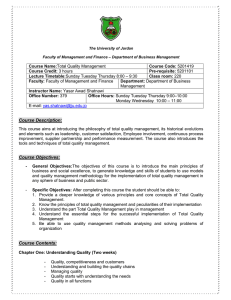

Relationships of TQM Philosophy, Methods and Performance: A Survey in Taiwan 全面品管哲學與方法對品質績效的相關性研究

advertisement

全面品管哲學與方法對品質績效的相關性研究 Relationships of TQM Philosophy, Methods and Performance: A Survey in Taiwan NSC 89-2416-H-218-005 黃峰蕙(Fenghueih Huarng)1 1南台科技大學企管系 (Department of Business Administration, Southern Taiwan University of Technology, Tainan, Taiwan 710) 1 Literature Review • The relationships of CSF and performances – Powell (1995)__USA, N=63 • open culture • employee empowerment • executive commitment • quality training • process improvement • benchmarking Produce advantage No help – Control variables: • years since TQM adoption (experience) • number of employees (firm size) • industry (manufacturing vs. service) 2 – Samson & Terziovski (1999)__ Australian and New Zealand, N=1024, No control variable • leadership Current operational • management of people performance • customer focus – Sun(1999)__Norway, N=316, No control variable • quality leadership Increase customer satisfaction & business • human resource development performance • quality information 3 – Huarng, Horng & Chen(1999) __ISO in Taiwan, N=376 • all employee’ empowerment • open culture • use of information system • documentation through auditing Quality, cost internationalization sales • quality control activity before ISO – Control variables • the age of corporation (experience) • the number of employee (firm size) • the percentage of overseas sales 4 Research Method literature review & pre-tested by two site managers • • top 1000 manufacturing firms 1999 on China Credit Information Service,Ltd. • data collected in Summer 2000 • 42 items for implementation practices (cronbach a = 0.9604), 1:highly disagree, 4: indifferent, 7: highly agree • 16 items for performance (cronbach a = 0.8997), 1: highly worsen, 4: remain the same, 7: highly improved • Non-response test (73 TQM vs. 142 TQM non-response) -No difference in total sales, # of employees, industry distribution • TQM have greater size than non-TQM TQM Sample frame 215 Respondents 73 Return Rate 34.0% Non-TQM 785 71 9.0% Total 1000 144 14.4% 5 Results • Factor analysis – Table:performance variables – Table: implementation practices • Factor 1 : employee empowerment • Factor 2 : all employee perception through top executive support • Factor 3 : training • Factor 4 : measuring product and service • Factor 5 : benchmarking on quality and service • Factor 6 : statistical method • Factor 7 : benchmarking on cost • Factor 8 : supplier co-operation • Factor 9 : employee involvement. 6 • Table: performance variables I t e m Factor 1: cost reduction (cronbach a = 0.9251) B14 Reducing customer complaints B12 Reducing defect rate B4 Reducing cost of reworks and waste B9 Reducing process variance B10 Reducing manufacturing cost B13 Reducing quality cost B3 Reducing delivery time B1 Reducing management cost Factor 2: business performance (cronbach a = 0.8851) B7 Improving capacity of machinery and equipment B16 Increasing market share B5 Increasing orders B11 Speeding new product introduction B6 Improving product functionality B8 Improving overall profitability B2 Improving product reliability Loading .884 .861 .839 .834 .786 .772 .744 .578 .858 .837 .808 .718 .713 .699 .686 7 Table: implementation practice Item Factor 1: employee empowerment (cronbach a = 0.9374) P26 A more active employee suggestion system P7 Ideas from production operators are actively used in production management P16 These customer requirements are effectively disseminated and understood throughout the workforce P40 Employee training in problem-solving skills P8 Database is built for analysis P17 All employees believe that quality is their responsibility P15 Environmental (‘green’) protection issues are proactively managed Factor 2: all employee quality perception through top executive support(cronbach a = 0.9228) P38 Our plan always incorporate external customers, suppliers and other stakeholders P1 Top manager clearly understand the fundamental spirits and principles of quality management P5 Written statement of strategy clearly articulated and agreed to P39 Increased employee autonomy in decision-making P41 Employee satisfaction is formally and regularly measured P11 We proactively pursue continuous improvement rather than reacting to crisis ‘firefighting’ P3 A top executive decision to commit fully to a quality program P4 Employees clearly understand the fundamental spirits and principles of TQM P21 Employee training in teamwork P23 Data is analyzed using computer for managers to make decisions Loading .822 .784 .671 .665 .646 .636 .580 .682 .678 .674 .641 .633 .618 .510 .454 .432 .401 8 Table: implementation practice Item Factor 3: training (cronbach a = 0.91) P35 Management training in quality principles P33 Customer complaints are used as a method to initiate improvements in our current processes P36 Statistical methods to measure and monitor quality P27 Have organization-wide training & development process for all employees P28 Production operators training regularly in quality P34 Mission statement communicated and supported by employees P12 Measurement of quality performance in all area Factor 4: measuring product and service (cronbach a = 0.7232) P24 We have well established methods to measure the quality of our product and services P30 We have side-wide standardized and documented