A Train of Closed Feed Water Heaters Professor

advertisement

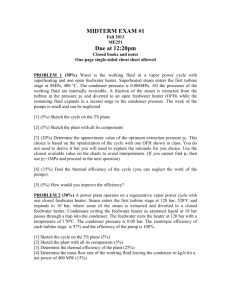

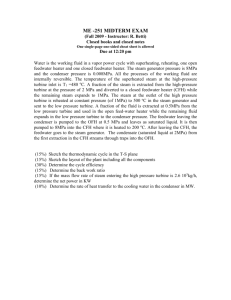

A Train of Closed Feed Water Heaters P M V Subbarao Professor Mechanical Engineering Department I I T Delhi A Trade off between Irreversibility and Reliability !!! Diagram of Large Power Plant Turbine Typical Modern Power Plant Turbine HP Turbine Rotor LP Turbine Rotor LP Turbine Rotor Block Diagram of A Large Steam Turbine Main Steam Reheat Steam HP IP IP LP Steam for Reheating OFWH 4 CFWH 6 CFWH 5 LP CFWH 3 CFWH 2 CFWH 1 Condenser Thermodynamic Analysis of A Power Plant Radiation losses are Ignored HEAT RATE=1985.05 K CAL/KW 121.3 6.414 162.1 639.314 160.7 kg cm 2 T/HR KCAL/KG CEL 92.4 509.026 92.2 509.026 72.7 72.6 B 0.9069 642.9 16.833 107.1 619.8 0.4361 20.510 77.96 D 0.078 0.382 B C 0.299 99.9 748.8 H C 99.9 509.028 46.8 0.299 M 47.0 310.0 63.693 58.8 12.0K 2.389 683.2 26.299 195.8 0382 M 0.078 M 506.53 49.2 509.028 49.0 310.0 20.510 76.5 3.7 K 735.8 0.4143 619.8 735.8 58.8 424.5 7.135 63.693 76.3 34.700 C 76.2 789.9 7.135 34.520 43.183 95.0 B 95.0 537.0 A 16.883 106.8 2.8 K 572.156 0.057 M B 0.5616 642.9 1.251 M 4.352 M 26.299 123.8 740.70 572.218 352.2 40.57 2.8 K 843.89 2.269 683.2 26.299 195.5 36.52 34.520 309.4 777.2 H 124.0 16.70 6.564 735.8 205.5 168.3 639.314 164.1 816.06 509.026 120.8 95.766 170.0 0.946 M 0.043 M 0.701 M 0.018 M 2.154 M 0.024 M 0.935 M 2.186 M B C C 6.0 K 0.0 K 789.9 352.2 740.70 A 34.700 423.0 639.314 200.0 15.87 350.4 740.70 61.067 40.57 537.0 172.0 61.067 38.54 0.000 M C B A 205.5 0.0 K D 150.0 639.314 210.3 6.0 K 61.067 206.0 639.314 247.0 256.21 LAYOUT OF MODERN 210 MW COAL FIRED POWER PLANT C P=210.061 MW G 14.970 M 0.854 M D 0.1033 577.3 441.114 46.45 3.068 M D B 64.846 M 0.1033 509.028 D 46.1 46.4 19.38 509.028 46.3 46.7 THERMODYNAMIC CYCLE OPTIMIZATION Effect of Higher Steam Conditions on Unit Performance • As the first step in the optimization of cycle steam conditions, the potential cycle efficiency gain from elevating steam pressures and temperatures needs to be considered. • Starting with the traditional 165 bar/5380C single-reheat cycle, dramatic improvements in power plant performance can be achieved by raising inlet steam conditions to levels up to 310 bar and temperatures to levels in excess of 600 C. • It has become industry practice to refer to such steam conditions, and in fact any supercritical conditions where the reheat steam temperatures exceed 566 C, as “ultrasupercritical”. • Heater Selection and Final Feedwater Temperature • • • • In order to maximize the heat rate gain possible with ultrasupercritical steam conditions, the feedwater heater arrangement also needs to be optimized. In general, the selection of higher steam conditions will result in additional feedwater heaters and a economically optimal higher final feedwater temperature. In many cases the selection of a heater above the reheat point (HARP) will also be warranted. The use of a separate desuperheater ahead of the top heater for units with a HARP can result in additional gains in unit performance. Other cycle parameters such as reheater pressure drop, heater terminal temperature differences, line