SECONDARY DISTRIBUTION SYSTEM OPTIMIZATION METHODOLOGY

AND MATLAB PROGRAM

A Project

Presented to the faculty of the Department of Electrical and Electronic Engineering

California State University, Sacramento

Submitted in partial satisfaction of

the requirements for the degree of

MASTER OF SCIENCE

in

Electrical and Electronic Engineering

by

Steve Ghadiri

Majid Hosseini

FALL

2013

© 2013

Steve Ghadiri

Majid Hosseini

ALL RIGHTS RESERVED

ii

SECONDARY DISTRIBUTION SYSTEM OPTIMIZATION METHODOLOGY

AND MATLAB PROGRAM

A Project

by

Steve Ghadiri

Majid Hosseini

Approved by:

_________________________________, Committee Chair

Turan Gönen, Ph.D.

_________________________________, Second Reader

Salah Yousif, Ph.D.

_________________________

Date

iii

Student: Steve Ghadiri

Majid Hosseini

I certify that these students have met the requirements for format contained in the

University format manual, and that this project is suitable for shelving in the Library

and credit is to be awarded for the Project.

_________________________________, Graduate Coordinator

Preetham B. Kumar, Ph.D.

_________________________

Date

Department of Electrical and Electronic Engineering

iv

ACKNOWLEDGMENTS

The authors would like to acknowledge Dr. Turan Gonen, Professor of Electrical

Engineering at California State University, Sacramento, for his guidance, supervision,

patience, and care in recommending and evaluating this project in the area of Power

Engineering at California State University, Sacramento.

The authors are also appreciative of Dr. Salah Yousif, Professor of Electrical Engineering

at California State University, Sacramento, for his excellent instruction in the area of

Power Engineering at California State University, Sacramento, as well as being a reader

of this project.

The author would also like to acknowledge Dr. Preetham Kumar, Graduate Coordinator,

and Professor of Electrical Engineering at California State University, Sacramento, for his

guidance and direction in completion of this project.

v

Abstract

of

SECONDARY DISTRIBUTION SYSTEM OPTIMIZATION METHODOLOGY

AND MATLAB PROGRAM

by

Steve Ghadiri

Majid Hosseini

The goal of many utilities is to provide an economically balanced energy delivery

system that will provide customers with safe, reliable, and efficient means of power while

not subjecting them to over-designs with unjustifiable cost. In achieving that goal, the

utility company must rely on system designers to optimize several key parts of their

delivery system. The distribution system secondary, e.g., is one of these subsystems, and

therefore, it can pose optimization type challenge for the distribution system designers.

Arriving at optimal solutions, serves the best interests of the utility and the long-term

objectives of the customers and ratepayers.

In this paper, the authors analyze many alternative intelligent choices when considering a

simplified distribution system selection and show, thru the formulation and Matlab

computer programming, how a simple optimization technique can arrive at a standard

selection of the system components. Total Annual Cost (TAC) is the reviewed concept,

vi

and essentially, it reduces to a sum of initial capital investment, maintenance, and

operating costs including the costs of system losses. The optimization process is pivotal

in minimization of the TAC. Customer loadings are a key part of this selection and have

been considered in the program formulation, as well. Matlab program provides the ease

in selection of the components and speed in calculation performance to arrive at a most

feasible answer among optimized choices. Voltage drop is the constraint in this

optimization process, which is usually limited by the utility company’s requirement.

_________________________________, Committee Chair

Turan Gönen, Ph.D.

_________________________

Date

vii

DEDICATION

We dedicate this paper to our family for supporting and inspiring us in this journey.

viii

TABLE OF CONTENTS

Page

Acknowledgement ...............................................................................................................v

Dedication ....................................................................................................................... viii

List of Tables ......................................................................................................................x

List of Figures ................................................................................................................... xi

Chapter

1. INTRODUCTION ..........................................................................................................1

2. DISTRIBUTION SYSTEM DESCRIPTION .................................................................5

2.1 Distribution System Design Requirement ..............................................................5

2.2 Distribution System Planning Methodology ........................................................7

3. LITERATURE REVIEW .............................................................................................10

3.1 Design Criteria .....................................................................................................10

3.2 Components of Secondary Distribution System .................................................15

3.3 Voltage and Load Criteria ...................................................................................16

3.4 Main Factors ........................................................................................................17

3.5 Changing Paradigm of the Power Distribution System .......................................19

4. OPTIMIZATION METHODOLOGY ..........................................................................24

5. ECONOMIC ESTIMATION AND ANALYSIS .........................................................43

6. NUMERICAL RESULTS ...........................................................................................49

7. CONCLUSIONS ..........................................................................................................64

Appendix A: Matlab Optimization Program for Secondary Distribution System ............68

Appendix B: Instruction for Matlab TAC Program in Distribution System ....................79

Appendix C: Secondary Distribution System Voltage Drop Program ............................83

Appendix D: Distribution System Component Information Background ........................91

Bibliography .....................................................................................................................96

ix

LIST OF TABLES

Table

Page

4.1 Load Data for Book Example 6.1 ...............................................................................39

6.1 Summary of the Runs .................................................................................................53

x

LIST OF FIGURES

Figures

Page

1.1 One Line Diagram of Typical Primary Distribution Feeders .......................................2

3.1 Radial-type Primary Feeders .......................................................................................11

3.2 One Line Diagram of a Typical Distribution System .................................................14

4.1 Flow Chart of Safigianni’s Optimization Process ......................................................25

4.2 Matlab Program Flow Chart .......................................................................................30

4.3 One Line Diagram of Multiple Primary System for JHC ...........................................32

4.4 Typical Residential Area Lot Layout and Service Arrangement ................................33

4.5 Illustration of a Typical Residential Secondary Pattern ..............................................33

5.1 Current Transformer Cost ............................................................................................45

5.2 Historic Cost of Transformers ....................................................................................45

5.3 Current Cable Cost .......................................................................................................47

5.4 Historic Cable Cost ......................................................................................................48

6.1 Transformer Cost Fit into Third Order Model ............................................................51

6.2 Cable Cost Fit into Second Order Model ....................................................................52

6.3 Cable Cost For Different Sizes ...................................................................................52

xi

1

Chapter 1

INTRODUCTION

1. Introduction

The power distribution systems, which carry electric energy to even far-flung

customers utilizing the most appropriate voltage level, are divided into primary and

secondary. The part of the electric utility system, which is between the distribution

substation and the distribution transformers, is the primary feeders or primary

distribution feeders. The secondary power distribution systems include step-down

distribution transformers, secondary circuits, consumer services, and meters to measure

the consumer energy consumption. They are single-phase when they serve residential

customers and three-phase when they serve industrial or commercial customers.

The most commonly used secondary power systems are the radial systems. The

general requirements from a secondary power distribution system are that it gives

customers as stable a voltage as possible, operate safely and effectively at the minimum

possible cost and is well balanced. One line diagram of a typical primary distribution

feeder is shown in Figure 1.1 below, as depicted from standard Handbook for electrical

Engineers [3].

2

Figure 1.1 One-line diagram of typical primary distribution feeders.

Source: (From Fink, D.G., and H. W. Beaty, Standard Handbook for Electrical Engineers,

11th edition, McGraw-Hill, New York, 1978. With permission.)

