ME 322: Instrumentation Lecture 5

advertisement

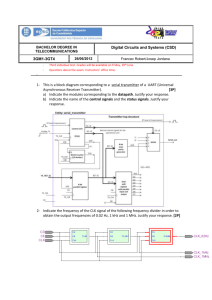

ME 322: Instrumentation Lecture 5 January 27, 2016 Professor Miles Greiner Lab 3, transmitter characteristics, least-squares, standard error of the estimate Announcements • HW 2 due Monday – Joseph Young will hold a tutorial after this class (10 am) on Friday in PE 2 (not ME Kitchen) • HW will be returned in Lab • All assignments and reading on the course website – L3PP = Lab 3 preparation problem • Part of Lab 3 instructions • Process sample data • Bring resulting spreadsheet to lab (lab participation grade) • Lab 2 - Statistical Analysis of UNR Quad Measurements – Download and read Lab 2 Instructions and Lab Guidelines – How were the Monday and Tuesday labs? Lab 3 Pressure Transmitter Calibration Proximity Sensor or DMM IT PHI PLO • Dwyer Series 616 Pressure Transmitter – Power must be supplied to pins 1 and 2 (10-35 VDC) • Measurand: Pressure difference between HI and LO ports, – DP = PHI – PLO • Sensor: diaphragm with a strain or proximity gage • The Output or “Reading” is current, IT [mA], measured by a Digital Multimeter (DMM) – May be affected by orientation due to gravity (undesired) Transmitter Characteristics • See Lab 3 website, ~$150 • Different transmitters use different diaphragm thickness or flexibilities to get different deformations (sensitivities) to vary Full Scale (FS) range and resolution • Output Signal: 4 to 20 mA (h = 0 to FS, linear) • Accuracy: 616: ±0.25% F.S. • Stability: ±1% F.S./yr. • Two models in lab: – 616-1: FS = 3 in WC; Accuracy = 0.0025*3 = ±0.0075 in WC – 616-5: FS = 40in WC; Accuracy = 0.0025*40 = ±0.1 in WC Manufacturer’s Transfer Function • Output Signal: 4 to 20 mA (h = 0 to FS, linear) • Manufacturer’s Transfer Function (R vs M) 16 𝑚𝐴 – 𝐼= ℎ + 4 𝑚𝐴, ℎ = 𝑖𝑛𝑐ℎ𝑒𝑠 𝑊𝐶; 𝐹𝑆 = 𝑖𝑛𝑐ℎ𝑒𝑠 𝑊𝐶 𝐹𝑆 – Try to confirm this in Lab 3 • Inverted Transfer Function – Measurand vs Reading, needed to use the gage • Pressure head: – ℎ = 𝐹𝑆 𝐼−4𝑚𝐴 16 • Pressure Difference: – Δ𝑃 = 𝑃𝐻𝐼 − 𝑃𝐿𝑂 = 𝜌𝑤 𝑔ℎ 𝑘𝑔 𝑚 2.54 𝑐𝑚 1𝑚 𝐼−4𝑚𝐴 = 998.7 3 9.81 2 𝐹𝑆 𝑚 𝑠 𝑖𝑛𝑐ℎ 100 𝑐𝑚 16 • What is the confidence level (probability) that the real pressure head is within the interval h ± Accuracy? • Determine this in Lab 3 Pressure Standard Characteristics • Martel BetaGage Model 321A, ~$2000 • More stable (less calibration drift) than Dwyer 616’s (More expensive) • Each devise has two pressure gages – FS = 25 mBar (10 in WC); ±0.1% FS • Accuracy (uncertainty) = 10*0.001= 0.01 in WC • Use this to calibrate 3 in WC transmitter – ±0.0075 in WC – FS = 350 mBar (141 in WC), ±0.035% FS • Accuracy (uncertainty)=141*0.00035=0.05 in WC • Use this to calibrate 40 in WC transmitter – ±0.1 in WC • Only have 4 of these for 8 pairs of lab groups Gage Characteristics Pressure Standard Full Scale Range 25 mBar (10 in-WC) 350 mBar (141 in-WC) Relative Accuracy ±0.1% FS ±0.035% FS Absolute Accuracy ±0.01 inch-H2O ±0.05 inch-H2O Model 616-1 Model 616-4 Transmitter Full Scale Range 3 inch-WC 40 inch-WC Relative Accuracy ±0.25% FS ±0.25% FS Absolute Accuracy ±0.0075 inch-H2O ±0.1 inch-H2O Manufacturer's Inverted h = (3 inch-H2O)(I T-4mA)/16mA h = (40 inch-H2O)(IT-4mA)/16mA Transfer Function • High pressure transmitters will be connected to high pressure calibrator port • Low pressure transmitters to low calibrator port • One calibrator will be shared by 2-3 pairs of groups • Accuracy of the transmitter and Standard are roughly the same, but Standard drifts less Lab 3 Set-up and Procedure • • Transmitter LO port open to atmosphere Bulb, standard, HI transmitter