The Quality Improvement Model

advertisement

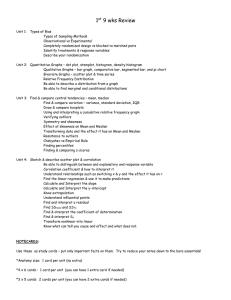

Collect & Interpret Data The Quality Improvement Model Define Process Select Measures Collect & Interpret Data Collect & Interpret Data: Displaying Measures Purpose: Begin collecting and analyzing data from the process. Is Process Stable ? No Investigate & Fix Special Causes Yes Improve Process Capability No Is Process Capable ? Yes Use SPC to Maintain Current Process 4-1 Collect & Interpret Data Graphical Tools for Displaying Measures from Processes Run Charts Histograms Pareto Charts 4-2 Collect & Interpret Data Run Charts A plot of the data in time order. Time is on the horizontal axis and the data values are plotted on the vertical axis. Run charts show the process variation over time. Measure 200 150 100 50 0 -50 -100 5 10 15 Day 20 25 30 4-3 Collect & Interpret Data Histograms Frequency A bar chart showing frequency of occurrence is shown on the vertical axis. Histograms show the pattern of variation. 25 20 15 10 5 0 -50 0 50 100 150 200 Measure 4-4 Collect & Interpret Data Pareto Charts A bar chart showing the relative importance of some observed characteristic. The frequency, percent or cost is shown on the vertical axis. The characteristic (type of defect, cause, etc.) is shown on the horizontal axis. The characteristic is usually plotted in order of decreasing magnitude. Frequency 25 20 15 10 5 0 C A E B D F Cause 4-5 Collect & Interpret Data Pump Maintenance Pump Failure Pump Maintenance 6 failed 1 failed 2 failed 4 failed 7 failed Week 1 Week 3 Week 4 Week 20 Week 2 One possible run chart would be to plot the number of pump failures for each week (time period). The opportunity for failures should remain constant from week to week. Collect information about causes for each failure for use in a Pareto Chart. Pareto Charts could also be based on pump location, pump environment, etc. For each week (time period) record the number of pump failures. Week # Failures Failure Type 1 6 Seal, Align... 2 1 Fitting, Seal... 3 2 Align, Gear... 4 4 Seal, Fitting... . . . . . . 20 7 Align, Seal... 4-6 Collect & Interpret Data Pump Maintenance Data Run Chart 20 18 Number of Failures 16 14 12 10 8 6 60 4 2 1 50 0 3 5 Pareto Chart # Failures 7 9 11 13 15 17 19 21 Week 23 25 40 30 Histogram Frequency 6 20 5 10 4 0 3 Seal 2 Alignment Fitting Gear Other Type Failure 1 0 0-1 2-3 4-5 6-7 8-9 # Failures 10-11 12-13 4-7 Collect & Interpret Data Shipping Process Shipments Made Shipping On-Time On-Time Late On-Time On-Time For a specified time period: A good run chart would be to plot p for each time period. A time period could be a week or month. It would also be good to collect other information about the late shipments for use in a Pareto Chart. n = Shipments Made x = Late Shipments p = x/n Week n # Late p Reason 1 75 10 0.13 A,C,F... 2 84 6 0.07 B,F,A... 3 78 12 0.15 F,B,B... . . . . . . . . . . 30 70 0.14 B,F,I... 10 4-8 Collect & Interpret Data Shipping Data P r o p o r t i o n Run Chart 0.25 0.20 Pareto Chart Frequency 0.15 100 90 0.10 80 70 L 0.05 a t e 0.00 60 50 40 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 30 Week 20 10 Histogram Frequency 0 B F A E I D J C G H Reason for Being Late 0.050 0.075 0.100 0.125 0.150 0.175 0.200 Proportion Late 4-9 Collect & Interpret Data Purchase Order Process Purchase Order Process A possibility would be to subgroup the data( i.e. combine 5 purchase orders and plot their average.) It might also be informative to plot a histogram of all the times to see the pattern of variation. Completed Purchase Orders 2,7,5,4,5 3,10,2,5,3 5,7,3,12,1 4,7,8,3,5 3,3,9,2,4 Week 1 Week 2 Week 3 Week 4 Week 20 5 Purchase Orders are selected each week. The time (in days) it took to process each of the 5 PO’s is recorded, and the average of the 5 calculated. The average is the measure tracked. Week 1 2 3 4 . . A 2 3 5 4 . . B 7 10 7 7 . . C 5 2 3 8 . . D 4 5 12 3 . . E 5 3 1 5 . . Average 4.6 4.6 5.6 5.4 . . 20 3 3 9 2 4 4.2 4-10 Collect & Interpret Data Purchase Order Data Frequency Histogram of 100 total observations 25 20 Time (Days) 15 10 5 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15>15 Time (Days) Run Chart of 20 Averages (of size 5) 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 1 3 5 7 9 11 13 15 17 19 Week Sample Taken 4-11 Collect & Interpret Data Polymer Manufacturing Process Material Produced (lots) Production Process Samples One possibility would be to collect a sample of the product every 4 hours, and measure the characteristic of interest on that sample. A run chart could then be constructed of this data. It would also be informative to plot a histogram of all the times to see the pattern of variation. A quality characteristic is measured on each sample. Sample b* 1 1.51 2 1.89 3 1.42 . . . . 134 1.63 b* is a measure of yellowness 4-12 Collect & Interpret Data Polymer Manufacturing Data 6 Run Chart Histogram 5 LS 4 b* US 3 2 1 0 -1 0 20 40 60 80 100 Sample 120 140 1 2 3 4 5 b* LS is the Lower Specification Limit US is the Upper Specification Limit Note: b* is a measure of yellowness 4-13