3

Unfortunately, the reliability of service continuity of the radial primary feeders is

low. A fault occurrence at any location on the radial primary feeder causes a power

outage for every consumer on the feeder unless the fault can be isolated from the source

by a disconnecting device such as a fuse, sectionalizer, disconnect switch, or recloser.

Additionally, the operation and planning of electric power systems involve even a long

list of challenging activities, many of which are directly or indirectly related with the

optimization of certain objective functions [13].

The complex algorithms can be obtained from the cited references, which have

been developed in order to examine whether a radial secondary power distribution system

fulfills several criterions. Conductor tapering, network conductors having sufficient

thermal short-circuit strength, power flow in each network segment less than the thermal

of the conductor used there, acceptable percent voltage drop from the distribution

transformer (source node) up to any one of the ends of the network, and adequate fault

current to operate the network protection are essential part of this criteria [4].

While we acknowledge those methodologies and we ideally wish to create those

features in a comprehensive software program, we are somewhat limited to essential

math functions in our Matlab program, and therefore, we recognize that we have no way

of implementing all of them in our Matlab program. Use of power flow programs can

perhaps facilitate their implementation caption.

4

Switching mechanisms and over current protections are usually associated with

the type of configurations and they do not necessarily follow exactly into an optimization

program. Additionally, the cost of the over-current protection does not always vary

linearly with the size of the system. For simplicity, they have been put aside here as an

economical or fault current constraint in our program [6].

Safigianni has shown the methodology behind an elaborate optimization program

[4] and [5]. In her program, each stage is analyzed for the constraints by examination. If

the result of the above examination is that any of the previously mentioned technical

constraints is not satisfied, the program which implements the algorithm suggests a

number of alternative solutions concerning transformer changes or conductor

replacement combinations or both of them, in order to optimize technically the system

operation. This number depends on the load distribution and the conductor types and

sizes, which are available for the network construction. Finally, the program estimates

economically the alternative technically acceptable solutions and selects the most

economical one. The algorithm of Safigianni is an improvement and extension of the

algorithm used in her first reference and it is using more constraints, a load flow analysis

method to calculate the currents, voltages, economic data, and functions to estimate the

resulting technical solutions, which make final results more accurate and reliable.

Ultimately, a capable optimization method could expand to power flow modeling of a

portion of network.

5

Chapter 2

DISTRIBUTION SYSTEM DESCRIPTION

2.1 Distribution System Design Requirement

Secondary power distribution systems are used to deliver power to consumers in

residential or commercial businesses. We cannot imagine living without efficient

constant source of power. The best distribution system is one that will supply adequate

power to present and future loads safely and cost effectively. Distribution design

engineers choose the best distribution system, when they have considered all the design

parts, installation, and the cost. Design needs to be safe, effective, and reliable. Then, at

the same time, it needs to be not necessarily cheap, but cost effective.

In order to design the best distribution system, the system design engineer must

have information concerning the loads and knowledge of the various types of distribution

systems that are applicable. The various categories of buildings have many specific

design challenges, but certain basic principles are common to all. Such principles, if

followed, will provide a soundly executed design.

Understanding of the entire component in the power distribution system and their

functions are essential for implementing a proper design. The components in such a

system are power distribution transformers, primary and secondary conductors, and

power poles. For choosing the right component in this system, the most important

6

information is how consumer uses this power. Most important piece of information is the

amount of load that consumer will use considering present load and future load given the

load value will constantly change both within a day and over time. The future load

increase also needs to be considered because the system will not be cost effective if the

system need to be replace in 1, 2, or even 10 years.

In this paper, we report on the creation of a Matlab program for a simplified

residential block, which is illustrative of city development, and it explores a secondary

distribution system design that supply an area block with 24 loads. A reasonable load

demand could be input for each consumer. The demand assumption relies on average

monthly electrical usage for the area with some extra spare capacity (20 percent) for

safety before reaching the threshold and of course some extra room for future usage. The

program calculates the total annualized cost for the design and then this cost is optimized

with transformers, primary system enhancements, service laterals, and service drop

secondary conductors. The service is size optimized (or sub-optimized) based on

optimized cost and number of pertaining constraints. After the entire initial components’

selection, the program calculates the voltage drop to ascertain, if it is in an acceptable

range and if it is not, the design needs to be changed. Conductors can be overhead or

underground. In case of overhead conductor, the cost of poles and other component will

add to the overall layout cost, and for underground distribution, the cost of trenching,

conduits, and pull boxes will have to be added which usually are substantially more.

7

2.2 Distribution System Planning Methodology

The costs and reliability of power distribution systems are beginning to receive as

much attention as those of power generation and transmission systems. Modern planning

of these large-scale and complicated systems relies heavily on computers and

mathematical optimization tools [12].

Especially, in the developing countries where the growing power demand

provides needs for substantial expansion of power distribution systems, the long-term

benefit brought by using computerized optimization tools are tremendous, as compared

to widely practiced ad hoc methods involving only local computation.

The goal of modern power distribution system planning is to satisfy the growing

and changing system load demand during the planning period and within operational

constraints, economically, reliably and safely, by making optimized decisions on the

following: voltage levels of the distribution network; locations, sizes, servicing areas,

loads and building or expanding schedules of the substations; routes, conductor types,

loads and building schedules of the sub-transmission lines and feeders; other important

issues such as the types and locations of switching devices, load voltage levels, network

configuration, and load reliability levels, etc. The optimization problem is usually very

complicated, considering the scale of the system and the existence of many interrelated

factors.

8

The new approach for the systemized optimization of power distribution systems

is presented in Yifan Tang’s paper [12]. In Yifan’s paper the distribution system

reliability is modeled in the optimization objective function via outage costs and costs of

switching devices, along with the nonlinear costs of investment, maintenance and energy

losses of both the substations and the feeders. The optimization model establishes a

multi-stage, mixed-integer and nonlinear function, which is solved by a network-flow

programming algorithm. A multi-stage interlacing strategy and a nonlinearity iteration

method are also designed by him.

It is noteworthy to mention that the investment and maintenance costs of the

substations and the feeders are fixed costs (zero-order), while their operational costs are

variable costs squarely depending on their loads (second-order) [16], making the

objective function inherently nonlinear.

The need to seriously consider reliability in terms of capital costs in distribution system

planning is being recognized, as emphasized recently by an IEEE task force on

distribution reliability modeling and applications [17]. Unfortunately, few papers had

extensively tackled this problem [18] and [19]. Most of methodology by Yifan Tang is

based on the original Dr. Gonen’s work on Optimal Multi-Stage Planning of Power

System [21], and Pseudo-Dynamic Planning of Dr. Ramirez-Rosado and Gonen [22].

9

In this paper, of course for simplicity reasons we do not model reliability in our

simple secondary distribution optimization solution, however, when a designer is

considering the primary distribution design or a large portion of a city, one needs to

account for it. Usually selection of the switching configurations and degrees of

redundancy provide a certain level of reliability. Reliability inherently reflects into the

overall objective function via outage costs and costs of switching devices, along with the

present value of the costs of investment, maintenance and energy losses for both the

substations and the feeders.

