterilised before disposal. Liquid cultures can be killed either by chemicals or by autoclaving. Culture plates should be autoclaved. Culture flasks, centrifuge tubes, bottles and caps must be properly sterilised after use with live cultures. Glassware should be autoclaved. Polypropylene tubes (but

not polycarbonate ones) can be autoclaved. Polycarbonate tubes may be disinfected by soaking them in 0.25% chloros.

Bags containing items awaiting autoclaving should be further contained with a robust container such as a plastic bin.

Accidents with Biological Hazards

All spillages must be reported using an Injury or Dangerous Occurrence form even when no personal injury is involved.

If hands become contaminated, they should then be washed using a suitable disinfectant

(eg 70% methylated spirit containing 0.5% Hibitane or a 1% solution of Savlon), before putting on disposable gloves in order to clean up. A contaminated laboratory coat must be removed to be autoclaved if practicable, or disinfected immediately and autoclaved later. A fresh laundered coat should be put on. Any contaminated personal clothing must also be removed and treated in the same way.

If a tube, culture bottle, or flask is broken, the area should be flooded with disinfectant

(e.g. 1% chloros or Hibitane 1/1000 or Virkon) immediately which should be allowed to act for 30-60 minutes after which the area should be cleaned up with water and allowed to dry. Broken glass should never be picked up with the fingers. Forceps or pan and brush should always be used and these should be disinfected after use.

If bacterial cultures are spilt on the bench or floor, the nearest window must be opened and 10 minutes allowed for the aerosol and droplets to disperse. Work must be stopped in the area and a warning noticed posted. The spilt material should then be mopped up with suitable disinfectant (e.g. Hibitane) which should be allowed to act for 30-60 minutes, after which time the area should be cleaned up with water and allowed to dry.

The hands should then be washed with a suitable skin disinfectant (e.g. Hibiscrub).

Opening of ampoules

Ampoules may be opened with the minimum of risk as follows:

The bottom of the ampoule should be held in several layers of tissue to protect the hands and a file mark made at about the level of the middle of the cotton wool plug which is inside the tube. A red hot glass rod or sealed Pasteur pipette should be applied to the mark.

The glass will crack allowing air to enter the ampoule and equalise the pressures. After a few seconds the ampoule should be wrapped in a few layers of tissue or held in a small ball of plasticine and broken along the crack. The tissues and ampoule neck can then be discarded into disinfectant. About 0.5ml of broth is added to the ampoule, very slowly, drop by drop, with a Pasteur pipette to avoid blowing dried material out. The contents may then be mixed without bubbling and withdrawn into a culture tube.

Aerosols and droplets

Aerosols constitute a major infection hazard and may persist in the air for some time.

Sources of aerosols and droplets include:-

opening the screw-caps of universal containers

opening of snap-on closures on plastic containers or plug stoppers

rinsing Pasteur pipettes when transferring dilutions etc.

breakage of containers in centrifuges

accidental breakages

homogenising by mechanical means (particularly at high speeds)

ultrasonic treatment

operation of centrifuges

Guard against excessive production of aerosols by, for example, careful, non-violent pipetting. When pipettes are rinsed, e.g. between dilutions, or the contents are discharged into media or disinfectant, the tip of the pipette should be submerged and the contents expelled gently, without bubbling.

For Modifications of pathogens in ACDP hazard group 2 which involve risk of aerosol production, a Class 1 microbiological safety cabinet or equipment designed to contain the aerosol must be used.

Special Procedures

Anyone embarking on work involving the handling of pathogenic organisms/viruses for gene Modification should consult the appropriate member of staff and have your technique fully checked by that staff member before proceeding.

Microbiological Safety Cabinets must be serviced every 6 months. Additionally, a service operator protection test (KI-discus) test should be carried out once a year.

See also: Fumigation of Microbiological Safety Cabinets , Health & Safety Note, 95/003

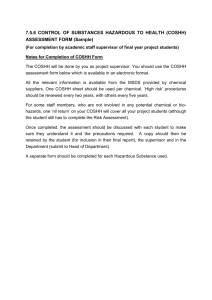

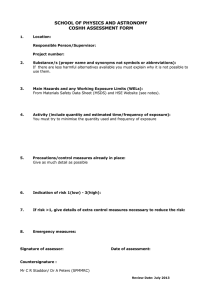

Control of Substances Hazardous to Health (CoSHH) 2002

Risk Assessment – Biological Risks (RA1b)

1

Assessment Ref Nr: ………………………

1.1

College/Institute or School :…………../………….………………....................

