lecture 6 : hard or

advertisement

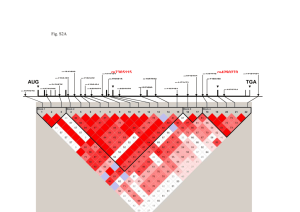

lecture 6 : hard or • classifications of problem situations • functionalist, interpretive and emancipatory systems approaches • hard OR, hard ST – formulation – modelling – implementation • example : the LOD project Spring 2011 - ÇG IE398 - lecture 6 1 Jackson & Keys’ classification of problem situations: divergence of values and interests unitary weak strong systemicity hard OR hard OR/ST Spring 2011 - ÇG pluralistic conflicting soft ST soft OR/ST IE398 - lecture 6 (emancipatory st critical ST etc.) 2 it is useful to distinguish between ways that complexity acts in, the three dimensions of complexity: 1. technical complexity e.g. in pickup and delivery vehicle scheduling there is a huge number of courses of action 2.probabilistic complexity ie. uncertainty e.g. in the same problem situation demands and traffic congestion are not known in advance 3. purposive complexity ie. diversity of interests and values e.g. in screening for breast cancer there will be conflicting objectives among stakeholders another example: greenhouse gases causing global warming: high degree of complexity in all three dimensions Spring 2011 - ÇG IE398 - lecture 6 3 • Figure 1 shows the 3-dimensional space of problem situations • three zones Z1, Z2 and Z3 are shown, enclosed by thick-gray boundary lines • the relative size of these zones do not indicate the level of complexity of the problem situation, • for example a situation that falls into Z3 can involve a degree of probabilistic complexity as high as that of a situation that falls into Z1 • the size of each zone indicates the type of systems thinking that is more suitable for the problem situation of interest Spring 2011 - ÇG IE398 - lecture 6 4 probabilistic complexity Z2 Z1 Z3 purposive complexity technical complexity Spring 2011 - ÇG IE398 - lecture 6 5 • functionalist ST can deal with technical and probabilistic complexity much more effectively than it can deal with purposive complexity • hence the boundaries of Z1 extend further along the technical and probabilistic axes, implying that we have the possibility of using quantitative techniques and mathematical models when inquiring into situations that can be addressed by functionalist ST Spring 2011 - ÇG IE398 - lecture 6 6 • functionalist ST can deal with technical and probabilistic complexity much more effectively than it can deal with purposive complexity • hence the boundaries of Z1 extend further along the technical and probabilistic axes, implying that we have the possibility of using quantitative techniques and mathematical models when inquiring into situations that can be addressed by functionalist ST Spring 2011 - ÇG IE398 - lecture 6 7 • interpretive ST can deal with – technical and probabilistic complexity to a lesser extent, – whereas it can deal with purposive complexity to a greater extent than functionalist ST can • hence the boundaries of Z2 – extend further along the purposive axis – but not along the technical and probabilistic axes compared to the case of functionalist ST Spring 2011 - ÇG IE398 - lecture 6 8 • emancipatory ST is suitable for problem situations lying far out on the purposive axis; these are situations involving irreconcilable conflict (emancipation means freedom from legal, social, or political restrictions) • such situations can also involve – high levels of uncertainty and – a certain level of technical complexity – but purposive complexity is so dominant that the priority in emancipatory ST is on conflict, rather than on technical and probabilistic aspects; that is why Z3 is drawn smaller Spring 2011 - ÇG IE398 - lecture 6 9 probabilistic complexity Z2 Z1 Z3 purposive complexity technical complexity Spring 2011 - ÇG IE398 - lecture 6 10 functionalist systems approaches • subject-object duality assumed to hold in general • systems regarded more as out-there, ontological constructs • different points of view about the system are allowed • there can be multiple objectives but they are reconcilable; therefore there is a common goal • the question is not what to do, it is how to do it • widespread applicability in situations involving – high technical complexity, and – managable uncertainty (eg. when probability distributions are available) • hard OR, systems engineering, systems analysis, cybernetics Spring 2011 - ÇG IE398 - lecture 6 11 interpretive systems approaches • systems regarded more as epistemological constructs • there are multiple objectives that are not necessarily irreconcilable • hence the question is more about what to do, and less about how to do it • so technical complexity and uncertainty are less relevant and are not handled routinely • the goal is to learn about the system so that shared commitment to action becomes possible; even though values may not be shared • soft OR Spring 2011 - ÇG IE398 - lecture 6 12 emancipatory systems approaches • systems regarded as epistemological constructs • essentially different system conceptualisations by stakeholders • so boundaries are subject to disagreement • there are multiple, irreconcilable objectives • the question is all about what to do • full emancipation is often