Investigation of coupled cobalt–silver nanoparticle system by plan view TEM

advertisement

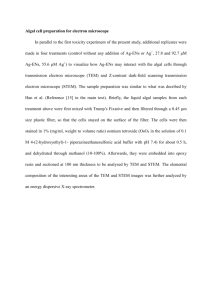

Investigation of coupled cobalt–silver nanoparticle system by plan view TEM Daniel Foxa, Ruggero Verrea, Brendan J. O’Dowda, Sunil K. Aroraa, Colm C. Faulknerb, Igor V. Shvetsa, Hongzhou Zhanga a,* a. School of Physics and CRANN, Trinity College Dublin, Dublin 2, Ireland b. CRANN Advanced Microscopy Laboratory, Trinity College Dublin, Dublin 2, Ireland *. Corresponding author. E-mail address: Hongzhou.Zhang@tcd.ie (H. Zhang) KEYWORDS Focused ion beam; Transmission electron microscopy; Lift-out; Co; Ag; Nanoparticle Abstract We present a transmission electron microscopy (TEM) investigation of a coupled cobalt and silver nanoparticle system. A plan view in situ lift-out method for preparing samples for TEM using the focused ion beam (FIB) microscope was used. This technique is used to prepare high quality TEM samples with site specificity in a short time and with a high success rate. We demonstrate the ability of the plan view sample preparation technique to provide information about an ordered system of nanoparticles which could not be observed using standard FIB cross sectioning of the sample. High resolution TEM and energy dispersive X-ray spectroscopy mapping of both cross sectional and plan view samples are presented, clearly showing the significant benefit of plan view TEM analysis for certain samples. 1. Introduction High resolution imaging and analysis are required for a broad range of materials and devices. As the development of semiconductor devices with ever smaller features [1], and the study of nanomaterials become more common, the need for high resolution imaging and analysis is more prevalent than ever [2–4]. The transmission electron microscope (TEM) can be used to provide a wealth of information about the structure and composition of materials at the atomic scale [5,6]. One requirement of TEM analysis is that the samples must be sufficiently thin, typically around 100 nm [7]. Conventional TEM sample preparation is achieved by a series of time consuming steps involving grinding, dimpling and ion milling of samples in order to thin them sufficiently [8]. A more efficient method of TEM sample preparation is achieved by the gallium focused ion beam (FIB). The FIB can extract thin sections of material from bulk samples. Modern FIBs have both an ion beam for selective removal of material by milling, and an electron beam which provides high resolution imaging and charge compensation [9]. Regions of interest on the bulk sample can be located with the electron beam before being cross sectioned by the ion beam, allowing site-specific TEM analysis of samples. An ex situ lift out method was initially employed in FIB sample preparation [10]. In this technique a lamella of material is cut free from the sample with the FIB. The sample is then placed under an optical microscope. The electrostatic attraction between a glass rod and the lamella is used to transfer the lamella to a TEM grid. This method had inherent limitations such as the inability to re-thin samples after lift out, it also had a relatively high failure rate (50–90% success yield) when compared with more recent techniques [11]. The FIB in situ lift-out technique, whereby the TEM lamella is removed from the sample and transferred to a TEM grid within the FIB chamber, has reduced the time and failure rates (90–100% success yield) traditionally associated with conventional TEM sample preparation. However, this cross sectioning technique can only provide a limited view of the sample. When analysing features which reside on or near the surface, a plan view of the sample would prove far more useful. Many previous attempts to prepare plan view TEM samples have involved polishing and chemical etching [12] or ex situ FIB lift-out [13]. We propose the use of the plan view in situ lift-out [14], this technique provides greater surface sampling and a view direction which cannot be achieved by typical cross sectioning. In this article the plan view FIB in situ lift-out technique has been successfully demonstrated on a system consisting of Ag and Co nanoparticle