Product Form Feature Selection for Numerical Definition-Based Design Chih-Chieh Yang

advertisement

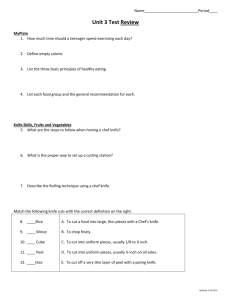

Product Form Feature Selection for Numerical Definition-Based Design Chih-Chieh Yang Department of Multimedia and Entertainment Science, Southern Taiwan University, Tainan County, Taiwan 71005 Hung-Yuan Chen Department of Visual Communication Design, Southern Taiwan University, Tainan County, Taiwan 71005 Abstract For developing appealing products, it is important for designers to pin point critical product form features (PFFs) that influence consumers’ affective responses (CARs) toward a product design. Manual inspection of critical form features based on expert opinions has not proved to meet with the acceptance of consumers. In this paper, a product form feature selection model based on CARs and a numerical definition-based systematic approach (NSDA) is proposed. First, NSDA was used to generate an explicit numerical definition of product form design. Next, CARs were described using single adjectives as affective dimensions. The evaluation data of consumers can be gathered by a semantic differential (SD) experiment. The prediction models of CARs were constructed using support vector regression (SVR) and multiple linear regression (MLR). Two feature selection methods, namely SVR with support vector machine recursive feature elimination (SVM-RFE) and MLR with the stepwise procedure, were used to select critical form features. A case study of knife design is given to demonstrate the experimental results of the two feature selection methods. The results of our experiment show that the feature ranking obtained from SVM-RFE is very helpful to determine the importance of the form features. It is also possible to select a subset of features with a given predictive performance of the SVR model. On the other hand, the results of MLR with the stepwise procedure provide several useful statistics to analyze the form features. The effects of the form features for inducing specific CAR of knife design can also be interpreted by the standardized regression coefficients. Since only a small data set of knife design was adopted in this study, a further study using different kinds of product samples is worthy of ongoing investigation. Keywords: Feature selection; support vector regression; support vector machine recursive feature elimination (SVM-RFE); Multiple linear regression; Kansei engineering; Product form design. 1 1. Introduction A product’s appearance is one of the most important factors affecting a consumer’s purchasing decision. Many systematic product design studies have been carried out to get a better insight into consumers’ subjective perceptions. The most notable research is Kansei engineering (KE) (Jindo et al., 1995). The basic assumption of KE studies is that there exists a cause-and-effect relationship between product form features (PFFs) and consumers’ affective responses (CARs) (Han and Hong, 2003). Therefore, a prediction model can be constructed from collected product samples and the CAR data. Using these models, the relationship between PFFs and CARs can be analyzed and a specially designed product form for specific target consumer groups can be produced more objectively and efficiently. The construction of the prediction model can be regarded as a regression problem taking PFFs of product samples as input data and the CAR data as output values. Various methods can be used to build the prediction model including multiple linear regressions (MLR) (Chen and Chang, 2009), quantification theory type I (QT1) (Lai et al., 2006), partial least squares regression (PLSR) (Han and Kim, 2003), neural networks (NN) (Hsiao and Huang, 2002) and support vector regression (SVR) (Yang and Shieh, 2010). Of these methods, SVR’s remarkable performance makes it the first choice in a number of real-world applications but it is seldom adapted to the product design field. In the study of Yang and Shieh (2010), SVR was introduced to develop a model that predicts CARs for product form design with a very satisfactory predictive performance. However, the PFFs of product samples (mobile phone design) were analyzed by a morphological analysis (Jones, 1992), which results in a product form representation with a mixed of continuous and discrete design attributes. This kind of product form encoding is actually an abstract and simplified representation of the form design and not directly linked to the form features of a product. A convincing remedy, proposed by Chang and Chen (2008), to this problem is to employ a numerical definition-based systematic approach (NSDA) to generate an explicit numerical definition for product form design. Using NSDA, it is beneficial that not only the importances of the form features obtained from feature selection methods can be directly interpreted in the domain of the form features, but also the integration with hybrid Kansei engineering system, such as the automatic product design systems proposed by Hsiao and Tsai (2005) and Tsai and Chou (2007), to generate new product form design according to the specified affective responses is quite straightforward. Although being an important research topic for KE, the problem of product form 2 feature selection according to CARs has not been intensively investigated. CARs are often