not possible since positions of power will not be given up willingly • coercion may leave no possibility except conflict, passive resistance and disobedience • technical complexity and uncertainty are much less relevant than conflict Spring 2011 - ÇG IE398 - lecture 6 13 • hard OR and hard systems thinking in general are functionalist approaches • the traditional applications of IE are often based on the hard, functionalist approaches • soft OR and soft systems thinking in general use interpretive and in some cases, emancipatory approaches (only a few emancipatory methodologies have been developed, applicability is limited since such situations are very complex) • soft approaches are mostly experiential, they can only be developed and learned through practice Spring 2011 - ÇG IE398 - lecture 6 14 the hard OR paradigm assumes that: 1. the problem has been clearly defined, implying that – the objectives of the decision maker are known and there exist criteria to see when they have been achieved, – even if there are conflicting objectives, tradeoffs can be defined, – the alternative courses of action are known, as a list of options or a set of decision variables, – the constraints on the decision choices are known, and – the input data needed is available; 2. the problem is relatively well structured, meaning that – the relationships between the variables are known – system behaviour can be captured in mathematical models, – the computational effort for determining solutions is economically feasible; Spring 2011 - ÇG IE398 - lecture 6 15 3. the problem can be sufficiently well insulated from its wider system, ie. boundary setting is relatively straightforward 4. optimisation of the objectives, whenever possible, is the ideal 5. the problem is of a technical nature, free of politics; people are mainly seen as passive objects 6. if there are multiple stakeholders, a consensus can be reached about how objectives can be achieved 7. the decision maker has the power to implement or enforce the implementation of the solution Spring 2011 - ÇG IE398 - lecture 6 16 Spring 2011 - ÇG IE398 - lecture 6 17 • the figure implies that hard-OR is not all hard: • the formulation phase (involving issue and problem structuring) and the implementation phase (involving human considerations) relate to ontological aspects, that are qualitative and messy • the modelling phase relates to epistemological aspects that accepts quantification • this means that the hard/soft, or the functionalist/interpretive distinction is not as distinct as black/white; both will be relevant in the same problem situation Spring 2011 - ÇG IE398 - lecture 6 18 formulation • this phase either involves formulation directly (for example if the problem owner is doing the inquiry herself), or it may involve some preliminary problem scoping first • problem scoping may produce a project proposal • formulation requires full definitions of the narrow and the wider systems, often aided by influence diagrams • such a proposal should discuss whether: – a quantitative approach is feasible – data is available – the project is cost-effective as openly and honestly as possible Spring 2011 - ÇG IE398 - lecture 6 19 modelling • this phase involves the hard aspects of OR • if the situation fits a well-known structure, a structural approach can be followed in modelling; eg. using a known LP model for production planning, or a known DP model for equipment replacement • otherwise a process approach will be needed, building the model from scratch; this is the more usual case • an influence diagram can be constructed to help modelling: – if technical complexity is not very high, a low scale, – otherwise a high scale diagram can be used at the start Spring 2011 - ÇG IE398 - lecture 6 20 •the model should have as many of the desirable properties of “good” models as possible •most importantly the model must have: –internal validity; meaning that the model is logically and mathematically correct and complete; internal validity should be tested logically and numerically and as early as possible – and external validity or generalisability meaning that the model must be representative of reality, that its findings must make sense in respect of applications; ensuring external validity is problematic; but showing that the model is not externally valid is possible Spring 2011 - ÇG IE398 - lecture 6 21 • concepts such as validity and reliability are fundamental also to research design, and to measurement in all sciences • validity is about measuring what we want to measure and not something else • in experimental sciences the internal validity of an experimental design ensures that an observed effect (ie. ∆y) is indeed the result of a certain cause (ie. ∆x) and not that of some other cause; ie. if y = f(x,w,z, ...), then we must make sure that ∆y = f(x+∆x,w,z, ...)-f(x,w,z, ...) Spring 2011 - ÇG IE398 - lecture 6 22 • (note that we do not know how many variables x,w,z, .. there are that affect y) • validity would be assured if we could exercise complete control over measurement • control means that all other possible causes are kept unchanged (∆w = ∆z = ... 