arrays previously deposited on an optically transparent substrate. Bimetallic nanoparticle systems are currently under intense research in a range of fields due to their unique properties [15]. Such a system is of extraordinary interest as it supports localised plasmon resonances, i.e. oscillations of the free carrier within the nanoparticles [16]. As the system is also ferromagnetic, coupling between the magnetic and plasmonic properties of the nanocomposite layer can also be realized. The advanced functionalities have been previously demonstrated to produce novel interesting phenomena, such as plasmon enhanced magneto-optic activity [17,18]. Such a system is of potential interest for modulated sensing, imaging of magnetic fields and miniaturised magneto-optical devices and for enhanced spectroscopy due to the presence of ‘‘hot spots’’ in the interstitial space between the nanoparticles [19]. The work reported in this paper was used to locate and identify each individual nanoparticle within the prepared region. From this information the distribution and proximity of the two deposited materials was identified, giving a greatly enhanced understanding of the system. 2. Experimental The sample investigated was produced using a novel selfassembly procedure named ATLAS (Atomic Terrace Low Angle Shadowing). In this method material is deposited using an e-beam evaporator in ultra-high vacuum (base pressure of 5x10^-7 Pa) at a glancing angle onto a stepped substrate [20]. The stepped substrate was produced by annealing single crystal Al2O3 (0001) with a 6° miscut in the [1-2 1 0] direction as previously described [21]. The sample was then loaded in the deposition chamber and inclined at 6° with respect to the flux of evaporated material. Co was deposited at a rate at normal incidence of 0.15 nm/minute for a nominal thickness of 1 nm. Subsequently, Ag was deposited at 11° using the same rate and nominal thickness. The result of the process consisted of nanoparticle arrays of both Co and Ag, deposited in an ordered fashion as shown in Fig. 1. This image has been taken using a Carl Zeiss Ultra Plus scanning electron microscope (SEM). However, the SEM utilised cannot establish where each material was exactly placed due to the small dimensions of the structures produced. TEM analysis was rendered necessary to establish where the Co and Ag were placed and how they interact due to their close proximity. In order to protect the sample surface before FIB milling a thin gold coating would usually be sputtered onto the surface of the sample. However, the similar atomic mass of the gold coating and the deposited silver would lead to poor image contrast. Instead the surface was protected by coating the sample with a 75 nm layer of carbon using a Cressington 108 carbon/A carbon coater. A 5 nm layer of gold was finally deposited in a Cressington 108 auto sputter coater. The FIBs used in these experiments were an FEI Strata 235 and a Carl Zeiss Auriga. In the Strata FIB the ion beam axis is orientated 521 relative to the electron beam, in the Auriga FIB the angle between the beams is 541. In both microscopes a working distance of 5 mm was used. The Auriga FIB is equipped with a Kleindeik Nanotechnik micromanipulator needle and a Picoprobe GIS system for the lift-out procedure. The Auriga FIB can also mill with an ion beam energy as low as 2 keV which, when used as a final milling step, provides high quality samples with a damage layer as thin as 2–3 nm [22]. The TEM used for high resolution analysis was an FEI Titan 80–300 (S)TEM operating at an accelerating voltage of 300 kV. 2.1. Cross section lift-out The sample was brought to the eucentric height at 5 mm working distance and the electron and ion beams were aligned to coincidence at 01 relative to the ion beam. The first step in any liftout procedure is to deposit a protective layer of platinum on the region of interest in the FIB. Electron beam induced decomposition of an organo-metallic precursor was used to deposit a 300 nm thick layer of platinum over an area of 4x1.5 mm. Ion beam induced deposition was then used to deposit a further 1 mm thick layer of platinum over an 8x2 mm area (Fig. 2(a)). A 10 nA ion beam