The future of Industry

advertisement

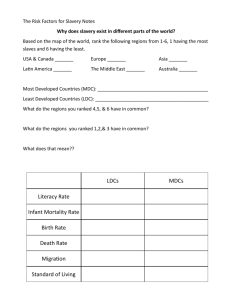

The future of Industry • Labor most important factor changing location of industry in the 21st century • Shifts within MDC – US – Europe – Japan • International Shifts – Countries – Distribution – outsourcing • Industry is shifting away from traditional areas of northwestern Europe and northeastern United States – In U.S. it has shifted west and south – In Europe, government has encouraged relocation toward economically distressed areas • NE U.S. lost 6 million jobs in manufacturing between 1950-2009 – Especially large declines in NY and PA • Once served as hub of clothing, textiles, steel, and fabricated metal manufacturing • 2 million jobs added to the South and West between 1950-2009 • Why the south? – Right-to-work laws • Enacted in South • Requires a factory to maintain “openshop” and prohibits “closed-shop” – Closed shop » A company and union agree that everyone must join a union – Open shop » A union and company must not negotiate a contract that requires workers to join a union • Textile Production – Also moved to south and west • Lower wages • Little interest in joining unions • Manufacturing has shifted from NW Europe to southern and eastern Europe – European government policies have encouraged • EU provides assistance to convergence regions and competitive and employment regions – Convergence= Eastern and Southern Europe – Competitive and Employment= Western Europe’s traditional core • Spain has had most manufacturing growth since late 20th century – Growth had been retarded by physical and political isolation • Regions east of Germany and west of Russia have become industrial centers since fall of Communism – Called “Central Europe” – Poland, Czech Republic, and Hungary – Two attractive site and situation factors • labor, market proximity – Good value for money Shifts • In 1970 nearly ½ of world industry was in Europe and nearly 1/3rd was in North America – Today both regions only account for ¼ • Increasingly important industrial areas – East Asia • Rapid industrial growth in China • Also includes Japan and South Korea – South Asia • Led by India – Textiles, motor-vehicle production – Important center for business services – Latin America • Brazil leading industry country • Closest low-wage region to the United States – Cost of shipping lower – Maquiladoras • Changing distributions – Shift to new industrial regions can be seen clearly in steel and clothing – MDCs losing production to these key industries to LDCs • Steel production declined in MDCs 40% and increased in LDCs by 60% between 1980 and 2008 – Labor-intensive industries have been especially attractive • U.S. apparel workers declined from 900,000 in 1990 to 150,000 in 2009 • Outsourcing – Transnational corporations have been especially aggressive in using low-cost labor in LDCs – Operations that can utilize lowskill, low-wage workers will relocate to LDCs despite increase in transportation costs – Selective transfer of jobs to LDCs is known as the new international division of labor • TNCs corporations allocate production to low-wage countries through outsourcing – Definition: turning over much of the responsibility for production to independent suppliers • Outsourcing contrasts vertical integration • Outsourcing has had a major impact on the distribution of manufacturing – Each step scrutinized closely in order to determine the optimal location • Definition: – Foreign owned factories located in Mexico • Spatial distribution: – Located close to U.S. border/ major cities/ entry points • Why Mexico? – – – – Inexpensive labor costs NAFTA Mexico’s proximity to U.S. market Improved transportation • Reorganization/relocation of economic activities (jobs) from a national to a global scale • LDCs now ideal for manufacturing jobs • Features: – MDCs rely on lower-cost production from LDCs – Comparative advantage – Offshoring/ outsourcing – Trade agreements • Consequences: – – – – Unemployment in MDCs Deindustrialization Internal migration International migration • In LDCs – – – – – – Added job opportunities More gender equality Increase in wage gap Migration Environment issues westernization • Two factors encouraging some industries to located in traditional regions – Availability of skilled labor – Rapid delivery to market • Proximity to skilled labor – Skilled labor often found in traditional industrial regions • Example: Computer Industry – Traditional approach= Fordist (mass production) – Today = post- Fordist • Teams • Problem solving • Leveling • Just-in-time delivery – Increased in importance • BRIC?? – – – – Brazil Russia India China