10

Chapter 3

LITERATURE REVIEW

3.1 Design Criteria

Problem formulation and definition is important to arrive at a correct optimized

value in a multi- variable equation. There are various yet interrelated factors affecting the

selection of a primary-feeder rating [1]. Examples are:

1. Nature of the load connected

2. The load density of the area served

3. The growth rate of the load

4. The need for providing spare capacity for emergency operations

5. The type and cost of circuit construction employed

6. The design and capacity of the substation involved

7. The type of regulating equipment used

8. The quality of service required

9. The continuity of service required

There are many methods to design the distribution system and we will not concern

ourselves to discuss the other methods in detail here. However, we chose a radial type

primary feeder with uniform loading for the simplicity and ease of developing established

methodology into a Matlab optimization program. The simplest and the lowest cost, and

11

hence, the most common form of the primary feeder is the radial-type primary feeder as

shown in Figure 3.1, as shown below.

Figure 3.1 Radial-type Primary Feeders

Source: Electric Power Distribution System Engineering by Gonen [1]

12

The main primary feeder branches into various primary laterals, which in turn

separate into several sub-laterals to serve all the distribution transformers. Generally, the

main feeder and sub feeders are three-phase three-or four-wire circuits and laterals are

three or single-phase. The current magnitude is the greatest in the circuit conductors that

leave the substation. The current magnitude continually lessens out toward the end of the

feeder as laterals and sub-laterals are branched off the feeder, tapering down. Usually, as

the expected current value reduces in the service lateral, the size of feeder conductors

reduces in the design. However, the permissible voltage regulation may restrict any

feeder size reduction, since the thermal capacity of the feeder is also a consideration.

The reasons for making a secondary power distribution system radial are the low

investment cost, the simplicity of the protection circuits, and the easy control of the

power method convenient for radial networks. In this project, we analyzed and

concentrated on the three important components of the secondary distribution system.

These components are distribution transformers, primary electrical conductors, and

secondary electrical conductors. Focus of this paper will be cost effectiveness of the

design and optimizing this cost. Cost, reliability, and life of the component will be

discussed and these components will be analyzed and chosen mainly based on load

demands and voltage drops. Electrical companies are facing very challenging situation,

not only the energy price for the consumer need to be reasonably affordable and

comparative in value, but the electric supply system also need to be reliable and

13

available constantly. In addition, the electric utility needs to be adapting to the change in

load demand continuously.

In the older neighborhood, the secondary distribution system is aging and need to

be replaced. The cost of components, installation and labor, and maintenance compared

to fifty years ago is significantly more, and with all the new technology that consumers

use, the demand tends to be significantly higher, also. The design should be efficient and

cost effective otherwise it will cost the utility company a lot of money and that extra cost

will pass on to the consumer, and consequently, the price of electricity will go up.

The operational objectives of a power grid are to provide continuous quality service at an

acceptable voltage and frequency with adequate security, reliability, and an acceptable

impact upon the environment—without damage to power grid equipment—all at a

minimum cost. In Figure 3.2, the direction of arrows indicates the priority in which the

objectives are implemented.

14

Figure 3.2 One-line diagram of a typical distribution system

Source: Electric Power Distribution System Engineering by Dr. Gonen

15

Quality service that is environmentally acceptable, secure, and reliable, and

entails minimum cost is the main objective in power grid operations. However, during the

emergency conditions, the system may be operated without regard for the economy and

environmental restriction such as the use of high polluting energy source, instead

concentrating on the security and reliability of the service for energy users, while

maintaining power grid stability. [7]

The term continuous service means “secure and reliable service.” The term

secure, as it is used here, means that upon occurrence of a contingency, the power grid

could recover to its original state and supply the same quality electric power energy as

before. Later definitions have been added to signify the innovative technologies in the

smart grid arena, such as resiliency, and self- healing characteristics.

3.2 Components of Secondary Distribution System

In the design of secondary distribution system, three essential components are

distribution transformers, primary conductors, and secondary conductors. Load demand,

voltage drop, and voltage fluctuation should be considered and examined for sizing the

components because of their effect on both transformers and conductors. Overhead or

underground cables will be discussed in brief in this paper since most likely the

underground installation requires the trenching and conduit, and therefore, it will be

substantially more expensive than the overhead’s cost of the poles and reinforcements.

16

3.3 Voltage and Load Criteria

The present and future electrical needs of the consumers must be anticipated by

utility companies and system should be planned accordingly. An electric load defines the

rate at which the supply system is required to do work [24]. The unit of power

measurement is Watt and electric power is the rate at which electric circuit performs

work. The electric load power consumption is measured by kilowatt-hour, which the

amount of work (1000watt) is done over the period of an hour. The amount of energy per

unit time, which should be supplied by the utility, is load. (This is the total energy

consumers are using or need in worst-case scenario to run all their electrical equipment

such as lights, appliances, motors, etc. This load can be changed depending on time of the

day or year. Planning an efficient design requires that a good forecast of load

characteristics to be developed. It is very important that the utility can meet this

maximum load demand. This maximum load demand is usually determined after review

of a residential neighborhood over a year. The total power consumption (household load)

for each residential unit is determined, or at least estimated. Then, the total power for that

area is calculated. The utility can develop their plan for the size of components when they

arrive at the load calculations.

Not only the load demand fluctuates hourly, daily, monthly and yearly, but it also

can increase and grow over time due to technology changes. Also of importance is

estimating how the load may grow over time and at what rate [25]. Usually the new

technology brings newer energy efficient devices that should decrease the load demand.

17

However, since we are using more devices the load demand is still higher. In particular,

we can refer to the air conditioning loading, the most variable and disproportionally

dominant component of bus load, which has brought to older neighborhoods that were

not designed or built with it in the designer’s mind [26]. Another example, is super screen

televisions that consume increasingly more watts than their older smaller predecessors. It

is necessary for utility companies to re-evaluate the existing distribution system

frequently to make sure the size of existing component are adequate for the increased

loads. Furthermore, one can step in future and explore the frustration felt by homeowners

when they may encounter difficulty in charging their electric vehicles all simultaneously,

and finding that the neighborhood distribution circuit to be inadequate [10].

3.4 Main Factors

Utility companies consider two factors for load demands when designing a

secondary distribution system. These two factors are Diversity factor and Coincident

factor. The diversity factor is ratio of sum of the individual demands of the individual

loads to maximum demand of the entire system [25]. Maximum individual demand for

each customer does not occur at the same time and if all maximum individual demands

are added, the result will be much higher than the maximum load of the system. If there

was no diversity of the maximum load timing for each customer, then there would be a

need for very large system capacity. Hence, the diversity factor is an important economic

consideration for electric utilities when designing distribution system [24]. Diversity

factor is usually equal to or greater than unity.

18

The coincident factor, the reciprocal of diversity factor, is often preferred because

it is a way to describe load characteristics using a value that is usually less than unity

[25]. This factor is used to calculate secondary voltage drops.

One of the most critical components of the distribution system is transformers.

When a transformer breaks and fails, it is noticeable to customers and whole

neighborhood. It is hard to replace overhead transformer in timely manner and it is hard

to service them. “Hot Spot Area”, or the highest temperature in the winding Area, is the

most important factor relating to the loading capacity and aging of an oil-paper-installed

distribution transformer. Hot spot temperature and data for life span of transformers are

unknown and because of this lack of information transformers are often overrated.

However, due to possible over-loading situation in the face of unavailable monitoring

techniques, it is still possible that hot-spot temperatures can rise to undesirable levels

[27].

In order to maintain transformer ageing within desirable limits, the goal is to keep

the maximum hot –spot and top oil temperatures and the current load under allowed

limits [28]. The following limits are given in [29]. Hot-spot temperature can range

between 120C and 160C and top oil temperature can be between 105C and 115C.