was then used to mill a trench to a depth of 10 mm either side of a 1.5 mm thick section of material. This lamella was then thinned to 1 mm with a 2 nA ion beam (Fig. 2(b)). One side of the lamella was freed from the substrate with a 2 nA ion beam. The lamella was undercut at 49° relative to the ion beam, leaving it supported on only one side. A micromanipulator needle was then brought into contact with the free side of the lamella and affixed with platinum. The lamella was then cut free from the substrate with a 2 nA ion beam and transferred to an Omniprobe TEM liftout grid mounted vertically on a sample holder (Fig. 2(c)). The sample was thinned to 300 nm with an ion beam current of 200 pA at an angle of 1° relative to the ion beam, and then to 100 nm with 20 pA at an angle of 0.7°. Finally a 5 keV gallium beam energy at a beam current of 20 pA was used to reduce FIB induced damage by scanning the beam at 2° to the face of the sample on either side for one minute each. The final lamella is shown in Fig. 2(d). The sample was plasma cleaned for 3 min in a Fischione model 1020 plasma cleaner to further remove contamination before TEM analysis. 2.2. Plan view lift-out For the plan view lift-out the sample was again brought to the eucentric height and the beams co-aligned. A protective platinum layer was deposited on a larger area of 5x9 mm to protect the surface area for TEM analysis. A trench was milled either side of the protective region, except this time the ion beam was at 52° to the surface normal in order to cut under the region. The beam current used was 10 nA and the milling time allowed for each trench was 15 min. The sample was then tilted 15° such that the ion beam was at 67° to the surface normal. A 10 nA beam was used to mill each side of the protected region for a further 5 min in order to ensure the sample was fully undercut. The sample was milled to the wedge shape illustrated in Fig. 3(a) and observed in Fig. 3(b). One final trench was milled with a 10 nA beam for 10 min to free one side of the sample from the substrate, and also to observe undercutting had completed successfully. As in the cross section lift-out the micromanipulator needle was brought into contact with the free side of the sample and fixed with platinum, the sample was then cut free from the substrate. This time the sample was transferred to an Omniprobe TEM lift-out grid which was mounted horizontally on the sample holder. This was achieved by overhanging the grid over the edge of carbon tape, as shown in Fig. 3(c). The sample was affixed to the grid with platinum and the micromanipulator needle was cut free. The grid was then unloaded from the microscope and the mounted in the usual vertical position as shown in Fig. 2(c). The sample was thinned on the side with the wedge shape (the side observed in Fig. 3(d)) with a 200 pA ion beam in order to make the front and rear sides of the lamella parallel. A 20 pA beam was used to further thin this side until the nanoparticles could be observed with the electron beam. The rear side of the sample (observed in Fig. 3(e)) was thinned with a 20 pA beam until the sample was observed to be electron transparent at an electron beam energy of 5 keV, an indication that the sample is thin enough for TEM analysis. Finally a 5 keV ion beam energy at a beam current of 20 pA was again used to reduce the FIB induced damage on the sample. The finished sample is shown in Fig. 3(f). The sample was plasma cleaned for 3 min. 3. Results An overview of the cross section TEM lamella is shown in Fig. 4(a). In the TEM analysis of the sample prepared in cross section view the location of the nanoparticles can be clearly identified, as seen in the STEM–high angle annular dark field (HAADF) image in Fig. 4(b). The nanoparticles have high contrast with the surrounding carbon which we deposited on the sample. The Al2O3 substrate was tilted onto the [2 1 0] zone axis before imaging. A high magnification bright field TEM image of a particle on the substrate step is shown in Fig. 4(c). One of the problems we need TEM to solve is the geometrical distribution of the cobalt and silver on the sample. We used EDX mapping to analyse the distribution of the