influenced by a wide variety of form features. The number of form features could be many and might be highly correlated to each other. The relative importance of each form feature is hard to identify so the selection of the critical form features that please the consumer is a difficult task. When designing new products, critical design features are often arrived at based on the opinions of expert (such as product designers) or focus groups. However, the selection of features based on expert opinion has its drawbacks such as a lack of objectivity and expert availability (Han and Kim, 2003). Moreover, the designers often need to combine or re-organize form features. Therefore, if the relative importance and the ranking of the form features can be analyzed, it can facilitate the decision making of designers. Since the feature selection methods are connected with the prediction model of CAR, not only the critical form feature can be selected but also their influence to produce specific CARs can be extracted. Only a few attempts have been made to overcome these above-mentioned shortcomings in the product form feature selection process. Han and Kim (2003) used several statistical methods for screening critical design features including principal component regression (PCR), cluster analysis, and PLSR. In Han and Yang (2004), a genetic algorithm-based partial least squares method (GA-based PLS) was applied to screen design variables. In the present study, a product form feature selection model is constructed based on CARs and NSDA in the context of KE. CARs were described using single adjectives and NSDA was used to define the product form design. In order to gather the evaluation data of consumers, a semantic differential (SD) experiment was conducted using questionnaire investigation. The prediction models of CARs were constructed using both SVR and MLR. Two feature selection methods, including SVR with support vector machine recursive feature elimination (SVM-RFE) and MLR with the stepwise procedure, were used to pin point critical form features. A case study of knife design is given to demonstrate the analysis result. The reminder of the paper is organized as follows: Section 2 reviews the problem of product form feature selection and introduces the two feature selection methods, namely SVR with SVM-RFE and MLR with the stepwise procedure. Section 3 presents the proposed model for product form feature selection. Section 4 describes the experimental results and analyses of the two feature selection methods. Section 5 offers some brief conclusions. 2. Background review 2.1. The problem of product form feature selection 3 Although there are only sparse literatures existing for product form feature selection, the problem of feature selection can be found in many other fields besides that of product design. The crux of the problem is how to find the subset of PFFs with the least possible generalization errors and to select the smallest possible subset with a high predictive capability. Different approaches have been proposed for solving the feature selection problem including rough sets (Wakaki et al., 2004), rough-fuzzy (Jensen, 2005), neuro-fuzzy (Pal et al., 1996), and support vector machine (SVM) (Liu and Zheng, 2006). Another crucial issue in solving the PFFS problem is how to deal with the nonlinear correlations between PFFs and CARs effectively (Park and Han, 2004). The most widely adapted techniques such as MLR and QT1 do not handle nonlinear relationships very well. In contrast, SVM and SVR are known for their elegance in solving nonlinear problems by applying the kernel trick, which automatically maps a feature space nonlinearly. Based on whether or not feature selection is performed independently of the learning algorithm that constructs the prediction model, feature selection methods can be grouped into two categories: the filter method and the wrapper method (Kohavi and John, 1997). The wrapper method is model-dependent. Based on the predictive performance, the method evaluates directly the goodness of the selected feature’s subset, which should intuitively yield a better performance. Many reported experimental results also favored the wrapper method (Juang and Katagiri, 1992; Wakaki et al., 2004). A well-known wrapper method, SVM-RFE, which was proposed to select a relevant set of features for cancer classification problem (Guyon et al., 2002). SVM-RFE, as a sequential backward feature elimination method, has been successfully applied for product form feature selection based on a multiclass fuzzy SVM classification model (Shieh and Yang, 2008b). In this study, SVM-RFE was integrated into the SVR model to identify critical form features and obtain the feature ranking. However, from a product designer’s point of view, the predictive performance of the constructed model or which subset of the form features was selected may not be main concern. On the contrary, it is more appealing for a design practitioner to get better insight into the relationships of the form features and to examine the effects of the features for inducing specific affective responses. Therefore, MLR, as a linear model, is also adapted for product form feature selection in this study. MLR equipped with a couple of well-developed analyzing statistics yields a simple but intuitive manner to study the form features. 