Transformers current rating can exceed its typical rating for a short duration by 30 to 100

percent. Distribution Transformers are usually designed for peak efficiency at or near

19

average power level. However, their actual efficiency is dependent upon their loading

schedule [30].

3.5 Changing Paradigm of the Power Distribution Systems

Over the last twenty years, renewable energy sources have been attracting great

attention due to the cost increase, limited reserves, and adverse environmental impact of

fossil fuels. In the meantime, technological advancements, cost reduction, and

governmental incentives have made some renewable energy sources more competitive in

the market. Among them, wind energy is one of the fastest growing renewable energy

sources. [11]

Solar technology is also developing fast and has much to offer despite the

currently high costs. However, to make a significant contribution to bulk electricity

generation, a major technology and cost reduction is required. Thin film PV has the

potential to deliver cheaper electricity. Currently, commercial interest centers around

thin film nano-crystalline hybrid cells and the hetero junction cells based on copper

indium di-selenide and cadmium telluride. Both of the latter provide reasonably stable

efficiencies and are expected to benefit from improved manufacturing techniques. There

is currently a flurry of investment activity in these technologies that includes

manufacturing on to glass, and metal and polymer foils. Industry experts confidently

expect that the new mass production technologies will deliver cells capable of generating

20

electricity competitively with conventional forms and nuclear perhaps within the next 10

years. [2]

Future grid developments undoubtedly will have to accommodate for the

integration of renewable energies in the transmission and distribution grid. Due to rapid

development of renewable energies and their integration into the grid, the grid codes in

many countries have been updated to address the issues related to renewable energy

power generation. Differences in various grid codes also stem from regional and

geographical conditions, usually based on the experience of operating the power system,

acquired by the utility. However, their ultimate goal is to ensure safe, reliable, and

economic operation of power system. The main elements in the grid codes include fault

ride through requirements, active / reactive power control, frequency / voltage regulation,

power quality, and system protection. [9]

Power systems have developed over the years to supply a varying demand from a

centralized generation sourced from fossil and nuclear fuels, There seems to be a

universal agreement that by the end of this century the majority of our electrical energy

will be supplied from Renewable Energy (RE) sources. Unfortunately, due to the small

sizes of these generators, they cannot connect to the transmission system because of the

high cost of high voltage transformers and switchgears. In addition, the transmission

system is often a long way away as the geographical location of the generator is

constrained by the geographical availability of the resource. Small generators must

21

therefore connect to the distribution network. Such generation is known as distributed or

dispersed generation. [2]

In traditional power systems power invariably flows from the large centralized

power stations, which connect to the EHV network down through the HV and LV

systems to distribute power to consumers. In power system with the distributed

generation, power may travel from point to point within the distribution system. This

unusual flow pattern has some serious implications in the effective operation and

protection of the distributed network [35].

It may be concluded that present power systems will gradually have to evolve and

adapt so that, in the far future, a managed demand will be supplied from distributed,

mostly variable, RE generation. This transformation will be aided by the liberal use of

power electronic interfaces capable of maximizing the effectiveness of RE sources,

controlling power flows, and ensuring reliability of supply.

Additionally, other changing technology changes are affecting the utility planning

process. Today, e.g., we have more than 3,300 plug-in vehicles on San Diego roads, and

the numbers could grow quickly. However, the challenge for operating utility is not

necessarily the number, as much as it is when the vehicles charge. The utility’s goal is to

make sure the vehicles are grid integrated, which means that the majority of charging will

happen at times of day when the grid has an abundance of energy, and not at times when

22

energy is scarce. With this kind of integration, charging costs and emissions will be lower

due to more efficient use of the grid and our generation resources, which will help the

utility customers to realize the many benefits of these environmentally friendly vehicles.

This concept of effective integration is vital because of the charging capability of each

vehicle. Right now most of these vehicles can charge at a rate of about 3 to 7 kilowatts,

and some models just entering the market are capable of charging at up to 20 kilowatts or

more [14].

Another technique the utility company has in their tool box of solutions is the

Conservation Voltage Reduction (CVR) [15]. CVR is a proven technology for reducing

energy and peak demand. By more fully utilizing existing distribution automation

equipment, smart grid technologies, and communicating with meters and switchable

devices, capital purchases can be avoided or delayed. In addition, CVR has the potential

to be Energy Efficiency (EE) resource by helping utilities maximize returns while

meeting EE goals. Today, technologies exist to change the CVR operating paradigm.

Pilot projects based on smart grid technologies and real-time operating systems show

energy savings and demand reductions of 3% are possible. In fact, the Pacific Northwest

National Laboratory (PNNL) estimated total CVR energy savings in the US alone to be

6,500 MWs or 56,940,000 MWh—or the equivalent of Grand Coulee Dam operating at

nameplate capacity for a year [15]. Pilot projects, funded in part with stimulus dollars, are

uncovering promising results: Voltage regulation has been a critical part of power system

operation since Thomas Edison first lit electric lights over Menlo Park on New Year's

23

Eve in 1880. For many years, electric utility companies initiated load reductions during

critical peak load periods by reducing voltages delivered to air conditioners, home

appliances and industrial machinery.

CVR can be accomplished through a variety of conventional technologies (tapchanging transformers, line drop compensators, generator excitation controls, voltage

regulators, line switchable capacitor banks, static VAR compensators, circuit

reconfiguration, and load control) enhanced with microprocessor controls and

communication packages.

The challenge quickly becomes defining specific control schemes, monitoring points,

sensor technologies, protocols, triggering mechanisms, etc. Energy is saved by

maintaining voltages close to lower thresholds without going below them. If the priority

is to regulate end-user voltages, energy consumption is reduced, saving dollars for the

end-user. If losses are to be minimized, feeder volts and VARs are regulated, reducing

energy, releasing line capacity and saving dollars for the utility company.

24

Chapter 4

OPTIMIZATION METHODOLOGY

The dynamic programming technique should be used to optimize the objective

function of power distribution system planning. In its simplest sense, dynamic

programming can be thought of as an attempt to break large, complex problems into a

series of smaller problems that are easier to solve separately.

There are number of decision stages in the dynamic programming at each stage

and there are several alternate courses of action with each stage. The decision generated

by stage one, acts as conditions of the problem for stage two and so on. In other words, at

each of the several stages there is a choice of decisions and the decisions, initially taken

affect the choice of subsequent decisions. The various rules of decision making can be

established after considering the effects of each decision (separately) and the optimum

policy for further decisions. The basis of dynamic programming is to select the best

amongst the final possible alternative decisions. This process is then repeated, ignoring

all those alternatives which do not lead to selected best (optimum). The best sequence of

decisions can thus be defined, by repeating the above process. Safigianni’s paper [4] has

shown remarkably that the full optimization process depends on optimization of a full

multi-objective function. Please refer to the flow chart of the optimization process as

shown below.

25

Figure 4.1 Flow Chart of Safigianni’s Optimization Process

Role of optimization undoubtedly can be broad and comprehensive, or narrow and

specific. For example based on the pioneering earlier works cited by Dr. Gonen, a

Nigerian team took it one step further by the use of integer programming technique.

