Dual Winding Method of a BLDC Motor for

advertisement

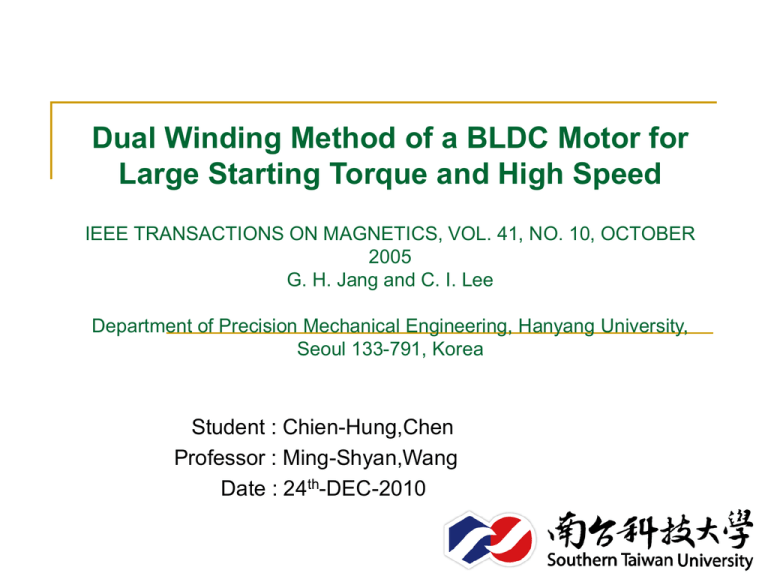

Dual Winding Method of a BLDC Motor for Large Starting Torque and High Speed IEEE TRANSACTIONS ON MAGNETICS, VOL. 41, NO. 10, OCTOBER 2005 G. H. Jang and C. I. Lee Department of Precision Mechanical Engineering, Hanyang University, Seoul 133-791, Korea Student : Chien-Hung,Chen Professor : Ming-Shyan,Wang Date : 24th-DEC-2010 Outline Abstract Introduction DUAL WINDING METHOD AND ITS INVERTER CIRCUIT A. Dual Windings in Parallel Connection B. Inverter Topology for Dual Windings PROTOTYPING AND EXPERIMENTAL VERIFICATION CONCLUSION REFERENCES Abstract • This paper presents a novel winding method and its inverter circuit to drive a brushless dc (BLDC) motor to high speed with large starting torque. • The proposed winding coils are composed of dual windings, i.e., main and auxiliary windings, and the proposed invertercircuit has nine switches. • In the starting period, it energizes both main and auxiliary windings in parallel connection to generate large starting torque. • After the motor is accelerated, the proposed inverter circuit is automatically switched to energize main winding, which generates small back-electromotive force, to reach high speed. • The proposed method is applied to the spindle motor of a hard disk driveand its effectiveness is verified through experiment. Introduction 〔1/2〕 A BRUSHLESS dc (BLDC) motor has been widely used in the driving source of many precision electromechanical devices not only because it has high efficiency but also because it has good controllability. [1]. The linear torque–speed characteristics of a BLDC motor make it easy to control its speed over the wide range. However, a BLDC motor cannot be run at high speed with large starting torque at the same time because its inherent back-electromotive force (EMF) is proportional to the speed. In order to run a BLDC motor at high speed, back-EMF constant is designed to be small in order to reduce the voltage drop due to back-EMF. However, it generates small starting torque because back-EMF constant is identical to torque constant, and it consequently results in a long transient period. It is one of the drawbacks of a BLDC motor in high-speed applications. Several researchers have addressed the driving methods to run the motor at high speed with large starting torque. Jang and Kim proposed a method to drive a BLDC motor at high speed with large starting torque by utilizing a bipolar-starting and unipolar-running algorithm. Introduction 〔2/2〕 [2]. It uses the existing windings of a BLDC motor, but it cannot improve the torque–speed characteristics better than those of the unipolar or bipolar winding configuration of the BLDC motor. Tsai et al. presented a winding method and a driving method to run the motor at high speed with large starting torque. [3]. They proposed a variable winding BLDC motor, i.e., two sets of windings for a BLDC motor. It has the serial and parallel windings together. The former is used for low-speed operation with large torque, which results from series connection, and the latter is used for high-speed operation with small backEMF constant, which results from parallel connection. However, their inverter circuits require additional switching devices and more complex control logic, and two sets of windings of their motor are required to have the same backEMF constant. This paper presents a novel winding method and its inverter circuit to drive a BLDC motor at high speed with large starting. torque. The proposed BLDC motor and inverter circuits are prototyped, and their effectiveness is verified through the experiment. DUAL WINDING METHOD AND ITS INVERTER CIRCUIT 〔1/11〕 A. Dual Windings in Parallel Connection Fig. 1 shows the proposed winding method and inverter circuit of the BLDC motor. The winding coils of each phase are composed of dual windings, i.e., main and auxiliary windings in parallel connection. The proposed inverter circuit can be controlled in such a way that the current flows in either main and auxiliary windings or main winding only. Fig. 1. Dual winding configuration and its inverter topology. DUAL WINDING METHOD AND ITS INVERTER CIRCUIT 〔2/11〕 Torque–speed characteristics of a BLDC motor can be derived as follows [4]: where and are the supplied voltage and the rotating speed, and , and are torque constant, back-EMF constant, and phase resistance of main and auxiliary windings, respectively. In the case where only the main winding is energized, the starting torque and the maximum speed at no load can be written as follows: DUAL WINDING METHOD AND ITS INVERTER CIRCUIT 〔3/11〕 Fig. 2. Current flow through the auxiliary winding of phase AB when the conventional inverter energizes the main winding of phase AB. DUAL WINDING METHOD AND ITS INVERTER CIRCUIT 〔4/11〕 In the case where both main and auxiliary windings are energized, the starting torque can be written as follows: It can be concluded from (2) and (4) that energizing both main and auxiliary windings in parallel connection always generates larger starting torque than energizing only the main winding. DUAL WINDING METHOD AND ITS INVERTER CIRCUIT 〔5/11〕 In the case where both main and auxiliary windings are energized, the maximum speed at no load can be written as follows: In the proposed dual windings, the number of coil turns of the main winding is designed to be smaller than that of the auxiliary winding. It makes the torque constant and the back-EMF constant of the main winding smaller than that of the auxiliary winding. It can be concluded from (3) and (5) that energizing the main winding always generates higher maximum speed than energizing both main and auxiliary windings in parallel connection because the denominator is bigger than the numerator in (5). DUAL WINDING METHOD AND ITS INVERTER CIRCUIT 〔6/11〕 B. Inverter Topology for Dual Windings • The proposed dual windings cannot be properly operated by the conventional inverter circuit. In the high-speed range when only the main winding is energized, back-EMF voltage is generated in the auxiliary winding. It allows the current to flow along any closed path including the auxiliary winding and it may generate negative torque. • Fig. 2 shows the undesirable current flow through the auxiliary winding of phase AB when the main winding of phase AB is energized by using the conventional inverter circuit. Back-EMF voltage of the auxiliary winding makes the negative current flow through the auxiliary winding which results in negative torque. Eventually, it prevents the BLDC motor from being accelerated to high speed. DUAL WINDING METHOD AND ITS INVERTER CIRCUIT 〔7/11〕 • Fig. 3 shows the measured phase current at main and auxiliary windings when only the main winding is energized by using the conventional inverter circuit. It shows that negative current flows in the auxiliary winding even though the auxiliary winding is not energized by the conventional inverter circuit. This research develops an inverter circuit as shown in Fig. 1 to prevent the negative current from flowing in the auxiliary winding due to back-EMF at high speed. Fig. 3. Measured phase current at main and auxiliary windings when only the main winding is energized. DUAL WINDING METHOD AND ITS INVERTER CIRCUIT 〔8/11〕 • A developed inverter circuit energizes the main and auxiliary windings in parallel connection at starting period, and it energizes only the mainwinding at high speed. • As shown in Fig. 1, the proposed inverter circuit has nine switches, i.e., the upper three, middle three, and lower three switches. Each of the three middle switches is composed of one n-channel MOSFET and four diodes. In these middle switches, drain and source voltage of the MOSFET is determined by the voltage of the main and auxiliary windings, and the gate voltage is controlled by supplied voltage. • Table I shows the firing sequences of the proposed inverter circuit. DUAL WINDING METHOD AND ITS INVERTER CIRCUIT 〔9/11〕 • Fig. 4. shows the operation of both main and auxiliary windings at the starting period by the proposed inverter circuit. When inverter switches of A , A, B, C and B are turned on, the current flows through the solid lines of main and auxiliary windings of phase A and B, respectively, as shown in Fig. 4. Fig. 4. Current flow by the operation of both main and auxiliary windings. DUAL WINDING METHOD AND ITS INVERTER CIRCUIT 〔10/11〕 • Once the motor is accelerated, the back-EMF voltage of the auxiliary winding is increased. When it reaches higher than the supplied voltage, the source voltage of the MOSFET connected to the auxiliary winding is bigger than the gate voltage and the corresponding middle inverter