2.2. Feature selection using SVR with SVM-RFE For a regression problem, a set D of l data samples, each represented are 4 given as ( xi , yi ) where xi Rn is the input feature vector, yi R is the desired output value. In a standard SVR with a linear -insensitive loss function the objective is to find a function y f ( x) , where is a precision parameter representing the radius of the tube located around f ( x) . Then, the SVR problem can be regarded as the solution to minimize l 1 2 w C (i i* ) 2 i 1 yi w ( xi ) bi i , i 0 subject to w ( xi ) bi yi i* , i* 0 i 1,..., l (1) where ( x) is the high dimensional feature space that is nonlinearly mapped from the input space R n . The parameter C 0 is a regularized constant determining the trade-off between the empirical error and the regularization term. i is the upper training error ( i* is lower), subject to the -insensitive tube y (w ( x) b) . SVR fits f ( x) to the data by minimizing the empirical error ( i and i* ) and the regularization term 1 2 w . The regularization term is a measure for the model’s 2 complexity, and can be interpreted as a measure for the flatness of the regression hyperplane in feature space. By introducing the Lagrange multipliers , * , a kernel function K and exploiting the optimality constraints, the constrained optimization problem in Eq. (1) can be solved and the values of multipliers and * can be obtained. For detailed derivations the reader is referred to Vapnik (1995). The weight vector w can be expressed as follows: l l w (i i* )( j *j ) K ( xi , x j ) (2) i 1 j 1 An efficient wrapper approach called SVM-RFE was used to conduct product form feature selection in this study. The selection criterion of SVM-RFE was developed according to Optimal Brain Damage (OBD) which has proved to be better than earlier methods (Rakotomamonjy, 2003). OBD was first proposed by LeCun et al. (1990) and uses the change of the cost function as the feature selection criterion, which is defined as the second order term in the Taylor series of the cost function: 1 2 L (3) ( D f )2 f 2 2 ( ) in which L is the cost function of any learning machine, and is the weight of cf features. OBD uses c f to approximate the change in the cost function caused by 5 removing a given feature f by expanding the cost function in the Taylor series. Therefore, for SVR, the measure of OBD can be considered as the removed feature that has the least influence on the weight vector norm w 2 in Eq. (1). The ranking criterion can be written as c f w w( f ) 2 1 2 l l ( i 1 j 1 l l i ( i 1 j 1 2 i* )( j *j )K ( xi , x j ) ( f ) i (4) i*( f ) )( (j f ) *(j f ) ) K ( f ) ( xi , x j ) where and * is the corresponding solution of Eq. (1), the notation f means that the feature f has been removed, and K is the kernel function calculated using xi and x j . SVM-RFE starts with all the features. At each step, feature weights are obtained by comparing the training samples with the existing features. Then, the feature with the minimum c f is removed. This procedure continues until all features are ranked according to the removed order. 2.3. Feature selection using MLR with the stepwise procedure MLR is a traditional statistical method for modeling the linear relationship between the input vector (independent variables) xi R n and a desired output value (dependent variable) yi R . The regression equation of MLR constructed with l data samples is yi b0 b1 xi ,1 ... bn xi ,n ei , i 1,..., l (5) where b0 is the regression constant, b1 ,..., bn are the partial regression coefficients corresponding to the n input variables, and ei is the error term. The coefficients of MLR are often estimated using ordinary least squares (OLS) procedure such that the l sum of the squared errors ( ei ) is minimized. The coefficient of determination, R2 , i 1 indicates the percentage of the variation in yi explained by the independent variables xi . The value of R2 (ranged from 0 to 1) determines the goodness of fit for the 6 regression model. The coefficients b1 ,..., bn in Eq. (5), which are also denoted as unstandardized regression coefficients, can be used to construct the regression equation directly. However, the standardized regression coefficients 1 ,..., n , instead of unstandardized regression coefficients, are more suitable for analyzing the importance of variables. Each standardized regression coefficient represents the change in response per standard deviation change in one output value y . Since the input variables are often highly correlated with one another, the variance inflation factor (VIF) can be used to assess the problem of multicollinearity. For the task of product form feature selection in this study, MLR is combined with the stepwise procedure to select significant independent variables based on the statistic of F-test. In the stepwise procedure a variable that added into the model in the earlier stage of selection may be deleted at the later stages. At each step, the independent variable not in the model which has the smallest probability of F is added, and the probability is sufficiently small (say 0.05). On the other hand, the variables already included in the model are removed if the probability of F is sufficiently large (say 0.1). In fact, the inclusion and exclusion of variables in the stepwise procedure is the same as forward selection and backward elimination. 