concentrations of each element and generated an elemental colour map to illustrate the results, shown in Fig. 4(d) (top right). From this map the cobalt and silver appeared to have come together to form a composite particle. There was very little separation between the locations of cobalt and silver in this view direction, suggesting close proximity between the two materials deposited on the steps of the substrate. Critically, in this view direction our sample orientation is such that we are observing a projection of approximately 2 to 3 nanoparticles; we cannot obtain information about an individual nanoparticle from this sample. When imaged in plan view, rows of individual nanoparticles were observed (see Fig. 5) and the number of particles observable is greatly increased over the cross section view, thus allowing for much greater sampling using a single lamella. The contrast between the particles and the surrounding material is high as shown in the bright field TEM image in Fig. 5(a) and HAADF image in Fig. 5(b). A high magnification bright field TEM image is shown in Fig. 5(c). We note that, due to this new viewing direction, we can use EDX mapping to observe the exact distribution of cobalt and silver on the sample, without the complication of multiple nanoparticles overlapping. The EDX map is shown in the second image in Fig. 5(d). This map shows a clear spatial separation between the two elements deposited on our sample. This information gives a clear understanding of the distribution of the deposited elements on the sample, thus revealing the exact location of each nanoparticle. This TEM measurement can help to establish the origin of any coupling effect between the magnetic Co and the plasmonic Ag nanoparticles produced. 4. Discussion Cross sectional TEM analysis using FIB sample preparation is an invaluable microscopy technique for the characterisation of chip based or solid samples. The in situ FIB lift-out technique provides reproducible sample fabrication with high quality, good throughput, site-specificity, thickness control, sample dimension control, and a high sample yield. Critically, the orientation of the FIB prepared sample has typically been limited to a cross sectional view and may not provide sufficient information about the sample regardless of the TEM analysis technique employed. An in situ lift-out for plan view TEM samples has been demonstrated to provide information beyond that observed in a conventional cross sectional sample. The self-assembled nanoparticle arrays on the stepped template, investigated herein, is just one sample type which benefits from plan view TEM. Plan view TEM analysis can potentially be of great interest for a wide range of samples such as: sub 10 nm featured wire [23] and dot arrays [24] fabricated using block copolymer techniques, nanowires, nano-contacts, and a large variety of structures and geometries patterned using top down lithography [25]. This will lead to higher resolution imaging and enhanced understanding and control of these physical systems. We have noted that a wide range of samples can be explored using plan view TEM samples. Furthermore, the FIB plan view TEM sample preparation technique will allow advanced TEM imaging and analytic techniques to be used on samples that could not previously be probed by these techniques. For example one can imagine tomography, revealing 3-D relationships between features, or Lorentz microscopy, giving micro-magnetic understanding [26] of appropriate TEM samples prepared in this manner. With this technique the success rate is similar to that of the standard in situ lift-out of 90–100%. Finally, we note that the time required to produce a plan view TEM sample in the FIB is similar to that of the standard cross sectional TEM sample geometry, typically 3 h for a skilled operator. 