0) • this may be possible in a laboratory • if there is no laboratory, what we can do is to apply the stimulus ∆x > 0 to an experimental group and the stimulus ∆x = 0 to a control group that are two random samples selected from the same population Spring 2011 - ÇG IE398 - lecture 6 23 • in this way the effects of ∆w > 0, ∆z > 0 etc... will cancel out between the groups as we test the difference ∆ye -∆yc, where: ∆ye= f(x+∆x, w+∆w, z+∆z, ...)-f(x,w,z, ...), ∆yc= f(x, w+∆w, z+∆z, ...)-f(x,w,z, ...) since the groups are members of the same population and will be affected in the same way • the relationship established between x and y in this way will be nonspurious • experiments conducted with control groups are said to have strong designs, ie. their internal validity is assured Spring 2011 - ÇG IE398 - lecture 6 24 • hence the controlled experiment is the most powerful research instrument in science • experimental designs will be weaker if there is no control group) • in some disciplines experimentation is normally not possible with or without control groups; hence disciplines such as economics have to rely on much weaker research designs with limited validity • the internal validity of models that are used in economics, in OR or IE is restricted to logical and mathematical correctness Spring 2011 - ÇG IE398 - lecture 6 25 • external validity is about the generalisability of research findings • even when a nonspurious relationship is established between x and y under laboratory conditions, the relation can fail to hold under real world conditions where all the other variables w, z, ... are simultaneously changing • outside a laboratory, the concern is about the representativeness of samples; (samples may not be truly random or of sufficient size) Spring 2011 - ÇG IE398 - lecture 6 26 • the presence of reactive arrangements such as the Hawthorne effect is another concern for external validity • in general there is no definite way to ensure the external validity of research designs or of mathematical models • hence generalising research findings to real world situations is always problematic and requires caution, (if we do not want to end up in bullshit) Spring 2011 - ÇG IE398 - lecture 6 27 • reliability is another key attribute of research design and of measurement • reliability is about stability, or about the absence of random errors in measurement • a reliable measurement may not be valid • the reliability of mathematical models is usually not a problem since a model will produce exactly the same output when the same input data set is used • however we should know how sensitive model results are to input data Spring 2011 - ÇG IE398 - lecture 6 28 • sensitivity analysis is a very important step in hard OR, helping to question, – model robustness and vulnerability to errors, as well as – the external validity of the model • modelling should end with the submission of a project report complete with findings, recommendations, an account of the strong and weak parts of the inquiry and all supporting evidence that is necessary Spring 2011 - ÇG IE398 - lecture 6 29 implementation would involve steps such as: – planning the implementation – establishing control over the solution (ie. when is it necessary to update the current solution and why?) – implementing – auditing (ie. monitoring and evaluation) Spring 2011 - ÇG IE398 - lecture 6 30 the LOD case study • this is a simple application of hard OR that illustrates the first seven steps of Figure 6-1 • LOD manufactures and sells 400 types of lubricants in containers to over 1000 customers made from refinery products • auditors report that LOD stock turnover averages 12 per year, well below the company target of 24 • the vice-president for finance brings this to the attention of the VP for production, who then asks the LOD manager to deal with this issue • the manager of the LOD then seeks advice from the OR team at company headquarters and a preliminary (scoping) study is initiated Spring 2011 - ÇG IE398 - lecture 6 31 Spring 2011 - ÇG IE398 - lecture 6 32 • the rich picture indicates a number of issues: – batch size and cut-off levels can be adjusted for better turnover – current service level can also be adjusted for better turnover • VP-Finance & LOD Manager share the common W: – make efficient use of LOD resources, ie. minimise costs • VP-Finance thinks: – speed-up stock turnover --ie. reduce inventories -- save from capital costs • LOD Manager thinks: – consider also the set-up costs – maintain current service quality • the narrow system is defined as the LOD productioninventory system, the wider system is the LOD Spring 2011 - ÇG IE398 - lecture 6 33 the six elements of the problem are: • immediate decision maker: the LOD manager. • objective: achieving low operating cost for the LOD's operation subject to maintaining the same level of customer service • performance measure: the total operating costs of the LOD. • decision criterion: minimising total costs • alternative courses of action: (i) adjusting stock replenishment batch size and (ii) adjusting the cutoff point separating big and small orders • wider system of interest: the LOD operation and the Sandpoint refinery Spring 2011 - ÇG IE398 - lecture 6 34 • problem