operating procedure P13 Use of computer to record daily data P2 We know our external customers’ current and future requirements (both in terms of volume and product characteristics P37 We work closely with our suppliers to improve each others’ processes Factor 5: benchmarking on quality and service (cronbach a = 0.8253) P10 We are engaged in extensive benchmarking of competitors’ quality procedures P19 We are engaged in extensive benchmarking of competitors’ operating processes P31 We are engaged in extensive benchmarking of competitors’ customer service Loading .818 .718 .550 .550 .545 .532 .494 .787 .735 .635 .622 .453 .855 .825 .646 9 Table: implementation practice Item Factor 6: statistical method (cronbach a = 0.7456) P29 Use of Statistical Process Control (SPC) P22 Charts and graphs to measure and monitor quality P25 We have an effective process for resolving external customers’ complaints Factor 7: benchmarking on cost (cronbach a = 0.7049) P6 We are engaged in extensive benchmarking of competitors’ relative cost position P20 Building database system with our suppliers P18 Have a comprehensive and structured planning process P32 We are engaged in extensive benchmarking of competitors’ sale dollars Factor 8: supplier co-operation P14 Our suppliers work closely with us in product development Factor 9: employee involvement P9 Employees involve in design and planning P42 We proactively champion certification of quality management system Loading .782 .621 .494 .751 .556 .502 .484 .874 .738 .588 10 • Linear Regression analysis (stepwise) – two control variables • C1:starting date of TQM adoption • C2:the corporate sales – VIF is 1.222 for 2 CV & 9 independent variables – α=0.05 • BF1: cost reduction • BF2: business performance • Regression : interaction models • BF1:cost reduction • BF2:business performance 11 Discussions & conclusions • Both TQM philosophy & tools help business performance – Two P’s: • employee empowerment (PP1) • all employee quality perception through top executive support (PP2) – Four M’s: • • • • training (PM1) use of statistical method (PM4) benchmark on cost (PM5) supplier co-operation (PM6) 12 • The relationship may vary from country to country – confirm Sun (Norway, 1999) – different from Powell (USA, 1995) & Dow et al (Australian, 1999) • Integration of P & M help – PP1 & PM1 integration help cost down » capable employee with empowerment – PP2 & PM6 integration help business perform » cooperation of top executive, employees & suppliers • TQM P & M help in all sizes of firms with or without experience of TQM adoption 13 ~ The End ~ Fenghueih Huarng1 14 Stepwise regression analysis for BF1: cost reduction Total Removed 38 28.40502800 Parameter Standard Type II Step 2 R-square = 0.17497146 C(p) = -0.32275978 DF Sum of Squares Variable PM3 Mean Square F Prob>F Regression Error 2 36 Variable Prob>F Estimate INTERCEP C1 C2 1.03111045 -0.01222440 0.00001748 4.97006916 23.43495884 Error 0.69260951 0.00832172 0.00001009 2.48503458 0.65097108 3.82 Sum of Squares 1.44276358 1.40472186 1.95244855 0.0314 F 2.22 2.16 3.00 0.1453 0.1505 0.0919 15 Stepwise regression analysis for BF2:business performance Step 6 Variable PP2 Entered DF R-square = 0.77875330 Sum of Squares C(p) = 6.04972662 Mean Square F Prob>F Regression Error Total 8 30 38 Variable Parameter Estimate INTERCEP C1 C2 PP1 PP2 PM1 PM4 PM5 PM6 -0.12140026 -0.00052287 0.00002242 0.30132279 0.20107267 0.39869318 0.37898169 0.29009042 0.27021406 29.74715928 8.45127831 38.19843759 3.71839491 0.28170928 Standard Type II Error Sum of Squares 0.49484736 0.00593385 0.00000728 0.08916881 0.09605692 0.09756178 0.09969803 0.08382673 0.08585940 0.01695500 0.00218731 2.67586120 3.21691180 1.23438301 4.70456343 4.07065629 3.37367214 2.79023880 13.20 0.0001 F Prob>F 0.06 0.01 9.50 11.42 4.38 16.70 14.45 11.98 9.90 0.8079 0.9304 0.0044 0.0020 0.0449 0.0003 0.0007 0.0016 0.0037 16 Interaction regression analysis for (BF1) cost reduction Dependent Variable: BF1 Source Model Error C Total Root MSE Dep Mean C.V. Variable INTERCEP C1 C2 PP1 PM1 INT11 DF 1 1 1 1 1 1 DF 5 33 38 Analysis of Variance Sum of Mean Squares Square F Value 9.63959 1.92792 3.390 18.76543 0.56865 28.40503 0.75409 R-square 0.3394 0.21200 Adj R-sq 0.2393 355.70213 Parameter Estimates Parameter Standard T for H0: Estimate Error Parameter=0 1.039845 0.65116048 1.597 -0.012329 0.00779727 -1.581 0.000012789 0.00000988 1.295 0.131120 0.12489734 1.050 0.272192 0.16965090 1.604 0.299498 0.10702288 2.798 Prob>F 0.0140 Variance Prob > |T| Inflation 0.1198 0.00000000 0.1234 1.12515107 0.2043 1.22757722 0.3014 1.11286691 0.1182 1.59782785 0.0085 1.63222334 17 Interaction regression analysis for (BF2) business performance Dependent Variable: BF2 Source Model Error C Total Root MSE Dep Mean C.V. Variable DF INTERCEP 1 C1 1 C2 1 PP2 1 PM6 1 INT26 1 DF 5 33 38 Analysis of Variance Sum of Mean Squares Square 17.77247 3.55449 20.42597 0.61897 38.19844 0.78675 0.03390 2320.95928 R-square Adj R-sq F Value 5.743 Prob>F 0.0006 0.4653 0.3842 Parameter Estimates Parameter Standard T for H0: Estimate Error Parameter=0 -0.082211 0.70708157 -0.116 -0.002021 0.00845772 -0.239 0.00003188 0.00001014 3.144 0.379872 0.13900000 2.733 0.309924 0.13250136 2.339 0.286577 0.10385201 2.759 Variance Prob > |T| Inflation 0.9081 0.00000000 0.8126 1.21621001 0.0035 1.18848112 0.0100 1.13216780 0.0255 1.14217095 0.0094 1.15005292 18