26

(Alternatively, and more comprehensively, one may look at the distribution system sizing

to include the reliability of the distribution system as well [13]. Depending on the choice,

these many other considerations may do enter into the algorithm formulation. Ultimately,

distribution engineers need to present a dynamic approach towards the sustainability of

power distribution system using a comprehensive application. The cost of energy losses,

substation cost, feeder cost, and outage cost can be developed using dynamic

programming technique and a three stage iterative solution with the aim to optimize the

outage costs. For example, the three stages of optimization could be carried out to

determine, the number of substation sites and exact location, the feeder routes and the

load flow in the network, and the outage cost to cover system node reliability evaluation.

In our paper, we implemented a method for minimizing Total Annual Cost (TAC)

of installing and operating the secondary portion of a three-wire single-phase distribution

system in a residential area, as has been elaborated in Dr. Gonen’s Distribution Book.

This can be applied to underground or overhead distribution. Similarly, one can apply

the optimization techniques to sectors of the power system, ignoring the reliability

aspects for the moment (since integer programming is beyond our current solution to the

problem). We have formulated and written a MATLAB program for the calculation and

we obtained the near optimized results, by using computer math power for speed and

accuracy in selecting the most economically justified alternative in a simple residential

radial distribution section.

27

The numerical tabulated example run results in chapter 6 are the testimony to this

endeavor. A few of these MATLAB computer calculations have been compared with

hand formulated calculation, for verification purpose. Results match very well for all

practical purposes.

The constraint in the program is the degree of voltage drop that system

encounters.

The distribution system design engineer must of course take the optimum design size

calculated and assure the utility with confidence that load is not going to affect the

system voltage severely. Sometimes, the design requires upsizing the secondary

conductors and occasionally in the existing systems, re-conductoring with bigger size

wires will be needed. The aim of the re-conductoring process is the satisfaction of the

voltage drop criterion or the protective devices condition, or both of them.

Every

combination of conductor replacements, which satisfies the above conditions, is a

solution to the problem. Theoretically, there are many solutions for a given network but

only a few of them are technically acceptable.

Our implementation of the Matlab

program depended on making some assumptions. The technically acceptable solutions

satisfy the given constraints below:

1. A conductor of a bigger size but of the same type must always replace one span

conductor. (There are three conductor types: overhead bare lines, underground

cables and overhead twisted cables).

28

2. New type conductors must replace old type conductors, which are no longer in

use (e.g. XLPE cables replace paper insulated cables).

3. Because of the big replacement cost, the underground cables are the last solution

in the reconductoring process and they are replaced if nothing else can be done.

Obviously, our approach has to contain simplicity to be programmed with the help of

computer program. (Dr. Gonen has added the costs of a uniform residential distribution

system in his Distribution book.) It entails dividing the costs into installation costs and

operating costs of the distribution system, annualized over the asset life. (It is important

to use asset life annualized since different modifications may have different life and it

provides a uniform basis for our comparison).

We then take a partial differential

derivative with respect to each variable, size of the transformer, cross section area of

service lateral, and cross area of the Service Drop. Equating each of these equations to

zero will yield us the computationally optimal value. However, this value does not

necessarily yield to a standard size of transformer or wire, per se. Therefore, we have

created a logic ladder where the program ascertains the sizes against the input given

values and automatically progresses to the next size. When the transformer is chosen,

then the next wire SL will be selected, and then finally SD size will be determined by the

program. We have provided the voltage drop as a major constraint where the value

obtained will be tested with a logic statement for being over five (5) percent of the value

29

allowed in distribution voltage drop. A sample of the Optimization Program is provided

in Appendix A.

Furthermore, we have completed this constraint as a separate Matlab program by

itself where students can input different distribution problem input data and verify the

voltage drop within a sector of a secondary radial configuration. A sample of this

program is shown in Appendix C.

Of course the extent of introducing a multi objective function with the introduction

of reliability parameters, maintenance, protection systems, etc. into our study is beyond

the concept of this master’s project, given the wealth of information topics that were

collected for these authors,. What we had to reduce, however, was the essential parts of a

secondary system that we could grapple with and could introduce it with our simple

Matlab programming. The following page flow chart Figure 4.1 shows the concept of

our work from the adapted flow chart as shown by Safigianni’s paper [4].

30

Read the Input Data

Calculate Load

Obtain the second order

polynomials and obtain

the derivative equations

Calculate Optimum

Transformer Size

and Distribution Wires

Provide a Safe

Reserve Margin

For Future Growth

Formulate Criteria

Choose Next Standard

Available Transformer

Size

Block dimensions are asked

via queries Input to the

Program

Standard Lateral Distribution

configuration is assumed

Calculate Optimum and then

Choose Standard Available

Service Lateral Size

Is the Chosen Standard

Size Cost Optimal?

Yes

No

Calculate Optimum and then

Choose standard Service

Drop available Size

Calculate the Voltage Drop

Constraint to see Feasibility

Is the Voltage

Regulation too high?

Yes

No

Print the Optimal

Combinations that met the

Criteria

MATLAB PROGRAM FLOW CHART

Figure 4.2 Matlab Program Flow Chart

Source Provided by Authors

Comments ?

Requested

31

We recognize, of course, that the primary and secondary systems can be simple

or complex as well. Figure 4.3 below shows an extensive primary system. Typically, in

the residential developments, one block of residential area consists of two pole mounted

distribution transformers, which feed twelve houses. This design determines the optimal

size for transformers, primary conductors, and secondary conductors. The optimization

process requires meeting a certain condition and perhaps holding some assumptions as

well to do it properly.

In this project, we constructed and analyzed the Total Annual Cost (TAC) of

initial procurement, installation, and operating cost of secondary distribution system and

provided a Matlab computer program to solve for optimum commercially available size

of transformer and wires. We also elaborated on the calculation method to minimize TAC

and approximately optimize the system the way that will be most efficient. Furthermore,

we illustrated thru the program that this minimized design satisfies the voltage drop

constraint, and therefore, the voltage dip will not exceed the tolerance criteria.

32

Figure 4.3 One Line Diagram of Multiple Primary System for John Hancock Center

Source: (From Fink, D.G., and H. W. Beaty, Standard Handbook for Electrical Engineers,

11th edition, McGraw-Hill, New York, 1978. With permission.)

The Following Figure 4.4 shows one section of secondary distribution system

which has two transformers, and each is feeding 12 customers (loads). This system is in a

straight line design and is expected to have width ‘d’ which makes each section of

secondary line (SL) length ‘2d’. If a secondary line is not used every four customer will

have one transformer.

33

Figure 4.4 Typical Residential Area Lot Layout and Service Arrangement

Source: Electric Power Distribution System Engineering, by Dr. Gonen

In this system over head cable or underground cable can be used. If over head

cable is used, then the transformers are pole mounted and if the underground cable is

used, the transformers are grade-mounted on a concrete slab. The SL and the SD can be

either open-wire or triplex cable construction.