3. The proposed product form feature selection model This study aims to construct a product form feature selection model based on CARs and NSDA. First, NSDA is used to generate an explicit numerical definition of product form design. Next, CARs are described using single adjectives as affective dimensions. The representative affective dimensions are extracted using factor analysis. In order to gather the evaluation data of consumers, an SD experiment is conducted using questionnaire investigation. The SVR prediction models according to the representative adjectives can be constructed using the form features of NSDA as input data and the evaluated SD scores as output. Optimal training parameters of the SVR model are determined using a grid search with leave-one-out cross validation (LOOCV). In order to streamline the selection of critical product form features, SVM-RFE is capable to identify the smallest feature subset with a given predictive performance. Finally, MLR with the stepwise procedure is adopted to analyze the importance of the form features and to interpret their effects to the designated CARs. 3.1. Preparing numerical definition-based product form samples A numerical definition-based form representation for generic knife form, which was previously proposed by Chang and Chen (2008), was adopted in this study. The 7 development of this form representation was based on an extensive investigation of commercially-available knives. As shown in Fig. 1, the main structure of the knife form was defined using three NURBS curves and 15 control points, namely the blade profile (P1~P7), the lower edge of the handle (P8~P12), and the shape of the tail-section (P13~P15). These NURBS curves were used to construct a extrude surface with a fixed height for the knife blade. Note that control point p1 , located at the intersection of the two blade curves, is specified as the origin (0, 0, 0) . As for the modeling of the knife handle, it can be achieved by manipulating six adjustable design elements, namely a centric curve to define the contour of the lower edge of the handle, the width-to-height proportion, the proportional scale of the sectional area, the rounded radius parameter, the sectional inclined angle, and a tail arc curve. In addition, five sectional contours were uniformly distributed along the axis of the knife handle and construct a loft surface. The resulting 39 form features for the numerical definition of the knife form are listed in Table 1. A total of 43 knife model were created using 3D software by three experienced product designers. The corresponding form features for each 3D model were recorded. In order to reduce the perceived differences caused by the materials and textures of the 3D model, the blade was assigned with a gray material and the handle a black material. All models were rendered under the same lighting and camera settings. < Insert Fig. 1 about here > < Insert Table 1 about here > 3.2. Extracting representative affective dimensions In product design research, adjectives are often used to describe CARs. Prior to conducting the adjective evaluation experiment, it is important to reduce the number of adjectives and extract the most representative ones to allow consumers to describe their subjective perceptions. By doing so, not only the phenomena of relevancy, dependency, redundancy, cause/effect, and similarity existing among adjectives can be reduced, but the experimental results of questionnaire investigation can also be improved with better mental consistency for the subjects. 31 candidate adjectives, which can be used to describe the affective responses toward knife design, were collected in a previous study (Chen and Chang, 2009). These adjectives were used as initial affective dimensions for consumers to evaluate a small amount of representative knife samples in an SD experiment. The evaluated SD data of the initial adjectives were then analyzed using factor analysis. The extracted three factors 8 account for 37.5%, 32.9% and 21.5% of explained-variance, respectively. For the task to select representative adjectives, a simple and intuitive way is to pick up the adjectives with the largest absolute factor loadings in each factor. Three extracted adjectives including elegant, modern, and individualized were used in the following adjective evaluation experiment. For detailed reports to extract these adjectives for knife design the authors refer to the article of Chen and Chang (2009). 3.3. Questionnaire investigation for adjective evaluation In order to collect the CAR data for knife design, 56 subjects (31 male and 25 female) were asked to evaluate each knife using a 9-point Likert scale using three representative adjectives. The rendered images of the knife samples were presented to the subjects in the format of questionnaires. In order to collect the evaluation data in a more effective way, a user-friendly interface for the questionnaire was provided (see Fig. 2). The images of the knife samples are displayed in the interface. The presentation order of the knife samples was randomized to avoid any systematic effects. After each section of the experiment, the evaluation data of each subject can be recorded directly, thus simplifying the data post-processing time. The adjective data was normalized to the range [0, 1]. All the subjects’ evaluation scores toward each knife were averaged to reach a final utility score. These scores were applied as the output values in the SVR and MLR models. < Insert Fig. 2 about here > 3.4. Constructing the SVR prediction model SVR was used to construct a prediction model based on the form features of the knife samples and the average CAR ratings obtained from all the respondents. Since SVR can only deal with one output value at a time, each prediction model need to be constructed according to different adjectives. The training scheme of a single prediction model based on SVR is depicted in Fig. 3. First, the knife samples consist of a series of input vectors are fed into the training model. These input vectors are mapped into feature space by a map function . The mapping is usually nonlinear and unknown. Instead of calculating , the kernel function K is used to compute the inner product of two vectors xi and x j in the feature space ( xi ) and ( x j ) , that is, K ( xi , x j ) ( xi ) ( x j ) . SVR is also known as its elegance in solving 9 the nonlinear problem with the kernel functions that automatically do a nonlinear mapping to a feature space. Any function satisfying Mercer’s condition can be used as the kernel function (Vapnik, 1995). Of the commonly used kernel functions, the Gaussian kernel is favored for many applications due to its good features (Wang et al., 2003); and thus was adapted as follows: Gaussian kernel: K ( xi , x j ) exp( xi x j 2 / 2 2 ) , where is the spread width parameter determining the influence of squared distance between xi and x j to the kernel value. Using Gaussian kernel, dot products are computed with the output values of the training samples under the map . The weights in the SVR represent the knowledge acquired from the knife samples. Finally, the dot products are added up using the weights in terms of the Lagrange multipliers, i and i* . This, plus a constant term b yields the final predictive output value as follows: l y f ( x) ( i i* ) K ( x, xi ) b . i 1 The following procedure was used to train the knife samples: (1) Transform data to the format of SVR; (2) Normalize the form features linearly to the range [0, 1]; (3) Conduct a grid search with LOOCV to optimize the best parameter C , and the spread width of Gaussian kernel; (4) Use the best parameter set to train the whole training set. <Insert Fig. 3 about here> 3.5. Selecting critical form features using SVM-RFE The SVM-RFE process was conducted based on the optimal SVR model using the parameters obtained from a grid search, thus enabling critical product form features according to each affective dimension to be selected. The relative importance of the form features can be identified by analyzing the weight distribution in each iterative step of the SVM-RFE process. The ranking criterion c f of SVR was computing using Eq. (4). Since the SVM-RFE is a wrapper approach, the SVR model was retrained and the weight values of features were updated during each iterative step. Consequently, product designers can not only obtain the information about the 10 feature ranking but also that on the relative importance of the form features in each iterative step of the SVM-RFE process. The complete SVM-RFE procedure for product form feature selection, modified from Shieh and Yang (2008b), is described as follows: (1) Start with an empty ranked features list R [] and the selected feature list F [1,..., n] ; (2) Repeat until all features are ranked: (a) Train SVR with all the training samples, with all features in F ; (b) Compute the ranking criterion c f of SVR for features in F using Eq. (4); (c) Find the feature with the smallest ranking criterion: a arg min f c f ; (d) Add the feature a into the ranked feature list R : R [a, R] ; (e) Remove the feature a from the selected feature list F : F F [a] ; (3) Output: Ranked feature list R . 3.6. Analyzing the importance of form features using MLR 4. Experimental results 4.1. Results of form feature selection using SVR with SVM-RFE 4.1.1. Analysis of feature ranking Table 2 shows the results of the feature ranking obtained by SVM-RFE. For the sake of clarity, only the top 12 selected form features for the three adjectives are listed. Also, if a feature from v1~ v30 is selected, the feature name is assigned with an additional subscript x or y to indicate the direction of the NURBS control points explicitly. As shown in Table 2(a), for the adjective “elegant”, there are 9 features belong to the knife handle except for the features v8 y (6th), v14 y (11th) and v12 y (12th). Another characteristic for the results of “elegant” is that the dominant dimension of the NURBS control points is the y axis. According to the top 5 selected features a design suggestion for producing an “elegant” knife can be made. A designer can first manipulate the features v18 y (3rd), v 20 y (1st) and v 26 y (4th) to determine the main form of the knife handle; then adjust the features v31 (2nd) and v32 (5th) to refine the knife form by tuning the inclined angle of the fore- and tail- sections. The feature ranking of the adjective “modern” is shown in Table 2(b). 