pressure drops and drain cooler temperature differences have a lesser impact on turbine design, but should also be optimized as part of the overall power plant cost/performance trade-off activity. Analysis of Regeneration through CFWH Define y as fraction of mass extraction: y mextraction m SC Q in m SG h1 h8 m SG ym SG m SG 1 y Q out m SG 1 y h3 h4 y h7 h4 W turbine m SG h1 h2 1 y h2 h3 W pump mh5 h4 m SG Energy Balance for CFWH m SG y & h2 m SG h8 m SG h5 m SG y h2 h6 h2 h6 y h8 h5 m SG & h8 mSG & h5 h8 h5 y h2 h6 m SG y & h6 m SG y & h7 HP Closed Feed Water Heater Bleed Steam Feed Water in C=Condenser DC C DS Feed Water out Feedwater heater with Drain cooler and Desuperheater DC=Drain cooler DS=Desuperheater m SG y & h2 Condensate Bled steam TTD m SG & h8 m SG y & h6 T -TTD=Terminal temperature difference mSG & h5 C DC DS L • Desuperheating Zone - The integral desuperheating zone envelopes the final or hotest feed water pass and is thermally engineered to assure dry wall tube conditions with a minimum zone pressure loss. • Dry wall conditions in this zone provide maximum heat recovery per square foot of transfer surface by taking full advantage of the available temperature differential between the superheated steam and the feedwater. • Dry wall conditions also prevent flashing, which is detrimental to proper desuperheating zone operation. • All desuperheating zones are analyzed to make sure they are free of destructive vibration. HP Closed Feed Water Heater HP Turbine Tbi, pbi, Tbsi Condensing Shell Drain Cooler Desuperheater Tfi Tfi+1 TRAP Tbi, pbi, Tbsi Condensing Shell Drain Cooler Desuperheater Tfi Tfi+1 TRAP Tf Tube length LP Closed Feed Water Heater • LP Closed Feed Water Heater LP Turbine Tbi, pbi, Tbsi Condensing Shell Tfi Drain Cooler Tfi+1 TRAP • Drain Subcooling Zone - When the heater drains temperature is required to be lower than the heater saturation temperature, a drain subcooling zone is employed. • The drain subcooling zone may be either integral or external, and as a general rule, it is integral. • The integral drain subcooling zone perates as a heat exchanger within a heat exchanger, since it is isolated from the condensing zone by the drain subcooling zone end plate, shrouding, and sealing plate. • This zone is designed with generous free area for condensate entrance through the drains inlet to minimize friction losses which would be detrimental to proper operation. • The condensate is subcooled in this zone, flowing up and over horizontally cut baffles. Tbi, pbi, Tbsi Drain Cooler Tfout Condensing Shell TRAP Tf Tube length Tfin Work done by Bleed Steam h1 h2 h5 h8 h6 Work done by bleed (extracted) steam: wbleed wbleed yh1 h2 h8 h5 h1 h2 h2 h6 Closed Feed Water Heaters (Throttled Condensate) 1 2 3 12 9 10 11 5 6 7 4 8 Analysis of Regeneration through Two CFWH 1 Define y as fraction of mass extraction: y1 mb,1 & y2 m SG mb , 2 m SG Q in m SG h1 h12 T 10 2 9 11 7 6 8 5 s 3 12 4 Q out m SG y1 y2 h8 h5 1 y1 y2 h4 h5 W turbine m SG h1 h2 1 y1 h2 h3 1 y1 y2 h3 h4 W pump mh6 h5 Energy Balance for LP-CFWH m y2 & h3 m y1 & h11 h9 h6 h8 h11 y2 y1 h3 h8 h3 h8 m& h9 m y1 y2 & h7 m & h6 m y1 y2 & h8 m h9 m y1 y2 h8 m h6 m y1 h11 m y2 h3 Energy Balance