Pole or underground pad-mounted

submersible transformer

Pedestal or hand hole

(on pole or underground)

ST

SD

SD

SD

SD

SD

SD

SD

SD

SD

SD

SD

SD

Alley or Near Lot Line

Illustration of a Typical Pattern

Figure 4.5 Illustration of a Typical Residential Secondary Pattern

Source By Authors

34

The following parameters are used in our calculations:

ST=transformer capacity, continuously rated kVA

Iexc=per unit exciting current (based on ST)

PT, Fe=Transformer core loss at rated voltage and rated frequency, kW

PT, Cu=transformer copper loss at rated kVA load, kW

ASL and ASD=conductor area, kcmil

P=conductor resistivity, (Ω- cmil)/ft

The following assumptions are made to make the calculation easier and possible:

1. All services are single-phase, three-wire, 120/240V

2. All three wire circuits have perfectly balanced loading

3. The system is energized at all the time 8760 hours per year

4. The annual loss factor is calculated by Fls=0.3*Fld+j0.7*Fld^2

5. All loads have the same power factor (constant)

The total cost depends on number of transformer, type and size of conductors,

distance and other parameters, which for simplicity and calculation purposes we will

make some assumption in our calculation. For calculation of the TAC we need to

know the followings:

1. Annual installed cost of transformer and associated protective equipment(ICT)

2. Annual installed cost of triplex aluminum SL cable (ICSL)

3. Annual installed cost of triplex aluminum SD cable (ICSD)

4. Annual installed cost of pole and hardware on it (ICPH)

35

5. Annual operation cost of transformer exciting current (OCexc)

6. Annual operating cost of transformer due to iron losses (OCT, Fe)

7. Annual operating of transformer due to copper losses (OCT, Cu)

8. Annual operating cost of copper loss in a unit length of SL (secondary

line)(OCSL)

9. Annual operating cost of copper loss in a unit length of SD (Service

Drop)(OCSD)

TAC formula has three main variables: Transformer Capacity, Conductor Area of

SL (ASL), and Conductor Area of SD (ASD). For minimizing the ATC, we will take

three partial derivatives and set each derivative to zero.

However, this optimized number is not necessarily a practical one by any means.

Since the sizes of materials are usually given in discrete values, we must choose the

next size Up or Down, depending on the choice. Here is where our logic selection

ladder automatically chooses the next commercial available size, subject to the

voltage constraint.

MATLAB programs are written for the calculation and getting the result faster

and more accurately. Towards the end of this assignment, we will have some

examples to test our MATLAB program and compare the result in MATLAB with

hand calculation.

36

1. ICT which is the annual installed cost of distribution transformer and associated

protective devices is calculated by following formula

ICT = (2000 + 58.08 x ST) x i

$/transformer

ST is transformer rated kVA and is between 15kVA and 100kVA

2. ICSL is annual installed cost of triplex aluminum SL cable is calculated by

following formula:

ICSL = (480+ 36 x ASL) x i $/1000ft

ASL is conductor Area in kcmil. This cost is for 1000 ft of cable, which is 3000

ft conductor.

3. ICSD is annual installed cost of triplex aluminum SD cable is calculated by

following formula

ICSL= (480+36 x ASD) x i $/1000ft

ASD is conductor Area in kcmil.

The ICSD and ICSL are alike since in this example the same kind of conductor

will be used for both SL and SD

4. ICPH is the annual installed cost of pole and hardware on it.

ICPH =1280 x i

$/pole

37

5. OCexe is the annual operating cost of transformer exciting current

OCexe = Iexc x ST x ICcap x i

$/transformer

ICcap is total installed cost of primary-voltage shunt capacitor = $5.00 /kvar

Iexc is the average value of the transformer exciting current base on ST = 0.015

pu

6. OCTFe is annual operating cost of transformer due to core (iron) losses.

OCTFe = (ICsys x i + 8760 x ECoff) x PTFe $/transformer

ICsys is the average investment cost of power system upstream toward the

generator from distribution transformer = $2,800/kVA

ECoff is incremental cost of electric energy (off-peak) = $ 0.015/kWh

PTFe is the annual transformer core loss kW = 0.004 x ST

7. OCTCu is the annual operation cost of transformer due to copper losses

OCTCu = (ICsys x i +8760 x Econ x FLS) (Smax/ST)^2 x PTCU $/transformer

ECon is the incremental cost (on-peak) = $0.02 /kWh

Smax is the annual maximum kVA demand on transformer

PTCu is the transformer copper loss, kW at rated kVA

PTCu = 0.073 + 0.00905 x ST

FLS is the annual loss factor

8. OCSLCu is the annual operating cost of copper loss in unit length of SL

OCSLCu = (ICsys x i +8760 x ECon x FLS) x PSLCu

38

PSLCu is the power loss in unit of SL at the time of annual peak load due to

copper losses kW

PSLCu is an R x I^2, and it must be related to conductor area ASL with R =

pL/ASL

9. OCSDCu is the annual operating cost of copper loss in unit length of SD

OCSDCu = (ICsys x i +8760 x Econ x FLS) x PSDCu

PSLCu is the power loss in unit of SD at the time of annual peak load due to

copper losses kW

PSDCu is an R x I^2, and it must be related to conductor area ASL with R =

pL/ASD

To find the equation for TAC, the above nine formulas need to be added together.

When these formulas are added together (and with some assumption), TAC equation will

be reduced to a function of three design variables,

TAC = f (ST, ASD, ASL)

It has to be noted that many parameter, such as the fixed charge rate i, transformer core

and copper losses, installed cost of poles and lines are contained in constant coefficients

A to H in TAC function.

TAC = A+ B/ST^2 + C/ST + D x ST + E x ASD + F/ASD + G x ASL + H/ASL

39

After substituting the fixed parameter (approximate assumption) we will have;

TAC = (6.048*ASD) + (4.32*ASL) + (14.9522*ST) + 374.536*L1*(L1/ASD) +

2141.28*L4*(L4/ASL) + (6589.33*(L12/ST)*(L12/ST)) + (816.9*L12*(L12/ST)) +

1306.24;

L1= Max load for 1 costumer

L4= Max load for 4 customers

La12= Max load for 12 customers

From Table (4.1), Class 2, we have:

L1=10, L4=6, and La12= 4.4

TABLE 4.1

Load Data for Book Example 6.1,

Source: Electric Power Distribution System Engineering Book, by Dr. Gonen

40

Basically, if above loads and the dimensions of SL and SD cable and the size of

transformer are known, TAC for secondary distribution system can be calculated.

For example if 39 kVA transformer with ASL of 205 kcmil and ASD of 85.4 kcmil are

used with above loads the TAC = $4595 /block

And if 50 kVA transformer with ASL of211.6 kcmil and ASD of 105.5 kcmil are used

with above loads the TAC = $4693 /block

And if 50 kVA transformer with ASL of250 kcmil and ASD of 133.1 kcmil are used

with above loads, the TAC = $4896 /block

Minimizing TAC

For minimizing TAC, since TAC is a function of three variable, using TAC

equation and taking three partial derivatives will set each derivative equal to zero and it

follows;

d(TAC) / d(ST) = 0

d(TAC) / d(ASL) = 0

d(TAC) / d(ASD) = 0

The result of above equations that are used henceforth merely serve as indicators

of the region that contains the minimum TAC achievable with standard commercial

equipment size. The problem is further continued by computing TAC for the standard

commercial sizes of equipment nearest to the results of above equations.

41

There are additional criteria which must be met in the total design of the

distribution system, whether or not minimum TAC is realized. The further

criteria involve quality of utility service. Minimum TAC designs may be

encountered which will violate one or more of the commonly used criteria:

1. A minimum allowable steady-state voltage at the most remote service

entrance may have been set by law, public utility commission order, or

company policy.

2. A maximum allowable motor-starting voltage dip at the most remote service

entrance similarly may have been established.

3. Ordinarily the ampacity of no section of SLs or SDs should be exceeded by the

designer.

4. The maximum allowable distribution transformer loading, in per unit of

the transformer continuous rating should not be exceeded, by the designer.