11 The top 6 selected features include v6 y (5th), v7 x (1st), v9 x (3rd), and v14 y (4th) on the control points of the knife blade, plus v 26 y (6th) and the inclined angle v32 (2nd) of the knife handle. Note that the two features v 26 y and v32 are important for both the adjectives “elegant” and “modern”. The feature ranking of the adjective “individualized” is shown in Table 2(c). The obtained feature ranking using SVM-RFE is very helpful to product designers when they are determining the importance of the form features while designing a knife. < Insert Table 2 about here > 4.1.2. Predictive performance of selected feature subset As described in the previous section, the feature ranking can be obtained from the process of SVM-RFE. Since the number of form features is large, it is vital to select the more important features according to the predictive performance of the SVR model. During the elimination steps, each feature is screened out one at a time according to the criterion c f . Therefore, the features which have less influence on the prediction results will be eliminated in the earlier steps than those which have more influence. Fig. 4 shows the predictive performance, measured in the root mean squared error (RMSE), of the selected feature subset for the three adjectives. In the beginning of the process before removing any feature, the SVR model performs best with the lowest RMSE for the three adjectives. During the following steps, the tendency of the RMSE increased gradually until a certain critical step, for example, the 34th step of the adjective “elegant” (drawn in red line). Product designers can select the smallest feature subset with a given predictive performance. If the allowable RMSE for the adjective “elegant” is 0.08, the top 5 features can be selected without deducting the performance significantly. It also seems to be a suitable threshold of the RMSE using the value of 0.08 for the adjective “modern” (drawn in green line). According to this threshold, the top 6 feature can be selected. As for the adjective “individualized” (drawn in blue line), the threshold is difficult to determine since the increase of the RMSE is not obvious. < Insert Fig. 4 about here > 4.2. Results of form feature selection using MLR with the stepwise procedure 4.2.1. Selected features by the stepwise procedure 12 The results of the selected form features using MLR with the stepwise procedure are shown in Table 3. The selection criterion of the form features is determined by the probability of F in the stepwise procedure. For the adjective “elegant”, 11 features are selected including v13x , v19 x , v 20 y , v23x , v25x , v27 x , v31 , v33 , v34 , v35 , and v38 . It can be observed that the features selected by MLR are very different from the top 12 features selected by SVM-RFE (see Table 2[a]). More specifically, there are only two selected features are identical ( v 20 y and v31 ). The results for the other two adjective, modern and individualized, also exhibit the same phenomenon. This difference is mainly due to the linear or nonlinear nature of these two methods. MLR, as a linear model, does not have good predictive performance. The coefficients of determination ( R2 ) for the three adjectives are 0.758, 0.685, and 0.759, respectively. Another reason for the unsatisfactory predictive performance of MLR is that the number of knife samples (43) is not sufficient enough for a relative larger number of features (39), that is, suffered from the problem of “curse of dimensionality”. Nevertheless, the unstandardized regression coefficients still can be used to construct the regression equation, as a simplified model neglecting the underlying nonlinear relationships between the form features. The problem of multicollinearity is not found in the models of the three adjectives since the VIF values of all the selected features are less than 10, following to the suggestion of Hair et al. (1995). < Insert Table 3 about here > 4.2.2. Effects of form features for inducing affective responses The effects of the form features for inducing specific CAR of knife design can be interpreted by the standardized regression coefficients shown in Table 3. Recall that each standardized coefficient represents the change of a form feature in response per standard deviation change in the value of CAR. Moreover, a positive value indicates the change of the feature and the CAR value are in the same direction, vice versa. For the adjective “elegant”, for instance, the selected feature v13x , which represents the x -axis coordinate of the NURBS control point P7 , has a positive value 0.379 for the standardized coefficient. To explain the effects of the features in a graphical manner, as shown in Fig. 5, if P7 on the curve of the blade edge was translated along the x -axis for 1 standard deviation distance, it can produce a more “elegant” feeling in a magnitude of 0.379. Similarly, a designer can consider the following suggestions: translating the control point P10 ( v 20 y ) along the y -axis; rotating the fore-section 13 ( v31 ) in a clockwise direction; reducing the proportional scale of the 2nd section shape ( v34 ); reducing the width-to-height proportion ( v38 ). By interpreting the standardized regression coefficients of MLR, not only the critical form features can be identified but it also provides direct suggestions on how to produce a specific affective response. However, since this analysis is based on a linear model, the joint effects for adjusting these features at the same time need to be further examined. < Insert