for HP-CFWH m y1 & h2 m h12 m h9 m y1 h2 h10 m& h12 m y1 & h10 h2 h10 y1 h12 h9 m & h9 h12 h9 y1 h2 h10 m y1 & h11 Work done by Bleed Steam h12 h9 h1 h2 wbleed ,1 m y1 h1 h2 h2 h10 wbleed , 2 wbleed , 2 wbleed ,tot h9 h6 h8 h11 m y2 h1 h3 y1 h1 h3 h3 h8 h3 h8 h9 h6 h12 h9 h8 h11 m y2 h1 h3 h1 h3 h3 h8 h2 h10 h3 h8 h9 h6 h12 h9 h8 h11 h12 h9 h1 h2 h1 h3 h2 h10 h3 h8 h2 h10 h3 h8 wbleed ,tot h9 h6 h12 h9 h8 h11 h12 h9 h1 h2 h1 h3 h2 h10 h3 h8 h2 h10 h3 h8 1 T wbleed ,tot 10 2 9 11 7 6 8 5 s 3 12 4 hLPfeed hHPfeed hwastebleed hHPfeed wunitext1 wunitext2 hHPbleed hLPbleed hHPbleed hHPbleed Thermodynamic Analysis of A Power Plant Train of Shell & Tube HXs. Variation of Feedwater T emperature and Enthalpy along the FeedWater Heater 6 Enthalpy 250 1000 5 200 800 4 150 600 3 2 100 400 1 GSC DC 50 200 0 0 5 6 4 3 2 1 DC 6.0 K 6.0 K 0.0 K 0.0 K GSC D Temperature ( C) 1200 Temperature Enthalpy (kJ/kg) 300 C The Mechanical Deaerator • The removal of dissolved gases from boiler feedwater is an essential process in a steam system. • Carbon dioxide will dissolve in water, resulting in low pH levels and the production of corrosive carbonic acid. • Low pH levels in feedwater causes severe acid attack throughout the boiler system. • While dissolved gases and low pH levels in the feedwater can be controlled or removed by the addition of chemicals. • It is more economical and thermally efficient to remove these gases mechanically. • This mechanical process is known as deaeration and will increase the life of a steam system dramatically. • Deaeration is based on two scientific principles. • The first principle can be described by Henry's Law. • Henry's Law asserts that gas solubility in a solution decreases as the gas partial pressure above the solution decreases. • The second scientific principle that governs deaeration is the relationship between gas solubility and temperature. • Easily explained, gas solubility in a solution decreases as the temperature of the solution rises and approaches saturation temperature. • A deaerator utilizes both of these natural processes to remove dissolved oxygen, carbon dioxide, and other non-condensable gases from boiler feedwater. • The feedwater is sprayed in thin films into a steam atmosphere allowing it to become quickly heated to saturation. • Spraying feedwater in thin films increases the surface area of the liquid in contact with the steam, which, in turn, provides more rapid oxygen removal and lower gas concentrations. • This process reduces the solubility of all dissolved gases and removes it from the feedwater. • The liberated gases are then vented from the deaerator. • Correct deaerator operation requires a vessel pressure of about 20 – 30 kPa above atmospheric, and • a water temperature measured at the storage section of 50C above the boiling point of water at the altitude of the installation. • There should be an 45 – 60 cm steam plume from the deaerator vent, this contains the unwanted oxygen and carbon dioxide. • The following parameters should be continuously monitored to ensure the correct operation of the deaerator. • Deaerator operating pressure. • Water temperature in the storage section. Principle of Operation of A Dearator