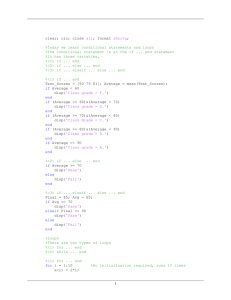

Matlab Programs

There are two Matlab program written for TAC. An extra third Matlab program is

also provided to calculate voltage drop in a secondary system.

The first one is called Optimize-TAC.Rev24 (Appendix A) and it minimizes TAC

by asking for loads as inputs. It then calculates the optimized sizes for ST, ASL and

ASD, and it finally determines the optimized TAC. In this program not only the

42

optimized sizes of equipment and TAC are calculated, but also, the standard size and

TAC for standard size equipment will be picked by the program.

The second one (Appendix B) calculates the TAC by asking the three loads and

sizes of ST (in kVA), ASL (in kcmil) and ASD (in kcmil), as inputs. It is called TACtotal and it is basically serving as a calculator for arriving at TAC value.

The third program (Appendix C) is provided as a courtesy in addition to the other

matlab programs so the future students can calculate or analyze a typical secondary

system voltage drop. This program is called OnlyVoltageDrop and it queries for the size

of transformer, SL, and SD and it then calculates the voltage drop total and by element.

Voltage drop is an independent constraint set to alter program calculation in the

Optimize-TAC program. However, we felt it will be useful to provide it also

independently as a calculator.

Copies of each program and program instructions are also attached for your

review (in Appendices). Furthermore, the computer program flow diagram was also

provided in Chapter 3.

43

Chapter 5

ECONOMIC ESTIMATION AND ANALYSIS

We began our master’s project, of course, with the understanding that we will be

solving the Secondary Distribution System Optimization problem with the help of

computer provided Matlab programming and using a simplified radial distribution as an

example. In doing so, we had to gather a more current set of data, which we also verified

by a utility company recent purchases for a close approximation and validity of material

and labor costs. Similarly, we obtained in place unit cost of these material and equipment

with National Construction Estimator (NCE) tabulated book index to arrive at the Total

Annualized Cost function.

Consequently, several other factors, such as the cost of electricity, capacitors, and

transformers had to be revised upward from the figures initially shown in Dr. Gonen’s

Distribution System book about three decades earlier. We wanted to compare the

efficiency of the transformers to earlier values, as it was not clear to us if significant

technological advances have been made in this area. We then provided several linear

regressions of Matlab algorithms to be able to categorize choices and result in the final

determined values in our Optimization Program.

Cost analyzes have been discussed in this paper. The Two Matlab programs that

have been provided work out the TAC cost if the input data file is provide in the Matlab

44

folder. The OptimizeTAC program will figure out the best combination of elements when

optimized for their size and subject to the voltage constraints and its TAC cost, as shown

in Appendix A. This optimization program provides the near optimized cost for the

components. It will further reflect the annualized cost for the given design parameters of

our distribution system.

We have surveyed the L.E Means and National Construction Estimator books to

obtain more recent cost data. The cost figures reported are for the mineral insulated

aluminum conductors with the steel cores. We had to provide the linear regression

function for the obtained data to make sure it would be in that window of 4 to 8 times

cost escalation that we had arrived at before. The data is shown in the input Excel sheet

that the program reads from.

Additionally, we contacted SMUD for transformers and capacitors data, and we

obtained their more recent purchases. We have performed linear regression functions on

these data as well, to arrive at the best-fit cost for the given size. Across the board, we

observed the typical economical values have increased between 4 to 8 times of

preliminary Westinghouse number reported by Dr. Gonen in his Distribution book

example, page 299. (Refer to Transformer cost in Figure 5.1 and 5.2, shown below

retrospectively.)

45

Current Cost vs. Transformer kVA

14000

12000

Cost ($)

10000

8000

6000

4000

2000

0

10

15

25

37.5

50

75

100

167

100

167

Transformer in kVA

Figure 5.1 Current Transformers Cost

Source Provided by NCE

Historic Cost vs. Transformer KVA

1600

1400

Cost ($)

1200

1000

800

600

400

200

0

10

15

25

37.5

50

75

Transformer in kVA

Figure 5.2 Historic Cost of Transformers

Source Provided by NCE

46

Surprisingly, capacitor mass production technology has managed to provide

relatively lower cost despite the inflation. SMUD purchases reflect cost to be about three

to four times the original indicated values. Similarly, the utilities markup for on-peak and

off-peak energy generation has been relatively contained due to the competition in a

heavily regulated electric market. We suspect that markup to be between three to four

times what originally assumed in the reference.

Given the approximation that cost of material and labor have at least risen four to

six percent a year, Every 12 to 14 years it will be twice the cost. Carrying that

methodology forward 36 years, one can reasonably expect the material and prices to have

increased by a factor of 6 to 8 times more than original reported in the Distribution Book

Since these data were originally taken from the late seventies references, it translate into

4 to 8 times the original estimates. In fact, current cost of transformers and wires support

this assertion, and furthermore, the two graphs we have provided above and below

(Figures 5.3 and 5.4) sustain this assertion.

47

Current Cable Cost vs. kcmil

12000

10000

Cost ($)

8000

6000

4000

2000

0

41.74

52.74

66.36

83.69

105.6

133.1

kcmil

Figure 5.3 Current Cable Cost

Source Provided by NCE

167.8

211.6

250

48

Historic Cable Cost vs. kcmil

1600

1400

1200

Cost ($)

1000

800

600

400

200

0

41.74

52.74

66.36

83.69

105.6

133.1

kcmil

Figure 5.4 Historic Cable Cost

Source Provided by NCE

167.8

211.6

250

49

Chapter 6

NUMERICAL RESULTS

Many low voltage distribution networks in the United States are typically a 12 kV

primary 120/ 240 secondary system, and in the residential areas they are usually served

by single-phase distribution circuit, as shown in Figure 4.5.

We performed linear regression data fit into a third order polynomial function based on

the transformer cost data we had obtained from the utility company (SMUD in this case)

and also the typical construction cost reporting (Means). The data from transformers cost

was fit perfectly into a third order polynomial, per earlier book citation [1]. The total

variations never exceeded more than about 2 to 4 percent from the data, and that is

practically the error margin in the survey in the first place. The conductor data were also

consecutively fit into the second order polynomial, as well. Matlab command Polyfit was

extremely powerful to help fit data into other polynomial orders. The results are shown in

Figures 6.1 and 6.2.

The data provided below along with the Figures are the testimony for this data

match:

50

Single-Phase Residential Distribution Transformers

No

Total

Rated

Load

Load

Cu

Z

Mat.

Labor

OH

Total

Volt

Z

Actual

I@

208

V

Loss

Losses

Loss

(%)

$

$

$

$

Base

Ohms

X

10

48.1

28.5

176

148

1.900

1100

455

325

1880

240

9.480

0.109

15

72.1

31.9

265

233

1.900

1500

605

445

2550

240

6.325

0.073

25

120.2

53.6

344

290

2.200

2050

730

545

3325

240

4.393

0.051

37.5

180.3

71

462

391

1.800

2650

910

715

4275

240

2.396

0.028

50

240.4

90.1

566

476

1.800

3150

1050

800

5000

240

1.797

0.021

75

360.6

130.5

694

564

2.300

4175

1125

950

6250

240

1.531

0.018

100

480.8

185

864

679

2.000

5747

995

1011

7753

240

0.998

0.012

167

802.9

500

2100

1600

2.100

9000

1125

1513

11638

240

0.628

0.007

Size

51

Transformer Data Vs. Third order model

Series1

Series2

Unit Cost ($)

11567

7391

6297

11638

5031

4249

3322

2453

1970

1880

1

2550

2

3

5000

4275

3325

4

5

7431

6250

6

7

8

Transformer Sizes

Figure 6.1 Transformer Cost Fit Into Third Order Model

Source Provided by NCE

Distribution Aluminum Wires in Triplex arrangement for Residential Sectors

Wire

(Values given are for 1000 ft length)

Wire

No.