Fig. 5 about here > 5. Conclusions In the product design field, selecting critical form features and analyzing their effects for inducing designated affective responses are very helpful to produce successful products. However, there are only sparse literatures existing for this problem. In this study, a product form feature selection model based on CARs and NSDA is proposed. NSDA was employed to generate an explicit numerical definition for product form design and CARs were described using single adjectives. The adjective evaluation can be gathered by the SD experiment. Two feature selection methods, namely SVR with SVM-RFE and MLR with the stepwise procedure, were used to analyze the form features using knife design as an example. The SVM-RFE process, as a state-of-the-art machine learning approach, is capable to obtain the form feature ranking and select a subset of features with a given performance of the SVR model. MLR combined with the stepwise procedure, as a traditional statistical method, can be used to select significant form features based on the F-test. Further analysis can be made using the statistics such as the regression coefficients and the VIF values. The standardized regression coefficients also provide a useful means how to produce a specific affective response. The proposed method for product form feature selection provides product designers a potential tool for systematically studying the form features and their effects on affective responses. References Chang, Y. M. and Chen, H. Y. (2008). Application of novel numerical definition-based systematic approach (NDSA) to the design of knife forms. Journal of the Chinese Institute of Industrial Engineers, 25(2), 148-161. Chen, H. Y. and Chang, Y. M. (2009). Extraction of product form features critical to determining consumers' perceptions of product image using a numerical definition-based systematic approach. International Journal of Industrial 14 Ergonomics, 39(1), 133-145. Guyon, I., Weston, J., Barnhill, S. and Bapnik, V. (2002). Gene selection for cancer classification using support vector machines. Machine Learning, 46(1-3), 389-422. Hair, J., Anderson, R., Tatham, R. and Black, W. (1995). Multivariate data with readings. US America: Prentice Hall Inc. Han, S. H. and Hong, S. W. (2003). A systematic approach for coupling user satisfaction with product design. Ergonomics, 46(13/14), 1441-1461. Han, S. H. and Kim, J. (2003). A comparison of screening methods: selecting important design variables for modeling product usability. International Journal of Industrial Ergonomics, 32, 189-198. Han, S. H. and Yang, H. (2004). Screening important design variables for building a usability model. International Journal of Industrial Ergonomics, 33, 159-171. Hsiao, S. W. and Huang, H. C. (2002). A neural network based approach for product form design. Design studies, 23, 67-84. Hsiao, S. W. and Tsai, H. C. (2005). Applying a hybrid approach based on fuzzy neural network and genetic algorithm to product form design. International Journal of Industrial Ergonomics, 35, 411-428. Jensen, R. (2005). Combining rough and fuzzy sets for feature selection. School of Informatics, University of Edinburgh. Doctor of Philosophy. Jindo, T., Hirasago, K. and Nagamachi, M. (1995). Development of a design support system for office chairs using 3-D graphics. International Journal of Industrial Ergonomics, 15, 49-62. Jones, J. C. (1992). Design Methods. New York, Van Nostrand Reinhold. Juang, B. H. and Katagiri, S. (1992). Discriminative learning for minimum error classification. IEEE Transactions of Signal Process, 40(12), 3043-3054. Kohavi, R. and John, G. (1997). Wrapper for feature subset selection. Artificial Intelligence, 97(1-2), 273-324. Lai, H. H., Lin, Y. C., Yeh, C. H. and Wei, C. H. (2006). User-oriented design for the optimal combination on product design. International Journal of Production Economics, 100, 253-267. LeCun, Y., Denker, J., Solla, S., Howard, R. and Jackel, L. D. (1990). Optimal brain damages. Advances in Neural Information Processing Systems. D. S. Touretzky. CA: Mateo, Morgan Kaufmann. 2: 598-605. Liu, Y. and Zheng, Y. F. (2006). FS_SFS: A novel feature selection method for support vector machines. Pattern Recognition, 39, 1333-1345. Pal, S. K., Basak, J. and De, R. K. (1996). Feature selection: a neuro-fuzzy approach. IEEE International Conference on Neural Networks, Washington, DC. 15 Park, J. and Han, S. H. (2004). A fuzzy rule-based approach to modeling affective user satisfaction towards office chair design. International Journal of Industrial Ergonomics, 34, 31-47. Rakotomamonjy, A. (2003). Variable selection using SVM-based criteria. Journal of Machine Learning Research, 3, 1357-1370. Shieh, M. D. and Yang, C. C. (2008b). Multiclass SVM-RFE for product form feature selection. Expert Systems with Applications, 35(1-2), 531-541. Tsai, H. C. and Chou, J. R. (2007). Automatic design support and image evaluation of two-colored products using color association and color harmony scales and genetic algorithm. Computer-Aided Design, 39(9), 818-828. Vapnik, V. N. (1995). The nature of statistical learning theory. New York, Springer. Wakaki, T., Itakura, H. and Tamura, M. (2004). Rough set-aided feature selection for automatic web-page classification. Proceedings of the IEEE/WIC/ACM International Conference on Web Intelligence. Wang, W., Xu, Z., Lu, W. and Zhang, X. (2003). Determination of the spread parameter in the Gaussian kernel for classification and regression. Neurocomputing, 55, 643-663. Yang, C. C. and Shieh, M. D. (2010). A support vector regression based prediction model of affective responses for product form design. Computers & Industrial Engineering, doi:10.1016/j.cie.2010.07.019. 