scoping -- rather than a full formulation -- was the first step • boundary judgements: – orders and facilities lie outside the wider system • sharing equipment and depot capacity by different products assumed independent at the beginning • investing in equipment and depot capacity is not an option • demand management is not an option – these are not strictly true but permissible, as long as reconsideration of boundaries remains an option – in fact any solution produced by the LOD study is likely to affect facilities and customers Spring 2011 - ÇG IE398 - lecture 6 35 Spring 2011 - ÇG IE398 - lecture 6 36 • a project proposal is submitted – to justify a prelimiary work on a sample of products, – because data collection for a full scale study is costly and therefore needs to be justified, – and since it would be easy to extend the preliminary work into a full scale study Spring 2011 - ÇG IE398 - lecture 6 37 PROJECT PROPOSAL PRODUCTION INVENTORY CONTROL STUDY LUBRICATION OIL DIVISION, SANDPOINT REFINERY Table of Contents 1. Introductory statement 2. Executive summary ofrecommendations 3. Statement of the problem situation 4. Brief description of proposed analysis 5. Resources required and time-table 1. INTRODUCTORY STATEMENT In the middle of March, Mr Black, Manager of the LOD, approached the Management Science Group at the Company's Headquarters with a request to study the LOD production/inventory operations of packaged goods and make recommendations concerning appropriate stock levels. It is my understanding that this request is a follow-up on remarks in the Company's internal auditors' report about the current level of investments in stocks at the LOD. In particular, the auditors pointed out that the LOO's stock turnover of packaged goods was well below the Company's target of24 times per year, resulting in a level offunds tied up in packaged goods judged as excessive. I arranged for a visit to the LOO's production and warehousing facilities at Sandpoint on March 27 and 28, during which 1 had extensive discussions with Mr Black, Mary C1arke, the stock control clerk, Bill Quick, the data processing supervisor, and all four operations supervisors. I also consulted with the Cost Control Department at Headquarters. The following report outlines my recommendations for a preliminary study, briefly motivates and describes the proposed analysis, and lists the resources required and a time-table for undertaking the study. Spring 2011 - ÇG IE398 - lecture 6 38 2. EXECUTIVE SUMMARY OF RECOMMENDATIONS It is recommended that the Company's Management Science Group undertakes a preliminary study of the production/inventory operations. The study would develop a model for finding optimal stock replenishment sizes as well as the minimum size when it becomes more economical to meet individual customer orders by a separate mixing and filling run. Based on this model. reliable estimates of the potential savings in operating costs can be computed with the aim of establishing whether a full-scale investigation can be justified. The results of the study would be available within 4 weeks and the internal charge to the LOD would amount to $6,400. Spring 2011 - ÇG IE398 - lecture 6 39 3. STATEMENT OF THE PROBLEM SITUATION The auditors' report states that the LOO's stock turnover rate over the last two years averaged 12 times per year and hence is well below the company's target rate of 24. As a result, they conclude that the amount of funds tied up in stocks is about twice as high as it should be. What are the cost implications of a given stock turnover rate? For the current customer deliwry policy and production lead time, the average amount of funds tied up in stocks and hence the cost of carrying this investment for any given product, is proportional to the size of its stock replenishment batches. On the other hand, the annual production setup cost is inversely proportional to the size of replenishment batches. Any reduction in average stock levels and the annual cost of carrying the corresponding investment can therefore only be achieved by increasing the annual production setup cost. It can easily be shown that there is a best size for each replenishment batch for which the sum ofthese two costs is at its lowest possible level. This also implies a best turnover rate for each product, which is likely to be different from product to product. Only by coincidence will the average turnover rate over all products be equal to the target rate of 24. A target turnover rate of24 may thus not achieve the lowest total cost for the LOD operations. ¨¨ Spring 2011 - ÇG IE398 - lecture 6 40 4. BRIEF DESCRIPTION OF PROPOSED ANALYSIS The preliminary analysis will be done for a random sample of products. Its results will be extrapolated to all products carried by the LaD. The following major steps are involved: (a) Development of model: After further on-site study, a model for the total annual relevant cost. suitable for use on all products carried by the LOO, will be developed. It will be used for detennining the best combination of stock replenishments and cutoff point for special production runs for each product. The objective is to minimize the total annual