Size

Rating

Resis

I (A)

R

Z

DC

AC

#6

X

IZ

I2R

Mat.

Labor

Indirect

Total

Area

$

$

& OH $

$

kcmils

26.24

#4

1

140

0.4

0.52

0.3323

2130

1660

1000

4790

41.74

#3

2

155

0.32

0.41

0.2563

2310

1740

1080

5130

52.74

#2

3

185

0.25

0.32

0.1997

2520

1820

1150

5490

66.36

#1

4

210

0.2

0.27

0.1814

2890

1820

1150

5860

83.69

#1/0

5

240

0.16

0.21

0.136

3200

1920

1230

6350

105.6

#2/0

6

275

0.12

0.17

0.1204

4000

2020

1380

7400

133.1

#3/0

7

315

0.1

0.14

0.098

4600

2150

1520

8270

167.8

#4/0

8

360

0.08

0.12

0.0894

5200

2280

1670

9150

211.6

#250

9

450

0.06

0.08

0.0529

6450

2430

1870

10750

250

52

Cable Data Vs. Second Order Model

Axis Title

300

200

Series1

100

Series2

0

1

2

3

4

5

6

Series1

7

8

Cable Sizes

Figure 6.2 Cable Cost Fit Into Second Order Model

Source Provided by Authors

Cable Size vs. Cost

12000

10000

Cost $

8000

6000

4000

2000

0

#4

#3

#2

#1

#1/0

#2/0

#3/0

Cable Size

Figure 6.3 Cable Cost For Different Sizes

Source Provided by Authors

#4/0

#250

53

Table 6.1 --Summary of the Runs

(Source Provided by Authors)

i=10%

Run 1

Run 2

Run 3

Run 4

Run 5

Run 6

Class 1

10,12,18

kVA

SL=320ft

SD=80ft

Class 1

10,12,18

kVA

SL=480ft

SD=120ft

Class 2

4.4,6,10

kVA

SL=320ft

SD=80ft

Class 2

4.4,6,10

kVA

SL=480ft

SD=120ft

Class 3

1.2,1.5,

2.5 kVA

SL=320ft

SD=80ft

Class 3

1.2,1.5,

2.5 kVA

SL=480ft

SD=120ft

ST-kVA

80.94

80.94

38.71

38.71

13.217

13.217

ASL-kcmil

267.19

267.19

133.59

133.59

33.4

33.4

ASD-kcmil

141.7

141.7

78.72

78.72

19.68

19.68

TAC-$

8127

10447

4750

6005

2254

2626

ST-kVA

100

100

50

50

15

15

ASL-kcmil

300

300

167.8

167.8

41.74

41.74

ASD-kcmil

167.8

167.8

83.69

83.69

41.74

41.74

TAC-$

8230

10573

4827

6099

2348..5

2766

Total -percentage (%)

6

7.27

6.18

7.45

5.55

6.364

VDT-Transformer

2

2.4

1.9

1.9

1.824

1.824

3

3.845

3.539

4.44

3.365

3.997

0.684

1.026

0.742

1.113

0.3615

0.542

Low Electric Markup ,

ECoff= 0.015, ECon = 0.02,

Power Factor = 0.9

Optimized

Standard

Voltage Drop

VDSL-Service Lateral

VDSD-Service Drop

54

Table 6.1 --Summary of the Runs Continued

(Source Provided by Authors)

i=15%

Run7

Run 8

Run 9

Run 10

Run 11

Run 12

Low Electric Markup ,

ECoff= 0.015, ECon = 0.02,

Power Factor = 0.9

Class 1

10,12,18

kVA

SL=320ft

SD=80ft

Class 1

10,12,18

kVA

SL=480ft

SD=120ft

Class 2

4.4,6,10

kVA

SL=320ft

SD=80ft

Class 2

4.4,6,10

kVA

SL=480ft

SD=120ft

Class 3

1.2,1.5,

2.5 kVA

SL=320ft

SD=80ft

Class 3

1.2,1.5,

2.5 kVA

SL=480ft

SD=120ft

ST-kVA

80.48

80.48

38.5

38.5

13.15

13.15

ASL-kcmil

262.4

262.4

131.2

131.2

32.8

32.8

ASD-kcmil

139.16

139.16

77.31

77.31

19.32

19.32

TAC-$

11968

15387

7016

8866

3350

3901

ST-kVA

100

100

50

50

15

15

ASL-kcmil

300

300

133.1

133.1

41.74

41.74

Optimized

Standard

ASD-kcmil

167.8

167.8

83.69

83.69

41.74

41.74

TAC-$

12142

15603

7086

8939

3498

4120

Total -percentage (%)

5.648

7.2719

6.923

7.45

5.55

6.364

VDT-Transformer

2.4

2.4

1.9

1.9

1.824

1.824

VDSL-Service Lateral

2.563

3.845

4.28

4.44

3.365

3.997

VDSD-Service Drop

0.684

1.0264

0.742

1.113

0.3615

0.0542

Voltage Drop

55

Table 6.1 --Summary of the Runs Continued

(Source Provided by Authors)

i=10%

Run13

Run14

Run15

Run16

Run17

Run18

Class 1

10,12,18

kVA

SL=320ft

SD=80ft

Class 1

10,12,18

kVA

SL=480ft

SD=120ft

Class 2

4.4,6,10

kVA

SL=320ft

SD=80ft

Class 2

4.4,6,10

kVA

SL=480ft

SD=120ft

Class 3

1.2,1.5,2.5

kVA

SL=320ft

SD=80ft

Class 3

1.2,1.5,2.5

kVA

SL=480ft

SD=120ft

82.2

82.2

39.28

39.28

13.39

13.278

ASL-kcmil

281.07

281.07

140.54

140.54

35.134

33.99

ASD-kcmil

149.06

149.06

82.81

82.81

20.7

20.03

8563

10999

4966

6282

2313

3977

ST-kVA

100

100

50

50

15

15

ASL-kcmil

300

300

167.8

167.8

41.74

41.74

ASD-kcmil

167.8

167.8

83.69

83.69

41.74

41.74

TAC-$

8638

11084

5027

6354

2397

4179

Total -percentage (%)

5.648

7.272

6.182

7.453

5.55

6.364

VDT-Transformer

2.4

2.4

1.9

1.9

1.824

1.824

VDSL-Service Lateral

2.563

3.845

3.539

4.44

3.365

3.997

VDSD-Service Drop

0.684

1.026

0.742

1.113

0.3615

0.5423

High Electric Markup ,

ECoff= 0.03, ECon =

0.04, Power Factor = 0.9

Optimized

ST-kVA

TAC-$

Standard

Voltage Drop

56

Table 6.1 --Summary of the Runs Continued

(Source Provided by Authors)

i=15%

Run19

Run20

Run21

Run22

Run23

Run24

High Electric Markup ,