5. Conclusion We have demonstrated the utility of site-specific plan view TEM analysis for our material system. Plan view analysis of our sample was required in order to gain a complete understanding of the material distribution and structure of the sample. As the distribution of the materials in the system can now be clearly observed, further modifications to the sample preparation process can be made in order to tune the properties of the nanoparticle system and the interactions within. The information provided by this view direction is complimentary to the typical cross section lift-out and can provide information which may not be available from other lift-out geometries. Plan view sample TEM sectioning can provide insight into a range of nano-structured surfaces which would be inaccessible by standard FIB cross sectioning techniques. Acknowledgements The work at the School of Physics and the Centre for Research on Adaptive Nanostructures and Nanodevices at Trinity College Dublin is supported by Science Foundation Ireland under Grant 07/SK/I1220a. The TEM work was conducted under the framework of the INSPIRE program, funded by the Irish Government’s Program for Research in Third Level Institutions, Cycle 4, National Development Plan 2007–2013 Fig. 1 SEM image of the cobalt and silver nanoparticles deposited on a stepped sapphire substrate Fig. 2 (a) Platinum strap deposited on the substrate surface by electron beam and ion beam induced deposition. (b) Plan view of the two trenches cut with the ion beam leaving a thin section of material isolated at the centre. (c) Omniprobe TEM lift-out grid mounted vertically on a sample holder. (d) SEM image of the final lamella. Fig. 3 (a) Illustration of the ion beam angles used to undercut a wedge of material from the sample surface. (b) The wedge of material (coated with platinum) after undercutting. (c) Omniprobe TEM liftout grid mounted horizontally on carbon tape on an SEM stub. (d) The bottom of the wedge of material after lift-out and transfer to the TEM grid. (e) The top of the wedge, the opposite side to (d). (f) The final lamella with a region thinned for TEM analysis. Fig. 4 (a) Bright field TEM image of an overview of the cross section lamella. (b) HAADF image of the region indicated in (a). The nanoparticles (NPs) are observed at the steps of the substrate. (c) High magnification image of a nanoparticle on a sapphire step. (d) Top left: HAADF image of a nanoparticle. Top right: Elemental colour map of the distribution of silver (cyan) and cobalt (red). Bottom left and bottom right: individual maps of the silver and cobalt locations, respectively. Fig. 5 (a) Bright field TEM image of an overview of the plan view lamella. (b) HAADF image of the nanoparticle array. (c) High magnification image of individual nanoparticles. (d) First image: HAADF image of nanoparticles. Second image: Elemental colour map of the distribution of silver (cyan) and cobalt (red). Third and fourth images: individual maps of the silver and cobalt locations, respectively. (For interpretation of the references to color in this figure legend, the reader is referred to the web version of this article.) References [1] R.S. Rai, S. Subramanian, Role of transmission electron microscopy in the semiconductor industry for process development and failure analysis, Progress in Crystal Growth and Characterization of Materials 55 (3–4) (2009) 63–97. [2] T. Sato, H. Matsumoto, K. Nakano, M. Konno, M. Fukui, I. Nagaoki, Y. Taniguchi, Application of lattice strain analysis of semiconductor device by nano-beam diffraction using the 300 kV Cold-FE TEM, Journal of Physics: Conference Series 241 (1) (2010) 012014. [3] B. Westenfelder, J.C. Meyer, J. Biskupek, S. Kurasch, F. Scholz, C.E. Krill, U. Kaiser, Transformations of carbon adsorbates on graphene substrates under extreme heat, Nano Letters 11 (12) (2011) 5123–5127. [4] J.N. Coleman, M. Lotya, A. O’Neill, S.D. Bergin, P.J. King, U. Khan, K. Young, A. Gaucher, S. De, R.J. Smith, I.V. Shvets, S.K. Arora, G. Stanton, H.-Y. Kim, K. Lee, G.T. Kim, G.S. Duesberg, T. Hallam, J.J. Boland, J.J. Wang, J.F. Donegan, J.C. Grunlan, G. Moriarty, A. Shmeliov, R.J. Nicholls, J.M. Perkins, E.M. Grieveson, K. Theuwissen, D.W. McComb, P.D. Nellist, V. Nicolosi, Two-dimensional nanosheets produced by liquid exfoliation of layered materials, Science 331 (6017) (2011) 568–571. [5] O.L. Krivanek, M.F. Chisholm, V. Nicolosi, T.J. Pennycook, G.J. Corbin, N. Dellby, M.F. Murfitt, C.S. Own, Z.S. Szilagyi, M.P. Oxley, S.T. Pantelides, S.J. Pennycook, Atom-by-atom structural and chemical analysis by annular dark-field electron microscopy, Nature 464 (7288) (2010) 571–574. [6] R.M. Wang, O. Dmitrieva, M. Farle, G. Dumpich, H.Q. Ye, H. Poppa, R. Kilaas, C. Kisielowski, Layer resolved structural relaxation at the surface of magnetic FePt icosahedral nanoparticles, Physical Review Letters. 