operating costs. The model will be in the form of a computer spreadsheet. (b) Sample selection and data collection: With a view to increasing the accuracy of potential sayings estimates for the new policy, products will be grouped according to annual sales and a representative sample selected from each, making up about 5% of all products. Demand and cost data will be estimated for all products in the sample using readily avaiJable data from the LOO data base of customer orders and costing data from the Cost Control Department. (c) Estimation of total saving: The total annual operating cost for the best policy will be determined individually for each product in the sample. These costs will be extrapolated for each product group and finally to the entire product line. This extrapolation is an estimate of the total annual cost of using the best policy for all products. This estimate will be compared with the annual costs incurred for the current policy. The difference represents the potentia] annual savings. No change in the expected office costs of running the new policy is expected. (d) Estimation offurther expenses for a full-scale study: The expense in terms of internal employee charge-out rates, materials, and computer running costs for undertaking a fullscale study will be estimated. (e) Forming of recommendations and preparation of project report: The recommendation will state whether a full-sca]e study should be undertaken, based on the norma] company criterion that all expenses for such a study must be recovered by the savings generated within one year of implementation of the recommendations. If appropriate, the project report "'ill also present a detailed budget of resources needed and a timetable for undertaking the full-scale study. Spring 2011 - ÇG IE398 - lecture 6 41 5. RESOURCES REQUIRED AND TIMETABLE Task Analyst time Other staff time Elapse time Model dewlopment 2 days I day (LOO staff) 2 days Sampling design 1 days 2 days (LOO staff) 4 days Data collection 4 days 3 days (cost control) 8 days 3 days (LOO staff) Savings estimates 2 days 1 day (cost contra]) 4 days 2 days (LOO staff) Writing recommendations 3 days Totals 12 days 4 days 4 days (cost control) 22 days 8 days (LOO staff) Chargeable costs: 12 days at $400/day Spring 2011 - ÇG $4,800 IE398 - lecture 6 42 Spring 2011 - ÇG IE398 - lecture 6 43 the LOD model: consider first the batch-size problem, assuming the cutoff point L is held constant : min T(Q) = 0.5Qvr + (sD1/Q) + h1D1 + vD1 therefore the EOQ is : Q* = (2sD1/vr)½ D1 is that part of the total annual demand D = 7132 to be met from stock; (for example if the cut-off point is L=12 drums, then D1= 7132 - 2992 = 4140) s=$18 is the set-up cost r=%18 is the cost of capital v=$320 is the price of one drum of oil h1=$1.10 is the handling charge for drums stored Spring 2011 - ÇG IE398 - lecture 6 44 • the total relevant cost will be: T(L,Q) = sN + h2D2 + 0.5Qvr + sD1/Q + h1D1 where N is the annual number of big orders; D2 = 7132 – 4140 = 2992 is the total number of drums to be shipped directly to big customers and h2= $0.45 is the handling charge per drum • eg. since the number of all orders = 1266, when L = 12, N = 1266 – 1079 = 187, and Q* = EOQ = 50.9, in which case the total minimal cost for L =12 will be: T(12,50.9) = (18)(187) + (0.45)(2992) + (0.5)(50.9)(320)(0.18) + (18)(4140)/50.9 + (1.10)(4140) = 12 196.37 • the optimal solution can be determined by enumeration, ie. by trying out different values for L; so: L* = 20, Q* = 61.8 (see the Excel chart) Spring 2011 - ÇG IE398 - lecture 6 45 Spring 2011 - ÇG IE398 - lecture 6 46 • extending the project from scoping to full analysis would include steps such as: – repeating the solution for all the remaining 803 products – determining whether equipment and capacity constraints are satisfied – combining same-day big orders – combining small orders with big orders – combining all orders and then deciding a special run if these exceed the cut-off level – combining special runs with replenishments etc. Spring 2011 - ÇG IE398 - lecture 6 47 • testing the LOD model – internal validity assessed by hand; external validity assured by theory – performance evaluation possible by sampling after an A-B-C analysis • sensitivity analysis – the LOD model is fairly robust. EOQ model is not very sensitive to parameters. – capacity or equipment resources may reflect high marginal values (ie. the shadow price of resources) – further investigation of uncertain data may or may not be called for • error analysis – sensitivity analysis to establish all parameter intervals for optimality – to see how far past data can be relied on to predict the future Spring 2011 - ÇG IE398 - lecture 6 48 PROJECT REPORT PRODUCTION/INVENTORY CONTROL FOR PACKAGED GOODS AT THE LUBRICATION OIL DIVISION, SANDPOINT REFINERY Table of Contents Introductory statement Executive summary of findings and recommendations Statement of the problem Major steps of analysis Major findings Recommendations for implementation Appendices: Spreadsheet for finding optimal policy for product Y Computations performed Detailed description of model Spring 2011 - ÇG IE398 - lecture 6 49 Spring 2011 - ÇG IE398 - lecture 6 50