switch is automatically turned off. Then, it does not allow the current to flow through the auxiliary winding in the speed range higher than this threshold speed. The firing sequence at high speed is exactly the same one as thatof the starting period as shown in Table I. DUAL WINDING METHOD AND ITS INVERTER CIRCUIT 〔11/11〕 • Fig. 5 shows the operation of the main winding at high speed by the proposed invertercircuit. Even though the inverter switches A , A, B, C and B are turned on as shown in Table I, the source voltage of the inverter switch A connected to the auxiliary winding is bigger than the gate voltage and the inverter switch A is automatically turned off. The current flows through the solid lines of the main winding of phases A and B as shown in Fig. 5. Fig. 5. Current flow by the operation of main winding at high speed. PROTOTYPING AND EXPERIMENTAL VERIFICATION 〔1/3〕 • The proposed BLDC motor and its inverter circuit are prototyped for a spindle motor of a hard disk drive (HDD). The operating speed is 10 000 r/min and the number of coil turns of the main and auxiliary windings are 25 and 50, respectively. The proposed inverter circuit is also developed as shown in Fig. 1, and its switching action is controlled by a TMS320F240 digital signal processor (DSP) from Texas Instruments. • Fig. 6 shows the measured torque–speed curves of the prototyped motor with the operation of dual windings and main winding. The proposed motor with dual windings has a starting torque of 15.9 mN m which is 60% larger than the motor operated by only the main winding. In the speed range lower than 6000 r/min, the main and auxiliary windings are energized to maximize the torque. Fig. 6. Measured torque–speed curves. PROTOTYPING AND EXPERIMENTAL VERIFICATION 〔2/3〕 • From 6000 r/min, the back-EMF voltage of the auxiliary winding starts to be higher than the supplied voltage so that the corresponding middle inverter switch connected to the auxiliary winding is automatically turned off. • In the speed range higher than 6000 r/min, the developed inverter energizes only the main winding so that it reaches the same maximum speed of 14 000 r/min which can be obtained by the operation of the main winding. • The proposed dual winding operation reduces the starting time of the BLDC motor with a 3.5-in disk to reach 10 000 r/min from that of a conventional motor by 16.7%. PROTOTYPING AND EXPERIMENTAL VERIFICATION 〔3/3〕 • Fig. 7 shows the measured efficiency curves of the prototyped motor with the operation of dual windings and main winding. Efficiency of the prototyped motor with dual windings is bigger than that with the main winding in the speed range lower than 6000 r/min because the torque output of the former is bigger than the latter. Fig. 7. Measured efficiency curves. CONCLUSION • This paper has developed a novel winding method and its inverter circuit to drive a BLDC motor to high speed with large starting torque. The proposed BLDC motor and inverter circuits were prototyped, and their effectiveness was verified through experiment. The proposed inverter circuit can automatically switch from dual windings to main winding to maximize the torque output and high-speed operation. It may be effectively applied to reduce the starting time of high-speed electromechanical devices with heavy load. It may also reduce the power consumption of the BLDC motor with frequent on–off operation because the proposed dual winding has high efficiency during the startup period. REFERENCES [1] E. Grochowski and R. F. Hoyt, “Future trends in hard disk drives,” IEEE Trans. Magn., vol. 32, no. 3, pp. 1850–1854, May 1996. [2] G. H. Jang and M. G. Kim, “A bipolar-starting and unipolar-running method to drive a HDD spindle motor at high speed with large starting torque,” IEEE Trans. Magn., vol. 41, no. 2, pp. 750–755, Feb. 2005. [3] M. C. Tsai, M. C. Chou, and C. L. Chu, “Control of a variable-winding brushless motor with the application in electric scooters,” in Proc. IEEE Int. Conf. Electric Machines and Drives, 2001, pp. 922–925. [4] J. R. Hendershot and T. J. E. Miller, Design of Brushless Permanent- Magnet Motors. Oxford, UK: Oxford Univ. Press, 1994. Thank you for your attention!!

![FORM NO. 157 [See rule 331] COMPANIES ACT. 1956 Members](http://s3.studylib.net/store/data/008659599_1-2c9a22f370f2c285423bce1fc3cf3305-300x300.png)