100 (2008) 1. [7] D.B. Williams, C.B. Carter, The transmission electron microscope, Transmission Electron Microscopy: A Textbook for Materials Science, 2nd ed. Springer, 2009, pp 3–17. [8] L.C. Wagner, Sectioning techniques for TEM imaging. In: Failure Analysis of Integrated Circuits: Tools and Techniques, Kluwer Academic Publishers, 1999, pp 168–173. [9] H. Luo, R. Jing, Y.M. Cui, H.L. Wang, R.M. Wang, Improvement of fabrication precision of focused ion beam by introducing simultaneous electron beam, Progress in Natural Sciience: Material International 20 (2010) 111–115. [10] L.A. Giannuzzi, J.L. Drown, S.R. Brown, R.B. Irwin, F.A. Stevie, Applications of the FIB lift-out technique for TEM specimen preparation, Microscopic Research Technology 41 (4) (1998) 285–290. [11] R.M. Langford, M. Rogers,In situ lift-out:stepsto improve yield and a comparison with other FIB TEM sample preparation techniques, Micron 39 (8) (2008) 1325–1330. [12] N. Kato, H. Maruyama, H. Saka, Preparation of TEM plane view sections on semiconductor device using the tripod polisher and chemical etching, Journal of Electron Microscopy 50 (1) (2001) 9–13. [13] F. Stevie, R. Irwin, T. Shofner, S. Brown, J. Drown, L. Giannuzzi, Plan View TEM Sample Preparation Using the Focused Ion Beam Lift-out Technique, IOP Institute of Physics Publishing Ltd, 1998, pp 868–872. [14] J. Mayer, L.A. Giannuzzi, T. Kamino, J. Michael, TEM sample preparation and FIB-induced damage, MRS Bulletin 32 (05) (2007) 400–407. [15] N. Toshima, T. Yonezawa, Bimetallic nanoparticles-novel materials for chemical and physical applications, New Journal of Chemistry 22 (11) (1998) 1179–1201. [16] S.A. Maier, Plasmonics: Fundamentals and Applications, Springer, 2007. [17] P.K. Jain, Y. Xiao, R. Walsworth, A.E. Cohen, Surface plasmon resonance enhanced magneto-optics (SuPREMO): Faraday rotation enhancement in gold-coated iron oxide nanocrystals, Nano Letters 9 (4) (2009) 1644–1650. [18] L. Wang, C.s. Clavero, Z. Huba, K.J. Carroll, E.E. Carpenter, D. Gu, R.A. Lukaszew, Plasmonics and enhanced magneto-optics in coreshell Co–Ag nanoparticles, Nano Letters 11 (3) (2011) 1237–1240. [19] R. Verre, K. Fleischer, O. Ualibek, I.V. Shvets, Self-assembled broadband plasmonic nanoparticle arrays for sensing applications, Applied Physics Letters 100 (3) (2012) 031102–031103. [20] R. Verre, K. Fleischer, R.G.S. Sofin, N. McAlinden, J.F. McGilp, I.V. Shvets,In situ characterization of one-dimensional plasmonic Ag nanocluster arrays, Physical Review B 83 (12) (2011) 125432. [21] R. Verre, K. Fleischer, J.F. McGilp, D. Fox, G. Behan, H. Zhang, I.V. Shvets, Controlled in situ growth of tunable plasmonic self-assembled nanoparticle arrays, Nanotechnology 23 (3) (2012) 035606. [22] M. Konno, Y. Suzuki, H. Inada, K. Nakamura, K. Kimoto, Y. Zhu, High-resolution secondary electron imaging of a FIB prepared Si sample with an aberration corrected electron microscope, Microscopy and Microanalysis 16 (Supplementary S2) (2010) 128–129. [23] D. Borah, M.T. Shaw, S. Rasappa, R.A. Farrell, C. O’Mahony, C.M. Faulkner, M. Bosea, P. Gleeson, J.D. Holmes, M.A. Morris, Plasma etch technologies for the development of ultrasmall feature size transistor devices, Journal of Physics D: Applied Physics 44 (17) (2011) 174012. [24] J.G. Son, J.-B. Chang, K.K. Berggren, C.A. Ross, Assembly of sub-10-nm block copolymer patterns with mixed morphology and period using electron irradiation and solvent annealing, Nano Letters 11 (11) (2011) 5079–5084. [25] C.C. Faulkner, D.A. Allwood, R.P. Cowburn, Tuning of biased domain wall depinning fields at Permalloy nanoconstrictions, Journal of Applied Physics 103 (7) (2008) 073914. [26] E.S. Wilhelm, D. McGrouther, L. Heyne, A. Bisig, M. Klaui, Vortex domain wall chirality rectification due to the interaction with end domain spin structures in permalloy nanowires, Applied Physics Letters 95 (25) (2009) 252501–252503.