16 Fig. 1. The numerical definition of generic knife form. Origin (0,0) P2 (v3x, v4y) P3 (v5x, v6y) P4 (v7x, v8y) P9 (v17x, v18y) P1 (v1x, v2y) P11 (v21x, v22y) p8 (v15x, v16y) P13 (v25x, v26y) P5 (v9x, v10y) P10 (v19x, v20y) P7 (v13x, v14y) P6 (v11x, v12y) P12 (v23x, v24y) P14 (v27x, v28y) P15 (v29x, v30y) The fore-section shape (v33) and its inclined angle (v31) 3rd section shape (v35) 2nd section shape (v34) The tail-section shape (v37) and its inclined angle (v32) 4th section shape (v36) Proportion of width and height (v38); Rounded size (v39) 17 Fig. 2. An interface of questionnaire for adjective evaluation. 18 Fig. 3. Training scheme of the SVR model. Input vectors Mapped vectors x1 ( x1 ) x2 ( x2 ) Kernel function Weights K ( x, x1 ) K ( x, x2 ) 1 1* 2 2* y ... ... ... xl ( xl ) K ( x, xl ) 19 l l* predictive output Fig. 4. Performance of feature subset (RMSE) of the three adjectives for SVM-RFE: y1 (elegant), y 2 (modern), and y3 (individualized). 20 Fig. 5. Effects of the form features in creating an “elegant” feeling. Reducing the width-to-height proportion (v38) creates a more “elegant” feeling. Reducing the proportional scale of the 2nd section (v34) creates a more “elegant” feeling. Curve of blade back Translating control point P10 (v20y) in the upward direction creates a more “elegant” feeling. (0, 0) Rotating the fore-section (v31) in a clockwise direction produces a more “elegant” feeling. Curve of blade edge Translating control point P7 (v13x) in the rightward direction to reduce the radian of the arc curve of the blade edge (as shown by dotted line) produces a more “elegant” feeling. 21 Table 1. The list of form features for the numerical definition of the knife form. Knife form decomposed descriptions Feature specifications Features Curve of blade back ( x, y ) coordinate of 4 NURBS control points (P1~P4) v1 ~ v8 Curve of blade edge ( x, y ) coordinate of 3 NURBS control points (P5~P7) v9 ~ v14 Centric curve of knife handle ( x, y ) coordinate of 5 NURBS control points (P8~P12) v15 ~ v24 Tail arc curve of knife handle ( x, y ) coordinate of 3 NURBS control points (P13~P15) v25 ~ v30 Knife blade Knife handle Fore-section inclination of knife handle Inclined angle (60°/90°/120°) v31 Tail-section inclination of knife handle Inclined angle (60°/90°/120°) v32 Fore-section shape Proportional scale (1/0.75/0.5) v33 2nd section shape Sectional variation 3rd section shape of knife handle 4th section shape Proportional scale (1/0.75/0.5) v34 Proportional scale (1/0.75/0.5) v35 Proportional scale (1/0.75/0.5) v36 Tail-section shape Proportional scale (1/0.75/0.5) v37 Proportion of all sections Width to height proportion (1/0.67/0.5) v38 Rounded radius of all sections Rounded radius (1mm/3mm/5mm) v39 22 Table 2. Top 12 of feature ranking of the adjectives obtained by SVM-RFE: (a) elegant (b) modern and (c) individualized. Elegant (a) Rank 1 2 3 4 5 6 7 8 9 10 11 12 (b) Modern (c) Individualized Feature v 20 y *b/h Rank Feature *b/h Rank h 1 b 1 v31 v18 y v 26 y h h h h b h h 2 3 4 5 6 7 8 v7 x v32 v9 x v14 y v6 y v 26 y h b b b h h h 2 3 4 5 6 7 8 h h b b 9 10 11 12 h h h h 9 10 11 12 v32 v8 y v 28 y v 24 y v30 y v 22 y v14 y v12 y v29x v39 v25x v30 y v33 v36 *b/h denotes that the form feature belongs to a knife blade or handle (b: blade; h: handle). 23 Feature v30 v14 y v36 v38 v37 v23x v2 y v1x v17 x v34 v35 v33 *b/h h b h h h h b b h h h h Table 3. Regression coefficients of selected features obtained from MLR with the stepwise procedure. Form features Elegant (Constant) v13x v19 x v 20 y v23x v25x v27 x v31 v33 v34 v35 v38 Unstandardized coefficients B Std. Error 4.380 0.034 0.640 0.033 0.102 0.009 0.489 0.011 -7.840 -0.077 0.041 Standardized coefficients Beta - Sig. Collinearity statistics VIF - 0.379 0.131 0.275 0.000 0.001 0.020 0.007 1.361 1.285 1.168 3.796 0.040 0.021 -0.226 -0.195 0.188 0.047 0.062 0.056 1.529 1.298 1.154 -0.009 1.714 -2.157 1.043 -2.941 0.005 0.536 0.556 0.537 0.536 -0.171 0.298 -0.382 0.180 -0.501 0.085 0.003 0.001 0.016 0.000 1.192 1.108 1.241 1.104 1.068 4.235 0.042 0.039 0.749 -0.747 -10.043 0.175 -1.918 0.122 0.010 0.017 0.590 0.423 4.436 0.047 0.659 - - 0.439 0.264 0.142 -0.193 -0.268 0.416 -0.315 0.000 0.000 0.024 0.013 0.087 0.030 0.001 0.006 1.251 1.307 1.316 1.249 1.469 1.291 1.226 1.998 -2.376 0.642 0.651 0.316 -0.375 0.004 0.001 1.081 1.108 5.732 -0.008 -0.044 0.052 0.004 0.020 - 0.000 0.028 0.035 - R 2 0.758 Modern (Constant) v13x v14 y v19 x v21x v23x v29x v34 v37 v38 R 2 0.685 Individualized (Constant) v3x v9 x -0.211 -0.243 24 1.705 1.454 v17 x v19 x v 20 y v21x v 24 y v25x v 28 y v33 v34 v36 v38 4.549 1.829 0.289 0.039 1.630 -0.620 -0.021 0.666 -0.089 0.218 0.087 -0.790 0.492 0.475 0.428 0.262 0.007 0.206 0.027 0.034 0.023 0.301 0.282 0.269 0.287 -0.259 -0.356 0.378 -1.497 1.122 1.803 -0.280 0.178 0.168 0.149 0.025 0.007 0.003 0.003 0.000 0.001 0.014 0.032 0.059 0.047 1.446 1.776 1.638 2.488 1.747 1.566 1.367 1.247 1.096 1.193 R 2 0.759 25