2.0

Title of activity:

______________________________________________________________

3.0

Postdoctoral, postgraduates or senior technical staff may complete the form but the responsibility for ensuring that the risk assessment is completed and checked lies with the academic supervisor.

Completed by: ______________________

Staff No: __________________________

E-mail address: _____________________

Signature: _________________________

Date: ______________________________

Checked by: ____________________

Staff No: ________________________

E-mail address: __________________

Signature: ______________________

Date ____________________________

4.0

Brief description of work: It is only necessary to give broad outlines of the components of the activity covered by the risk assessment. (e.g., size of group, location, level of supervision, nature of work)

5.0

Name of Biological Agent(s)/Microorganisms:

6.0

Synonym if any:

7.0

Hazard identification :

When categorizing individual pathogens, the definition of hazard is the disposition of a thing, a condition or a situation to produce injury; or an event, sequence of events or combination of circumstances which could potentially have adverse consequences. Define the hazard and its potential harm explicity stating any essential assumptions made, in terms of the pathogenic organism and the circumstances in which harm may be expected. Such a definition will possibly require consideration of several questions including:

Where does the hazard occur? (air/water/food/blood).

If relevant, what is the life cycle of the organism (vectors/alternative hosts/ etc)

What is the route of transmission?

Does secondary transmission occur?

How frequently does infection give rise to clinical disease?

What are the short-term and long-term consequences? (sero-conversion/ illness/ death)

What are the prevention strategies?

8.0

Name the Biological agent(s) to be used in this activity

RISK AND COSHH ASSESSMENT FORM FOR CHEMICALS

IBLS SAFETY COMMITTEE NOVEMBER 2004

Control of Substances Hazardous to Health (CoSHH) 2002

Risk Assessment – Biological Risks (RA1b)

9.0

Categorize each of the biological agent(s) in the Table below

HAZARD RATINGS

9.1 Name of Biological agent

10.0

Risk

9.2 ACDP Category

This is the probability that a specified hazard will be realised. The expression of risk should take into account not only the probability of harm occurring, but also its potential seriousness.

What is the probability of the hazard being expressed?

Decide whether or not the biological agent(s) as used in the procedure presents a Low, Medium or High Risk to the user:

What are the biological risks and any special circumstances which may exclude a person from carrying out the activity?

Tick the appropriate boxes

Risk to user

Low

Medium

High

Other special provisions which may increase risk

Low

Medium

High

The biological agent/microorganism could cause an infection in an individual

Worker may be undergoing treatment/therapy

The biological agent/microorganism produces a soluble toxin

Worker may be allergic to materials used in the procedure

The biological agent/microorganism may induce cancer

Worker may atopic

The biological agent/microorganism may endanger the foetus in pregnant women

10.1

Routes by which exposure to the biological agent / microorganism present a risk to health, if control measures are not adopted. Tick the relevant boxes in the table below:

Contact with or bite from infected animal

Penetration or absorption through skin or cut in skin

Direct splash contact with eyes

Inhalation of aerosol containing biological agent/ microorganism

Oral selfinoculation

Accidental parenteral inoculation via needle stab

10.2

What could be the effect of exposure to the above biological agent/microorganism, if control measures are not adopted? Tick the relevant boxes in the table below:

Single acute exposure

Repeated low exposure

Duration of adverse effects

Serious – requires immediate medical attention

Serious – may require treatment

Long – term

Serious – may require treatment

Not serious

Short-term

Unknown

Unknown

Unknown

RISK AND COSHH ASSESSMENT FORM FOR CHEMICALS

IBLS SAFETY COMMITTEE NOVEMBER 2004

Control of Substances Hazardous to Health (CoSHH) 2002

Risk Assessment – Biological Risks (RA1b)

11.0

General Control Measures

What control measures are appropriate to contain the substances where the risks are either medium or high?

Describe the precautions to be taken to reduce this level of risk?

11.1

Where is the work to be done?

Location (incl room number and building) ______________________________________________

If parts of the work cannot be done on the open bench please specify where these stages will be carried out, e.g., in a fume cupboard or in specialised containment rooms.

On the open bench [ ] Other (specify) _____________________________________________

11.2

What protective equipment is required? Specify what is required and when this needs to be worn. Note - laboratory coats must be worn in all laboratories.

