Meditech Surgical: Supply Chain Management Case Study

advertisement

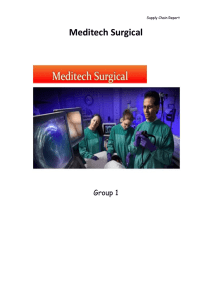

Supply Chain Management. Case Study 1: Meditech Surgical. 1. What are Meditech’s problems in introducing new products? In manufacturing ALL products? Seems like the main business strategy of Meditech is to introduce new products into the market to satisfy the customers’ needs and be up-to-date in the market. And this might be one of the reasons, which made the company successful among their competitors. For the company, introducing and selling the new product wasn’t an issue, since their products, mostly, updated based on existing products. However, whenever, Meditech introducing new products, the customer service level were getting low or to be specific, customers were unsatisfied with order deliver. The company were facing huge drawback in supply chain to keep up with customer demand, their initial demand. On the other hand, the inventory of finished products was extremely high that they could decrease inventory level at least 40%. But they couldn’t meet the customers demand on time delivery and yet, couldn’t decrease the inventory! One of the reasons is their forecasting wasn’t accurate enough. I would say forecasting was terrible since “there was no routine way to see incoming demand, inventory, or production demand for particular instrument”. It was hard to do forecasting since they didn’t have any data on that, or it’s wasn’t in a same format. Another problem was panic ordering from dealers and buyers. It caused unrealistic increase in demand of a product and hard to control since the company can’t control buyers action. This panic ordering also, made hard to come up with accurate forecasting. 2. What is driving these problems, both systemically and organizationally? I think company’s strategy of persistent introduction of the new product was one the leading reason of creating problems. Not analyzing their customers’ demand, which causes the wrong forecasting, and Meditech’s supply, which causes them shortage with each product introduction, drive the company’s to the big problem. In the production, the policy of one week’s notice for responding to scheduling changes gives the production level acts one week behind the forecasted schedule. Moreover, the information to have accurate forecast had not been tracked or kept in the system, which makes forecasting more hard to obtain and time consuming. Another thing is that Meditech management ignorance on setting the fixed inventory level. Even though, they knew that inventory level was 40% higher than required, they didn’t do anything due to their fear of shortage. And lastly, the company’s decentralized organization, the dealers the dealers had no control over the demand from each warehouse, so warehouses could make a “panic order” creating delusional shortage. Plus, the format of data storage on different systems was not standardized, which leads to the problem to generate reports. 3. Why is the customer service manager the first person to recognize the major issues? First of all, the customer service manager is the one who directly contacts and in charge of the customer satisfaction. Therefore, he is the one, who receives positive or negative feedback from the customers. And since forecast hadn’t been compared with the actual demand in the past to track its accuracy, the company could see the problem and low service level only through customers complain. Moreover, he could directly see what the main problem is since customer will tell him what isn’t satisfying them. 4. How would you fix these problems? First of all, I would work on improving the forecast system. In order to have a accurate forecasting, the company need to keep a track and standardize data storage to compare the actual demand and forecast for the last few years. An easy statistical method (linear regression and etc.) based on past forecasting data will help them to do accurate analysis. It seems like, the demand for new product in high only first week and afterward more likely became stable. Second thing, which I will do, is improve the company’s IT system. The company should have centralized organizational system; therefore, they could have quick access to the required data (not going through the papers and hard copies). And having a standardize format for all forecasting and demand to utilize the report. Thirdly, since the Meditech reputation has being ruined due to on-time delivery mistake, the company needs to gain dealers and buyers trust again. They need to work closely with buyer to determine their real demand, which also, could help to decrease “panic order”. And lastly, it would have being really nice to have latest or innovative IT system, so they could have more convenient ways for order (online order), supply and delivery the product.