Identification and Validation of Cognitive Design Principles for Automated Generation of

advertisement

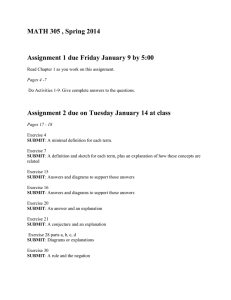

Identification and Validation of Cognitive Design Principles for Automated Generation of Assembly Instructions Julie Heiser, Doantam Phan, Maneesh Agrawala, Barbara Tversky and Pat Hanrahan Stanford University and Microsoft Research 1 2 3 4 5 6 Cognitive Design Principles Identify How people conceive of 3D assemblies How people comprehend visual instructions Validate Build automated instruction design system Evaluate usability of resulting instructions Prior Work: Identification Diagrams better for showing context Diagrams and text equivalent for showing actions [Bieger 85] [Bieger 86] High spatial prefer diagrams only Low spatial prefer diagrams and text together [Winn 80] [Mayer 94] [Hegarty 94] [Kalyuga 98] [Trafton 2001] Step-by-step better than showing only end state [Novick 00] Arrows and lines convey actions and sequences [Tversky 00] Prior Work: Validation IBIS AWI CATHI Automated presentation design systems COMET [Feiner 89], IBIS [Seligmann 91], WIP [Andre 93], AWI [Rist 94], CATHI [Butz 97], [Strothotte 98], [Tang 03] Our Approach Identification Production Preference Comprehension Validation Instantiation Usability Our Approach Identification Production Preference Comprehension Validation Instantiation Usability Our Approach Identification Production Preference Comprehension Validation Instantiation Usability Our Approach Identification Production Preference Comprehension Validation Instantiation Usability • Step-by-step, one diagram for each major step • Clear and explicit order • Parts added in each step should be visible • Mode of attachment should be visible Our Approach Identification Production Preference Comprehension Validation Instantiation Usability • Step-by-step, one diagram for each major step • Clear and explicit order • Parts added in each step should be visible • Mode of attachment should be visible Our Approach Identification Production Preference Comprehension Validation Instantiation Usability • Step-by-step, one diagram for each major step • Clear and explicit order • Parts added in each step should be visible • Mode of attachment should be visible TV Stand Contains several parts and actions Ordering constraints One person can assemble Representative of other furniture Spatial Ability Tests Mental Rotation [Vandenburg 78] Navigation [Money 78] Separate high and low spatial ability Stage 1: Production Stage 1: Production 43 Participants Assemble TV Stand without instructions Write instructions for novice assembler Stage 1: Mean Completion Time 16 Time to assemble (min) 14 12 12.76 10 8 7.29 6 4 2 0 low spatial Low spatial high spatial High spatial Stage 1: Instructions Produced Almost all contained diagrams Text redundant with diagrams 98% 62% Stage 1: Errors in Instructions Errors in low spatial instructions Errors in high spatial instructions 86% 12% Stage 1: Errors in Instructions support board sides Errors in low spatial instructions Errors in high spatial instructions 86% 12% Stage 1: Classes of Diagrams Structural diagrams Parts menu Action diagrams Parts menu to differentiate parts Structural diagrams depict completed step Action diagrams show assembly action/operation Stage 1: Action Diagrams 3.5 Mean number per set 3 2.5 2.67 2 1.5 1 0.5 0 0.64 low spatial Low spatial High spatial More action diagrams More 3D diagrams Less text high spatial High spatial Stage 2: Preference Stage 2: Preference 21 Participants Assemble TV Stand without instructions Rated 39 sets of redrawn instructions Stage 2: Highest Rated Ratings similar across all participants Spatial ability does not affect preference Stage 3: Comprehension Stage 3: Comprehension Set 1: Text + Action Set 3: Parts menu + Structural + Action 44 Participants Given 1 of 4 instruction sets from Stage 2 Assemble TV stand using instructions Stage 3: Results No difference in assembly time by condition Instruction consultations: Low 8.9 High 7.1 Box picture consultations: Low 9.1 High 3.4 Comments Should show relevant parts and attachments Structural diagrams and exploded view hard to use Text not very useful Cognitive Design Principles Sequence assembly operations Ensure visibility of parts Illustrate assembly operations Sequence Assembly Operations Single exploded view diagram Step-by-step diagrams Step-by-step, one diagram per major step Clear and explicit order Ensure Visibility of Parts Show parts added in each step Show mode and location of attachment Avoid changing viewpoint Use physically stable orientation Illustrate Assembly Operations Structural diagrams Action diagrams Use action diagrams rather than structural Use arrows and guidelines to indicate attachment Stage 4: Instantiation Stage 4: Instantiation [Agrawala et al. SIGGRAPH 03] All parts Search Leftover parts Best subset of parts Structural Diagrams Sequence Parts Action Diagrams Reorientation Sequence of assembly steps Stage 4: LEGO Stage 4: Bookcase Stage 5: Usability Stage 5: Usability 30 Participants Given 1 of 3 instruction sets: hand-drawn, factory, computer Assemble TV stand using instructions Stage 5: Hand-drawn Stage 5: Factory Produced Stage 5: Computer Generated Stage 5: Instructions Tested Hand-drawn Computer generated Factory Stage 5: Results 25 Time to assemble (min) 20 15 18.9 16.0 10 10.2 5 0 Hand-drawn Factory Computer Errors: Hand-drawn 1.6 Factory 0.6 Computer 0.5 Users rated task as easiest in computer condition Summary and Conclusions 5-Stage approach can give insight into effective design of assembly instructions Cognitive design principles Clear sequence of operations Maintain good visibility Use action diagrams Extend approach beyond assembly instructions Acknowledgements Boris Yamrom Christina Vincent John Haymaker Jeff Klingner Generalization Approach extends beyond assembly instructions Hand-drawn route map LineDrive route map [Agrawala 01]