Gloves [ ], Safety glasses [ ], Mask [ ],Visor [ ], Respirator [ ]

Other ............................................................ None required [ ]

11.3

What arrangements have been made to provide workers with the information to carry out the procedure safely?

Routine procedure described by trained staff [ ]

Simple verbal instructions [ ]

Written scheme of work [ ] – complete section 7.0

11.4

How are the training and supervision of personnel to be provided?

Supervisor supplying initial training [ ] Specific training courses [ ]

Direct supervision during one or more stages of the work [ ]

None – all work being undertaken by trained staff [ ]

11.5

Are there risk implications for persons not directly involved in the activity? (see 5.0)

The following people may need to have information about these control measures and sign the declaration?

Academic staff [ ]

Technical staff [ ]

Postgraduates [ ]

Secretaries [ ]

Undergraduates [ ]

Cleaners [ ]

Visiting staff [ ] Maintenance staff [ ] Contractors [ ]

11.6

Is a vaccine available? YES – specify | NO

If YES, are workers encouraged to be vaccinated? YES | NO

11.7

Emergency procedures :

Are written emergency instructions provided in the place of work? YES | NO | NOT REQUIRED

If yes, specify:

Are disinfectants provided for neutralising accidental spills of of the biological agent? YES | NO

If yes, specify:

Are the locations of the following known:

Safety shower | shower room | eye-wash bottles | antiseptic hand washing fluid | first-aid box.

(tick as appropriate)

11.8

Is biological monitoring of workers required?

11..9

Is monitoring for air-borne contaminant required?

YES | NO

YES | NO

12.0

Do the precautions above adequately control the risks of handling the microorganism/biological agent specified ? YES | NO

If not please specify the additional precautions required:

13.0

Inactivation of biological agents/microorganisms will be done by one of the following methods (tick appropriate boxes):

Exposure of liquids containing the microorganism / biological agent to an appropriate disinfectant at a known cidal concentration. For Category 2 work all liquids containing the agent need to be autoclaved.

Collection of inoculated petri-dishes, closed with clear tape to prevent lid from falling off, and culture flasks for autoclaving

Collection of all contaminated plastics for autoclaving

Collection of contaminated sharps in a CinBin for incineration (cost for this service)

Collection of clinical waste in a yellow bag for onward transmission via the University to a registered company (cost for this service)

To normal laboratory waste collection, after rendering safe by autoclaving

RISK AND COSHH ASSESSMENT FORM FOR CHEMICALS

IBLS SAFETY COMMITTEE NOVEMBER 2004

Control of Substances Hazardous to Health (CoSHH) 2002

Risk Assessment – Biological Risks (RA1b)

Other method of disposal (specify)

RISK AND COSHH ASSESSMENT FORM FOR CHEMICALS

IBLS SAFETY COMMITTEE NOVEMBER 2004

Control of Substances Hazardous to Health (CoSHH) 2002

Risk Assessment – Biological Risks (RA1b)

What legal permissions have been obtained?

SACGM approval for Genetic Manipulation? (list and attached copy of approved risk assessment).

Radioisotope permission YES | NO

RISK AND COSHH ASSESSMENT FORM FOR CHEMICALS

IBLS SAFETY COMMITTEE NOVEMBER 2004

Control of Substances Hazardous to Health (CoSHH) 2002

Risk Assessment – Biological Risks (RA1b)

A Name of Assessor: __________________

Signature of Assessor: _______________

Checked by: ___________________________

Signature: _____________________________

B

Date: _____________________________ Date: _________________________________

I have received a paper or computer disk copy of this Biological Risk and COSHH assessment and understand my responsibility in relation to the risks and the measures which must be taken to control such risks outlined in the above risk assessment.

Reference No:

Title of Risk Assessment:

NAME DATE SIGNATURE for copy held in lab

*

RISK AND COSHH ASSESSMENT FORM FOR CHEMICALS

IBLS SAFETY COMMITTEE NOVEMBER 2004

Control of Substances Hazardous to Health (CoSHH) 2002

Risk Assessment – Biological Risks (RA1b)

Review dates: When this assessment is reviewed, add the signature of the reviewer, the date, and whether the assessment was changed.. All signatories still covered by a modified assessment must then sign again to show that they are aware of the change.

RISK AND COSHH ASSESSMENT FORM FOR CHEMICALS

IBLS SAFETY COMMITTEE NOVEMBER 2004