port, and manometer high pressure port to “high” pressure tube – We don’t use the manometer for measurements, just to see the fluid shift • • • Open valve to allow high pressure tube to reach atmospheric – Set IT = 4.00 mA, and “zero” the Pressure Standard At each pressure level record hS (from Standard) and IT (from DMM) Record data from at least two ascending and descending pressure cycles, with at least 6 measurements in each direction Plot Manufacturer’s and Measured Transfer Functions Standard Reading, hS [in WC] Transmitter Output, IT [mA] 0 0.5328 1.0597 1.5617 2.0863 2.5295 1.9637 1.5483 0.9211 0.5216 0 0.5619 0.9595 1.4562 1.9927 2.6214 2.1092 1.6423 1.0696 0.5315 0 4 6.88 9.72 12.48 15.34 17.83 14.66 12.35 9.03 6.83 4.01 7.09 9.18 11.92 14.84 18.3 15.43 12.89 9.86 6.88 4.02 • Fit a line IT,F = ahS + b to the data – Measured transfer function (Use least-squares find a & b) • The data does not all fall along one single line due to gage imprecision (more like a “cloud” than a line) • The measured current for this gage is systematically larger than predicted by the Manufacturer Error of Manufacturer’s Transfer Function • Plotting e = IT – IM makes it easier to see error – IT= transmitter, IM = manufacturer (not a single line) • Increases with hS reaches ~0.35 mA (out of 20 mA) Deviation of Data form Fit Line • • • • Deviation plot d= IT – IT,F (above the fit) makes it easier to see ~Equally scatter above and below Same for ascending and descending data (no hysteresis) No systematic deviations (linear response) How to use the calibrated pressure transmitter? Measured Manufacturer Prediction • Measure gage current, I • Algebraically invert the transfer function (I = ah + b) to find h – h = (I – b)/a • If we did not calibrate, then we would assume the dotted line, which systematically gives higher pressures than actually applied • How to find a and b and the uncertainty in h? Least Squares Linear Fit di = yi – yF,i y or R yF = ax + b x or M • Find the “best” values of a and b (Two Unknowns) • Define deviation of data from best fit line for each data point – 𝑑𝑖 = 𝑦𝐹,𝑖 - 𝑦𝑖 = 𝑎𝑥𝑖 + 𝑏 − 𝑦𝑖 𝑛 2 𝑖=1 𝑑𝑖 𝑛 𝑖=1 • Total error: E = = 𝑎𝑥𝑖 + 𝑏 − 𝑦𝑖 • Find the values of a and b that minimize E 2 Details (or take my word for it) • Two constraints on E: – • 𝜕𝐸 𝜕𝑎 – • 𝜕𝐸 𝜕𝑏 𝑛 𝑖=1 E= = 𝑎 = – 𝑎 – 𝑏= – 𝑎𝑛 – 𝑎= 𝑛 𝑖=1 2 𝑎𝑥𝑖 + 𝑏 − 𝑦𝑖 𝑥𝑖 − 𝑛 2 =0 𝑥𝑖 𝑦𝑖 = 0 𝑎𝑥𝑖 + 𝑏 − 𝑦𝑖 1 = 0 𝑥𝑖 + 𝑏𝑛 − 𝑦𝑖 −𝑎 𝑛 𝑥𝑖2 + = 0 and 𝜕𝐸 𝜕𝑏 𝑎𝑥𝑖 + 𝑏 − 𝑦𝑖 𝑥𝑖 = 0 𝑥𝑖2 + 𝑏 𝑛 𝑖=1 2 𝜕𝐸 𝜕𝑎 𝑥𝑖 𝑦𝑖 = 0 ; 𝑎 𝑦𝑖 𝑥𝑖2 𝑥𝑖 − 𝑎 𝑥𝑖 𝑦𝑖 − 𝑥𝑖 𝑦𝑖 𝑛 𝑥𝑖2 − 𝑥𝑖 2 + 𝑦𝑖 −𝑎 𝑥𝑖 𝑛 𝑥𝑖 2 − 𝑛 ;…𝑏= 𝑥𝑖2 𝑥𝑖 − 𝑥𝑖 𝑦𝑖 = 0 𝑦𝑖 − 𝑛 𝑥𝑖 𝑦𝑖 = 0 𝑥𝑖2 − 𝑥𝑖 𝑥𝑖 𝑦𝑖 𝑥𝑖 2 Summary • Two constraints on E: 𝜕𝐸 𝜕𝑎 = 0 and 𝜕𝐸 𝜕𝑏 =0 – Solve simultaneously … and get 𝑛 𝑥𝑖 𝑦𝑖 − 𝑥𝑖 𝑎= Deno 𝑥𝑖2 𝑦𝑖 − 𝑥𝑖 𝑏= Deno Deno = 𝑛 𝑥𝑖2 − 𝑦𝑖 𝑥𝑖 𝑦𝑖 2 𝑥𝑖 Hint: You may use your calculator to find a & b – unless told otherwise. Learn how! How well does Best-Fit Line fit the data? • Best fit line – 𝑦𝐹 = 𝑎𝑥 + 𝑏 • Deviation of each estimate – 𝑑𝑖 = 𝑦𝑖 − 𝑦𝐹𝑖 = 𝑦𝐹 − 𝑎𝑥𝑖 − 𝑏 • Define Standard Error of the estimate of y, given x – 𝑠𝑦,𝑥 = 𝑛 (𝑦 −𝑎𝑥 −𝑏)2 𝑖 𝑖=1 𝑖 𝑛−2 – Note: if 𝑛 = 2, then 𝑑𝑖 = 0 • a line will pass through both points – Only has meaning if 𝑛 > 2 Standard Error of the Estimate of y given x sy,x y x • • • • Characterizes the vertical spread of the data 68% of all 𝑦𝑖 will be within 𝑦𝐹 𝑥𝑖 ± 𝑠𝑦,𝑥 95% are within 𝑦𝐹 𝑥𝑖 ± 2𝑠𝑦,𝑥 Assuming the error is the same for all 𝑥 Standard Error of the Estimate of x given y 𝑠𝑦,𝑥 𝑠𝑥,𝑦 y x • Characterizes the horizontal spread that contains 68% of the data • 𝑠𝑥,𝑦 = 𝑠𝑦,𝑥 /𝑎, where 𝑎 = slope of best fit line